Abstract

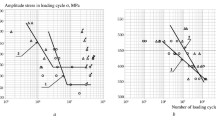

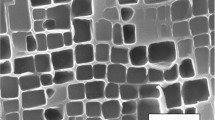

High-cycle fatigue of single crystals of nickel-rhenium-ruthenium-base superalloy VZhM4 with crystallographic orientation of 〈001〉, 〈011〉, and 〈111〉 within the temperature interval of 20–1000°C was investigated. Influence of the test temperature on the shape of the high-cycle fatigue curve was considered. It was found that single crystals of the alloy VZhM4 have negligible anisotropy of the fatigue limit at 1000°C on the basis of tests of 2× 107 cycles.

Similar content being viewed by others

References

Walston, S., Cetel, A., MacKay, R., et al., Joint development of a fourth generation single crystal superalloy, Proc. Tenth Int. Symp. on Superalloys 2004, Pennsylvania: Miner., Met. Mater. Soc., 2004, pp. 15–24.

Koizumi, Y., Kobayashi, T., Yokokawa, T., et al., Development of next-generation Ni-base single crystal superalloys, Proc. Tenth Int. Symp. on Superalloys 2004, Pennsylvania: Miner., Met. Mater. Soc., 2004, pp. 35–43.

Kablov, E.N., Petrushin, N.V., and Svetlov, I.L. Computer modeling of 4th generation heat resistant nickel alloy of for monocrystalline gas turbine blades, in Liteinye zharoprochnye slavy: Effekt S.T. Kishkina (Casting Heat-Resistant Alloys: Kishkin’s Effect), Moscow: Nauka, 2006, pp. 98–115.

Kablov, E.N., Innovative developments of the All-Russian Scientific Research Institute of Aviation Materials within the project “Strategic development of materials and technologies of their recycling until 2030,” Aviats. Mater. Tekhnol., 2015, no. 1 (34), pp. 3–33. doi 10.18577/2071-9140-2015-0-1-3-33

Harada, H., Development of Superalloys for 1700°C ultra-efficient gas turbines, Proc. 9th Liege Conf. “Materials for Advanced Power Engineering 2010,” Belgium: Univ. of Liège, 2010, pp. 604–614.

Argence, D., Vernault, C., Desvallées, Y., and Fournier, D., MC-NG: a 4th generation single-crystal superalloy for future aeronautical turbine blades and vanes, Proc. Ninth Int. Symp. on Superalloys 2000, Pennsylvania: Miner., Met. Mater. Soc., 2000, pp. 829–837.

Fifth Generation Nickel Base Single Crystal Superalloy TMS-196, Tokyo: Ishikawajima-Harima Heavy, 2006. https://doi.org/www.sakimori.nims.go.jp. Accessed December 21, 2011.

Sato A., Harada H, Yeh An-C., et al., A 5th generation SC superalloy with balanced high temperature properties and processability, Proc. 11th Int. Symp. on Superalloys 2008, Pennsylvania: Miner., Met. Mater. Soc., 2008, pp. 131–138.

Kablov, E.N., Petrushin, N.V., Svetlov, I.L., and Demonis, I.M., New nickel casted heat-resistant alloys, Aviats. Mater. Tekhnol., 2012, suppl., pp. 36–52.

Petrushin, N.V., Ospennikova, O.G., and Elyutin, E.S., Rhenium in monocrystalline heat resistant nickel alloys for gas turbine engine blades, Aviats. Mater. Tekhnol., 2014, suppl. 5, pp. 5–16. doi 10.18577/2071-9140-2014-0-s5-5-16

Shalin, R.E., Svetlov, I.L., Kachanov, E.B., Toloraiya, V.N., and Gavrilin, O.S., Monokristally nikelevykh zharoprochnykh splavov (Single Crystals of Nickel Heat-Resistant Alloys), Moscow: Mashinostroenie, 1997.

Svetlov, I.L., Petrushin, N.V., Golubovskii, E.R., Khvatskii, K.K., Shchegolev, D.V., and Elyutin, E.S., Mechanical properties of single crystals of a heat-resistant nickel alloy containing rhenium and ruthenium, Deform. Razrushenie Mater., 2008, no. 11, pp. 26–35.

Orlov, M.R., Ospennikova, O.G., and Avtaev, V.V., Deformation and destruction of single crystals of heatresistant nickel alloys under short-and long-term static loading, Deform. Razrushenie Mater., 2014, no. 3, pp. 17–23.

Petrushin, N.V., Visik, E.M., Gorbovets, M.A., and Nazarkin, R.M., Structure-phase characteristics and the mechanical properties of single-crystal nickelbased rhenium-containing superalloys with carbide–intermetallic hardening, Russ. Metall. (Engl. Transl.), 2016, vol. 2016, no. 7, pp. 630–641.

Golubovskiy, E.R., Svetlov, I.L., Petrushin, N.V., Cherkasova, S.A., and Volkov, M.E., Low-cycle fatigue of nickel superalloy single crystals at elevated temperatures, Russ. Metall. (Engl. Transl.), 2010, vol. 2010, no. 8, pp. 941–947.

