Abstract

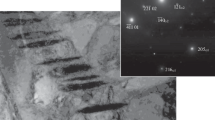

A rapidly quenched intermetallic VTI-4 titanium alloy, which is based on the orthorhombic Ti2AlNb phase and is formed by extraction from a molten hanging drop, has been hydrogenated. The phase composition and the microhardness of the alloy saturated to various hydrogen contents are studied. To study the opportunities of producing a fine alloy powder, fibers are ground in a ball mill. The alloy in the rapidly quenched β single-phase state is found to exhibit a high plasticity and is not fragmented upon ball milling, and sharp fiber embrittlement is observed as the alloy is saturated to a high hydrogen content (0.88 wt %). In this hydrogenated state, the alloy has a high hardness and its phase composition consists of the hydrogen-rich Ti2AlNb phase.

Similar content being viewed by others

Notes

Hereafter, the element contents are given in wt %.

REFERENCES

D. Banerjee, “The intermetallic Ti2AlNb,” Progr. Mater. Sci. 42 (1–4), 135–158 (1997).

W. Chen and J. W. Li, “Development of Ti2AlNb alloys: opportunities and challenges,” Advanc. Mater. Proc. 172 (4), 23–27 (2014).

J. Kumpfert, “Intermetallic alloys based on orthorhombic titanium aluminide,” Advanc. Eng. Mater. 3 (11), 851–864 (2001).

C. F. Yolton and J. P. Beckman, “Powder metallurgy processing and properties of the ordered orthorhombic alloy Ti–22 at % Al–23 at % Nb,” Mater. Sci. Eng. A 192–193 (Pt 2), 597–603 (1995).

Kaifeng Zhang, Yuanxin Wang, Gianbo Jia, and Baoyong Li, “Deformation properties and bending/diffusion bonding processing of a P/M Ti–22Al–25Nb alloy at elevated temperature,” Proc. Eng 81, 2153–2158 (2014).

Kyong-Ho Sim, Guo-Feng Wan, Ryong-Chol Son, and Sang-Lin Choe, “Influence of mechanical alloying on the microstructure and mechanical properties of powder metallurgy Ti2AlNb-based alloy,” Powder Technol. 317, 133—141 (2017).

H. Z. Niu, Y. F. Chen, D. L. Zhang, Y. S. Zhang, J. W. Lu, W. Zhang, and P. X. Zhang, “Fabrication of a powder metallurgy Ti2AlNb-based alloy by spark plasma sintering and associated microstructure optimization,”Mater. Design 89, 823–829 (2016).

J. Wu, L. Xu, Z. Lu, B. Lu, Y. Cui, and R. Yang, “Microstructure design and heat response of powder metallurgy Ti2AlNb alloys,” J. Mater. Sci. Technol. 31 (12), 1251–1257 (2015).

A. Grigoriev, I. Polozov, V. Sufiiarov, and A. Popovich, “In situ synthesis of Ti2AlNb-based intermetallic alloy by selective laser melting,” J. Alloys Comp. 704, 434–442 (2017).

Titanium Powder Metallurgy: Science, Technology, and Applications, Ed. by M. Qian and F. H. Froes (Elsevier, 2015).

K. S. Senkevich, O. Z. Umarova, and M. M. Serov, “Obtainment of fibers and porous materials from Ti2AlNb-based alloy,” Mater. Lett. 203, 85–88 (2017).

K. S. Senkevich, M. M. Serov, and O. Z. Umarova, “Fabrication of intermetallic titanium alloy based on Ti2AlNb by rapid quenching of melt,” Metal Sci. Heat Treat. 59 (7–8), 463–466 (2017).

A. N. Rubtsov, Yu. G. Olesov, and M. M. Antonova, Hydrogenation of Titanium Materials (Naukova Dumka, Kiev, 1971).

D. S. Schwartz, W. B. Yelon, R. R. Berliner, R. J. Lederich, and S. M. L. Sastry, “A novel hydride phase in hydrogen charged Ti3Al,” Acta Met. Mater. 39 (11), 2799–2803 (1991).

K. Ito, Y. Okabe, L. T. Zhang, and M. Yamaguchi, “Reversible hydrogen absorption/desorption and related phase transformations in Ti3Al alloy with the stoichiometry composition,” Acta Mater. 50 (19), 4901–4912 (2002).

S. P. Belov, A. A. Il’in, A. M. Mamonov, and A. V. Aleksandrova, “Theoretical analysis of ordering processes in Ti3Al-based alloys: II. Effect of hydrogen on the stability of intermetallic Ti3Al,” Izv. Ross. Akad. Nauk, Ser. Met., No. 2, 76–80 (1994).

A. M. Patselov, V. V. Rybin, V. A. Greenberg, and N. V. Mushnikov, “Hydrogen absorption in as-cast bcc single-phase Ti–Al–Nb alloys,” J. Alloys Comp. 505 (1), 183–187 (2010).

B. A. Kolachev, V. A. Livanov, and A. A. Bukhanova, Mechanical Properties of Titanium and Its Alloys (Metallurgiya, Moscow, 1974).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by Yu. Ryzhkov

Rights and permissions

About this article

Cite this article

Senkevich, K.S., Umarova, O.Z. & Zasypkin, V.V. Embrittlement of an Orthorhombic Ti2AlNb-Based Titanium Alloy in a Hydrogenated State. Russ. Metall. 2019, 31–35 (2019). https://doi.org/10.1134/S0036029519010130

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029519010130