Abstract

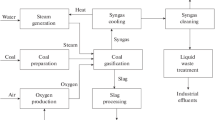

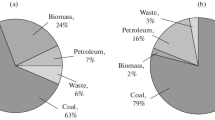

Perspectives of using coal in combined-cycle gas turbine units (CCGTs), which are significantly more efficient than steam power plants, have been associated with preliminary coal gasification for a long time. Due to gasification, purification, and burning the resulting synthesis gas at an increased pressure, there is a possibility to intensify the processes occurring in them and reduce the size and mass of equipment. Physical heat evolving from gasification can be used without problems in the steam circuit of a CCGT. The downside of these opportunities is that the unit becomes more complex and expensive, and its competitiveness is affected, which was not achieved for CCGT power plants with coal gasification built in the 1990s. In recent years, based on the experience with these CCGTs, several powerful CCGTs of the next generation, which used higher-output and cost-effective gas-turbine plants (GTPs) and more advanced systems of gasification and purification of synthesis gas, were either built or designed. In a number of cases, the system of gasification includes devices of CO vapor reforming and removal of the emitted CO2 at a high pressure prior to fuel combustion. Gasifiers with air injection instead of oxygen injection, which is common in coal chemistry, also find application. In this case, the specific cost of the power station considerably decreases (by 15% and more). In units with air injection, up to 40% air required for separation is drawn from the intermediate stage of the cycle compressor. The range of gasified coals has broadened. In order to gasify lignites in one of the projects, a transfer reactor was used. The specific cost of a CCGT with coal gasification rose in comparison with the period when such units started being designed, from 3000 up to 5500 dollars/kW.

Similar content being viewed by others

References

“Where have we been and where are we headed? (Operational IGCC plants. Proposed projects in North America. Proposed projects outside North America),” Gas Turbine World 37 (1), 11–18 (2007).

“GE reference plant targeting COE parity with SCPC plant,” Gas Turbine World 37 (1), 2–13 (2007).

“618MW Edwardsport IGCC plant in commercial service,” Gas Turbine World 43 (3), 36 (2013)

Q. Zhuang, “TRIGTTM for low rank coal: a new perspective on IGCC,” in Proc. 2014 Gasification Technology Conf., Washington, DC, October 26–29, 2014 (Curran Associates, Red Hook, NY, 2014).

Mitsubishi Heavy Industries, “High efficiency from low BTU gas,” Prospectus H480-48CCO8E2-C-2.

K. Sakamoto, “MHPS IGCC technology (Air-brown IGCC -From demonstration to commercial stage-,” in Proc. 2014 Gasification Technology Conf., Washington, DC, October 26–29, 2014 (Curran Associates, Red Hook, NY, 2014).

A. Allen, “Gasification at the crossroads,” in Proc. 2014 Gasification Technology Conf., Washington, DC, October 26–29, 2014 (Curran Associates, Red Hook, NY, 2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © G.G. Olkhovskii, 2016, published in Teploenergetika

Rights and permissions

About this article

Cite this article

Olkhovskii, G.G. New projects for CCGTs with coal gasification (Review). Therm. Eng. 63, 679–689 (2016). https://doi.org/10.1134/S0040601516100074

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601516100074