Abstract

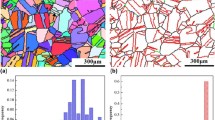

The recrystallization of pure iron deformed at 250°C by shear under pressure has been studied by scanning electron microscopy and durometry. The completeness of dynamic recrystallization has an effect on further static recrystallization: in a structure of a mixed type (formed by dislocation cells and individual recrystallized grains), the appreciable growth of a grain is started at a temperature that is 100°C lower than in a submicrocrystalline (SMC) structure (composed of grains formed as a result of dynamic recrystallization). An inhomogeneous character of the structure created under dynamic recrystallization conditions causes its low thermal stability. For the SMC structure, its propensity to secondary recrystallization has been revealed.

Similar content being viewed by others

REFERENCES

Y. Cao, S. Ni, X. Liao, M. Song, and Y. Zhu, “Structural evolutions of metallic materials processed by severe plastic deformation,” Mater. Sci. Eng., R 133, 1–59 (2018).

M. V. Markushev and M. Yu. Murashkin, “Structure and mechanical behavior of the AMg6 aluminum alloy after severe plastic deformation and annealing: I. Grain structure and texture,” Phys. Met. Metallogr. 91 (5), 522–527 (2001).

V. N. Chuvil’deev, V. I. Kopylov, A. V. Nokhrin, I. M. Makarov, L. M. Malashenko, and V. A. Kukareko, “Recrystallization in microcrystalline copper and nickel produced by equal-channel angular pressing: I. Structural investigations. Effect of anomalous growth,” Phys. Met. Metallogr. 96 (5), 486–495 (2003).

P. Ghosh, O. Renk, and R. Pippan, “Microtexture analysis of restoration mechanisms during high pressure torsion of pure nickel,” Mater. Sci. Eng., A 684, 101–109 (2017).

F. Yuan, P. Jiang, and X. Wu, “Annealing and strain rate effects on the mechanical behavior of ultrafine-grained iron produced by SPD,” Theor. Appl. Mech. Lett. 2, 021002 (2011).

M. V. Degtyarev, L. M. Voronova, V. V. Gubernatorov, and T. I. Chashchukhina, “On the thermal stability of the microcrystalline structure in single-phase metallic materials,” Dokl. Phys. 386 (2), 647–650 (2002).

L. M. Voronova, M. V. Degtyarev, and T. I. Chashchukhina, “Recrystallization of the ultradispersed structure of pure iron formed at different stages of the deformation-induced strain hardening,” Phys. Met. Metallogr. 104 (3), 262–273 (2007).

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, and J. J. Jonas, “Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions,” Prog. Mater. Sci. 60, 130–207 (2014).

K. Huang and R. E. Logé, “A review of dynamic recrystallization phenomena in metallic materials,” Mater. Des. 111, 548–574 (2016).

A. Vorhauer and R. Pippan, “On the onset of a steady state in body-centered cubic iron during severe plastic deformation at low homologous temperatures,” Metall. Mater. Trans. A 39, 417–429 (2008).

A. N. Aleshin, A. M. Arsenkin, and S. V. Dobatkin, “Study of grain growth kinetics in submicrocrystalline armco-iron,” Mater. Sci. Forum 550, 465–470 (2007).

S. V. Dobatkin, S. V. Shagalina, O. I. Sleptsov, and N. A. Krasil’nikov, “Effect of the initial state of a low-carbon steel on nanostructure formation during high-pressure torsion at high strains and pressures,” Metally 2006 (5), 445–452 (2006).

N. Jiang-li, E. Courtois-Manara, L. Kurmanaeva, A. V. Ganeev, R. Z. Valiev, C. Kübel, and Y. Ivanisenko, “Tensile properties and work hardening behaviors of ultrafine grained carbon steel and pure iron processed by warm high pressure torsion,” Mater. Sci. Eng., A 581, 8–15 (2013).

J. A. Muñoz, O. F. Higuera, J. A. Benito, Dj. Bradai, T. Khelfa, R. E. Bolmaro, J. A.M., Jr., and J. M. Cabrera, “Analysis of the micro and substructural evolution during severe plastic deformation of ARMCO iron and consequences in mechanical properties,” Mater. Sci. Eng., A 740–741, 108–120 (2019).

S. V. S. Murty Narayana, S. Torizuka, K. Nagai, N. Koseki, and Y. Kogo, “Classification of microstructural evolution during large strain high Z deformation of a 0.15 carbon steel,” Scr. Mater. 52, 713–718 (2005).

M. V. Degtyarev, V. P. Pilyugin, T. I. Chashchukhina, and L. M. Voronova, “Structure of iron deformed at 250°C by torsion under a pressure,” Phys. Met. Metallogr. 120 (12), 1193–1199 (2019).

H. H. Bernardi, H. R. Z. Sandim, K. D. Zilnyk, B. Verlinden, and D. Raabe, “Microstructural stability of a niobium single crystal deformed by equal channel angular pressing,” Mater. Res. 20, 1238–1247 (2017).

F. J. Humphreys, “Review grain and subgrain characterisation by electron backscatter diffraction,” J. Mater. Sci. 36, 3833–3854 (2001).

C. Moussa, M. Bernacki, R. Besnard, and N. Bozzolo, “About quantitative EBSD analysis of deformation and recovery substructures in pure Tantalum,” IOP Conf. Ser.: Mater. Sci. Eng. 89, 012038 (2015).

J. Duan, H. Wen, C. Zhou, R. Islamgaliev, and X. Li, “Evolution of microstructure and texture during annealing in a high-pressure torsion processed Fe–9Cr alloy,” Materialia 6, 100349 (2019).

ACKNOWLEDGMENTS

This study was carried out on the equipment of the Shared Facilities Center “Testing Center of Nanotechnologies and Promising Materials” of the Institute of Metal Physics (Ural Branch, Russian Academy of Sciences). The authors are grateful to N.V. Nikolaev and V.P. Pilyugin for their help in experiment.

Funding

This study was performed within the framework of state assignment from the Ministry of Science and Higher Education of Russia (project “Pressure” no. 122021000032-5).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Glushachenkova

Rights and permissions

About this article

Cite this article

Shugaev, K.E., Degtyarev, M.V., Voronova, L.M. et al. The Growth of a Grain during the Annealing of Iron Deformed at 250°C by Shear under Pressure. Phys. Metals Metallogr. 123, 979–986 (2022). https://doi.org/10.1134/S0031918X2260097X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X2260097X