Abstract—

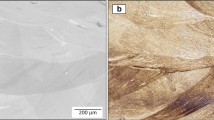

This paper presents numerical modeling results and experimental data on thermal conditions in Ti–Al–C MAX phase-based materials during self-propagating high-temperature synthesis (SHS) and extrusion. Based on a mathematical model for the thermal conditions of SHS extrusion, which makes it possible to analyze longitudinal and radial temperature profiles in an extruded sample with a model composition (64.2 wt % Ti + 27.1 wt % Al + 8.7 wt % C), we make recommendations as to favorable conditions for MAX phase formation in relation to strain, predict such conditions, and qualitatively compare the theoretical results and experimental data. We examine the effect of the delay time before compaction on the surface defect density of the samples and the effect of strain on the structure and surface quality of the extruded materials. Samples 10 mm in diameter are shown to be free of titanium carbide, whereas samples 5 and 8 mm in diameter contain 6–8 wt % titanium carbide.

Similar content being viewed by others

REFERENCES

Stolin, A.M., Bazhin, P.M., Averichev, O.A., Alymov, M.I., Gusev, A.O., and Simakov, D.A., Electrode materials based on a Ti–Al–C MAX phase, Inorg. Mater., 2016, vol. 52, no. 10, pp. 998–1001.

Zapata-Solvas, E., Hadi, M.A., Horlait, D., et al., Synthesis and physical properties of (Zr1 – x,Tix)3AlC2 MAX phases, J. Am. Ceram. Soc., 2017, vol. 100, no. 8, pp. 3393–3401. https://doi.org/10.1111/jace.14870

Radovic, M., Barsoum, M.W., Ganguly, A., et al., On the elastic properties and mechanical damping of Ti3SiC2, Ti3GeC2, Ti3Si0.5Al0.5C2 and Ti2AlC in the 300–1573 K temperature range, Acta Mater., 2006, vol. 54, no. 10, pp. 2757–2767. https://doi.org/10.1016/j.actamat.2006.02.019

Barsoum, M.W., The MAX Phases and Their Properties in Ceramics Science and Technology, New York: Wiley–VCH, 2010, vol. 2, pp. 299–345.

Christopoulos, S.-R.G., Filippatos, P.P., Hadi, M.A., et al., Intrinsic defect processes and elastic properties of Ti3AC2 (A = Al, Si, Ga, Ge, In, Sn) MAX phases, J. Appl. Phys., 2018, vol. 123, no. 2, paper 025 103. https://doi.org/10.1063/1.5011374

Prikhna, T.A., Starostina, A.V., Lizkendorf, D., et al., Studies of the oxidation stability, mechanical characteristics of materials based on MAX phases of the Ti–Al–(C,N) systems, and of the possibility of their use as tool bonds and materials for polishing, J. Superhard Mater., 2014, vol. 36, no. 1, pp. 9–17. https://doi.org/10.3103/S106345761401002X

Jeong, G., Baek, G., Zhang, T.F., et al., MAX-phase Ti2AlC ceramics: syntheses, properties and feasibility of applications in micro electrical discharge machining, J. Ceram. Proc. Res., 2016, vol. 17, no. 10, pp. 1116–1122.

Tomoshige, R. and Tanaka, H., Thermal properties of various Ti–Al–C composites prepared by hot shock compaction utilizing combustion synthesis, Arch. Metall. Mater., 2014, vol. 59, no. 4, pp. 1575–1578. https://doi.org/10.2478/amm-2014-0267

Stolin, A.M., Vrel, D., Galyshev, S.N., Hendaoui, A., Bazhin, P.M., and Sytschev, A.E., Hot forging of MAX compounds SHS-produced in the Ti–Al–C system, Int. J. Self-Propag. High-Temp. Synth., 2009, vol. 18, no. 3, pp. 194–199.

Bazhin, P.M., Kovalev, D.Yu., Luginina, M.A., and Averichev, O.A., Combustion of Ti–Al–C compacts in air and helium: a TRXRD study, Int. J. Self-Propag. High-Temp. Synth., 2016, vol. 25, no. 1, pp. 30–34. https://doi.org/10.3103/S1061386216010027

Khoptiar, Y. and Gotman, I., Ti2AlC ternary carbide synthesized by thermal explosion, Mater. Lett., 2002, vol. 57, no. 1, pp. 72–76. https://doi.org/10.1016/S0167-577X(02)00701-2

Hashimoto, S., Nishina, N., Hirao, K., Zhou, Y., Hyuga, H., Honda, S., and Iwamoto, Y., Formation mechanism of Ti2AlC under the self-propagating high-temperature synthesis (SHS) mode, Mater. Res. Bull., 2012, vol. 47, no. 5, pp. 1164–1168. https://doi.org/10.1016/j.materresbull.2012.02.003

Novikov, A.S., Paikin, A.G., and Shulov, V.A., Preparation, properties, and potential applications of titanium-based MAX materials, Uprochnyayushchie Tekhnol. Pokrytiya, 2006, no. 11, pp. 24–34.

Hendaoui, A., Andasmas, M., Amara, A., Benaldjia, A., Langlois, P., and Vrel, D., SHS of high-purity MAX compounds in the Ti–Al–C system, Int. J. Self-Propag. High-Temp. Synth., 2008, vol. 17, no. 2, pp. 129–135.

Stolin, A.M. and Bazhin, P.M., Manufacture of multipurpose composite and ceramic materials in the combustion regime and high-temperature deformation (SHS extrusion), Theor. Found. Chem. Eng., 2014, vol. 48, no. 6, pp. 751–764.

Stolin, A.M. and Stel’makh, L.S., Mathematical modeling of SHS compaction/extrusion: an autoreview, Int. J. Self-Propag. High-Temp. Synth., 2008, vol. 13, no. 1, pp. 53–70.

Stolin, A.M. and Stel’makh, L.S., General principles underlying mathematical modeling of SHS processes, Vestn. TGTU, 2014, vol. 20, no. 4, pp. 684–692.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Bazhin, P.M., Stel’makh, L.S. & Stolin, A.M. Effect of Strain on the Formation of a MAX Phase in Ti–Al–C Materials during Self-Propagating High Temperature Synthesis and Extrusion. Inorg Mater 55, 302–307 (2019). https://doi.org/10.1134/S0020168519030051

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168519030051