Abstract

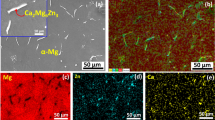

The strength of the Al2O3 powder coating formed by a cumulative detonation method on a steel St3 substrate is determined, and its structure is studied. The optimum conditions for deposition are chosen. They make it possible to form a dense high-strength coating with good adhesion to the substrate.

Similar content being viewed by others

References

S. Valette, A. Denoirjean, F. Limoges, et al., “Interaction between a thin noncontinuous d.c. plasma sprayed alumina layer and preoxidized low carbon substrate,” in Proceedings of Conference on Thermal Spray 2005, Basel, Switzerland (2005), pp. 1387–1392.

M. A. Riley and A. J. Sturgeon, “Influence of spraying parameters on the properties of HVOF alumina coatings,” in Proceedings of Conference on Thermal Spray 2005, Basel, Switzerland (2005).

B. Wielage, A. Wank, H. Pokhmurska, et al., “Correlation of microstructure with abrasion and oscillating wear resistance of thermal spray coatings,” in Proceedings of Conference on Thermal Spray 2005, Basel, Switzerland (2005).

S. Tao, X. Zhou, and C. Ding, “Friction and wear behavior of plasma sprayed Al2O3 and Cr2O3 coatings against copper alloy under high load dry sliding,” in Proceedings of Conference on Thermal Spray 2005, Basel, Switzerland (2005).

E. Turunen, U. Kanerva, T. Varis, et al., “Nanostructured ceramic HVOF coatings for improved protection,” in Proceedings of Conference on Thermal Spray 2007, Beijing, China (2007), pp. 484–488.

Y. N. Tyurin and A. D. Pogrebnjak, “Advances in the development of detonation technologies and equipment for coating deposition,” Surf. Coat. Techn. 111, 269–275 (1999).

A. D. Pogrebnyak, Yu. N. Tyurin, Yu. F. Ivanov, et al., “Preparation and study of the structure and properties of plasma detonation Al2O3 coatings,” Pis’ma Zh. Tekh. Fiz. 26(21), 53–60 (2000).

Yu. N. Tyurin, M. A. Zhadkevich, A. D. Pogrebnyak, and O. V. Kolisnichenko, “Pulse plasma equipment and technologies for the modification and deposition of coatings on equipment working surfaces of machinery,” in Proceedings of the VI International Conference on Films and Coatings (SPbGTU, St. Petersburg, 2001), pp. 71–81.

Yu. N. Tyurin, A. D. Pogrebnyak, O. V. Kolisnichenko, and I. M. Duda, “Comparative analysis of the efficiency of cumulative detonation and HVOF devices for gas thermal spraying of coatings,” Uprochnyayushchie Tekhnologii, No. 5, 27–33 (2009).

B. V. Mott, Tests for Microindention Microhardness (Metallurgizdat, Moscow, 1960).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © M.G. Kovaleva, M.S. Prozorova, M.Yu. Arseenko, Yu.N. Tyurin, O.V. Kolisnichenko, 2012, published in Deformatsiya i Razrushenie Materialov, 2012, No. 12, pp. 9–12.

Rights and permissions

About this article

Cite this article

Kovaleva, M.G., Prozorova, M.S., Arseenko, M.Y. et al. Structure and properties of an Al2O3 powder coating formed by a cumulative detonation method. Russ. Metall. 2014, 275–278 (2014). https://doi.org/10.1134/S0036029514040053

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029514040053