Abstract

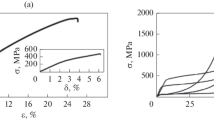

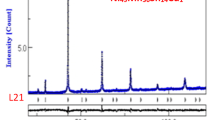

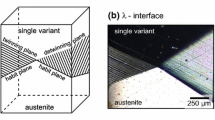

Data on premartensitic states and martensitic transformations in the shape memory alloys Сu–14 wt % Al–3 wt % Ni and 13.5 wt % Al–3.5 wt % Ni were obtained using electron microscopy and X‑ray analysis together with measurements of electrical resistivity and magnetic susceptibility. The fine structure and diffuse electron scattering have been studied in detail, including in situ heating and cooling experiments. On the basis of the observed diffuse scattering and internal defects of the martensitic substructure, a crystallographic model of martensitic rearrangement β1 → \(\beta _{1}^{'}\) and β1 → \(\gamma _{1}^{'}\) is suggested.

Similar content being viewed by others

REFERENCES

Shape Memory Effects in Alloys, Ed. by J. Perkins (Plenum, London, 1975).

Kh. Varlimont and L. Dilei, Martensitic Transformation in Alloys Based on Copper, Silver, and Gold (Nauka, Moscow, 1980) [in Russian].

K. Ootsuka, K. Simidzu, Yu. Sudzuki, Yu. Sekiguti, Ts. Tabaki, T. Khomma, and S. Miyadzaki, Shape Memory Alloys (Metallurgiya, Moscow, 1990) [in Russian].

Engineering Aspects of Shape Memory Alloys, Ed. by T. W. Duering, K. L. Melton, D. Stockel, and C. M. Wayman (Butterworth-Heineman, London, 1990).

V. N. Khachin, V. G. Pushin, and V. V. Kondrat’ev, Titanium Nickelide: Structure and Properties (Nauka, Moscow, 1992) [in Russian].

V. G. Pushin, V. V. Kondrat’ev, and V. N. Khachin, Pretransitional Phenomena and Martensitic Transformations (UrBr RAS, Yekaterinburg, 1998) [in Russian].

E. Bonnot, R. Romero, L. Mañosa, E. Vives, and A. Planes, “Elastocaloric effect associated with the martensitic transition in shape-memory alloys,” Phys. Rev. Lett. 100, 125901 (2008).

A. Planes, L. Mañosa, and M. Acet, “Magnetocaloric effect and its relation to shapememory properties in ferromagnetic Heusler alloys,” J. Phys.: Condens. Matter 21, 233201 (2009).

J. Cui, Y. Wu, J. Muehlbauer, Y. Hwang, R. Radermacher, S. Fackler, M. Wuttig, and I. Takeuchi, “Demonstration of high efficiency elastocaloric cooling with large δT using NiTi wires,” Appl. Phys. Lett. 101, 073904 (2012).

L. Mañosa, S. Jarque-Farnos, E. Vives, and A. Planes, “Large temperature span and giant refrigerant capacity in elastocaloric Cu–Zn–Al shape memory alloys,” Appl. Phys. Lett. 103, 211904 (2013).

R. Dasgupta, “A look into Cu-based shape memory alloys: Present Scenario and future prospects,” J. Mater. Res. 29, No. 16, 1681–1698 (2014).

V. Pushin, N. Kuranova, E. Marchenkova, and A. Pushin, “Design and development of Ti–Ni, Ni–Mn–Ga and Cu–Al–Ni-based alloys with high and low temperature shape memory effects,” Materials 12, 2616–2640 (2019).

A. V. Luk’yanov, V. G. Pushin, N. N. Kuranova, A. E. Svirid, A. N. Uksusnikov, Yu. M. Ustyugov, and D. V. Gunderov, “Effect of the thermomechanical treatment on structural and phase transformations in Cu–14Al–3Ni shape memory alloy subjected to high-pressure torsion,” Phys. Met. Metallogr. 119, 374–382 (2018).

A. E. Svirid, A. V. Luk’yanov, V. G. Pushin, E. S. Belosludtseva, N. N. Kuranova, and A. V. Pushin, “Effect of the temperature of isothermal upsetting on the structure and the properties of the shape memory Cu–14 wt % Al–4 wt % Ni alloy,” Phys. Met. Metallogr. 120, 1159–1165 (2019).

A. E. Svirid, V. G. Pushin, N. N. Kuranova, E. S. Belosludtseva, A. V. Pushin, and A. V. Lukyanov, “The Effect of Plastification of Cu–14Al–4Ni Alloy with the Shape Memory Effect in High-Temperature Isothermal Precipitation,” Tech. Phys. Lett. 46 (2), 118–121 (2020).

A. E. Svirid, A. V. Lukyanov, V. G. Pushin, N. N. Kuranova, V. V. Makarov, A. V. Pushin, and A. N. Uksusnikov, “Application of Isothermal Upset for Megaplastic Deformation of Cu–Al–Ni β Alloys,” Tech. Phys. 65 (7), 1044–1050 (2020).

P. Sedlak, H. Seiner, M. Landa, V. Novák, P. Šittner, and L. I. Manosa, “Elastic constants of bcc austenite and 2H orthorhombic martensite in CuAlNi shape memory alloy,” Acta Mater. 53, 3643–3661 (2005).

K. Otsuka, C. M. Wayman, and H. Kubo, “Diffuse Electron Scattering in β–phase alloys,” Metall. Trans. A 9, 1075–1085 (1978).

A. M. Glezer and B. V. Molotilov, Ordering and Deformation of Iron Alloys (Metallurgiya, Moscow, 1984).

ACKNOWLEDGEMENTS

Authors are grateful to A.V. Korolev for carrying out magnetic measurements. The work was performed using equipment of Collaborative Access Center “Testing Center of Nanotechnology and Advanced Materials” IMP UB RAS.

Funding

The work is performed in the framework of state assignment of the Ministry of Education and Science of Russia (theme “Structure”, No. АААА-А18-118020190116-6) and in the collaborative laboratory of IMP UBRAS and UrFU.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Golovnya

Rights and permissions

About this article

Cite this article

Pushin, V.G., Kuranova, N.N., Makarov, V.V. et al. Electron Microscopy Study of Metastable Shape Memory Cu–Al–Ni Alloys. Phys. Metals Metallogr. 122, 1112–1120 (2021). https://doi.org/10.1134/S0031918X21110119

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X21110119