Abstract

Mechanochemical process has attracted a worldwide interest in the synthesis of nanomaterials since reactions can be run in solid state without any organic solvent. Therefore, this method is an environmentally friendly reaction. Cadmium oxide is a category of the practical semiconductor metal oxides, which is widely applied in various scientific and industrial fields because of its catalytic, optical, and electrical properties. In this study, cadmium oxide spherical nanoparticles were successfully synthesized using a facile and effective solid-state process called mechanochemical reaction. This performance was carried out by employing cadmium acetate dihydrate and urea as reactants without any additives at room temperature and an adjusted rate of 30 Hz (1,800 rpm) for 130 min. Due to calcination of the resulting precursor at 500°C for 2 h in a furnace, the organic sections disappeared and only the CdO phase remained. The X-ray diffraction pattern confirmed the formation of the CdO phase with an excellent crystalline structure. Scanning electron microscopy and transmission electron microscopy images indicated that the morphology of the product is spherical nanoparticles with an average particle size of 46 nm and a standard deviation of 1.95. Particle size distribution was concluded using a statistical method and image processing program. Meanwhile, the solid-state diffuse reflectance spectrum of the resulting product was evaluated to study its optical property via measurement of the band gap energy value (Eg).

Similar content being viewed by others

Background

Recently, nanosized semiconductor metal oxides have attracted a wide attention because of their optical and electrical properties. Cadmium oxide, CdO, is a known n-type semiconductor with a direct band gap of 2.2 to 2.5 eV and an indirect band gap of 1.36 to 1.98 eV [1–4]. Some reports have presented that the band gap of this material can change in the range of 1.1 to 3.3 eV [5–8]. Such diversity can be assigned to lattice’s defects due to the Burstein-Moss effect [9]. Meanwhile, it can be originated from the nanosized structure, i.e., the preparation of the material in nanoscale can impress the optical and electrical characteristics. Because of the appropriate optical and electrical properties, cadmium oxide nanostructures are used in solar cells, gas sensors, transparent electrodes, photodiodes, catalysts, and optoelectronic devices [10–18].

Up to now, various methods have been employed to prepare the cadmium oxide nanostructures such as microemulsion [2], chemical precipitation [19], sonochemical/hydrothermal technique [20], solvothermal process [1], and also mechanochemical process [21–23]. The feasibility of the mechanochemical method to synthesize the nanomaterials has been of interest in the past few decades. This process is a facile solid-state reaction, which is performed via mechanical fragmenting and welding of the raw materials. The use of this procedure called as mechanical alloying was developed by Benjamin and his co-workers in the early 1960s. Mechanochemical process is a type of mechanical alloying technique, which was reported by McCormick in 1989 for the first time [24]. Mechanochemical reaction is an effective, useful, and low-cost technique that can be nominated as an applicable route to prepare nanomaterials in various industrial fields [25]. A lot of research in this area remains to be done.

In the present work, we prepared cadmium oxide spherical nanoparticles using mechanochemical process followed by calcination treatment. We used the low-cost chemical of urea as a promoter agent to prepare the precursor for the first time. The particle size distribution of the resulting product was measured via a statistical microstructure measurement program as an image processing program. Finally, the band gap energy of the product was estimated using diffuse reflectance spectroscopy (DRS) and Tauc relation. The products were characterized by thermogravimetric analysis (TGA), Fourier transform infrared (FT-IR), X-ray diffraction (XRD), scanning electron microscopy (SEM), and transmission electron microscopy (TEM) techniques.

Methods

Materials for synthesis

All of the chemicals used in this study were purchased from Merck Co. (Whitehouse Station, NJ, USA) and used without further purification.

Preparation

Cd(CH3COO)2·2H2O and CO(NH2)2 as the initial materials were mixed together with a molar ratio of 1:3. The supplied powder was put into a stainless steel container (10 mL) including two small stainless steel balls (10 mm). The grinding operation was performed by utilizing a mass ratio of 8:1 (ball to powder) in a Mixer Mill (Retsch MM-400, Retsch, Haan, Germany) apparatus. The rate of milling was adjusted at 30 Hz (1,800 rpm) for 130 min at room temperature. Finally, the obtained precursor was calcined at 500°C for 2 h in air to produce CdO nanostructures.