Liu, Y., Yu, J.J., Xu, Y., Sun, X.F., Guan, H.R., and Hu, Z.Q., High cycle behavior of a single crystal superalloy at elevated temperatures, Mater. Sci. Eng., A, 2007, vols. 454–455, pp. 357–366.

Morrissey, R.J., John, R., and Porter, W.J. III, Fatigue variability of a single crystal superalloy at elevated temperatures, Int. J. of Fatig., 2009, vol. 31, pp. 1758–1763.

Wright, P.K., Jain, M., and Cameron, D., High cycle fatigue in a single crystal superalloy: time dependence at elevated temperature, Proc. Tenth Int. Symp. on Superalloys 2004, Pennsylvania: Miner., Met. Mater. Soc., 2004, pp. 657–666.

Petukhov, A.N., Specific resistance of multi-cycle fatigue of casted parts from heat-resistant nickel alloys with particular crystallographic structure, in Novye tekhnologicheskie protsessy i nadezhnost’ GTD. Vyp. 7. Obespechenie prochnostnoi nadezhnosti rabochikh lopatok vysokotemperaturnykh turbin (New Technological Processes and Reliability of Gas Turbine Engines, No. 7: Strength of the Blades of Heat-Resistant Turbines), Moscow: Tsentr. Inst. Aviats. Motorostr., 2008, pp. 62–72.

Petrushin, N.V., Svetlov, I.L., Samoilov, A.I., Timofeeva, O.B., and Chabina, E.B., High-temperature phase and structural transformations in single crystals of a high-temperature nickel alloy containing rhenium and ruthenium, Part 1, Materialovedenie, 2008, no. 10, pp. 13–18

Petrushin, N.V., Svetlov, I.L., Samoilov, A.I., Timofeeva, O.B., and Chabina, E.B., High-temperature phase and structural transformations in single crystals of a high-temperature nickel alloy containing rhenium and ruthenium, Part 2, Materialovedenie, 2008, no. 11, pp. 26–31.

Svetlov, I.L., Iskhodzhanova, I.V., Evgenov, A.G., and Naprienko, S.A., High-temperature creep and the defect structure of nickel-based superalloy single crystals after hot isostatic pressing, Russ. Metall. (Engl. Transl.), 2012, vol. 2012, no. 4, pp. 330–335.

Epishin, A.I. and Svetlov, I.L., Evolution of pore morphology in single-crystals of nickel-base superalloys, Inorg. Mater.: Appl. Res., 2016, vol. 7, no. 1, pp. 45–52.

Svetlov, I.L., Khvatskii, K.K., Gorbovets, M.A., and Belyaev, M.S., Effect of hot isostatic pressing on the mechanical properties of casted heat-resistant nickel alloys, Aviats. Mater. Tekhnol., 2015, no. 3 (36), pp. 10–14. doi 10.18577/2071-9140-2015-0-3-10-14

Epishin, A.I., Bokstein, B.S., Svetlov, I.L., Fedelich, B., Feldmann, T., Le Bouar, Y., Ruffini, A., Finel, A., Viguier, B., and Poquillon, D., A vacancy model of pore annihilation during hot isostatic pressing of single crystals of nickel-base superalloys, Inorg. Mater.: Appl. Res., 2018, vol. 9, no. 1, pp. 57–65.

Stepnov, M.N. and Shavrin, A.V., Statisticheskie metody obrabotki rezul’tatov mekhanicheskikh ispytanii: spravochnik (Statistical Data Processing in Mechanical Tests: Handbook), Moscow: Mashinostroenie, 2005.

Belyaev, M.S., Gorbovets, M.A., and Komarova, T.I., Test methods and expected limit of endurance for horizontal part of the fatigue curve, Aviats. Mater. Tekhnol., 2012, no. 3, pp. 50–55.

Belyaev, M.S., Morozova, L.V., Markova, E.S., and Yakusheva, N.A., Estimation of the high cycle fatigue behavior and type of fatigue failure of the VKS-180 high-resistance steel, Inorg. Mater.: Appl. Res., 2017, vol. 8, no. 4, pp. 573–578.

Nikitin, A.D., Shanyavskiy, A.A., and Beklemishev, N.N., Fatigue behavior of titanium alloys under very high cycle fatigue loading, Inorg. Mater.: Appl. Res., 2018, vol. 9, no. 1, pp. 75–81.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © M.S. Belyaev, N.V. Petrushin, 2017, published in Materialovedenie, 2017, No. 12, pp. 10–17.

Rights and permissions

About this article

Cite this article

Belyaev, M.S., Petrushin, N.V. High-Cycle Fatigue of Single Crystals of Nickel-Base Superalloy VZhM4. Inorg. Mater. Appl. Res. 9, 655–662 (2018). https://doi.org/10.1134/S2075113318040044

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113318040044