Abstract

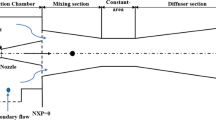

The nozzle structure parameters of a liquid-gas ejector have an important effect on the performance of the ejector. In this paper, a numerical simulation model of a liquid-gas ejector was developed. To optimize the gas induction and mixing performance of the ejector, the effect of the nozzle structure on the flow mixing characteristics inside the liquid-gas ejector is investigated. The rationality of the numerical simulation was verified by using the experimental equipment, and the maximum relative error between the experimental and simulated data was 9.72%, which proved the reliability of the numerical simulation. The results show that: conical, folded line, and arc-shaped three different shapes of the nozzle, which the conical nozzle has the best ability to induct gas. The injection coefficient will decrease gradually with the increase of nozzle length, and the injection coefficient will increase with the increase of nozzle outlet straight section length, etc. The research results of this paper can be used to improve the gas induction and mixing performance of the liquid-gas ejector, and play an important guiding role in the design optimization of the ejector.

Similar content being viewed by others

REFERENCES

Sagandira, C.R., Siyawamwaya, M., and Watts, P., 3D printing and continuous flow chemistry technology to advance pharmaceutical manufacturing in developing countries, Arab. J. Chem., 2020, vol. 13, no. 11, p. 7886.

Plutschack, M.B., Pieber, B., Gilmore, K., and Seeberger, P.H., The Hitchhiker’s Guide to Flow Chemistry, Chem. Rev., 2017, vol. 117, no. 18, p. 11796.

Mehta, H.B., Sagar, K.R., and Chaudhari, C.N., Influence of direct and co-flow pre-injection of a gas phase on gas–liquid two-phase flow through a vertical minichannel, Theor. Found. Chem. Eng., 2020, vol. 54, no. 1, p. 116.

Sharma, M., Mohapatra, T., and Ghosh, P., Hydrodynamics, mass and heat transfer study for emerging heterogeneous Fenton process in multiphase fluidized-bed reactor system for wastewater treatment: A review, Chem. Eng. Res. Des., 2021, vol. 171, p. 48.

Poissonnier, J., Callewaert, A., and Moonen, K., Comparison of jet loop and trickle-bed reactor performance in large-scale exploitation of glucose reductive aminolysis, Catal. Today, 2020, vol. 387, p. 119.

Xu, E., Jiang, X., and Ding, L., Optimizing conical nozzle of venturi ejector in ejector loop reactor using computational fluid dynamics, Korean J. Chem. Eng., 2020, vol. 37, no. 11, p. 1829.

Luo, P., Tai, Y., Fang, Y., and Wu, H., Mixing times in single and multi-orifice-impinging transverse (MOIT) jet mixers with crossflow, Chin. J. Chem. Eng., 2016, vol. 24, no. 7, p. 825.

Dolna, O., Mikielewicz, J., and Rolka, P., Analytical studies on deposition and entrainment present in the Venturi nozzle two-phase flow, Int. J. Energy Environ. Eng., 2021, vol. 12, no. 3, p. 487.

Jensen, M.B., Pedersen, P.L., Ottosen, L.D.M., Fauche, J., Smed, M.O.B., and Fischer, K., In silico screening of venturi designs and operational conditions for gas–liquid mass transfer applications, Chem. Eng. J., 2020, vol. 383, Article 123119.

Abiev, R.S. and Sirotkin, A.A., Effect of hydrodynamic conditions on micromixing in impinging-jets microreactors, Theor. Found. Chem. Eng., 2022, vol. 56, no. 1, p. 9.

Sanaye, S., Emadi, M., and Refahi, A., Thermal and economic modeling and optimization of a novel combined ejector refrigeration cycle, Int. J. Refrig., 2019, vol. 98, p. 480.

Zhao, J., Wei, X., Zou, J., Zhang, Y., Sun, J., and Liu, Z., Research on performance optimization of gas–liquid ejector in multiphase mixed transportation device, J. Mech., 2022, vol. 38, p. 22.

Schrimpf, M., Esteban, J., Rosler, T., Vorholt, A.J., and Leitner, W., Intensified reactors for gas-liquid-liquid multiphase catalysis: From chemistry to engineering, Chem. Eng. J., 2019, vol. 372, p. 917.

