Abstract

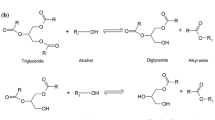

Biodiesel is an alternative non-petroleum based fuel, consisting of alkyl esters obtained either by esterification of free fatty acids with low molecular weight alcohols, or by transesterification of triglycerides. The realization of a biodiesel unit can pose several safety issues and inherent safety application opportunities as the production involves the transport, use and storage of hazardous materials, either flammable or toxic. In the experimental phase, we studied, at laboratory scale, different alkali catalysts and the relevant reaction parameters, considering inherent safety opportunities. An accurate kinetic model of the transesterification process was developed and validated, allowing to provide possible minimization and simplification plant options.

Similar content being viewed by others

References

Klemeš, J. and Friedler, F., Advances in Process Integration, Energy Saving and Emissions Reduction, Appl. Therm. Eng., 2010, vol. 30, no. 1, p. 1.

Pastorino, R., Budinis, S., Currò, F., et al., Syngas Fuel Cells: from Process Development to Risk Assessment, Chem. Eng. Trans., 2011, vol. 24, p. 1081.

Taal, M., Bulatov, I., Klemeš, J., and Stehlik, P., Cost Estimation and Energy Price Forecasts for Economic Evaluation of Retrofit Projects, Appl. Therm. Eng., 2003, vol. 23, no. 14, p. 1819.

Fabiano, B., Budinis, S., Currò, F., and Pastorino, R., Plant Design and Risk Assessment of Syngas Molten Carbonate Fuel Cells, AIDIC Conf. Ser., 2011, vol. 10, p. 119.

Utlu, Z. and Kocak, M.S., The Effect of Biodiesel Fuel Obtained from Waste Cooking Oil on Direct Injection Diesel Engine Performance and Exhaust Emissions, Renew. Energy, 2008, vol. 33, p. 1936.

Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the Promotion of the Use of Energy from Renewable Sources and Amending and Subsequently Repealing Directives 2001/77/EC and 2003/30/EC, Off. J. Eur. Union, 2009.

Kirillov, V.A., Kuzin, N.A., Kireenkov, V.V., et al., Use of Syngas as an Auto Fuel Additive: State of the Art and Prospects, Theor. Found. Chem. Eng., 2011, vol. 45, no. 2, p. 127.

Evtushenko, Yu.M., Krushevskii, G.A., Miroshnikov, Yu.P., et al., Tetrabutoxytitanium Adduct Formation in Esterification Reactions, Theor. Found. Chem. Eng., 2009, vol. 43, no. 5, p. 771.

Toikka, A.M., Toikka, M.A., Pisarenko, Yu.A., and Serafimov, L.A., Vapor-Liquid Equilibria in Systems with Esterification Reactions, Theor. Found. Chem. Eng., 2009, vol. 43, no. 2, p. 129.

Directive 96/82/EC. Council of the European Union, Off. J. Eur. Union, 1997, p. 13.

Directive 2003/105/EC. European Parliament and Council of the European Union, Off. J. Eur. Union, 2003, p. 97.

Kletz, T., Friendly Plants, Chem. Eng. Prog., 1989, vol. 85, no. 7, p. 18.

Rivera, S.S. and McLeod, N.J.E., Human Error in Biofuel Plant Accidents, Proc. World Congress on Engineering, London, 2008.

Fabiano, B. and Currò, F., From a Survey on Accidents in the Downstream Oil Industry to the Development of a Detailed Near-Miss Reporting System, Process Saf. Environ. Prot., 2012, vol. 90, no. 5, p. 357.

Riviere, C., Marlair, G., and Vignes, A., Learning of the Root Factors of Incidents Potentially Impacting the Biofuel Supply Chains from Some 100 Significant Cases, Proc. 13th EFCE International Loss Prevention Symposium, Brugge, 2010, vol. 2, p.35..

Saraf, S., 〈risk-safety.com〉, 2009. Accessed March, 22, 2012.

Salzano, E., Di Serio, M., and Santacesaria, E., Emerging Safety Issues for Biodiesel Production Plant, Chem. Eng. Trans., 2010, vol. 19, p. 415.

Directive 67/548/EEC. Council of the European Union, Off. J. Eur. Union, 1967, p. 1.

Directive 1999/45/EC. European Parliament of the European Union, Off. J. Eur. Union, 1999, p. 1.

Regulation EC N 1272/2008. European Parliament and Council of the European Union, Off. J. Eur. Union, 2008, p. 1.

Noureddini, H. and Zhu, D., Kinetics of Transesterification of Soybean Oil, J. Am. Oil Chem. Soc., 1997, vol. 60, no. 8, p. 1457.

Darnoke, D. and Cheryan, M., Kinetics of Palm Oil Esterification in a Batch Reactor, J. Am. Oil Chem. Soc., 2000, vol. 77, no. 12, p. 1263.

Jain, S. and Sharma, M.P., Kinetics of Acid-Base Catalyzed Transesterification of Jatropha Curcas Oil, Bioresour. Technol., 2010, vol. 101, p. 7701.

Jain, S., Sharma, M.P., and Rajvanshi, S., Acid Base Catalyzed Transesterification Kinetics of Waste Cooking Oil, Fuel Process. Technol., 2011, vol. 92, p. 32.

Kusdiana, D. and Saka, S., Kinetics of Transesterification of Rape Seed Oil to Biodiesel Fuel as Treated in Supercritical Methanol, Fuel, 2001, vol. 80, no. 5, p. 693.

He, H., Sun, S., Wang, T., and Zhu, S., Transesterification Kinetics of Soybean Oil for Production of Biodiesel in Supercritical Methanol, J. Am. Oil Chem. Soc., 2007, vol. 84, p. 399.

American Oil Chemists’ Society (AOCS) Ca5a-40: Free Fatty Acids, Official Methods and Recommended Practices of the AOCS, Champaign: American Oil Chemists Society, 1997, 5th ed.

Hayyan, A., Alam, M.Z., Mirghani, M.E.S., et al., Reduction of High Content of Free Fatty Acid Catalyst for Biodiesel Production, Fuel Process. Technol., 2011, vol. 92, no. 5, p. 920.

Cheng, S.F., Choo, Y.M., Ma, A.N., and Chuah, C.H., Kinetic Study on Transesterification of Palm Oil, J. Oil Palm Res., 2004, vol. 16, no. 2, p. 19.

Co, C.E.T., Tan, M.C., Diamante, J.A.R., et al., Internal Mass-Transfer Limitations on the Transesterification of Coconut Oil Using an Anionic Ion Exchange Resin in a Packed-Bed Reactor, Catal. Today, 2011, vol. 174, p. 54.

Georgogianni, K.G., Kontominas, M.G., Tegou, E., et al., Biodiesel Production: Reaction and Process Parameters of Alkali-Catalyzed Transesterification of Waste Frying Oils, Energy Fuels, 2007, vol. 21, no. 5, p. 3023.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Fabiano, B., Reverberi, A.P., Del Borghi, A. et al. Biodiesel production via transesterification: Process safety insights from kinetic modeling. Theor Found Chem Eng 46, 673–680 (2012). https://doi.org/10.1134/S0040579512060097

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040579512060097