Abstract

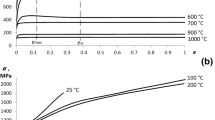

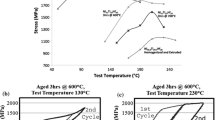

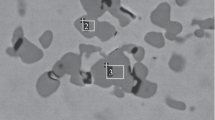

The effect of thermomechanical treatment on the structure and phase transformations of the Ti–50.5 at % Ni shape-memory alloy was studied. The data on the specific features of mechanical properties and character of fracture in the initial ultrafine-grained (UFG) alloy were gained by tension tests in combination with optical and electron microscopy and X-ray diffraction analysis. The UFG alloy structure was created by multipass plastic rolling deformation. The alloy was established to have high levels of its mechanical properties (ultimate strength of up to 1400 MPa at a relative elongation of more than 25%) due to the revealed effect of a complex reaction: recrystallization with the formation of a UFG structure and associated highly dispersed heterogeneous decomposition.

Similar content being viewed by others

REFERENCES

Shape Memory Effects in Alloys, Ed. by J. Perkins (Plenum, London, 1975).

K. Ootsuka, K. Simidzu, Yu. Sudzuki, Yu. Sekiguti, Ts. Tadaki, T. Khomma, S. Miyadzaki, Shape Memory Alloys (Metallurgiya, Moscow, 1990) [in Russian].

Engineering Aspects of Shape Memory Alloys, Ed. by T. W. Duering, K. L. Melton, D. Stockel, and C. M. Wayman (Butterworth-Heineman, London, 1990).

V. N. Khachin, V. G. Pushin, and V. V. Kondrat’ev, Titanium Nickelide: Structure and Properties (Nauka, Moscow, 1992) [in Russian].

V. G. Pushin, V. V. Kondrat’ev, and V. N. Khachin, Pre-Transitional Phenomena and Martensitic Transformations (UrBr RAS, Yekaterinburg, 1998) [in Russian].

E. Bonnot, R. Romero, L. Mañosa, E. Vives, and A. Planes, “Elastocaloric effect associated with the martensitic transition in shape-memory alloys,” Phys. Rev. Lett. 100, 125901 (2008).

J. Cui, Y. Wu, J. Muehlbauer, Y. Hwang, R. Radermacher, S. Fackler, M. Wuttig, and I. Takeuchi, “Demonstration of high efficiency elastocaloric cooling with large δT using NiTi wires,” Appl. Phys. Lett. 101, 073904 (2012).

J. Cui, “Shape memory alloys and their applications in power generation and refrigeration,” In Mesoscopic Phenomena in Multifunctional Materials, Ed. by A. Saxena and A. Planes (Springer, Berlin, 2014), pp. 289–307.

S. D. Prokoshkin, V. G. Pushin, E. P. Ryklina, and I. Yu. Khmelevskaya, “Application of titanium nickelide–based alloys in medicine,” Phys. Met. Metallogr. 97, 56–96 (2004).

J. Wilson and M. Weselowsky, “Shape memory alloys for seismic response modification: A state-of-the-art review,” Earthquake Spectra 21, 569–601 (2005).

T. Yoneyama and S. Miyazaki, Shape Memory Alloys for Medical Applications (Wordhead, Cambridge, 2009).

J. Dong, C. Cai, and A. O’Keil, “Overview of potential and existing applications of shape memory alloys in bridges,” J. Bridge Eng. 16, 305–315 (2011).

V. G. Pushin, “Alloys with a thermomechanical memory: Structure, properties, and application,” Phys. Met. Metallogr. 90 (Suppl. 1), S68–S95 (2000).

V. G. Pushin, V. V. Stolyarov, R. Z. Valiev, N. I. Kourov, N. N. Kuranova, E. A. Prokofiev, and L. I. Yurchenko, “Features of structure and phase transformations in shape memory TiNi-based alloys after severe plastic deformation,” Ann. Chim. Sci. Mat. 27, 77–88 (2002).

R. Z. Valiev and V. G. Pushin, “Bulk Nanostructured metallic materials: Production, structure, properties and functioning,” Phys. Met. Metallogr. 94, S1–S4 (2002).

V. G. Pushin, V. V. Stolyarov, R. Z. Valiev, N. I. Kourov, N. N. Kuranova, E. A. Prokofiev, and L. I. Yurchenko, “Development of methods of severe plastic deformation for the production of high-strength alloys based on titanium nickelide with a shape memory effect,” Phys. Met. Metallogr. 94, S54–S68 (2002).

V. G. Pushin and R. Z. Valiev, “The nanostructured TiNi shape-memory alloys: New properties and applications,” Solid State Phenom. 94, 13–24 (2003).

