Abstract

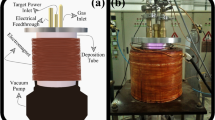

The microstructure and functional properties of zinc oxide magnetron thin films depend on a number of factors: substrate temperature, mutual arrangement of the target and substrates, composition and pressure of residual and working gases, discharge power characteristics, target depletion rate, layer deposition rate, etc. At present, to study the influence of certain factors on the structure and properties of thin films, the method of successive deposition of a series of films with a stepwise change in one of the controlled parameters is used. At the same time, due to the large number of operating factors, as well as the complex nature of their impact, highlighting the contribution of each individual factor is a difficult and nontrivial task. The effect of the substrate temperature and the “target–substrate” distance on the structure and properties of zinc oxide films has been studied. At the same time, to minimize the influence of other factors with the help of an original system of heating and positioning of substrates, the concept of deposition of layers on substrates of the entire series with a change in only one controlled factor is implemented. This concept of deposition in a single vacuum cycle significantly lowers the requirements for the accuracy of controlling technological parameters of the process, reduces the impact on the final result of random unaccounted for factors, and also accelerates the preparation of the entire series of investigated thin-film samples.

Similar content being viewed by others

REFERENCES

S. D. Ponja, S. Sathasivam, I. P. Parkin, and C. J. Carmalt, Sci. Rep. 10, 638 (2020). https://doi.org/10.1038/s41598-020-57532-7

A. Sh. Asvarov, A. Kh. Abduev, A. K. Akhmedov, V. M. Kanevsky, and A. E. Muslimov, Crystallogr. Rep. 63, 994 (2018). https://doi.org/10.1134/S0023476118060036

M. A. Shiryaev, Y. J. Jin, H. C. Bong, and A. Baranov, Nanotechnol. Russ. 12, 613 (2017). https://doi.org/10.1134/S199507801706009X

Y.-P. Lee, Ch.-Ch. Lin, Ch.-Ch. Hsiao, et al., Micromachines 11, 14 (2020). https://doi.org/10.3390/mi11010014

Z. Tseng, C. Chiang, and C. Wu, Sci. Rep. 5, 13211 (2015). https://doi.org/10.1038/srep13211

A. Varanytsia, L. Weng, T. Lin, et al., J. Disp. Technol. 12, 1033 (2016). https://doi.org/10.1109/JDT.2016.2584779

J. Costa, T. Peixoto, A. Ferreira, et al., J. Biomed. Mater. Res. A 107, 2150 (2019). https://doi.org/10.1002/jbm.a.36725

H.-Y. Huang, H.-J. Chiang, C.-Z. Wu, et al., Micromachines 10, 434 (2019). https://doi.org/10.3390/mi10070434

X.-Q. Tan, J.-Y. Liu, J.-R. Niu, et al., Materials 11, 1953 (2018). https://doi.org/10.3390/ma11101953

A. K. Akhmedov, A. K. Abduev, V. M. Kanevsky, et al., Coatings 10, 269 (2020). https://doi.org/10.3390/coatings10030269

N. M. S. Jahed, M. Mahmoudysepehr, and S. Sivoththaman, “Highly conductive TCO by RF sputtering of Al:ZnO for thin film photovoltaics,” in Proceedings of the 2015 IEEE 42nd Photovoltaic Specialist Conference PVSC, New Orleans, LA, 2015, pp. 1–4. https://doi.org/10.1109/PVSC.2015.7356300

H. B. Zhou, H. Y. Zhang, M. L. Tan, et al., Mater. Res. Innov. 16, 390 (2012). https://doi.org/10.1179/1433075X12Y.0000000002

F. Bittau, A. Abbas, K. L. Barth, et al., Thin Solid Films 633, 92 (2017). https://doi.org/10.1016/j.tsf.2016.10.068

A. Abduev, A. Akhmedov, A. Asvarov, and V. Belyaev, SID Symp. Digest Tech. Pap. 50, 977 (2019). https://doi.org/10.1002/sdtp.13089

M. Toma, D. Marconi, M. Pop, et al., Anal. Lett. 52, 2227 (2019). https://doi.org/10.1080/00032719.2019.1606819

A. M. Ismailov, L. L. Emiraslanova, M. Kh. Rabadanov, M. R. Rabadanov, and I. Sh. Aliev, Tech. Phys. Lett. 44, 528 (2018). https://doi.org/10.1134/S1063785018060202

A. K. Akhmedov, A. S. Asvarov, A. E. Muslimov, and V. M. Kanevsky, Coatings 10, 1076 (2020). https://doi.org/10.3390/coatings10111076

A. Sh. Asvarov, A. E. Muslimov, A. K. Akhmedov, A. Kh. Abduev, and V. M. Kanevsky, Instrum. Exp. Tech. 62, 726 (2019). https://doi.org/10.1134/S0032816219050033

E. Muchuweni, T. S. Sathiaraj, and H. Nyakotyo, Heliyon 3, e00285 (2017). https://doi.org/10.1016/j.heliyon.2017.e00285

K. Ellmer and A. Bikowski, J. Phys. D 49, 413002 (2016). https://doi.org/10.1088/0022-3727/49/41/413002

H. Rotella, Y. Mazel, S. Brochen, et al., J. Phys. D 50, 485106 (2017). https://doi.org/10.1088/1361-6463/aa920b

F. Chaabouni, J. B. Belgacem, and M. Abaab, Chin. J. Phys. 52, 272 (2014). https://doi.org/10.6122/CJP.52.272

Z. Huafu, L. Hanfa, Z. Aiping, and Y. Changkun, J. Semicond. 30, 113002 (2009). https://doi.org/10.1088/1674-4926/30/11/113002

W. M. Lu, J. Zhang, H. W. Diao, et al., Mater. Sci. Forum 685, 134 (2011). https://doi.org/10.4028/www.scientific.net/msf.685.134

M. Chaves, R. Ramos, E. Martins, et al., Mater. Res. 22, e20180665 (2019). https://doi.org/10.1590/1980-5373-mr-2018-0665

A. Bikowski, T. Welzel, and K. Ellmer, Appl. Phys. Lett. 102, 242106 (2013). https://doi.org/10.1063/1.4811647

Z. Ghorannevis, M. T. Hosseinnejad, M. Habibi, and P. Golmahdi, J. Theor. Appl. Phys. 9, 33 (2015). https://doi.org/10.1007/s40094-014-0157-1

ACKNOWLEDGMENTS

The work was carried out using the equipment of the Center for Collective Use of the Federal Scientific Research Center Crystallography and Photonics with the support of the Ministry of Education and Science (project RFMEFI62119X0035) and the Analytical Center for Collective Use of the Dagestan Federal Research Center.

Funding

This work was supported by the Ministry of Science and Higher Education of the Russian Federation within the framework of the State Assignments for the Dagestan Federal Research Center (Russian Academy of Sciences) and the Federal Scientific Research Center Crystallography and Photonics (Russian Academy of Sciences) as well as with the support of the Russian Foundation for Basic Research (grant nos. 20-07-00760 A, 18-29-12099 mk).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akhmedov, A.K., Abduev, A.K., Asvarov, A.S. et al. ZnO-Based Nanocrystalline Films Obtained in a Single Vacuum Cycle. Nanotechnol Russia 15, 741–746 (2020). https://doi.org/10.1134/S1995078020060026

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1995078020060026