Abstract

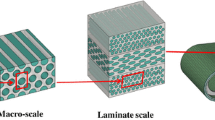

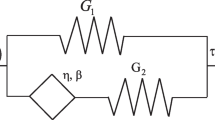

The correspondence between the porosity and ultrasonic attenuation coefficient are not unique due to the randomness and complexity of pore morphology in ultrasonic nondestructive testing of composite materials. Thus, the fractal box dimension is used to describe the pore morphology, and the influence of pore morphology on ultrasonic attenuation coefficient is studied in this paper. Firstly, based on the random medium theory, random pore models with different morphologies were constructed. Then the fractal box dimension was used to characterize the pore morphology, and the sensitivity of fractal box dimension to pore morphology such as length, width and distribution was studied. Finally, the relationship between fractal box dimension and ultrasonic attenuation coefficient was established to analyze the influence of fractal box dimension on ultrasonic attenuation. The research shows that the fractal box dimension is sensitive to pore size and pore distribution. The increase of pore length and width size and the aggregation of pore distribution under the same porosity all cause the increase of fractal box dimension. At the same time, the larger the porosity, the larger the fractal box dimension. The influence of pore size change on ultrasonic attenuation coefficient characterized by fractal box dimension under different porosity is more distinguishable than that of pore size change characterized by average length or width. Therefore, fractal box dimension is a parameter that can better characterize the pore morphology of composite materials, which is more conducive to analyzing the influence of pore morphology on ultrasonic testing.

Similar content being viewed by others

REFERENCE

Thamizh Selvan, R. et al., Recycling technology of epoxy glass fiber and epoxy carbon fiber composites used in aerospace vehicles, J. Compos. Mater., 2021, vol. 55, no. 23, pp. 3281–3292.

Muharrem Pul, Effect of sintering temperature on pore ratio and mechanical properties of composite structure in nano graphene reinforced ZA27 based composites, Int. J. Miner. Metall. Mater., 2020, vol. 27, no. 2, pp. 232–243.

Li, D., Song, S., Zuo, D., et al., Effect of Pore Defects on Mechanical Properties of Graphene Reinforced Aluminum Nanocomposites, Metals, 2020, vol. 10, no. 4, pp. 468–477.

Sokolovskaya, Y.G., Podymova, N.B., and Karabutov, A.A., Application of Laser-Ultrasonic Technique of Acoustic Impedance Measurement with Signals Detection by Backward-Mode Scheme for Porosity Content Evaluation in CFRP Laminates, J. Nondestr. Eval., 2020, vol. 39, no. 3, pp. 55–67.

Hudson, T.B., Follis, P.J., Pinakidis, J.J., et al., Porosity Detection and Localization During Composite Cure Inside an Autoclave Using Ultrasonic Inspection, Compos. A Appl. Sci. Manuf., 2021, vol. 147, no. 3, p. 106337.

Shen Yang, Guo Zhiwen, Feng Yanqing, Zheng Yaqin, and You Yong, Ultrasonic Estimation of Porosity in Composite Materials Using Acoustic Attenuation, Insight, 2019, vol. 61, no. 6, pp. 310–315.

Wang, Z. et al., Identification of Localized Void Defects in Composite by Recurrence Quantification Analysis of Ultrasonic Backscattered Signal, Russ. J. Nondestr. Test., 2019, vol. 55, no. 3, pp. 192–201.

Li Lin et al., A novel random void model and its application in predicting void content of composites based on ultrasonic attenuation coefficient, Appl. Phys. A, 2011, vol. 103, no. 4, pp. 1153–1157.

Li, L., Chen, J., Xiang, Z., et al., A novel 2-D random void model and its application in ultrasonically determined void content for composite materials, NDT & E Int., 2011, vol. 44, no. 3, pp. 254–260.

Liu Huan, Research on ultrasonic attenuation caused by voids in CFRP based on real morphology void model, Dissertation, Dalian Univ. Technol., 2015.