V. G. Pushin, R. Z. Valiev, and L. I. Yurchenko, “Processing of nanostructured TiNi-shape memory alloys: Methods, structures, properties, application,” J. Phys. IV 112, 659–662 (2003).

V. G. Pushin, “Structure, properties, and application of nanostructures shape memory TiNi-based alloys,” in Nanomaterials by Severe Plastic Deformation (Wiley, Weinheim, 2004), pp. 822–828.

V. Brailovski, I. Yu. Khmelevskaya, S. D. Prokoshkin, V. G. Pushin, E. P. Ryklina, and R. Z. Valiev, “Foundation of heat and thermomechanical treatments and their on the structure and properties of titanium nickelide-based alloys,” Phys. Met. Metallogr. 97, S3–S55 (2004).

V. G. Pushin, R. Z. Valiev, Y. T. Zhu, D. V. Gunderov, N. I. Kourov, T. E. Kuntsevich, A. N. Uksusnikov, and L. I. Yurchenko, “Effect of severe plastic deformation on the behavior of Ti–Ni shape memory alloys,” Mater. Trans. 47, 694–697 (2006).

R. Z. Valiev, D. V. Gunderov, and V. G. Pushin, “The new SPD processing routes to fabricate bulk nanostructured materials,” in Ultrafine Grained Materials IV. TMS (The Minerals, Metals & Materials Society), Ed. By Y. T. Zhu, T. G. Langdon, S. L. Semiatin, Z. Horita, M. J. Zehetbauer, and T. C. Lowe (Warrendale, 2006), pp. 105–112.

V. G. Pushin, R. Z. Valiev, Y. T. Zhu, S. Prockoshkin, D. V. Gunderov, and L. I. Yurchenko, “Effect of equal channel angular pressing and repeated rolling on structure, phase transformation and properties of TiNi shape memory alloys,” Mater. Sci. Forum 503–504, 539–544 (2006).

R. Valiev, D. Gunderov, E. Prokofiev, V. Pushin, and Yu. Zhu, “Nanostructuring of TiNi alloy by SPD processing for advanced properties,” Mater. Trans. 49, 97–101 (2008).

N. N. Kuranova, D. V. Gunderov, A. N. Uksusnikov, A. V. Luk’yanov, L. I. Yurchenko, E. A. Prokof’ev, V. G. Pushin, and R. Z. Valiev, “Effect of heat treatment on the structural and phase transformations and mechanical properties of TiNi alloy subjected to severe plastic deformation by Torsion,” Phys. Met. Metallogr. 108, 556–568 (2009).

S. Prokoshkin, V. Brailivski, A. Korotitskiy, K. Inaekyan, S. Dubinsky, M. Filonov, and M. Petrzhic, “Formation of nanostructures in thermo-mechanically-treated Ti–Ni and Ti–Nb–(Zr,Ta) SMAs and their roles in martensite crystal lattice changes and mechanical behavior,” J. Alloy. Comp. 509, 2066–2075 (2011).

K. Tsuchiya, Y. Hada, T. Koyano, K. Nakajima, M. Ohnuma, T. Koike, Y. Todaka, and M. Umimota, “Production of TiNi amorphous/nanocrystalline wires with high-strength and elastic modulus by severe cold drawing,” Scr. Mater. 60, 749–752 (2009).

A. I. Lotkov, V. N. Grishkov, A. A. Baturin, E. F. Dudarev, D. Yu. Zhapova, and V. N. Timkin, “The effect of warm deformation by abc-pressing on the mechanical properties of titanium nickelide,” Lett. Mater. 5, 170–174 (2015).

V. Pushin, N. Kuranova, E. Marchenkova, and A. Pushin, “Design and development of Ti–Ni, Ni–Mn–Ga and Cu–Al–Ni-based alloys with high and low temperature shape memory effects,” Materials 12, 2616–2640 (2019).

ACKNOWLEDGMENTS

This study was carried on the scientific equipment of the Collaborative Access Center of the Institute of Metal Physics (Ural Branch, Russian Academy of Sciences).

Funding

This study was performed within the framework of state assignment (code “Structure”) (grant no. 122021000033-2) to the Institute of Metal Physics (Ural Branch, Russian Academy of Sciences).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Glushachenkova

Rights and permissions

About this article

Cite this article

Kuranova, N.N., Makarov, V.V. & Pushin, V.G. The Effect of Thermomechanical Treatment on the Structure and Mechanical Properties of the Ti49.5Ni50.5 Shape-Memory Alloy. Phys. Metals Metallogr. 123, 996–1003 (2022). https://doi.org/10.1134/S0031918X22600993

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X22600993