Abstract

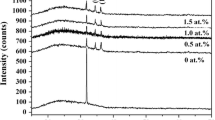

La-doped nanostructured NiO films are fabricated by the sol-gel spin-coating technique on a fluorine-doped tin-oxide glass. The atomic-force microscopy of La : NiO films demonstrates a change in the grain size of the film due to doping with La. X-ray diffraction shows that La : NiO films are of a nanocrystalline nature, the crystallite size decreases as the La content increases. The optical constants are calculated by the Kramers–Kronig method. The band gap decreases at a higher La dopant content due to the quantum-confinement effect. The values of the nonlinear susceptibility of the films of first and third orders are also calculated, and these parameters behave in a similar way. A highly effective radiation-protective material based on La : NiO films is obtained.

Similar content being viewed by others

REFERENCES

B. Sasi, K. G. Gopchandran, P. K. Manoj, P. Koshy, P. Prabhakara Rao, and V. K. Vaidyan, Vacuum 68, 149 (2003). https://doi.org/10.1016/s0042-207x(02)00299-3

S. Mohseni Meybodi, S. A. Hosseini, M. Rezaee, S. K. Sadrnezhaad, and D. Mohammad Yani, Ultrason. Sonochem. 19, 841 (2012). https://doi.org/10.1016/j.ultsonch.2011.11.017

M. Awais, D. Dini, J. M. Don Macelroy, Y. Halpin, J. G. Vos Johannes, and D. P. Dowling, J. Electroanal. Chem. 689, 185 (2013). https://doi.org/10.1016/j.jelechem.2012.11.025

I. Hotovy, J. Huran, and L. Spiess, J. Mater. Sci. 39, 2609 (2004). https://doi.org/10.1023/B:JMSC.0000020040.77683.20

A. A. A. Darwish, M. Rashad, and H. A. Al-Aoh, Dyes Pigm. 160, 563 (2019). https://doi.org/10.1016/j.dyepig.2018.08.045

M. Bonomo, J. Nanopart. Res. 20, 222 (2008). https://doi.org/10.1007/s11051-018-4327-y

D. B. Menzies, L. Bourgeois, Y. B. Cheng, G. P. Simon, N. Brack, and L. Spiccia, Surf. Coat. Technol. 197, 61 (2005). https://doi.org/10.1016/j.surfcoat.2004.10.11

A. M. Soleimanpour, A. H. Jayatissa, and G. Sumanasekera, Appl. Surf. Sci. 276, 291 (2013). https://doi.org/10.1016/j.apsusc.2013.03.085

K. Tian, X. Wang, H. Li, R. Nadimicherla, and X. Guo, Sens. Actuators, B 227, 554 (2016). https://doi.org/10.1016/j.snb.2015.12.104

J. Choia, J. Byunb, and S. Kimb, Sens. Actuators, B 227, 149 (2016). https://doi.org/10.1016/j.snb.2015.12.014

F. Yang and Z. Guo, J. Colloid Interface Sci. 467, 192 (2016). https://doi.org/10.1016/j.jcis.2016.01.033

Attieh A. Al-Ghamdi, M. Sh Abdel-wahab, A. A. Farghali, and P. M. Z. Hasan, Mater. Res. Bull. 75, 71 (2016). https://doi.org/10.1016/j.materresbull.2015.11.027

J. H. Kim, K. Zhu, Y. F. Yan, C. L. Perkins, and A. J. Frank, Nano Lett. 10, 4099 (2010). https://doi.org/10.1021/nl102203s

P. Justin, S. K. Meher, and G. R. Rao, J. Phys. Chem. C 114, 5203 (2010). https://doi.org/10.1021/jp9097155

M. Krunks, J. Soon, T. Unt, A. Mere, and V. Mikli, Vacuum 107, 242 (2014). https://doi.org/10.1016/j.vacuum.2014.02.013

W. L. Jang, Y. M. Lu, W. S. Hwang, and W. C. Chen, J. Eur. Ceram. Soc. 30, 503 (2010). https://doi.org/10.1016/j.jeurceramsoc.2009.05.041

N. P. Klochko, K. S. Klepikova, D. O. Zhadan, S. I. Petrushenko, V. R. Kopach, G. S. Khrypunov, V. M. Lyubov, S. V. Dukarov, V. O. Nikitin, M. O. Maslak, A. Yu. Zakovorotniy, and A. L. Khrypunova, Mater. Sci. Semicond. Process. 83, 42 (2018). https://doi.org/10.1016/j.mssp.2018.04.010

S. C. Chen, T. Y. Kuo, Y. C. Lin, and H. C. Lin, Thin Solid Films 519, 4944(2011). https://doi.org/10.1016/j.tsf.2011.01.058

M. Ben Amor, A. Boukhachem, K. Boubaker, and M. Amlouk, Mater. Sci. Semicond. Process. 27, 994 (2014). https://doi.org/10.1016/j.mssp.2014.08.008

M. Ben Amor, A. Boukhachem, A. Labidi, K. Boubaker, and M. Amlouk, J. Alloys Compd. 693, 490 (2017). https://doi.org/10.1016/j.jallcom.2016.09.207

