Abstract

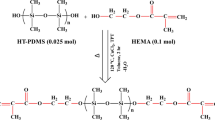

Polyacrylate emulsions can be used as adhesives. However, low water resistance and insufficient adhesion have restricted their application. In this study, polyacrylate/silica composite adhesives were prepared by emulsifier-free polymerization. Fourier transform infrared spectroscopy results confirm that modified silica is successfully introduced into the emulsion. Thermogravimetry and differential scanning calorimeter indicate that with the increase of modified silica sol content, the thermal stability of the composite film is improved. When modified silica sol content increases from 0 to 8 wt %, the water contact angle increases from 74° to 98°, and the water sorption rate decreases from 16.5 to 7.8%. Moreover, with the addition of modified silica sol, the peel strength and tack of the modified latex changed slightly. Still, the shear strength on paper materials ranges from 148 min to over 1000 min when the content of modified silica sol reaches 8 wt %. The results show that adding modified silica sol can enhance the adsorption interaction between adhesive and paper material, effectively improving latex adhesive properties.

Similar content being viewed by others

REFERENCES

A. Romo-Uribe, Prog. Org. Coat. 129, 126 (2019).

Y. Bao, J. Ma, X. Zhang, and C. Shi, J. Mater. Sci. 50, 6839 (2015).

F. Sbardella, L. Pronti, M. Santarelli, J. Asua Gonzàlez, and M. Bracciale, Coatings 8, 283 (2018).

D. G. Gao, R. Chang, B. Lyu, J. Z. Ma, and X. Y. Duan, Appl. Surf. Sci. 435, 196 (2018).

G. Bok, G. Lim, K. Park, and Y. Kim, Ceram. Int. 47, 25738 (2021).

T. Ren, B. Yuan, G. Tang, M. Zhao, Y. Yang, Z. Yan, L. Ma, and X. Huang, ChemistrySelect 7, 1 (2022).

H. Chen, S. X. Zhou, G. X. Gu, and L. M. Wu, J. Dispersion Sci. Technol. 25, 838 (2004).

M. S. Ganjeh, N. Ahmadinejad, and A. Akbarzadeh, Polym. Sci., Ser. B 61, 493 (2019).

X. Zhao, H. Hao, Y. Duan and J. Wang, Prog. Org. Coat. 135, 417 (2019).

J. H. Zhou, L. Zhang, and J. Z. Ma, Polym. Plast. Technol. Eng. 50, 16 (2011).

S. Guo, D. Wang, J. Shi, X. Li, B. Feng, L. Meng, Z. Cai, H. Qiu, and S. Wei, Prog. Org. Coat. 135, 601 (2019).

Z. Buhin Šturlić, M. Leskovac, K. Žižek, and S. Lučić Blagojević, Pigm. Resin. Technol. 51, 254 (2021).

Y. Zhang, Y. Sheng, M. Wang, and X. Lu, Prog. Org. Coat. 172, 1 (2022).

D. Zhang, Y. Li, Y. Huang, Z. Zhao, and Z. Zhang, Appl. Surf. Sci. 604, 1 (2022).

Z. Luo and H. Huang, J. Appl. Polym. Sci. 137, 2 (2019).

I. Márquez, N. Paredes, F. Alarcia, and J. I. Velasco, J. Adhes. Sci. Technol. (2022). https://doi.org/10.1080/01694243.2022.2095152

A. Sarkar and R. V. Jayaram, Polym. Sci., Ser. B 60, 631 (2018).

P. X. Chen, X. R. Zeng, H. Q. Li, X. D. Liu, D. D. Liu, and X. L. Li, Polym. Plast. Technol. Eng. 51, 124 (2012).

F. Yang, W. Yang, L. Zhu, Y. Chen, and Z. Ye, Prog. Org. Coat. 95, 3 (2016).

W. Xu, Q. An, L. Hao, D. Zhang, and M. Zhang, Appl. Surf. Sci. 268, 376 (2013).

J. Zhou, X. Chen, H. Duan, J. Ma, and Y. Ma, Appl. Surf. Sci. 331, 510 (2015).

H. Soleimani, R. Bagheri, and A. Asadinezhad, Prog. Org. Coat. 129, 280 (2019).

Z. Chen, Y. Zhang, Y. Liu, L. Duan, Z. Wang, C. Liu, Y. Li, and P. He, Prog. Org. Coat. 86, 82 (2015).

W. Lei, X. Yang, M. Wang, H. Yang, J. Liu, Z. Y. Wei, D. Shi, R. Wang, and L. Zhang, Polymer 228, 5 (2021).

C. R. Casas-Soto, A. S. Conejo-Dávila, V. Osuna, D. Chávez-Flores, J. C. Espinoza-Hicks, S. G. Flores-Gallardo, and A. Vega-Rios, Polymers 14, 11 (2022).

X. Lu, G. Cao, Z. Niu, and Q. Pan, J. Appl. Polym. Sci. 131, 9 (2014).

A. Romo-Uribe, J. A. Arcos-Casarrubias, A. Reyes-Mayer, and R. Guardian-Tapia, Eur. Polym. J. 76, 180 (2016).

C. Osterwinter, C. Schubert, C. Tonhauser, D. Wilms, H. Frey, and C. Friedrich, Macromolecules 48, 125 (2015).

S. Özlem and J. Hacaloglu, J. Anal. Appl. Pyrolysis 104, 168 (2013).

T. Xu, Q. Xiao, J. Chen, L. Li, X. Yang, L. Liu, W. Yuan, B. Zhang, and H. Wu, Polymers 11, 9 (2019).

S. S. Pathak, A. Sharma, and A. S. Khanna, Prog. Org. Coat. 65, 212 (2009).

T. T. Chau, W. J. Bruckard, P. T. L. Koh, and A. V. Nguyen, Adv. Colloid Interface Sci. 150, 109 (2009).

N. Wang, Y. Guo, H. Xu, X. Liu, L. Zhang, X. Qu, and L. Zhang, J. Appl. Polym. Sci. 113, 3122 (2009).

T. Wang, C. H. Lei, A. B. Dalton, C. Creton, Y. Lin, K. A. S. Fernando, Y. P. Sun, M. Manea, J. M. Asua, and J. L. Keddie, Adv. Mater. 18, 2732 (2006).

C. L. Zhao, J. Roser, W. Heckmann, A. Zosel, and E. Wistuba, Prog. Org. Coat. 35, 273 (1999).

K. W. Allen, Int. J. Adhes. Adhes. 13, 68 (1993).

P. Sundriyal, M. Pandey, and S. Bhattacharya, Int. J. Adhes. Adhes. 101, 2 (2020).

X. Yue, L. Huang, L. Huang and X. Luo, Waste Biomass Valorization 12, 5170 (2021).

Funding

The authors gratefully acknowledge the support from the “Research of modified polyacrylate adhesive for environmental paper bags” Project (no. XDHT2020225A). The author would like to thank Xiamen CYR Green-Tech Incorporated Co., LTD (Xiamen, China) for providing the production platform.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Zhou, W.Y., Chen, G.Y., Zhang, C.T. et al. Preparation of Polyacrylate Emulsion with High Adhesion Properties by Adding Modified Silica Sol. Polym. Sci. Ser. B 65, 209–219 (2023). https://doi.org/10.1134/S1560090423700914

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1560090423700914