Abstract

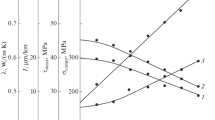

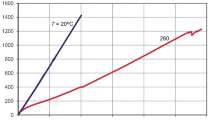

High-strength antifriction carbon plastics characterized by dimension stability are used mainly in the shipbuilding, turbine and pump manufacturing, armature engineering and heavy machinery construction. The paper analyzes modified epoxy carbon fiber reinforced plastics (UGET), operating in water at contact pressures up to 100 MPa and a low-speed sliding 0.005–0.5 m/s. The modification of epoxy carbon fibers has been described at the molecular, nano-, micro-, macrolevels. The modifiers—optimal for each level—have been selected.

Similar content being viewed by others

References

Bakhareva, V.E. and Nikolaev, G.I., Sovremennye mashinostroitel’nye materialy. Nemetallicheskie materialy: Spravochnik, (Contemporary Machine-Building Materials. Nonmetallic Materials. A Handbook), Gorynin, I.V. and Oryshchenko, A.S., Eds., St. Petersburg: Professional, 2012.

Rubin, M.B. and Bakhareva, V.E., Podshipniki v sudovoi tekhnike: Spravochnik (Bearings in Ship Technique: A Handbook), Moscow: Sudostroenie, 1987.

Oryshchenko, A.S., Bakhareva, V.E., Anisimov, A.V., and Lishevich, I.V., High-strength antifrictional elastoplastic slip bearings for shipbuilding and the power industry, Russ. Eng. Res., 2012, vol. 32, pp. 444–448.

Akhmatov, A.S., Molekulyarnaya fizika granichnogo treniya (Molecular Physics of Boundary Friction), Moscow: Fizmatgiz, 1963.

Trenie, iznashivanie i smazka: Spravochnik. V 2-kh t. (Friction, Wear and Lubrication: A Handbook. In 2 Vol.) Kragel’skii, I.V. and Alisin, V.V., Eds., Moscow: Mashinostroenie, 1979.

Goryacheva, I.G., Mekhanika friktsionnogo vzaimodeistviya (Mechanics of Friction Interaction), Moscow: Nauka, 2001.

Krasnov, A.P., Timofeev, V.A., Afonicheva, O.V., Buyaev, D.I., Chukalovsky, P.A., and Kuznetsov, V.V., Influence of tribochemical active bindings in creation of new reinforced antifrictional material, Vopr. Materialoved., 2006, no. 2, pp. 105–113.

Gorynin, I.V., Nanocomposites: Preferences and perspectives, Technopolis, 2006, vol. 21, pp. 20–21.

Bakhareva, V.E., Nikolaev, G.I., and Anisimov, A.V., Improvement of functional properties of antifriction polymer composites for slide friction nodes, Ross. Chim. J., 2009, vol. 53, no. 4, pp. 4–18.

Bakhareva, V.E., Anisimov, A.V., Blyshko, I.V., and Savelov, A.S., Modification of thermoset antifriction carbon plastics, Vopr. Materialoved., 2012, no. 4, pp. 66–80.

Bakhareva, V.E., Nikolaev, G.I., and Anisimov, A.V., Nonmetal antifriction materials for sliding friction units, Inorg. Mater.: Appl. Res., 2012, vol. 3, pp. 524–533.

Irzhak, V.I., Rozenberg, B.A., and Enikolopyan, N.S., Setchatye polimery (sintez, struktura, svoistvo) (Network Polymers (Synthesis, Structure, Properties)), Moscow: Nauka, 1979.

Deev, I.S. and Kobets, L.P., Microstructure of epoxy matrices, Mekh. Kompoz. Mater., 1986, no. 1, pp. 3–8.

Nikolaev, G.I., Abozin, I.Yu., Bahareva, V.E., Lobyntseva, I.V., and Petrova, L.V., Antifriction characteristics of carbon-reinforced plastics versus the chemical composition and structure of an epoxy matrix, Vopr. Materialoved., 2001, no. 2, pp. 30–38.

Cuthrell, R.E., Epoxy polymers. part 3. Factors affecting the cure, J. Appl. Polym. Sci., 1968, vol. 147, pp. 955–967.

Abozin, I.Yu., Bakhareva, V.E., and Rybin, V.V., Antifriction carbon-reinforced bearings versus the structure of carbon fibers, Vopr. Materialoved., 2001, no. 2, pp. 22–29.

Fitzer, E., Carbon Fibers and Their Composites, Berlin: Springer-Verlag, 1986.

Gunyaev, G.M., Struktura i svoistva polimernykh voloknistykh kompozitov (Structure and Properties of Polymer Fiber Composites), Moscow: Khimiya, 1981.

Bakhareva, V.E., Lishevich, I.V., and Sargsyan, A.S., New heat-resistant antifriction carbon plastics based on polyphenylene sulfide for friction units, operating without lubrication or greased by superheated water, Vopr. Materialoved., 2012, no. 4, pp. 160–171.

Author information

Authors and Affiliations

Additional information

Original Russian Text © V.E. Bakhareva, G.I. Nikolaev, A.S. Oryshchenko, published in Russian in Voprosy Materialovedeniya, 2012, No. 4(72), pp. 15–27.

The article was translated by the authors.

Rights and permissions

About this article

Cite this article

Bakhareva, V.E., Nikolaev, G.I. & Oryshchenko, A.S. Antifriction carbon plastics in the machinery construction. Inorg. Mater. Appl. Res. 4, 508–517 (2013). https://doi.org/10.1134/S2075113313060026

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113313060026