R. Lontio Fomekong, H. M. Tedjieukeng Kamta, J. Ngolui Lambi, D. Lahem, P. Eloy, M. Debliquy, and A. Delcorte, J. Alloys Compd. 731, 1188 (2018). https://doi.org/10.1016/j.jallcom.2017.10.089

V. Ganesh, L. Haritha, Mohd Anis, Mohd Shkir, I. S. Yahia, Arun Singh, and S. Al-Faify, Solid State Sci. 86, 98 (2018). https://doi.org/10.1016/j.solidstatesciences.2018.10.009

J. Keraudy, A. Ferrec, M. Richard-Plouet, J. Hamon, A. Goullet, and P.-Y. Jouan, Appl. Surf. Sci. 409, 77 (2017). https://doi.org/10.1016/j.apsusc.2017.02.229

X. Hou, Q. Lu, and X. Wang, J. Sci.: Adv. Mater. Devices 2, 41 (2017). https://doi.org/10.1016/j.jsamd.2017.02.006

A. Manikandan, E. Manikandan, B. Meenatchi, S. Vadivel, S. K. Jaganathan, R. Ladchumananandasivam, M. Henini, M. Maaza, and J. Sundeep Aanand, J. Alloys Compd. 723, 1155 (2017). https://doi.org/10.1016/j.jallcom.2017.06.336

K. Singh, R. Kumar, and A. Chowdhury, Mater. Today: Proc. 5, 22993 (2018). https://doi.org/10.1016/j.matpr.2018.11.027

L. Vimala Devi, S. Sellaiyan, S. Sankar, and K. Sivaji, Mater. Res. Express 5, 51085468 (2018). https://doi.org/10.1088/2053-1591/aaa7a3

J. Pan, W. Du, Y. Liu, Y. Cheng, and Sh. Yuan, J. Rare Earths 37, 602 (2019). https://doi.org/10.1016/j.jre.2018.10.004

D. Han, X. Jing, J. Wang, P. Yang, D. Song, and J. Liu, J. Electroanal. Chem. 682, 37 (2012). https://doi.org/10.1016/j.jelechem.2012.06.016

J. Jian, F. Luo, Ch. Gao, C. Suo, X. Wang, H. Song, and X. Hu, Ceram. Int. 40, 6973 (2014). https://doi.org/10.1016/j.ceramint.2013.12.024

M. M. El-Nahass, H. M. Zeyada, K. F. Abd-El Rahman, and A. A. A. Darwish, Eur. Phys. J. Appl. Phys. 62, 10202 (2013). https://doi.org/10.1051/epjap/2013120061

X. Yang, P. Gao, Z. Yang, J. Zhu, F. Huang, and J. Ye, Sci. Rep. 7, 44576 (2017). https://doi.org/10.1038/srep44576

S. Scheel, L. Knöll, and D. G. Welsch, Phys. Rev. A 60, 4094 (1999). https://doi.org/10.1103/PhysRevA.60.4094

A. Rahal, S. Benramache, and B. Benhaoua, J. Semicond. 34, 093003 (2013). https://doi.org/10.1088/1674-4926/34/9/093003

M. M. El-Samanoudy, Thin Solid Films 423, 201 (2003). https://doi.org/10.1016/S0040-6090(02)01042-8

M. M. El-Nahass, K. F. Abd-El-Rahman, A. A. M. Farag, and A. A. A. Darwish, Int. J. Mod. Phys. 18, 421 (2004). https://doi.org/10.1142/S0217979204023982

W. Xiong, S. Jimei, G. Lisheng, J. Jiayi, Z. Huagui, and Z. Zude, Nanotechnology 16, 37 (2004). https://doi.org/10.1088/0957-4484/16/1/009

M. Sesha Reddy, K. T. Ramakrishna Reddy, B. S. Naidu, and P. J. Reddy, Opt. Mater. 4, 787 (1995). https://doi.org/10.1016/0925-3467(95)00039-9

Saleem I. Qashou, M. Rashad, A. A. A. Darwish, and T.A. Hanafy, Opt. Quantum Electron. 49, 240 (2017). https://doi.org/10.1007/s11082-017-1069-5

H. Ticha and L. Tichy, J. Optoelectron. Adv. Mater. 4, 381 (2002). https://doi.org/10.1.1.457.9038

V. Ganesh, I. Yahia, S. AlFaify, and M. Shkir, J. Phys. Chem. Solids 100, 115 (2017). https://doi.org/10.1016/j.jpcs.2016.09.022

Funding

This work was financially supported by the Deanship of Scientific Research at King Khalid University within the framework of the research-group program (project no. R.G.P.2/43/40).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by N. Saetova

Rights and permissions

About this article

Cite this article

Aboraia, A.M., Darwish, A.A., Zahran, H.Y. et al. Structural, Morphological, and Optical Analysis of La-Doped NiO Films Fabricated by the Sol-Gel Spin-Coating Technique for Solid-State Electronics. J. Surf. Investig. 16, 1048–1054 (2022). https://doi.org/10.1134/S1027451022060027

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451022060027