Characterization

The powder XRD measurements were carried out by a JEOL diffractometer (JEOL Ltd., Akishima, Tokyo, Japan) with monochromatized Cu Kα radiation (λ = 1.5418 Å). FT-IR spectra were recorded on a Shimadzu-8400S spectrometer (Shimadzu Corporation, Kyoto, Japan) in the range of 400 to 4,000 cm−1 using KBr pellets. SEM images were obtained on a Philips XL-30 (FEI Co., Hillsboro, OR, USA) with gold coating. TEM images were taken on a Philips-Cm 120, Eb Leo-912 microscope (FEI) with an accelerating voltage of 120 kV. The solid-state absorption/diffuse reflectance spectra of the CdO nanoparticles were evaluated in the range of 190 to 800 nm by using a UV–vis spectrophotometer (Shimadzu-UV-2550-8030 with a slit width of 5.0 nm and a light source change wavelength of 360.0 nm) at room temperature. TGA measurement was carried out on a TGA PerkinElmer Pyris-US apparatus (PerkinElmer, Waltham, MA, USA) with a heating rate of 10°C min−1 under nitrogen flow.

Results and discussion

Structural and morphological studies

Thermogravimetric analysis of the milled powder is illustrated in Figure 1. According to this curve, the decay of this composition has been performed in the two-step pattern of weight loss. The first weight loss of 13% is observed in the temperature range of 178°C to 245°C, which can be attributed to the evaporation of the adsorbed water. The second weight loss step of 44% in the range of 350°C to 500°C can belong to the decay of the organic components in the precursor structure. It was found that the weight loss, as a result of thermal decomposition, ends in 500°C. Therefore, this temperature was determined as the calcination temperature to reach the metal oxide phase.

Figure 2 shows the FT-IR spectra from the resulting precursor after milling process (Figure 2 (a)) and the product after heating treatment at 500°C for 2 h (Figure 2 (b)). The peaks that appeared obviously belong to the organic functional groups of the synthesized precursor. The absorption bands at 3,450 and 3,350 cm−1 can be attributed to the N-H asymmetrical and symmetrical stretching vibration bands, respectively. The observed broad band in this area can be originated from the overlapping O-H stretching bands of H2O molecules with the NH2 vibration bands. The observed vibration modes at 2,900 and 2,850 cm−1 can be assigned to the C-H asymmetrical and symmetrical stretching vibrations, respectively. The specified strong peaks at about 1,660 cm−1 belong to the stretching vibration bands of the carbonyl groups. The observed absorption bands at 1,452 cm−1 can be attributed to the ν(CN). In addition, the weak peak at 1,165 cm−1 is related to the C-O vibration band. The appearance of the weak absorption band at 675 cm−1 indicates the formation of the cadmium-oxygen phase in the precursor structure [26]. By heat treatment at 500°C, the organic functional groups were removed and only the absorption band of metal oxide phase remained (Figure 2 (b)). Figure 3 depicts the proposed mechanism for the formation of the intermediate molecule (precursor) and CdO nanoparticles. As a matter of fact, the use of urea in a mechanochemical reaction for the formation of CdO nanostructures has not been reported. In fact, urea as a promoter agent can be easily coordinated to cadmium ions and lead to the production of the intermediate molecule. At the next step, the cadmium oxide phase is prepared as a function of heat treatment.

The XRD pattern of the final product is shown in Figure 4. This pattern clearly confirmed the presence of the CdO phase with a lattice parameter of a = 4.695 Å. The diffraction peaks at 2θ values of 32.90°, 38.20°, 55.20°, 65.80°, and 69.20° matching with the 111, 200, 220, 311, and 222 of cubic CdO (JCPDS 05–0640) indicated the formation of this compound. No other peaks for impurities were detected.

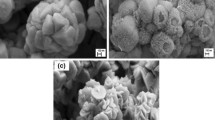

Figure 5 reveals the SEM images of the obtained CdO nanoparticles at 500°C. These images illustrate the uniform spherical morphology of the synthesized particles in the range of 40 to 50 nm. The TEM images confirmed the obtained data of the SEM images (Figure 6). Image processing via the microstructure measurement program and Minitab statistical software was used to evaluate the particle size and distribution particle size. It was found that the average size of the prepared nanoparticles is 46 nm with a standard deviation of 1.95. The histogram of the particle size distribution according to TEM images has been displayed in Figure 7. Although there are few reports in the synthesis of this material in nanoscale by the mentioned method, these obtained products are the agglomerated particles without any uniformity. Meanwhile, a long reaction time to synthesize this compound has been reported [21]. In our previous studies published elsewhere, we reported the preparation of CdO nanostructures by this method and using other reagents [22, 23]. In this work, we changed the reactants and used urea as a promoter of reaction. It was observed that the change of agents leads to the alteration of the morphology of the product [22, 23].

