Abstract

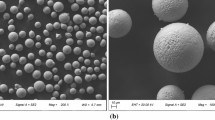

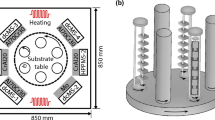

Physical vapor deposition (PVD) coatings are utilized to improve the service life of tools and components. Depending on the application, these tools and components undergo various stress types. For instance, in cold forging applications the tools predominantly endure cyclic impact loads. Previous studies on fatigue response of PVD coatings under cyclic impact loads focus on Ti-based or CrN coatings and attribute the coating fatigue behavior to the elastic-plastic deformation of the substrate. However, the influence of the coating chemical composition on the impact fatigue behavior, particularly for CrAlN coatings, is rather missing in the literature. The current work aims to investigate the influence of Al content on the impact fatigue response of CrAlN high-power pulsed magnetron sputtering (HPPMS) coatings. CrAlN coatings with low, medium and high Al content were deposited on HS6-5-2C steel substrates. The chemical and phase compositions were determined by electron probe microanalysis and X-ray diffraction analysis, respectively. The elastic-plastic properties of the coatings were determined by nanoindentation test. Rockwell C indentation test was used to analyze the adhesion between coating and steel substrate. The coated samples were subjected to a cyclic impact load of F = 1000 N and frequency of f = 50 Hz during the impact tests with N = 0.1 × 106, 0.5 × 106, 0.75 × 106, and 106 impacts. Finally, the fatigue behavior of the CrAlN coated steel substrates was analyzed inside the impact imprint area for fatigue cracks and plastic deformation using scanning electron microscopy and confocal laser scanning microscopy, respectively. Additionally, the impact fatigue response of the uncoated steel substrate was also taken into consideration. CrAlN/steel compounds showed better impact fatigue response as compared to the uncoated steel substrates. Moreover, the increase in Al content resulted in an improved impact fatigue behavior for the CrAlN/steel compounds.

Similar content being viewed by others

REFERENCES

Bobzin, K., Brögelmann, T., Kruppe, N., and Arghavani, M., Investigations on Mechanical and Tribological Behavior of dcMS/HPPMS CrN and (Cr, Al)N Hard Coatings Using Nanoscratch Technique, Adv. Eng. Mater., 2017, vol. 19, no. 6, p. 1600632. https://doi.org/10.1002/adem.201600632

Bouzakis, K.-D., Maliaris, G., and Makrimallakis, S., Strain Rate Effect on the Fatigue Failure of Thin PVD Coatings: An Investigation by a Novel Impact Tester with Adjustable Repetitive Force, Int. J. Fatigue, 2012, vol. 44, pp. 89–97. https://doi.org/10.1016/j.ijfatigue.2012.05.010

González-Velázquez, J.L., A Practical Approach to Fracture Mechanics, Elsevier, 2020. https://doi.org/10.1016/B978-0-12-823020-6.00001-3

Bouzakis, K.-D., Batsiolas, M., Skordaris, G., Stergioudi, F., and Michailidis, N., Repetitive Impact Test Near Uncoated and Coated Cutting Edges for Assessing Their Fatigue Behavio, CIRP J. Manuf. Sci. Technol., 2015, vol. 8, pp. 63–69. https://doi.org/10.1016/j.cirpj.2014.09.001

Mendibide, C., Steyer, P., Fontaine, J., and Goudeau, P., Improvement of the Tribological Behaviour of PVD Nanostratified TiN/CrN Coatings—An Explanation, Surf. Coat. Technol., 2006, vol. 201, no. 7, pp. 4119–4124. https://doi.org/10.1016/j.surfcoat.2006.08.013

Bouzakis, K.-D., Siganos, A., Leyendecker, T., and Erkens, G., Thin Hard Coatings Fracture Propagation during the Impact Test, Thin Solid Films, 2004, vol. 460, no. 1–2, pp. 181–189. https://doi.org/10.1016/j.tsf.2004.02.009

Chim, Y., Ding, X., Zeng, X., and Zhang, S., Oxidation Resistance of TiN, CrN, TiAlN and CrAlN Coatings Deposited by Lateral Rotating Cathode Arc, Thin Solid Films, 2009, vol. 517, no. 17, pp. 4845–4849. https://doi.org/10.1016/j.tsf.2009.03.038

Mo, J., Zhu, M., Leyland, A., and Matthews, A., Impact Wear and Abrasion Resistance of CrN, AlCrN and AlTiN PVD Coatings, Surf. Coat. Technol., 2013, vol. 215, pp. 170–177. https://doi.org/10.1016/j.surfcoat.2012.08.077

Brögelmann, T., Bobzin, K., Kruppe, N., and Arghavani, M., Understanding the Deformation and Cracking Behavior of Cr-Based Coatings Deposited by Hybrid Direct Current and High Power Pulse Magnetron Sputtering: From Nitrides to Oxynitrides, Thin Solid Films, 2019, vol. 688, p. 137354. https://doi.org/10.1016/j.tsf.2019.06.004

Fu, Y., Li, H., Ji, L., Liu, X., Liu, L., Zhou, H., and Chen, J., Insight into Al Existing Form and Its Role on Microstructure and Properties of Cr1–xAlxN Films, Surf. Interface Analysis, 2016, vol. 48, no. 1, pp. 26–33. https://doi.org/10.1002/sia.5882

Funding

The authors gratefully acknowledge the financial support from the German Research Foundation (DFG) within the project BO 1979/71-1.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizicheskaya Mezomekhanika, 2021, Vol. 24, No. 5, pp. 138–146.

Rights and permissions

About this article

Cite this article

Bobzin, K., Kalscheuer, C., Carlet, M. et al. Influence of Aluminum Content on the Impact Fatigue of HPPMS CrAlN Coatings on Tool Steel. Phys Mesomech 24, 625–632 (2021). https://doi.org/10.1134/S1029959921050143

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1029959921050143