Abstract

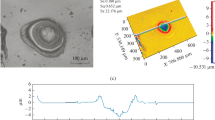

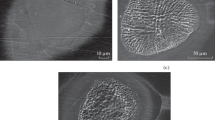

The effects on the surface of a nickel superalloy that are caused by the action of pulsed radiation from an Nd:YAG laser with a wavelength in the ultraviolet range (0.355 μm) and a pulse duration of 10 ns are studied. The surface layer is found to rise in a subthreshold irradiation regime. Traces of high-temperature plastic deformation via grain-boundary sliding and crystallographic slip are detected in the spot zone. The joints of nickel alloy samples with preliminary laser treatment are subjected to diffusion welding and mechanical tests; as a result, a noticeable improvement in the weld quality as compared to untreated samples is shown.

Similar content being viewed by others

REFERENCES

A. S. Oryshchenko, G. P. Karzov, A. S. Kudryavtsev, Yu. M. Trapeznikov, D. A. Artem’eva, and K. A. Okhapkin, “Nickel-based superalloy,” RF Patent 2543587, 2015.

A. L. Kashtanov, S. N. Petrov, A. S. Kudryavtsev, K. A. Okhapkin, and D. A. Gruzdev, “Analysis of the causes of crack formation during hot plastic deformation of a KhN55MVTs-ID alloy,” Vopr. Materialoved., No. 4 (84), 17–23 (2015).

A. K. Nikolaev and S. A. Kostin, Copper and High-Temperature Copper Alloys: Encyclopedia. Terminology. Words. Fundamental Handbook (DPK Press, Moscow, 2012).

A. V. Lyushinskii, Diffusion Welding of Unlike Materials (Akademiya, Moscow, 2006).

Yu. V. Khomich and V. A. Yamshchikov, “The effect of preliminary laser surface treatment on the mechanical properties of a solid-phase compound of an iron–nickel alloy in diffusion welding,” Adv. Mater. 6, 61–71 (2019).

Yu. A. Vashukov, S. F. Demichev, V. D. Elenev, T. V. Malinskii, S. I. Mikolutskii, Yu. V. Khomich, and V. A. Yamshchikov, “Laser surface treatment of metallic alloys for diffusion welding,” Prikl. Fiz., No. 1, 82–87 (2019).

R. E. Rovinskii, V. E. Rogalin, V. M. Rozenberg, and M. D. Teplitskii, “Changing the structure of a copper–chromium alloy irradiated by a CO2 laser pulse,” Fiz. Khim. Obrab. Mater., No. 3, 7–11 (1980).

M. E. Gurevich, L. N. Larikov, V. F. Mazanko, A. E. Pogorelov, and V. M. Fal’chenko, “Influence of multiple laser action on the mass transfer in iron,” Metallofiz. B 73, 80–83 (1978).

R. Le Harzic, D. Dorr, D. Sauer, M. Neumeier, M. Epple, H. Zimmermann, and F. Stracke, “Formation of periodic nanoripples on silicon and germanium induced by femtosecond laser pulses,” Phys. Procedia 12, 29–36 (2011).

S. I. Ashitkov, S. A. Romashevskii, P. S. Komarov, A. A. Burmistrov, V. V. Zhakhovskii, N. A. Inogamov, and M. B. Agranat, “Formation of nanostructures under femtosecond laser ablation of metals,” Quant. Electron. 45 (6), 547–550 (2015).

E. V. Struleva, P. S. Komarov, and S. I. Ashitkov, “Thermomechanical ablation of titanium under femtosecond laser action,” Teplofiz. Vys. Temp. 57 (4), 529–533 (2019).

D. V. Ganin, S. I. Mikolutskiy, V. N. Tokarev, V. Yu. Khomich, V. A. Shmakov, and V. A. Yamshchikov, “Formation of micron and submicron structures on a zirconium oxide surface exposed to nanosecond laser radiation,” Quant. Electron. 44 (4), 317–321 (2014).

F. Luo, W. Ong, Y. Guan, F. Li, S. Sun, G. C. Lim, and M. Hong, “Study of micro/nanostructures formed by a nanosecond laser in gaseous environments for stainless steel surface coloring,” Appl. Surf. Sci. 328 405–409 (2015).