The evaluation of band gap energy

Solid-state DRS was employed to determine the band gap energy value of the resulting CdO nanoparticles (Figure 8). Generally, the direct band gap energy is calculated by using the Tauc relation as follows [27]:

where hν is the photon energy, α is the absorption coefficient, B is a constant value, and Eg is the band gap energy. The value of n refers to direct (n = 2) or indirect (n = 1/2) electron transition [28]. The following equation was applied to calculate the absorption coefficient (α):

where T is the transmittance and t is the thickness of the substance placed under UV–vis irradiation. By plotting the (αhν)2 vs. hν (eV) (Figure 9), the band gap energy of 2.21 eV was estimated for synthesized nanoparticles, which can nominate this nanomaterial to be applied in photocatalytic activities and optical devices.

Conclusions

In summary, the spherical nanoparticles of cadmium oxide were synthesized using a high-energy ball milling process. This product was obtained by using Cd(CH3COO)2·2H2O and NH2CONH2 as starting materials without any template, catalyst, or surfactant at a short time reaction and room temperature. An average particle size of 46 nm with a standard deviation of 1.95 was estimated for the resulting nanoparticles by utilizing the image processing and statistical programs. The optical property of the produced nanoparticles was studied by measuring the band gap energy value based on the DRS spectrum. The obtained band gap energy is an accepted value for the photocatalytic activities in visible light and also for application in the photovoltaic and optical devices. The mechanochemical process used in this study is a simple, useful, and economic technique to prepare metal oxide nanoparticles and can be introduced as an effective route in the synthesis of nanomaterials in a large scale.

References

Ghosh M, Rao CNR: Solvothermal synthesis of CdO and CuO nanocrystals. Chem. Phys. Lett. 2004, 393: 493–497. 10.1016/j.cplett.2004.06.092

Dong W, Zhu C: Optical properties of surface-modified CdO nanoparticles. Opt. Mater. 2003, 22: 227–233. 10.1016/S0925-3467(02)00269-0

Vinodkumar R, Lethy KJ, Arunkumar PR, Krishnan RR, Venugopalan PN, Mahadevan PVP, Philip R: Effect of cadmium oxide incorporation on the microstructural and optical properties of pulsed laser deposited nanostructured zinc oxide thin films. Mater. Chem. Phys. 2010, 121: 406–413. 10.1016/j.matchemphys.2010.01.004

Kuo TJ, Huang MH: Gold-catalyzed low-temperature growth of cadmium oxide nanowires by vapor transport. J. Phys. Chem. B 2006, 110: 13717–13721.

Dakhel AA: Optoelectronic properties of Eu- and H-codoped CdO films. Current Appl. Phys. 2011, 11: 11–15. 10.1016/j.cap.2010.06.003

Atay F, Akyuz I, Kose S, Ketenci E, Bilgin V: Optical, structural and surface characterization of CdO:Mg films. J. Mater. Sci. Mater. Electron. 2011, 22: 492–498. 10.1007/s10854-010-0166-z

Mayén-Hernández SA, Torres-Delgado G, Castanedo-Pérez R, Mendoza-Alvarez JG, Zelaya-Angel O: Optical and structural properties of CdO + CdTiO 3 thin films prepared by sol–gel. Mater. Chem. Phys. 2009, 115: 530–535. 10.1016/j.matchemphys.2008.11.046

Saravanan R, Shankar H, Prakash T, Narayanan V, Stephen A: ZnO/CdO composite nanorods for photocatalytic degradation of methylene blue under visible light. Mater. Chem. Phys. 2011, 125: 277–280. 10.1016/j.matchemphys.2010.09.030

Grado-Caffaro MA, Grado-Caffaro M: A quantitative discussion on band-gap energy and carrier density of CdO in terms of temperature and oxygen partial pressure. Phys. Lett. A. 2008, 372: 4858–4860. 10.1016/j.physleta.2008.04.068

Yakuphanoglu F: Nanocluster n-CdO thin film by sol–gel for solar cell applications. Appl. Surf. Sci. 2010, 257: 1413–1419. 10.1016/j.apsusc.2010.08.045

