Abstract

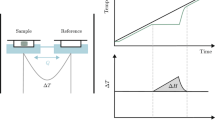

Magnesium hydride (MgH2) is a very promising hydrogen storage material due to its high hydrogen storage capacity (7.6 wt %) and low cost. It has been paid increasing attention as it may be employed in supplying hydrogen on-board. However, the production of MgH2 in high purity is still a challenging issue because the process requires high pressure and prolonged time. In this paper, high purity of MgH2 was achieved by the process of pre-milling assisted hydriding of Mg powder under a hydrogen pressure as low as 0.5 MPa. The effects of hydrogen pressure as well as hydriding and mechanical milling parameters, such as ball-to-powder ratio and milling time were investigated systematically. The relationship between the morphologies and the purities of products were discussed in detail. Our results revealed that MgH2 purity of 94.19 wt % can be achieved by hydriding with heating up to 853 K followed by cooling down to 593 K and keeping this temperature for 5 h after the milling pretreatment of Mg powder, at 400 rpm milling speed, 20 : 1 ball-to-powder ratio and 40 min milling time. SEM observation of the morphology of products indicated the achievement of the purity of MgH2 under a hydrogen pressure as low as 0.5 MPa was related to the structural defects and activation of Mg powders caused by the mechanical milling.

Similar content being viewed by others

REFERENCES

I. P. Jain, C. Lal, and A. Jain, Int. J. Hydrogen Energy 35, 5133 (2010).

L. Schlapbach and A. Züttel, Nature (London, U.K.) 414, 353 (2001).

E. S. Kikkinides, Comput. Chem. Eng. 35, 1923 (2011).

S. S. Muir and X. Yao, Int. J. Hydrogen Energy 36, 5983 (2011).

E. I. Shkolnikov, A. Z. Zhuk, and M. S. Vlaskin, Renewable Sustainable Energy Rev. 15, 4611 (2011).

Y. F. Liu, Y. X. Yang, M. X. Gao, et al., Chem. Rec. 16, 189 (2016).

P. Jena, J. Phys. Chem. Lett. 2, 206 (2011).

H. Fu, Y. Wu, J. Chen, et al., Inorg. Chem. Front. 3, 1137 (2016).

J. O. Bockris, Int. J. Hydrogen Energy 28, 131 (2003).

E. Y. Marreroalfonso, A. M. Beaird, T. A. Davis, et al., Ind. Eng. Chem. Res. 48, 3703 (2009).

T. Tayeh, A. S. Awad, M. Nakhl, et al., Int. J. Hydrogen Energy 39, 3109 (2014).

Y. L. Zhou, Y. Lu, Y. F. Zhu, et al., Rare Met. 33, 37 (2014).

J. Chen, H. Fu, Y. F. Xiong, et al., Nano Energy 10, 337 (2014).

S. Hiroi, S. Hosokai, and T. Akiyama, Fuel Energy Abstracts 36, 1442 (2011).

H. Zhong, H. Wang, J. W. Liu, et al., J. Alloys. Compd. 680, 419 (2016).

Z. L. Zhao, Y. F. Zhu, and L. Q. Li, Chem. Commun. 48, 5509 (2012).

H. Uesugi, T Sugiyama, H. Nii, et al., J. Alloys Compd. 509, S650 (2011).

Y. A. Liu, X. H. Wang, Z. H. Dong, et al., Energy 53, 147 (2013).

M. L. Tan, Z. J. Tan, and G. F. Quan, Adv. Mater. Chem. 03, 53 (2015).

L. J. Li, J. X. Zou, X. Q. Zeng, et al., Rare Met. Mater. Eng. 42, 1445 (2013).

Q. Yu, L. Qi, R. K. Mishra, et al., Appl. Phys. Lett. 106, 157 (2015).

J. Cui, H. Wang, D. L. Sun, et al., Rare Met. 35, 1 (2014).

K. F. Aguey-Zinsou and J. R. Ares-Fernández, Energy Environ. Sci. 3, 526 (2010).

H. Wang, H. J. Lin, W. T. Cai, et al., J. Alloys. Compd. 658, 280 (2016).

P. Chen and M. Zhu, Mater. Today 11, 36 (2008).

J. Huot, G. Liang, S. Boily, et al., J. Alloys. Compd. 293, 495 (1999).

A. Zaluska, L. Zaluski, and J. O. Ström–Olsen, J. Alloys. Compd. 288, 217 (1999).

D. M. Liu, Y. F. Zhu, and L. Q. Li, Int. J. Hydrogen Energy 32, 2417 (2007).

H. Gu, Y. F. Zhu, and L. Q. Li, J. Alloys Compd. 112, 218 (2008).

J. Yuan, Y. Zhu, L. Ying, et al., Int. J. Hydrogen Energy 39, 10184 (2014).

Y. J. Tan, Y. F. Zhu, and L. Q. Li, Chem. Commun. 51, 2368 (2014).

L. Q. Li, T. Akiyama, and J. I. Yagi, Intermetallics 7, 201 (1999).

J. G. Zhang, Y. F. Zhu, X. X. Zang, et al., J. Mater. Chem. A 4, 2560 (2016).

S. Li, D. Y. Gan, Y. F. Zhu, et al., T. Nonferr. Metal. Soc. 27, 562 (2017)

B. Bogdanovi, A. Ritter, and B. Spliethoff, Angew. Chem. Int. Ed. 29, 223 (1990).

ACKNOWLEDGMENTS

This work was supported by the National Natural Science Foundation of China (NSFC, grant nos. 51571112, 51471087, 51601090), the Natural Science Foundation of the Jiangsu Higher Education Institutions of China (grant no. 13KJA430003), the Natural Science Foundation of Jiangsu Province (BK20151405, BK20161004), and the Priority Academic Program Development (PAPD) of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding authors

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Deyu Gan, Zhang, J., Liu, Y. et al. Purity of MgH2 Improved by the Process of Pre-milling Assisted Hydriding of Mg Powder under a Hydrogen Pressure of 0.5 MPa. Russ. J. Phys. Chem. 93, 665–673 (2019). https://doi.org/10.1134/S0036024419040101

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036024419040101