Bo-Wen, H.U., Huang, C.P., Xia, C., et al., Effect of friction stir welding defects morphology on phased array ultrasonic testing, Chin. J. Nonferrous Met., 2019, vol. 29, no. 3, pp. 491–497.

Zhang Xiang, Chen Jun, Lin Li, and Li Ximeng, Effects on ultrasonic scattering attenuation coefficient of morphological characteristics of voids in composite materials, Chin. Mech. Eng., 2010, vol. 21, no. 14, pp. 1735–1741.

Liang, L., Zhou, L., Liu, X., et al., Study of effect of pore structure on ultrasonic attenuation, Chin. J. Rock Mech. Eng., 2015, vol. 34, no. s1, pp. 3208–3214.

Boychuk, A.S., Chertischev, V.Y., Dikov, I.A., et al., Pore morphology influence at porosity ultrasonic testing of CFRP by pulse-echo method, Kontrol’ Diagn., 2018, vol. 8, pp. 22–29.

Duan, Q. et al., Review about the application of fractal theory in the research of packaging materials, Materials, 2021, vol. 14, no. 4, p. 860.

Diamond, S. and Bonen, D., Microstructure of hardened cement paste—A new interpretation, J. Am. Ceram. Soc., 1993, vol. 76, no. 12, pp. 2993–2999.

Kimura, S., Matsuo, Y., Tanaka, S., et al., Toughening of carbon fiber/pitch-based carbon matrix composites by microspace control, Synth. Met., 2002, vol. 125, no. 2, pp. 213–221.

Arandigoyen, M. and Alvarez, J.I., Pore structure and mechanical properties of cement–lime mortars, Cem. Concr. Res., 2007, vol. 37, no. 5, pp. 767–775.

Qin Tao et al., Pore fractal characterization and calculation of flexural strength of carbon/carbon composites, Mater. Rev., 2013, vol. 27, no. 6, pp. 140–144.

Haiquan Sun et al.б Fractal characteristics of pore structure of compacted bentonite studied by ESEM and MIP methods, Acta Geotech., 2019, vol. 15, pp. 1–17.

Wang Xianghong et al., Simulation and experimental research on nonlinear ultrasonic testing of composite material porosity, Appl. Acoust., 2022, vol. 188, p. 108528.

Balyk, V.M. and Malenkov, A.A., Statistical Search for The Global Extremum in The Criterion Space, Int. J. Appl. Math. Stat., 2019, vol. 58, no. 1, pp. 98–108.

Bazulin, E.G., Konovalov, D.A., and Sadykov, M.S., Finite-difference time domain method. Calculating echo signals in homogeneous isotropic materials, Russ. J. Nondestr. Test., 2018, vol. 54, no. 7, pp. 469–478.

Lais, H., Lowe, P.S., Gan, T.H., et al., Numerical modelling of acoustic pressure fields to optimize the ultrasonic cleaning technique for cylinders, Ultrason. Sonochem., 2018, vol. 45, pp. 7–16.

Wei, Z. and Weavers, L.K., Combining COMSOL modeling with acoustic pressure maps to design sono-reactors, Ultrason. Sonochem., 2016, vol. 31, pp. 490–498.

Huang, H. and Talreja, R., Effects of void geometry on elastic properties of unidirectional fiber reinforced composites, Compos. Sci. & Technol., 2005, vol. 65, no. 13, pp. 1964–1981.

ACKNOWLEDGMENTS

This work was supported by the National Natural Science Foundation of China (grant nos. 61871060 and 52075049); the Natural Science Foundation of Hunan Province, China (grant nos. 2020JJ4614 and 2020JJ2028); and the Innovation Platform Open Fund of Education Department of Hunan Province, China (grant no. 19K009).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Supplementary Information

The online version contains supplementary material available at https://doi.org/10.1134/S1061830922040106

Rights and permissions

About this article

Cite this article

Wang, X., He, H., Xie, W. et al. Effect of Pore Morphology of Composites on Ultrasonic Attenuation Coefficient Based on Fractal Theory. Russ J Nondestruct Test 58, 289–300 (2022). https://doi.org/10.1134/S1061830922040106

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830922040106