Mane RS, Pathan HM, Lokhande CD, Han SH: An effective use of nanocrystalline CdO thin films in dye-sensitized solar cells. Sol. Energy 2006, 80: 185–190. 10.1016/j.solener.2005.08.013

Sarma TVS, Tao S: An active core fiber optic sensor for detecting trace H 2 S at high temperature using a cadmium oxide doped porous silica optical fiber as a transducer. Sens. Actuat. B: Chem. 2007, 127: 471–479. 10.1016/j.snb.2007.04.049

Salunkhe RR, Lokhande CD: Effect of film thickness on liquefied petroleum gas (LPG) sensing properties of SILAR deposited CdO thin films. Sens Actuat B: Chem. 2008, 129: 345–351. 10.1016/j.snb.2007.08.035

Kim MH, Kwon YU: Semiconductor CdO as a blocking layer material on DSSC electrode: mechanism and application. J. Phys. Chem. C 2009, 113: 17176–17182. 10.1021/jp904206a

Yakuphanoglu F, Caglar M, Caglar Y, Ilican S: Electrical characterization of nanocluster n-CdO/p-Si heterojunction diode. J. Alloys Compd. 2010, 506: 188–193. 10.1016/j.jallcom.2010.06.174

Liu X, Li C, Han S, Han J, Zhou C: Synthesis and electronic transport studies of CdO nanoneedles. Appl. Phys. Lett. 2003, 82: 1950–1952. 10.1063/1.1562331

Pawar SM, Pawar BS, Kim JH, Joo OS, Lokhande CD: Recent status of chemical bath deposited metal chalcogenide and metal oxide thin films. Current Appl. Phys 2011, 11: 117–161. 10.1016/j.cap.2010.07.007

Li J, Ni Y, Liu J, Hong J: Preparation, conversion, and comparison of the photocatalytic property of Cd(OH) 2 , CdO. CdS and CdSe. J Phys Chem Solid 2009, 70: 1285–1289. 10.1016/j.jpcs.2009.07.014

Manickathai K, Viswanathan SK, Alagar M: Synthesis and characterization of CdO and CdS nanoparticles. Indian J. Pure Appl. Phys. 2008, 46: 561–564.

Askarinejad A, Morsali A: Synthesis of cadmium (II) hydroxide, cadmium(II) carbonate and cadmium(II) oxide nanoparticles; investigation of intermediate products Chem. Eng. J. 2009, 150: 569–571.

Yang H, Qiu G, Zhang X, Tang A, Yang W: Preparation of CdO nanoparticles by mechanochemical reaction. J. Nanopart. Res. 2004, 6: 539–542. 10.1007/s11051-004-3327-2

Tadjarodi A, Imani M: Synthesis and characterization of CdO nanocrystalline structure by mechanochemical method. Mater. Lett. 2011, 65: 1025–1027. 10.1016/j.matlet.2010.12.054

Tadjarodi A, Imani M: A novel nanostructure of cadmium oxide synthesized by mechanochemical method. Mater. Res. Bull. 2011, 46: 1949–1954. 10.1016/j.materresbull.2011.07.016

Suryanarayana C: Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46: 1–184. 10.1016/S0079-6425(99)00010-9

Damonte LC, Hernández-Fenollosa MA, Marí B: Cation substitution in ZnO obtained by mechanical milling. J. Alloys Compd. 2007, 434: 813–815.

Nakamoto K: Infrared and Raman Spectra of Inorganic and Coordination Compounds. 6th edition. Hoboken: Wiley; 2009.

Tharayil N, Raveendran R, Vaidyan AV, Chithra PG: Optical, electrical and structural studies nickel-cobalt oxide nanoparticles. Indian J. Eng. Mater. Sci. 2008, 15: 489–496.

Butler MA: Photoelectrolysis and physical properties of the semiconducting electrode WO 3 . J. Appl. Phys. 1977, 48: 1914–1920. 10.1063/1.323948

Acknowledgments

The financial support of this study by the Iran University of Science and Technology and the Iranian Nanotechnology Initiative is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

AT designed the related subject, managed all of the process, and conceived this study. MI carried out all the experiments and drafted the manuscript. HK participated in the manuscript preparation. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Tadjarodi, A., Imani, M. & Kerdari, H. Application of a facile solid-state process to synthesize the CdO spherical nanoparticles. Int Nano Lett 3, 43 (2013). https://doi.org/10.1186/2228-5326-3-43

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2228-5326-3-43