Abstract

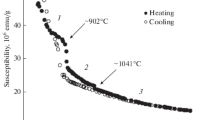

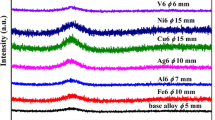

The influence of minor amounts of gallium, tin, zirconium, and antimony on the glass-forming ability of CoFeNbBSi metallic alloys is studied. The studies are performed by X-ray diffraction, transmission electronic microscopy, differential scanning calorimetry, measuring electric resistivity and magnetic susceptibility in crystalline and liquid states. Gallium and zirconium are shown to improve the glass-forming ability of the alloys whereas tin decreases it. The influence of the additions can be qualitatively described by means of the Curie paramagnetic temperature: if alloying increases it, the glass-forming ability of the alloy also increases.

Similar content being viewed by others

References

C. Suryanarayana and A. Inoue, Bulk Metallic Glasses (Boca Raton, CRC Press, 2011).

K. Mohri, K. Kawashima, and T. Kozhawa, Y. Yoshida, and L. V. Panina, “Magneto-inductive effect (MIeffect) in amorphous wires,” IEEE Trans. Magn. 28, 3150–3156 (1992).

L. V. Panina, K. Mohri, T. Uchiyama, M. Noda, and K. Bushida, “Giant magneto-impedance in Co-rich amorphous wires and films,” IEEE Trans. Magn. 31, 1249–1253 (1995).

H. Q. Guo, H. Kronmuller, T. Dragon, Z. H. Cheng, and B. G. Shen, “Influence of nanocrystallization on the evolution of domain patterns and the magnetoimpedance effect in amorphous Fe73.5Cu1Nb3Si13.5B9 ribbons,” J. Appl. Phys. 89, 514–518 (2001).

Q. Man, H. Sun, Y. Dong, B. Shen, H. Kimura, A. Makino, and A. Inoue, “Enhancement of glassforming ability of CoFeBSiNb bulk glassy alloys with excellent soft-magnetic properties and superhigh strength,” Intermetallics 18, 1876–1879 (2010).

Y. Dong, A. Wang, Q. Man, and B. Shen, “(Co1 - xFex)68B21.9Si5.1Nb5 bulk glassy alloys with high glass-forming ability, excellent soft-magnetic properties and super-high fracture strength,” Intermetallics 23, 63–67 (2012).

A. Inoue, “Stabilisation of metallic supercooled liquid and bulk amorphous alloys,” Acta Mater. 48, 279–306 (2000).

A. Inoue and A. Takeuchi, “Recent progress in bulk glassy, nanoquasicrystalline and nanocrystalline alloys,” Mater. Sci. Eng. A. 375–377, 16–30 (2004).

J. Hosko, I. Janotova, P. Svec, D. Janickovic, G. Vlasak, A. Illekova, I. Matko, and P. Sr. Svec, “Preparation of thin ribbon and bulk glassy alloys in CoFeBSiNb(Ga) using planar flow casting and suction casting methods,” J. Non-Cryst. Solids. 358, 1545–1549 (2012).

V. Sidorov, J. Hosko, V. Mikhailov, I. Rozkov, N. Uporova, P. Svec, D. Janickovic, I. Matko, P. Sr. Sve, and L. Malyshev, “Magnetic susceptibility of CoFeBSiNb alloys in liquid state,” J. Magn. Magn. Mater. 354, 35–38 (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.E. Sidorov, V.A. Mikhailov, A.A. Sabirzyanov, 2016, published in Rasplavy, 2016, No. 2, pp. 99–107.

Articles presented on 14 Russian conference “Structure and Properties of Metal and Slag Melts” (MIShR-14, September 21‒25, 2015, Yekaterinburg).

Rights and permissions

About this article

Cite this article

Sidorov, V.E., Mikhailov, V.A. & Sabirzyanov, A.A. Influence of alloying elements on the glass-forming ability of CoFeNbBSi alloys. Russ. Metall. 2016, 109–114 (2016). https://doi.org/10.1134/S0036029516020166

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029516020166