Abstract

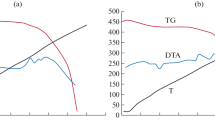

This paper presents the results of an investigation of the influence of the aluminum-powder concentration on the thermomechanical characteristics of the composites based on the high-density polyethylene. We show that use of a compatibilizer—maleic anhydride–polyethylene graft copolymer—in a mixture with high-density polyethylene has an influence on the regularity of variation of the thermomechanical curves. We study the influence of various cross-linking agents (dicumyl peroxide and sulfur) on the thermomechanical properties of composites. At a particular dicumyl peroxide and sulfur concentration, the composites might reside in three physical states: solid, highly elastic, and viscous flow.

Similar content being viewed by others

REFERENCES

A. A. Tager, Physicochemistry of Polymers, 4th ed. (Nauchnyi Mir, Moscow, 2007) [in Russian].

V. Nelyub and G. Malysheva, “Modern treatment technologies of carbon fibre foe ensuring the high strength carbon fibre reinforced plastic,” MATEC Web Conf. 129, 02001 (2017).

L. F. Kalistratova and V. A. Egorova, “Ordering of the amorphous phase as one of the characteristics of supramolecular structure of amorphous-crystalline polymer,” Inorg. Mater.: Appl. Res. 10, 933–938 (2019).

M. A. Gorodetskii, V. A. Nelyub, G. V. Malysheva, A. Y. Shaulov, and A. A. Berlin, “Technology of forming and the properties of reinforced based on an inorganic binder,” Russ. Metall (Engl. Transl.) 2018 (13), 1195–1198 (2018).

I. D. Simonov-Emel’yanov, “Structuring in dispersive filled polymers and properties of composite materials,” Plast. Massy, Nos. 9–10, 29–36 (2015).

N. T. Kakhramanov, A. D. Ismailzade, N. B. Arzumanova, U. M. Mammadli, and Q. S. Martinova, “Filled composites based on polyolefins and clinoptilolite,” Am. Sci. J. 4 (4), 60–65 (2016).

A. M. Kharaev, R. C. Bazheva, M. B. Begieva, V. A. Nelyub, and A. S. Borodulin, “Polyethersulfones with improved thermohysical properties,” Polym. Sci., Ser. D 12 (1), 24–28 (2019).

S. M. Terekhina, G. V. Malysheva, I. M. Bulanov, and T. V. Tarasova, “Investigation of tribological properties of polymer composite materials based on bismaleimide binder,” Polym. Sci., Ser. D 4 (2), 136–137 (2011).

N. T. Kakhramanov, A. G. Azizov, V. S. Osipchik, U. M. Mamedli, and H. B. Arzumanova, “Nanostructured composites and polymer materials science,” Int. Polym. Sci. Technol. 44 (2), 37–48 (2017).

N. T. Kakhramanov, Kh. V. Allakhverdieva, M. I. Abdullin, and F. A. Mustafayeva, “Influence of aluminum powder concentration on mechanism and kinetic regularities of crystallization of composites based on low density polyethylene,” Izv. Vyssh. Uchebn. Zaved. Khim. Khim. Tekhnol. 63 (2), 77–83 (2020).

N. T. Kakhramanov, Z. N. Guseinova, and V. S. Osipchik, “The influence of the technological parameters of injection molding on the physico-mechanical properties of dynamic elastoplastic based on polyolefins,” Polymer Sci., Ser. D 12 (3), 317–321 (2019).

I. P. Petryuk, “Influence of the parameters of a dispersed structure on the interphase layer content in filled polymers,” Plast. Massy, Nos. 5–6, 7–9 (2014).

A. A. Dyakonov, S. N. Danilova, A. P. Vasilyev, A. A. Okhlopkova, S. A. Sleptsova, and A. A. Vasilyeva, “Study of sulfur, diphenylguanidine and 2-mercaptobenzothiazole effect on physical and mechanical properties and structure of ultra-high molecular weight polyethylene,” Perspekt. Mater., No. 1, 43–53 (2020).

Kh. V. Allakhverdieva and N. T. Kakhramanov, “Thermal-mechanical properties of composites and their vulcanizers based on low-density polyethylene and aluminum powder,” Vse Mater., No. 5, 14–19 (2020).

G. V. Kozlov and I. V. Dolbin, “Transfer of mechanical stress from polymer matrix to nanofiller in dispersion-filled nanocomposites,” Inorg. Mater.: Appl. Res. 10, 226–230 (2019).

L. B. Atlukhanova, G. V. Kozlov, and I. V. Dolbin, “The correlation between the nanofiller structure and the properties of polymer nanocomposites: fractal model,” Inorg. Mater.: Appl. Res. 11, 188–191 (2020).

Yu. K. Mashkov, L. F. Kalistratova, and O. V. Kropotin, “Development of methods of formation of effective structure-phase states of polymer composites based on PTFE,” Plast. Massy, Nos. 3–4, 12–14 (2017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by I. Dikhter

Rights and permissions

About this article

Cite this article

Allahverdiyeva, K.V., Kakhramanov, N.T. & Namazly, U.V. Thermomechanical Properties of Composites Based on High-Density Polyethylene and Aluminum. Polym. Sci. Ser. D 14, 598–602 (2021). https://doi.org/10.1134/S1995421222010026

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1995421222010026