Abstract

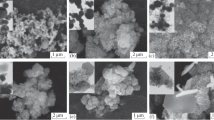

The possibility of the synthesis of bimetallic Janus nanoparticles from immiscible metals Ta and Cu by the method of electric explosion of two conductors in an argon atmosphere has been shown. Consolidation of Ta–Cu nanoparticles and spark plasma sintering yielded a composite material with a high microhardness and compressive strength, but a relatively low bending strength. The Ta–Cu composite inhibits the viability of bacteria Escherichia coli and Staphylococcus aureus with an efficiency of 99.99% owing to the slow release of small concentrations of Cu2+ ions. The synthesized composite material with high antibacterial activity for a long time is promising for the technologies of modern regenerative medicine.

Similar content being viewed by others

REFERENCES

Kulkarni, M., Mazare, A., Schmuki, P., and Iglič1, A., Biomaterial surface modification of titanium and titanium alloys for medical applications, in Nanomedicine, Seifalian, A., de Mel, A., and Kalaskar, D.M., Eds., One Central, 2014, ch. 5, pp. 111–136.

Li, Y., Wong, C., Xiong, J., Hodgson, P., and Wen, C., Cytotoxicity of titanium and titanium alloying elements, J. Dent. Res., 2010, vol. 89, pp. 493–497.

Liu, Y., Bao, C., Wismeijer, D., and Wu, G., The physicochemical/biological properties of porous tantalum and the potential surface modification techniques to improve its clinical application in dental implantology, Mater. Sci. Eng., 2015, vol. 49, pp. 323–329.

Matsuno, H., Yokoyama, A., Watari, F., Uo, M., and Kawasaki, T., Biocompatibility and osteogenesis of refractory metal implants, titanium, hafnium, niobium, tantalum and rhenium, Biomaterials, 2001, vol. 22, pp. 1253–1262.

Schierholz, J.M. and Beuth, J., Implant infections: a haven for opportunistic bacteria, J. Hosp. Infect., 2001, vol. 49, pp. 87–93.

Zhao, L., Wang, H., Huo, K., Cui, L., Zhang, W., Ni, H., Zhang, Y., Wu, Z., and Chu, P.K., Antibacterial nano-structured titania coating incorporated with silver nanoparticles, Biomaterials, 2011, vol. 32, pp. 5706–5716.

Liu, J., Li, F., Liu, C., Wang, H., Ren, B., Yang, K., and Zhang, E., Effect of Cu content on the antibacterial activity of titanium–copper sintered alloys, Mater. Sci. Eng., C, 2015, vol. 35, pp. 392–400.

Norambuena, G.A., Patel, R., Karau, M., Wyles, C.C., Jannetto, P.J., Bennet, K.E., Hanssen, A.D., and Sierra, R.J., Antibacterial and biocompatible titanium-copper oxide coating may be a potential strategy to reduce periprosthetic infection: An in vitro study, Clin. Orthop. Relat. Res., 2017, vol. 475, pp. 722–732.

Petzoldt, F., Knuëwer, M., Wichmann, K.H., and De Cristofaro, N., Metal injection molding of tungsten and molybdenum copper alloys for microelectronic packaging, in Advances in Powder Metallurgy and Particulate Materials: Proc. Int. Conf. on Powder Metallurgy and Particulate Materials (New Orleans, May 13–17, 2001), Eisen, W.B., Ed., Princeton: Met. Powder Industr. Feder., 2001, pp. 118–125.

Veltl, G., Scholz, B., and Kunze, H.D., Amorphization of Cu–Ta alloys by mechanical alloying, Mater. Sci. Eng., A, 1991, vol. 134, pp. 1410–1413.

Ibrahim, N., Peterlechner, M., Emeis, F., Wegner, M., Divinsky, S.V., and Wilde, G., Mechanical alloying via high-pressure torsion of the immiscible Cu50Ta50 system, Mater. Sci. Eng., A, 2017, vol. 685, pp. 19–30.

Darling, K.A., Tschopp, M.A., Guduru, R.K., Yin, W.H., Wei, Q., and Kecskes, L.J., Microstructure and mechanical properties of bulk nanostructured Cu–Ta alloys consolidated by equal channel angular extrusion, Acta Mater., 2014, vol. 76, pp. 168–185.

Zeng, L.F., Gao, R., Fang, Q.F., et al., High strength and thermal stability of bulk Cu/Ta nanolamellar multilayers fabricated by cross accumulative roll bonding, Acta Mater., 2016, vol. 110, pp. 341–351. https://doi.org/10.1016/j.actamat.2016.03.034

Edalati, K. and Horita, Z., Continuous high-pressure torsion, J. Mater. Sci., 2010, vol. 45, pp. 4578–4582.

Cui, J., Zhao, L., Zhu, W., Wang, B., Chao, C., Fang, L., and Ren, F., Antibacterial activity, corrosion resistance and wear behavior of spark plasma sintered Ta–5Cu alloy for biomedical applications, J. Mech. Behav. Biomed. Mater., 2017, vol. 74, pp. 315–323.

Lerner, M.I., Pervikov, A.V., Glazkova, E.A., Svarovskaya, N.V., Lozhkomoev, A.S., and Psakhie, S.G., Structures of binary metallic nanoparticles produced by electrical explosion of two wires from immiscible elements, Powder Technol., 2016, vol. 288, pp. 371–378.

ISO 22196:2011: Measurement of Antibacterial Activity on Plastics and Other Non-Porous Surfaces (for Escherichia coli ATCC 25922, for Staphilococcus aureus ATCC 6538), 2011.

GOST (State Standard) 10993-12-2015: Medical Devices. Biological Evaluation of Medical Devices. Part 12. Sample Preparation and Reference Materials, 2015.

Schoenfeld, C.M., Lautenschlager, E.P., and Meyer, Jr., P.R., Mechanical properties of human cancellous bone in the femoral head, Med. Biol. Eng., 1974, vol. 12, pp. 313–317. https://doi.org/10.1007/BF02477797

ACKNOWLEDGMENTS

Spark plasma sintering of the powder was carried out at the Nano-Center of the National Research Tomsk Polytechnic University.

Funding

The synthesis of bimetallic Ta–6Cu nanoparticles, the preparation of bulk composites, and the study of the structural and mechanical characteristics of materials were supported by Russian Science Foundation, grant no. 17-19-01319.

Studies of the antimicrobial properties and the isolation of Cu2+ ions from the bulk Ta–6Cu composite were carried out with the financial support of the Program of Basic Scientific Research of the State Academies of Sciences for 2013–2020, direction III.23.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

CONFLICT OF INTEREST

The authors declare that they have no conflicts of interest.

COMPLIANCE WITH ETHICAL STANDARDS

This article does not contain any studies involving animals or human participants performed by any of the authors.

Additional information

Translated by A. Bulaev

Rights and permissions

About this article

Cite this article

Pervikov, A.V., Dvilis, E.S., Khrustalev, A.P. et al. Synthesis of Ta–6Cu Bimetallic Nanoparticles and the Bulk Composite with Antimicrobial Activity. Inorg. Mater. Appl. Res. 12, 755–761 (2021). https://doi.org/10.1134/S207511332103028X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S207511332103028X