Abstract

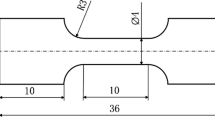

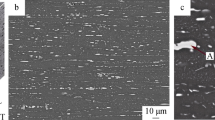

The widespread use of structural aluminum alloys AMg6 and V95 in modern mechanical engineering has led to the identification of such a problem as the non-optimal structure of commercial semi-finished products from these alloys. Traditional types of heat treatment do not always make it possible to correct the structure and obtain a high complex of operational properties. The most common structural defects in commercial semi-finished aluminum alloys containing magnesium and zinc are banding formed by the strengthening intermetallic phase MgZn2. The structure of magnesium–aluminum alloys has been studied by high-resolution optical microscopy under various heat treatment modes, which include long-term homogenization annealing. The studies were carried out on samples of AMg6 and V95 alloys. For heat treatment, a chamber furnace of the SNOL type equipped with a PID controller was used; the samples were loaded into a furnace preheated to a temperature of 500°C and kept in it for 8 and 16 h. After the exposure was completed, the samples were removed from the furnace and cooled in still air. The hardness was measured on the original samples, samples after heat treatment and 14 days after heat treatment. Studies have shown that an increase in the time of high-temperature holding at 500°C for both alloys leads to the dissolution of intermetallic particles. As a result of the ongoing structural-phase transformations during further cooling and subsequent natural aging, the intermetallic phase again precipitates from the solid solution, as shown by hardness measurements made on the original samples, then after high-temperature annealing and subsequently after natural aging for 14 days.

Similar content being viewed by others

REFERENCES

S. G. Ivanov, M. A. Gur’ev, A. M. Gur’ev, and V. V. Romanenko, Fundam. Probl. Sovrem. Materialoved. 17 (1), 74 (2020).

A. A. Kazakov, S. V. Ryaboshuk, D. A. Lyubochko, and L. S. Chigintsev, Microsc. Microanal. 21, 1755 (2015).

G. F. van der Voort, O. Pakhomova, and A. Kazakov, Mater. Perform. Character. 5, 521 (2016).

ASM Handbook, Vol. 9: Metallography and Microstructures (2004), p. 493.

A. Kazakov and D. Kiselev, Metallogr. Microstruct. Anal. 5, 294 (2016).

G. F. van der Voort, Mater. Characteriz. 27, 241 (1991).

A. A. Kazakov, D. V. Kiselev, and E. I. Kazakova, Chern. Met., No. 7, 65 (2021).

A. Kazakov, P. Kovalev, and S. Ryaboshuk, CIS Iron Steel Rev., Nos. 1–2, 7 (2007).

Aluminum Alloys. Metallurgy of Aluminum and Its Alloys, Reference Book (Metallurgiya, Moscow, 1971) [in Russian].

B. N. Arzamasov, I. I. Sidorin, G. F. Kosolapov, et al., Materials Science, The School-Book for Higher Technical School, Ed. by B. N. Arzamasov (Mashinostroenie, Moscow, 1986) [in Russian].

M. V. Mal’tsev, Metallography of Industrial Non-Ferrous Metals and Alloys, 2nd ed. (Metallurgiya, Moscow, 1970) [in Russian].

D. I. Budelovskii, S. Yu. Petrovich, V. A. Lipin, I. K. Bo-richeva, V. D. Andreeva, and A. L. Shakhmin, Tekhnol. Legk. Splavov, No. 3, 53 (2016).

A. S. Kalinichenko, V. A. Kalinichenko, V. S. Niss, and S. V. Grigor’ev, Lit’e Metall. 74 (1), 93 (2014).

O. E. Osintsev and V. Yu. Konkevich, Tekhnol. Legk. Splavov, No. 1, 157 (2010).

S. L. Tsukrov, Tekhnol. Legk. Splavov, No. 1, 68 (2016).

ACKNOWLEDGMENTS

This work was carried out in the Center of Collective Use of the Polzunov Altai State Technical University.

Funding

This work was supported by ongoing institutional funding. No additional grants to carry out or direct this particular research were obtained.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by Yu. Ryzhkov

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zenin, M.N., Guryev, A.M., Ivanov, S.G. et al. Influence of High-Temperature Annealing of Aluminum Alloys AMg6 and V95 on Their Structural-Phase State and Strength Properties. Phys. Solid State 65, 58–61 (2023). https://doi.org/10.1134/S1063783423700026

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063783423700026