Abstract.

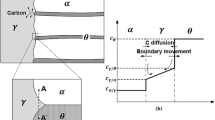

A two-dimensional multiphase cellular automaton (CA) model is proposed for the prediction of growth kinetics and microstructural evolution during peritectic transformation of Fe-C alloys. The proposed model is validated by comparing the simulation results with the experimental measurements and analytical predictions for the growth kinetics of the \( \gamma\) -phase and the concentration distributions. The simulated time evolution of the \( \gamma\) -phase thickness and the concentration distribution in the \( \gamma\) -phase agree well with the experimental data, demonstrating the quantitative capabilities of the proposed model. The influences of the holding temperature and \( \gamma\) -phase thickness on the \( \gamma\) -phase growth behavior are analyzed based on the simulation results. The \( \gamma\) -phase growth velocity is found to decrease with increasing the \( \gamma\) -phase thickness and holding temperature. Simulations are also performed for the microstructural evolution during isothermal peritectic transformation of Fe-C alloys with the primary \( \delta\) -phase being an equiaxed dendrite under different holding temperatures. It is found that the driving force for \( \gamma\) -phase growth increases with decreasing temperature.

Graphical abstract

Similar content being viewed by others

References

S. Griesser, C. Bernhard, R. Dippenaar, Acta Mater. 81, 111 (2014)

Y. Arai, T. Emi, H. Fredriksson, H. Shibata, Metall. Mater. Trans. A 36, 3065 (2005)

D.M. Liu, X.Z. Li, Y.Q. Su, P. Peng, L.S. Luo, J.J. Guo, H.Z. Fu, Acta Mater. 60, 2679 (2012)

A. Löffler, K. Reuther, H. Engelhardt, D.M. Liu, M. Rettenmayr, Acta Mater. 91, 34 (2015)

H.W. Kerr, J. Cisse, G.F. Bolling, Acta Metall. 22, 677 (1974)

D. Phelan, M. Reid, R. Dippenaar, Metall. Mater. Trans. A 37, 985 (2006)

A. Das, I. Manna, S.K. Pabi, Acta Mater. 47, 1379 (1999)

K. Matsuura, Y. Itoh, T. Narita, ISIJ Int. 33, 583 (1993)

K. Matsuura, H. Maruyama, Y. Itoh, M. Kudoh, K. Ishii, ISIJ Int. 35, 183 (1995)

K. Matsuura, M. Kudoh, T. Ohmi, ISIJ Int. 35, 624 (1995)

K. Matsuura, H. Maruyama, M. Kudoh, Y. Itoh, ISIJ Int. 35, 1483 (1995)

H. Shibata, Y. Arai, M. Suzuki, T. Emi, Metall. Mater. Trans. B 31, 981 (2000)

S. Griesser, C. Bernhard, R. Dippenaar, ISIJ Int. 54, 466 (2014)

S. Griesser, In-situ Study of the Influence of Alloying Elements on the Kinetics and Mechanism of the Peritectic Phase Transition in Steel, PhD Thesis (University of Wollongong, Australia, 2013)

H. Fredriksson, T. Nylen, Met. Sci. 16, 283 (1982)

A. Das, I. Manna, S.K. Pabi, Scr. Mater. 36, 867 (1997)

H. Nassar, H. Fredriksson, Metall. Mater. Trans. A 41, 2776 (2010)

S. Pan, M. Zhu, Acta Mater. 146, 63 (2018)

S. Pan, M. Zhu, M. Rettenmayr, Acta Mater. 132, 565 (2017)

J. Kundin, R. Siquieri, H. Emmerich, Phys. D 243, 116 (2013)

M. Ohno, K. Matsuura, Acta Mater. 58, 5749 (2010)

M. Ohno, K. Matsuura, Acta Mater. 58, 6134 (2010)

M. Yamazaki, J. Satoh, K. Ohsasa, K. Matsuura, ISIJ Int. 48, 362 (2008)

B. Su, Z.Q. Han, B.C. Liu, China Foundry 9, 221 (2012)

M.F. Zhu, D.M. Stefanescu, Acta Mater. 55, 1741 (2007)

S.Y. Pan, M.F. Zhu, Acta Mater. 58, 340 (2010)

H. Zhang, Q.Y. Xu, J. Mater. Process. Technol. 238, 132 (2016)

M.F. Zhu, L. Zhang, H.L. Zhao, D.M. Stefanescu, Acta Mater. 84, 413 (2015)

H. Fang, Q.Y. Tang, Q.Y. Zhang, T.F. Gu, M.F. Zhu, Int. J. Heat Mass Transfer 133, 371 (2019)

A. Pineau, G. Guillemot, D. Tourret, A. Karma, Ch.-A. Gandin, Acta Mater. 155, 286 (2015)

H.B. Dong, P.D. Lee, Acta Mater. 53, 659 (2005)

K. Reuther, M. Rettenmayr, Comput. Mater. Sci. 95, 213 (2014)

Q.Y. Zhang, H. Fang, H. Xue, Q.Y. Tang, S.Y. Pan, M. Rettenmayr, M.F. Zhu, Scr. Mater. 151, 28 (2018)

L. Yuan, P.D. Lee, Model. Simul. Mater. Sci. Eng. 18, 1 (2010)

Q.Y. Zhang, H. Fang, H. Xue, S.Y. Pan, M. Rettenmayr, M.F. Zhu, Sci. Rep. 7, 17809 (2017)

D. An, S.I. Baik, S.Y. Pan, M.F. Zhu, D. Isheim, B.W. Krakauer, D.N. Seidman, Metall. Mater. Trans. A 50, 436 (2019)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

The EPJ Publishers remain neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fan, Y., Fang, H., Tang, Q. et al. Cellular automaton modeling of peritectic transformation⋆. Eur. Phys. J. E 43, 17 (2020). https://doi.org/10.1140/epje/i2020-11939-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epje/i2020-11939-x