Abstract

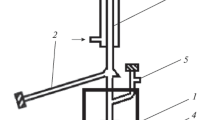

Using iron pentacarbonyl distillation as an example, we analyze the vaporization process in a closed vaporization–condensation system where vapor condenses on a flowing down liquid film. We jointly analyze the mechanisms behind vaporization, vapor transport, condensation, and flowing of the condensate on the inner surface of a vertical tube. We calculate the thickness of the flowing down liquid film, determine the vaporization coefficient for a closed system using experimentally determined temperature dependences of the vaporization rate and saturated vapor pressure, and present the vaporization rate as a function of the vaporization and condensation temperatures, the radius and height of the condensation tube, and the vaporization area of the still residue.

Similar content being viewed by others

References

Maruyama, T. and Shinyashiki, Y., Iron–iron oxide composite thin films prepared by chemical vapor deposition from iron pentacarbonyl, Thin Solid Films, 1998, vol. 333, nos. 1–2, pp. 203–206.

Van Worterghem, J., Mørup, S., Charles, S.W., et al., Formation and chemical stability of metallic glass particles prepared by thermolysis of Fe(CO)5, Hyperfine Interact., 1986, vol. 27, no. 1, pp. 333–336.

Comprehensive Organometallic Chemistry, Wilkinson, G., Eds., Amsterdam: Elsevier, 1982.

Wiesli, R.A., Beard, B.L., Braterman, P.S., et al., Iron isotope fractionation between liquid and vapor phases of iron pentacarbonyl, Talanta, 2007, vol. 71, no. 1, pp. 90–96.

Kuznetsov, V.I., Metalloorganicheskie soedineniya v razdelenii stabil’nykh izotopov (Metalorganic Compounds in the Separation of Stable Isotopes), Moscow: Al’fa-Labl, 2001.

Volkov, V.L., Syrkin, V.G., and Tolmasskii, I.S., Karbonil’noe zhelezo (Carbonyl Iron), Moscow: Metallurgiya, 1969.

Knacke, J. and Stransky, I.N., Evaporation mechanism, Prog. Met. Phys., 1956, vol. 5, no. 6, pp. 181–235.

Kirillov, Yu.P., Shaposhnikov, V.A., Kuznetsov, L.A., Shiryaev, V.S., and Churbanov, M.F., Modeling of the evaporation of liquids and condensation of their vapor during distillation, Inorg. Mater., 2016, vol. 52, no. 11, pp. 1183–1188.

Kirillov, Yu.P., Shaposhnikov, V.A., and Churbanov, M.F., Modeling the ultrapurification of substances by simple distillation, Inorg. Mater., 2017, vol. 53, no. 8, pp. 867–873.

Belozerov, Yu.S., Bulanov, A.D., Potapov, A.M., Sozin, A.Yu., Steshin, M.O., and Chernova, O.Yu., Ultrapurification of iron pentacarbonyl by distillation techniques, Inorg. Mater., 2017, no. 10, pp. 1103–1108.

Dil’man, V.V., Lotkhov, V.A., Kulov, N.N., and Naidenov, V.I., Evaporation dynamics, Theor. Found. Chem. Eng., 2000, vol. 34, no. 3, pp. 201–210.

Kaminskii, V.A. and Obvintseva, N.Yu., Evaporation of a liquid under the conditions of convective instability in the gas phase, Russ. J. Phys. Chem. A, 2008, vol. 82, no. 7, pp. 1215–1220.

Borodacheva, Yu.V., Lotkhov, V.A., Dil’man, V.V., and Kulov, N.N., Kinetics of the steady-state evaporation of single-component liquids into an inert gas, Theor. Found. Chem. Eng., 2011, vol. 45, no. 6, pp. 805–810.

Dil’man, V.V. and Lotkhov, V.A., Molecular turbulent evaporation in a gravitational field, Theor. Found. Chem. Eng., 2015, vol. 49, no. 1, pp. 102–106.

Siow, E., Ormiston, S., and Soliman, H., Fully coupled solution of a two-phase model for laminar film condensation of vapor-gas mixtures in horizontal channels, Int. J. Heat Mass Transfer, 2002, vol. 45, no. 18, pp. 3689–3702.

Lee, K.-Y. and Kim, M.H., Experimental and empirical study of steam condensation heat transfer with a noncondensable gas in a small-diameter vertical tube, Nucl. Eng. Des., 2008, vol. 238, no. 1, pp. 207–216.

Hammami, Y.El., Feddaoui, M., Mediouni, T., and Mir, A., Numerical study of condensing a small condensation of vapour inside a vertical tube, Heat Mass Transfer, 2012, vol. 48, no. 9, pp. 1675–1685.

Adil Charef, M’barek Feddaoui, Monssif Najim, and Hicham Meftah, Liquid film condensation from water vapour flowing downward along a vertical tube, Desalination, 2017, vol. 409, pp. 21–23.

Sivukhin, D.V., Obshchii kurs fiziki (General Course in Physics), vol. 1: Mekhanika (Mechanics), Moscow: Fizmatlit, 2010.

Powell, M.J.D., A Fortran Subroutine for Solving Systems of Nonlinear Algebraic Equations, London: H.M. Stationary Office, 1968.

Fletcher, C.A.J., Computational Techniques for Fluid Dynamics, New York: Springer, 1988.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.A. Shaposhnikov, Yu.S. Belozerov, Yu.P. Kirillov, A.D. Bulanov, M.F. Churbanov, 2018, published in Neorganicheskie Materialy, 2018, Vol. 54, No. 9, pp. 929–935.

Rights and permissions

About this article

Cite this article

Shaposhnikov, V.A., Belozerov, Y.S., Kirillov, Y.P. et al. Modeling Iron Pentacarbonyl Vaporization Accompanied by Vapor Condensation on a Flowing Down Liquid Film. Inorg Mater 54, 878–884 (2018). https://doi.org/10.1134/S0020168518090157

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168518090157