Abstract

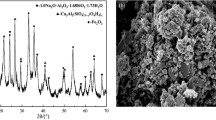

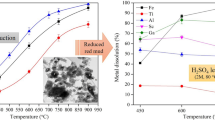

It is demonstrated that Bayer–hydrogarnet technology can be developed and applied to process red mud for separating important components such as Na2O, Al2O3, Ga2О3, and V2O5 and for obtaining iron oxide pigments from hydrogarnet mud, a product of autoclave leaching of red mud. The process consists of the autoclave leaching of red mud in the presence of lime to produce hydrogarnet mud (3CaO⋅Fe2O3 (Al2O3)⋅2SiO2⋅2H2O) as a low-alkaline (0.35% Na2O) precipitate and recover important components into the solution: 98.5% Na2O, 65.3% Al2O3, 55.5% Ga2О3, and 65.8% V2O5. As a result of the treatment, almost all of the alkali and most of the aluminum that were contained in the red mud return to alumina production. Further treatment of the leach solution by step precipitation and carbonation also shows that the solution can be used to recover Ga2О3 and V2O5 into a collective concentrate containing 1.58 wt % Ga2O3 and 27.3 wt % V2O5. A fine (0.17-μm) red-brown fraction (54% of the mud) is separated from the hydrogarnet mud and it can be used as an iron oxide pigment. Mössbauer spectroscopy determined the nature of the color of the fraction, which simultaneously contains iron in several oxidation states.

Similar content being viewed by others

REFERENCES

Ibragimov, A.T. and Budon, S.V., Razvitie tekhnologii proizvodstva glinozema iz boksitov Kazakhstana (Development of a Technology for Alumina Production from Bauxites in Kazakhstan), Pavlodar: Dom Pechati, 2010.

Kenzhaliyev, B.K., Akhmadiyeva, N.K., Abdulvaliyev, R.A., Gladyshev, S.V., Omarova, S.A., Manapova, A.I., and Zinov’eva, L.V., KZ Patent 33499, 2019.

Abdulvaliyev, R.A., Tastanov, E.A., Gladyshev, S.V., Beisembekova, K.O., and Akhmadiyeva, N.K., Wasteless processing of red mud by hydrogarnet technology, Proc. Bauxite Residue Valorisation and Best Practices Conference, Leuven, 2015, pp. 171–177.

Abdulvaliyev, R.A., Gladyshev, S.V., Pozmogov, V.A., Akhmadiyeva, N.K., and Beisembekova, K.O., A pilot plant for the testing of the processing of ferrous bauxites using the Bayer-hydrogarnet technology, Kompleksn. Ispol’z. Miner. Syr’ya, 2016, no. 3, pp. 8–14.

Abdulvaliev, R., Akhmadieva, N.K., Gladyshev, P.V., Imangalieva, L.M., and Manapova, A.I., The modified red mud reduction smelting, Kompleksn. Ispol’z. Miner. Syr’ya, 2018, no. 3, pp. 15–20. https://doi.org/10.31643/2018/6445.12

Pozmogov, V.A., Kuldeev, E.I., Dorofeev, D.V., Imangalieva, L.M., and Kvyatkovskaya, M.N., Determination of the composition and properties of the ferriferous sands of alumina production in a search for ways for their processing, Kompleksn. Ispol’z. Miner. Syr’ya, 2018, no. 3, pp. 69–77. https://doi.org/10.31643/2018/6445.19

Samchenko, S.V., Zemskova, O.V., and Kozlova, I.V., Tekhnologiya pigmentov i krasitelei. Uchebnoe posobie dlya vuzov (The Technology of Pigments and Dyes: A Textbook for Institutions of Higher Education), Moscow: Nats. Issled. Mosk. Gos. Stroit. Univ., 2015.

Shpigel’khauer, Sh., Inorganic iron oxide pigments and their use in paint and varnish materials, Sbornik dokladov 1-i Mezhdunarodnoi konferentsii “RuColor 2014” (Proc. 1st International Conference “RuColor 2014”), Gelendzhik, 2014.

Abdulvaliyev, R.A., Pozmogov, V.A., Gladyshev, S.V., Imangalieva, L.M., Manapova, A.I., and Baiduisenova, A.E., Hydrochemical processing of the ferriferous sands of bauxite enrichment to produce iron oxide pigments and cast iron, Materialy Mezhdunarodnoi nauchno-prakticheskoi konferentsii “Effektivnye tekhnologii proizvodstva tsvetnykh, redkikh i blagorodnykh metallov” (Proc. International Research and Practice Conference “Effective Technologies for the Production of Nonferrous, Rare, and Noble Metals”), Almaty, 2018, pp. 297–302.

Boldyrev, A.I., Infrakrasnye spektry mineralov (Infrared Spectra of Minerals), Moscow: Nedra, 1976.

Yurchenko, E.N., Kustova, G.N., and Batsanov, S.S., Kolebatel’nye spektry neorganicheskikh soedinenii (Vibration Spectra of Inorganic Compounds), Novosibirsk: Nauka, 1981.

Chekin, V.V., Messbauerovskaya spektroskopiya splavov zheleza, zolota i olova (Mössbauer Spectroscopy of Iron, Gold, and Tin Alloys), Moscow: Energoizdat, 1981.

Mössbauer Mineral Handbook, Stevens, J.G., Khasanov, A.M., Miller, J.W., Pollak, H., and Li, Z., Eds., Asheville, N.C.: Mössbauer Effect Data Center, 2005.

Funding

This work was supported by the Committee for Science of the Ministry of Science and Education of the Republic of Kazakhstan, grant no. AR05130549.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by V. Glyanchenko

Rights and permissions

About this article

Cite this article

Abdulvaliev, R.A., Gladyshev, S.V., Kenzhaliev, B.K. et al. Processing Red Mud Produced at the Eti Alüminyum A.Ş. Seydişehir Alumina Refinery to Recover Gallium and Vanadium and Obtain Iron Oxide Pigments. Theor Found Chem Eng 55, 797–801 (2021). https://doi.org/10.1134/S0040579521040023

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040579521040023