Haberschill, P., Nehdi, E., Kairouani, L., and Elakhdar, M.A., Experimental study of a two-phase ejector for CO2 transcritical refrigeration system, Arch. Thermodyn., 2021, vol. 42, no. 4, p. 217.

Falsafioon, M., Aidoun, Z., and Ameur, K., Numerical investigation on the effects of internal flow structure on ejector performance, J. Appl. Fluid Mech., 2019, vol. 12, no. 6, p. 2003.

Zou, H., Yang, T., Tang, M., Tian, C., and Butrymowicz, D., Ejector optimization and performance analysis of electric vehicle CO2 heat pump with dual ejectors, Energy, 2022, vol. 239, Article 122452.

Hou, Y., Chen, F., Zhang, S., Chen, W., Zheng, J., Chong, D., and Yan, J., Numerical simulation study on the influence of primary nozzle deviation on the steam ejector performance, Int. J. Therm. Sci., 2022, vol. 179, Article 107633.

Bi, R., Tang, J., Wang, L., Yang, Q., Zuo, M., Chen, C., and Xiang, S., Experimental study on bubble size distribution in gas–liquid reversed jet loop reactor, Int. J. Chem. React. Eng., 2020, vol. 18, no. 1, Article 20190102.

Wang, X., Xu, S., and Xing, C., Numerical and experimental investigation on an ejector designed for an 80 kW polymer electrolyte membrane fuel cell stack, J. Power Sources, 2019, vol. 415, p. 25.

Poirier, M., Influence of operating conditions on the optimal nozzle exit position for vapor ejector, Appl. Therm. Eng., 2022, vol. 210, Article 118377.

Duan, Z., Li, W., Lin, L., Qu, R., Li, S., and Zhang, J., Investigation on gas induction of liquid–gas ejector in jet loop reactor, Int. J. Chem. React. Eng., 2021, vol. 19, no. 12, p. 1271.

Song, Y., Shentu, Y., Qian, Y., Yin, J., and Wang, D., Experiment and modeling of liquid-phase flow in a Venturi tube using stereoscopic PIV, Nucl. Eng. Technol., 2021, vol. 53, no. 1, p. 79.

Besagni, G., Cristiani, N., Croci, L., Guedon, G.R., and Inzoli, F., Multi-scale evaluation of ejector performances: The influence of refrigerants and ejector design, Appl. Therm. Eng., 2021, vol. 186, Article 116502.

Bracconi, M., CFD modeling of multiphase flows with detailed microkinetic description of the surface reactivity, Chem. Eng. Res. Des., 2022, vol. 179, p. 564.

Sharma, D.V., Patwardhan, A.W., and Ranade, V.V., Estimation of gas induction in jet loop reactors: Influence of nozzle designs, Chem. Eng. Res. Des., 2017, vol. 125, p. 24.

Zheng, L., Hu, H., Wang, W., Zhang, Y., and Wang, L., Study on flow distribution and structure optimization in a mix chamber and diffuser of a CO2 two-phase ejector, Mathematics, 2022, vol. 10, no. 5, p. 693.

Chen, J., Li, Y., Chen, W., Luo, X., Chen, Y., Yang, Z., and Eames, I.W., Investigation of the ejector nozzle in refrigeration system, Energy, 2018, vol. 157, p. 571.

Fu, W., Liu, Z., Li, Y., Wu, H., and Tang, Y., Numerical study for the influences of primary steam nozzle distance and mixing chamber throat diameter on steam ejector performance, Int. J. Therm. Sci., 2018, vol. 132, p. 509.

Jiang, T.W., Huang, Z.W., Li, J.B., and Zhou, Y.S., Internal flow mechanism of cone–straight nozzle, Pet. Sci., 2021, vol. 18, no. 5, p. 1507. 1.

ACKNOWLEDGMENTS

This work was supported by a grant from the Natural Science Foundation of Shandong Province (Grant no. ZR2020MB122), Shandong Province Taishan Scholar engineering under special funding Foundations, and the Tackling Key Program of Science and Technology in Shandong Province (no. 2019GSF109009).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Duan, Z.Y., Peng, L.F., Liu, T.L. et al. Numerical Simulation Study of Nozzle Structure of Liquid-Gas Ejector. Theor Found Chem Eng 56, 1204–1214 (2022). https://doi.org/10.1134/S004057952233003X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S004057952233003X