Abstract

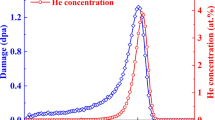

In this paper, we study the structural-phase state of the surface layers of commercially pure titanium (VT1-0 alloy) implanted with aluminum ions by transmission electron microscopy and energy-dispersive X-ray spectroscopy. The samples are foils cut perpendicular to the treated surface. The samples are studied in three states (submicrocrystalline, ultrafine-grained, and fine-grained) obtained after a combined method of multiple uniaxial pressing (abc pressing) followed by multi-pass rolling in grooved rolls at room temperature and subsequent annealing at 573, 673, and 773 K, respectively, for 1 h. Ion implantation is carried out for 8 h 20 min at an irradiation dose of 1018 ions/cm2 and 623 K. It is established that implantation led to the formation of a gradient structure consisting of five layers: (1) oxide layer, (2) ion-implanted layer, (3) layer with a crushed grain structure, (4) layer formed under the residual influence of implantation, and (5) layer corresponding to the nonimplanted state of the alloy. The structural-phase state of layers 1–3, where the concentration of implanted aluminum was maximum, is studied. For each layer, its thickness, phase composition, shape and arrangement of particles of the phases formed by the action of ion implantation are determined, and the sizes of α-Ti grains, sizes, distribution density, and volume fractions of precipitated particles are measured. It is established that the basis of layer 1 is aluminum and titanium oxides. The matrix of layer 2 is an α-Ti solid solution supersaturated with Al atoms, and that of layer 3 is a solid solution based on α-Ti. Aluminum implantation is found to lead to the formation of the intermetallic phases Ti3Al and TiAl3. The particles of these phases are present as separately located nanograins in layer 1, Ti3Al particles have a lamellar shape and are located inside α-Ti grains in layers 2 and 3, and TiAl3 particles have a rounded shape and are found both in the bulk and at the grain boundaries of α-Ti. The volume fractions of intermetallic phases in layer 3 are maximum.

Similar content being viewed by others

REFERENCES

V. V. Mikhailov, A. E. Gitlevich, A. D. Verkhoturov, A. I. Mikhailyuk, A. V. Belyakov, and L. A. Konevtsov, Surf. Eng. Appl. Electrochem. 49, 373 (2013).

V. I. Ivanov and A. Yu. Kostyukov, Ritm Mashinostr., No. 10, 36 (2016).

A. E. Ligachev, M. V. Zhidkov, S. A. Sorokin, Yu. R. Kolobov, and G. V. Potemkin, Inorg. Mater.: Appl. Res. 10, 541 (2018). https://doi.org/10.1134/S2075113319030225

S. Konovalov, K. Osintsev, A. Golubeva, V. Smelov, Y. Ivanov, X. Chen, and I. Komissarova, J. Mater. Res. Technol. 9, 8796 (2020). https://doi.org/10.1016/j.jmrt.2020.06.016

Y. Geng, S. V. Konovalov, and X. Chen, Prog. Phys. Met. 21, 26 (2020). https://doi.org/10.15407/ufm.21.01.026

Yu. R. Kolobov, S. S. Manokhin, V. I. Betekhtin, A. G. Kadomtsev, M. V. Narykova, G. V. Odintsova, and G. V. Khramov, Tech. Phys. Lett. 48, in press(2022).

D. A. Aleksandrov, S. A. Muboyadzhyan, A. N. Lutsenko, and P. L. Zhuravleva, Aviats. Mater. Tekhnol., No. 2, 33 (2018). https://doi.org/10.18577/2071-9140-2018-0-2-33-39

A. I. Ryabchikov, A. E. Shevelev, D. O. Sivin, I. A. Bozhko, E. B. Kashkarov, G. A. Bleykher, I. B. Stepanov, and A. I. Ivanova, J. Alloys. Compd. 793, 604 (2019).

X. Chen, A. Soveja, M. Chaussumier, P. Zhang, D. Wei, and F. Ding, Surf. Coat. Technol. 344, 572 (2018). https://doi.org/10.1016/j.surfcoat.2018.03.064

A. Kar, S. V. Kailas, and S. Suwas, Materialia 11, 100702 (2020). https://doi.org/10.1016/j.mtla.2020.100702

A. N. Didenko, Yu. P. Sharkeev, E. V. Kozlov, and A. I. Ryabchikov, Long-Range Effects in Ion-Implanted Metallic Materials (NTL, Tomsk, 2004) [in Russian].