Yu. A. Zheleznov, T. V. Malinskiy, Yu. V. Khomich, and V. A. Yamshchikov, “The effect of a scanning nanosecond laser pulse beam on the microtopography of ceramic Al2O3 coatings,” Inorg. Mater.: Appl. Res. 9 (3), 460–463 (2018).

V. Yu. Khomich and V. A. Shmakov, “Mechanisms and models of direct laser nanostructuring of materials,” Usp. Fiz. Nauk 185 (5), 489–499 (2015).

Yu. A. Zheleznov, T. V. Malinskii, S. I. Mikolutskii, V. N. Tokarev, R. R. Khasaya, Yu. V. Khomich, and V. A. Yamshchikov, “Experimental setup for micro- and nanostructuring the surface of solids by laser radiation,” Prikl. Fiz., No. 3, 83–87 (2014).

T. V. Malinskii, S. I. Mikolutskii, V. E. Rogalin, Yu. V. Khomich, V. A. Yamshchikov, I. A. Kaplunov, and A. I. Ivanova, “Plastic deformation of copper induced by a powerful ultraviolet nanosecond laser pulse,” Pis’ma Zh. Tekh. Fiz. 46 (16), 51–54 (2020).

Yu. Khomich, T. Malinskiy, V. Rogalin, I. Kaplunov, and A. Ivanova, “Features of microrelief formation during laser treatment of Cu–Cr–Zr alloy surface for diffusion welding,” IOP Conf. Ser.: Mater. Sci. Eng. 939, Art. 012035 (2020). https://doi.org/10.1088/1757-899X/939/1/012035

V. N. Elkin, T. V. Malinskii, Yu. V. Khomich, and V. A. Yamshchikov, “Changes in the bronze surface topography under irradiation with scanning pulsed nanosecond laser radiation,” Fiz. Khim. Obrab. Mater., No. 1, 27–34 (2019).

V. P. Veiko, Technological Lasers and Laser Radiation (St. Petersburg State University ITMO, St. Petersburg, 2007).

V. Ya. Panchenko, Laser Technologies of Material Processing: Modern Problems of Fundamental Research and Applied Development (Fizmatlit, Moscow, 2009).

V. N. Elkin, T. V. Malinskii, S. I. Mikolutskii, R. R. Khasaya, Yu. V. Khomich, and V. A. Yamshchikov, “Influence of irradiation by nanosecond laser pulses on the surface structure of metal alloys,” Fiz. Khim. Obrab. Mater., No. 6, 5–12 (2016).

A. N. Chumakov, I. S. Nikonchuk, B. Gakovic, S. Petrovic, and M. Trtica, “Multipulse nanosecond laser modification of steel surface,” Phys. Scr. 162, Art. 014016 (2014).

S. I. Mikolutskiy, R. R. Khasaya, Yu. V. Khomich, and V. A. Yamshchikov, “Formation of various types of nanostructures on germanium surface by nanosecond laser pulse,” J. Phys.: Conf. Ser. 987 Art. 012007 (2018).

R. R. Behera, M. R. Sankar, P. K. Baruah, A. K. Sharma, and A. Khare, “Experimental investigation of nanosecond-pulsed Nd:YAG laser beam micromachining on 304 stainless steel,” J. Micromach. 1 (1), 62–75 (2018).

O. A. Kaybyshev, R. Ya. Lutfullin, and V. K. Berdin, “The effect of superplasticity and solid state weldability of the titanium alloy Ti–4.5Al–3Mo–1V,” Acta Metall. Mater. 42 (8), 2609–2615 (1994).

A. M. Glezer, “On the nature of ultrahigh (megaplastic) deformation,” Izv. Ross. Akad. Nauk, Ser. Fiz. 71 (12), 1764–1772 (2007).

Funding

This work was supported by the Ministry of Education and Science of the Russian Federation in terms of state assignments no. 0057-2019-0005 and 0817-2020-0007 using the resources of the Center for Collective Use of Tver State University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Zheleznov, Y.A., Malinskii, T.V., Mikolutskii, S.I. et al. Deformation Processes at the Surface of a Nickel Alloy Subjected to Nanosecond Laser Pulses. Russ. Metall. 2021, 1233–1237 (2021). https://doi.org/10.1134/S0036029521100360

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029521100360