Abstract

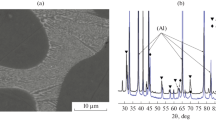

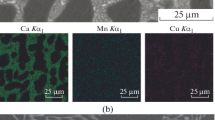

The regime of thermomechanical treatment of flat ingots of a high-strength sparingly alloyed alloy based on the Al–Zn–Mg–Ni–Fe system upon the production of thin-sheet rolled products with a reduction of more than 97% has been substantiated. Using experimental and calculated methods, the structure and phase composition of the experimental alloy in the as cast and deformed state and after heat treatment including quenching with subsequent aging have been studied. It has been found that the structure of the wrought semi-finished products after aging according to Т and Т1 regimes consists of the precipitation-hardened aluminum matrix and uniformly distributed isolated particles of Al9FeNi with a size of 1–2 μm, which provides a combination of high strength and satisfactory plasticity at the level of standard high-strength aluminum alloys of the Аl–Zn–Mg–Cu system. The fractographic analysis confirmed that the tested samples underwent a ductile fracture.

Similar content being viewed by others

References

I. J. Polmear, Light Metals: From Traditional Alloys to Nanocrystals (Elsevier, Oxford, 2006), 4th Ed.

S. G. Alieva, M. B. Al’tman, S. M. Ambartsumyan, S. N. Anan’in, N. A. Aristova, and F. I. Kvasov, Industrial Aluminum Alloys._A Handbook (Metallurgiya, Moscow, 1984) [in Russian].

V. M. Beletskii and G. A. Krivov, Aluminum Alloys (Composition, Properties, Technology, Application)._A Handbook, Ed. by I. N. Fridlyander (KOMINTEKh, Kiev, 2005).

N. A. Belov, Phase Conposition of Industrial and Perspective Aluminum Alloys (MISiS, Moscow, 2010) [in Russian].

R. O. Vakhromov, E. A. Tkachenko, and O. I. Popova, “Influence of the main alloying elements, microadditives, and impurities on the properties of forging alloys of Al–Zn–Mg–Cu system,” Tsvetn. Metall., no. 5 (845), 61–65 (2013).

Y. L. Duan, G. F. Xu, X. Y. Peng, Y. Deng, Z. Li, and Z. M. Yin, “Effect of Sc and Zr additions on grain stability and superplasticity of the simple thermalmechanical processed Al–Zn–Mg alloy sheet,” Mater. Sci. Eng., A 648, 80–91 (2015).

X. Huang, Q. Pan, B. Li, Z. Yin, Z. Liu, and Z. Huang, “Microstructure, mechanical properties and stress corrosion cracking of Al–Zn–Mg–Zr alloy sheet with trace amount of Sc,” J. Alloys Compd. 650, 805–820 (2015).

N. A. Belov, V. D. Belov, A. N. Alabin, G. S. Zlobin, and S. S. Mishurin, “High-strengthed economically doped Al-based alloy,” RF Patent 2484168, Byull. Izobr., 2013, no. 16.

N. A. Belov, M. V. Shcherbakov, and V. D. Belov, “On manufacturability of economically alloyed nikalyn ATs6N0.5F during casting, rolling and welding,” Tsvetn. Metally, no. 12, 94–98 (2011).

T. K. Akopyan, A. G. Padalko, and N. A. Belov, “Influence of hot isostatic pressing on the structure and properties of an innovative low-alloy high-strength aluminum cast alloy based on the Al–Zn–Mg–Cu–Ni–Fe system,” Russ. Metallurgy (Metally), no. 6, 937-942 (2015).

V. Kh. Mann, A. N. Alabin, A. Yu. Krokhin, A. V. Frolov, and N. A. Belov, “New generation of high strength aluminum casting alloys,” Light Metal Age 73, 44–47 (2015).

B. C. Zolotarevskii and N. A. Belov, Metal Science of Cast Aluminum Alloys (MISiS, Moscow, 2005) [in Russian].

A. F. Belov, V. I. Dobatkin, and G. I. Eskin, “On the nature of nondendrite solidification of metallic liquids,” in Metal Science and Treatment of Nonferrous Alloys (Nauka, Moscow, 1992), pp. 66–76 [in Russian].

www.thermocalc.com.

N. A. Belov, “Quantitative phase analysis of the Al–Zn–Mg–Cu–Ni phase diagram in the region of compositions of high-strength nikalines,” Russ. J. Non-Ferrous Meta 51, 243–249 (2010).

L. F. Mondol’fo, Aluminum Alloys: Structure and Properties (Butterworth, London, 1976).

C. M. Li, Z. Q. Chen, S. M. Zeng, N. P. Cheng, and T. X. Chen, “Intermetallic phase formation and evolution during homogenization and solution in Al–Zn–Mg–Cu alloys,” Science China, 56, 2827–2838 (2014).

P. A. Rometsch, Y. Zhang, and S. Knigh, “Heat treatment of 7xxx series aluminium alloys—Some recent developments,” Trans. Nonferrous Met. Soc. China 24, 2003–2017 (2014).

M. F. Ibrahim, A. M. Samuel, and F. H. Samuel, “A preliminary study on optimizing the heat treatment of high strength Al–Cu–Mg–Zn alloys,” Mater. Design 57, 342–350 (2014).

I. Ozbek, “A study on the re-solution heat treatment of AA 2618 aluminum alloy,” Mater. Characteriz. 58, 312–317 (2007).

F. Novy, M. Janecek, and R. Kral, “Microstructure changes in a 2618 aluminium alloy during ageing and creep,” J. Alloys Compd. 487, 146–151 (2009).

B. C. Zolotarevskii, Mechanical Properties of Metals (MISiS, Moscow, 1998) [in Russian].

J. Zang, K. Zhang, and S. Dai, “Precipitation behavior and properties of a new high strength Al–Zn–Mg–Cu alloy,” Trans. Nonferrous Met. Soc. China 22, 2638–2644 (2012).

B. A. Kolachev, V. I. Elagin, and C. A. Livanov, Metal Science and Heat Treatment of Non-Ferrous Metals and Alloys. A Tutorial for Higher Education Institutes (MISiS, Moscow, 1999) [in Russian], 3rd ed.

S. S. Gorelik, S. V. Dobatkin, and L. M. Kaputkina, Recrystallization of Metals and Alloys (MISIS, Moscow, 2005) [in Russian], 3rd ed.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © P.K. Shurkin, N.A. Belov, T.K. Akopyan, A.N. Alabin, A.S. Aleshchenko, N.N. Avxentieva, 2017, published in Fizika Metallov i Metallovedenie, 2017, Vol. 118, No. 9, pp. 941–949.

Rights and permissions

About this article

Cite this article

Shurkin, P.K., Belov, N.A., Akopyan, T.K. et al. Formation of the structure of thin-sheet rolled product from a high-strength sparingly alloyed aluminum alloy “nikalin”. Phys. Metals Metallogr. 118, 896–904 (2017). https://doi.org/10.1134/S0031918X17070109

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X17070109