Abstract

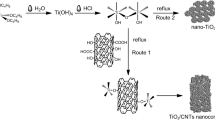

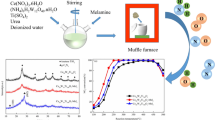

Novel titanium dioxide/graphitic carbon nitride (TiO2/g-C3N4) hybrid was prepared by a facile sol-reflux method. Then, the as-prepared TiO2/g-C3N4 hybrid was characterized by FESEM, XRD, FT-IR, XPS, and BET analysis. The results show that TiO2 is attached to the g-C3N4 thin pieces in the form of anatase. A mesoporous structure, which has a large specific surface area and is conducive to catalytic adsorption, is formed. Simultaneously, chemical bonds may be formed between the oxides and g-C3N4. Furthermore, in order to analyze its catalytic effect on the decomposition of ammonium perchlorate (AP), Differential Scanning Calorimetry (DSC) technique has been employed. The decomposition temperature of AP dropped by 26°C when 2 wt % TiO2/g-C3N4 hybrid was added in, and the activation energy (Ea) by 44%. Based on the experimental data, a possible catalytic reaction mechanism of TiO2/g-C3N4 hybrid has been proposed.

Similar content being viewed by others

REFERENCES

N. M. Mahmoodi, P. Rezaei, C. Ghotbei, and M. Kazemeini, Fibers Polym. 17, 1842 (2016).

P. Feng, X. Fu, Y. Hao, and H. Wang, New Carbon Mater. 22, 213 (2007).

Q. Liao, J. Sun, and L. Gao, Colloids Surf., A 345, 95 (2009).

Q. Ling, L. Y. Chen, A. J. Wang, et al., Fullerenes Nanotubes Carbon Nanostruct. 25, 23 (2017).

J. Huang, N. Zhu, T. Yang, et al., Biosens. Bioelectron. 72, 332 (2015).

Y. Chen, H. Yu, L. Yi, et al., Powder Technol. 325, 568 (2018).

C. Tian, Mater. Res. Bull. 103, 83 (2018).

Y. Fang, X. Lu, and W. Chen, Gen. Chem. 3, 125 (2017).

J. Schneider, M. Matsuoka, M. Takeuchi, et al., Chem. Rev. 114, 9919 (2014).

V. Etacheri, C. di Valentin, J. Schneider, et al., J. Photochem. Photobiol., C 25, 1 (2015).

A. J. Frank, N. Kopidakis, and J. van de Lagemaat, Coord. Chem. Rev. 248, 1165 (2004).

B. Bhanvase, T. Shende, and S. Sonawane, Environ. Technol. Rev. 6, 1 (2017).

E. Petersen, J. Small, M. Stephens, et al., US Patent No. 8066834 (2011).

D. L. Reid, A. E. Russo, R. V. Carro, et al., Nano Lett. 7, 2157 (2007).

N. Li, Z. Geng, M. Cao, et al., Carbon 54, 124 (2013).

A. Dey, V. Nangare, P. V. More, et al., RSC Adv. 5, 63777 (2015).

S. H. Meng, J. F. Liu, X. T. Kong, and S. G. Du, Trans. Met. Chem. 45, 545 (2020).

R. C. Dante, P. Martín-Ramos, L. M. Navas-Gracia, et al., J. Macromol. Sci., B 52, 623 (2013).

L. Tan, J. Xu, S. Li, et al., Materials 10, 484 (2017).

Z. Zhao, Y. Sun, and F. Dong, Nanoscale 7, 15 (2015).

F. He, G. Chen, J. Miao, et al., ACS Energy Lett. 1, 969 (2016).

K. Sridharan, E. Jang, and T. J. Park, Appl. Catal., B 142, 718 (2013).

M. R. Gholipour, F. Béland, and T. O. Do, Int. J. Chem. React. Eng. 14, 851 (2016).

Q. Li, Y. He, and R. Peng, RSC Adv. 5, 24507 (2015).

Q. Li, Y. He, and R. Peng, Eur. J. Inorg. Chem. 2015, 4062 (2015).

W. Zhou, F. Sun, K. Pan, et al., Adv. Funct. Mater. 21, 1922 (2011).

J. Hong, X. Xia, Y. Wang, and R. Xu, J. Mater. Chem. 22, 15006 (2012).

Y. Li, J. Zhang, Q. Wang, et al., J. Phys. Chem. B 114, 9429 (2010).

I. Balchev, N. Minkovski, K. Dimitrov, et al., J. Phys.: Conf. Ser. 682, 012033 (2016).

P. Babu, S. Mohanty, B. Naik, and K. Parida, ACS Appl. Energy Mater. 1, 5936 (2018).

R. Ren, Z. Wen, S. Cui, et al., Sci. Rep. 5, 10714 (2015).

J. Ma, X. Tan, T. Yu, and X. Li, Int. J. Hydrogen Energy 41, 3877 (2016).

G. Zhang, J. Zhang, M. Zhang, and X. Wang, J. Mater. Chem. 22, 8083 (2012).

F. Dong, Z. Zhao, T. Xiong, et al., ACS Appl. Mater. Interface 5, 11392 (2013).

S. Vyazovkin and C. A. Wight, Chem. Mater. 11, 3386 (1999).

G. Li, X. Liu, and W. Bai, Mater. Res. Express 5, 035036 (2018).

P. W. Jacobs and A. Russell-Jones, J. Phys. Chem. 72, 202 (1968).

A. A. Vargeese and K. Muralidharan, Mater. Chem. Phys. 139, 537 (2013).

V. Boldyrev, Thermochim. Acta 443, 1 (2006).

J. G. Amores, V. S. Escribano, G. Ramis, and G. Busca, Appl. Catal., B 13, 45 (1997).

ACKNOWLEDGMENTS

The authors thank the School of Mechanical Engineering of Tsinghua University for their assistance in the XPS characterization. Meanwhile, the technology was supported by the School of Materials Science and Engineering of Tsinghua University for performing FESEM and BET analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Meng, S., Mi, W., Liu, J. et al. Preparation of Titanium Dioxide/Graphitic Carbon Nitride Hybrid and Its Catalytic Effect on Ammonium Perchlorate Decomposition. Russ. J. Phys. Chem. 96, 2497–2504 (2022). https://doi.org/10.1134/S0036024422110280

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036024422110280