I. A. Kurzina, E. V. Kozlov, and Yu. P. Sharkeev, Gradient Surface Layers Based on Intermetallic Particles: Synthesis, Structure, Properties (NTL, Tomsk, 2013) [in Russian].

E. V. Kozlov, A. M. Glezer, N. A. Koneva, N. A. Popova, and I. A. Kurzina, Fundamentals of Plastic Deformation of Nanostructured Materials (Fizmatlit, Moscow, 2016) [in Russian].

F. F. Komarov, Physical Processes During Ion Implantation Into Solids (Tekhnoprint, Minsk, 2001) [in Russian].

D. A. Zatsepin, I. A. Vainshtein, and S. O. Cholakh, Ionic Modification of Functional Materials: Textbook (Ural. Fed. Univ., Yekaterinburg, 2014) [in Russian].

Yu. P. Sharkeev, A. Yu. Eroshenko, V. A. Kukareko, A. V. Belyi, and V. A. Bataev, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., No. 8, 60 (2012).

A. V. Nikonenko, N. A. Popova, E. L. Nikonenko, M. P. Kalashnikov, E. M. Oks, and I. A. Kurzina, Vacuum 189, 110230 (2021). https://doi.org/10.1016/j.vacuum.2021.110230

A. V. Nikonenko, N. A. Popova, E. L. Nikonenko, M. P. Kalashnikov, and I. A. Kurzina, Vestn. Permsk. Nats. Issled. Politekh. Univ., Ser. Mashinostr., Materialoved. 23 (4), 15. (2021). https://doi.org/10.15593/2224-9877/2021.4.02

G. A. Salishchev, V. R. Valiakhmetov, R. S. Galeev, and S. P. Malysheva, Metally, No. 4, 86 (1996).

A. Yu. Eroshenko, Yu. P. Sharkeev, A. I. Tolmachev, G. P. Korobitsyn, V. I. Dan, and V. I. Danilov, Perspekt. Mater., No. S7, 107 (2009).

I. A. Kurzina, I. A. Bozhko, M. P. Kalashnikov, A. Yu. Eroshenko, Yu. P. Sharkeev, Materialovedenie, No. 5, 48 (2010).

V. I. Gushenets, A. G. Nikolaev, E. M. Oks, L. G. Vintizenko, G. Yu. Yushkov, A. Oztarhan, and I. G. Brown, Rev. Sci. Instrum. 77, 063301 (2006). https://doi.org/10.1063/1.2206778

Saltykov, S. A., Quantitative Metallography (Metallurgiya, Moscow, 1970) [in Russian].

X. Sun, Y. Guo, Y. Li, S. Zhang, and Q. Wei, Mater. Sci. Eng., A 669, 226 (2016). https://doi.org/10.1016/j.msea.2016.05.093

M. I. Gol’dshtein and V. M. Farber, Dispersion Hardening of Steel (Metallurgiya, Moscow, 1979) [in Russian].

A. E. Vol, Structure and Properties of Binary Metal Systems (Fizmatgiz, Moscow, 1959), Vol. 1 [in Russian].

ACKNOWLEDGMENTS

The results were obtained using equipment at the Nano-Center of National Research Tomsk Polytechnic University (a JEOL JEM-2100F transmission electron microscope with a sample-preparation system).

Funding

The work was supported by the Ministry of Science and Higher Education of the Russian Federation, topic no. FEMN-2020-0004 and the Russian Foundation for Basic Research, project no. 20-38-90 066.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

We declare that we have no conflicts of interest.

Additional information

Translated by A. Ivanov

Rights and permissions

About this article

Cite this article

Nikonenko, A.V., Popova, N.A., Nikonenko, E.L. et al. Grain-Size Effect on the Structural-Phase State of the Surface Layer of VT1-0 Alloy Implanted with Aluminum Ions. J. Surf. Investig. 16, 1280–1290 (2022). https://doi.org/10.1134/S1027451022060441

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451022060441