Abstract

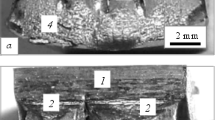

Zones on the fracture surfaces of Charpy specimens and profiles of the fractures of these specimens are examined using impact-bending tests carried out in the temperature range of +20 to–90°C and fractography. The specimens were cut out of hot-rolled plates produced from 05G2B super-low-carbon steels that contained Ti, Nb, V, and Cu microadditives using controlled rolling, followed by accelerated cooling. A detailed analysis of separations, including a study of the morphology, number, area of separations, and the surrounding stress-relaxation zones, and the structure of the walls, has allowed us to identify the mechanisms of the origination and growth of the separations. It has been found that the correlated changes in the length, width, and depth of the separations are accompanied by the formation and expansion of the stress-relaxation zones around the separations. The rate of expansion of the area of these zones is higher than that of the area of the separations, which favors the macroplastic fracture of the specimens.

Similar content being viewed by others

References

I. Pyshmintsev, A. Gervasyev, V. C. Olalla, R. Petrov, A. Arabey, “Mechanical and metallurgical aspects of the resistance to ductile fracture propagation in the new generation of gas pipelines,” Proc. 10th Int. Pipeline Conf. (IPC 2006) (Canada, Calgary, 2014), Vol. 3, pp 57–68.

L. I. Efron, Material Science in “Large” Metallurgy. Pipe Steels (Metallurgiya, Moscow, 2012) [in Russian].

I. Yu. Pyshmintsev, A. Gervasyev, R. H. Petrov, V. C. Olalla, and L. Kestens, “Crystallographic texture as a factor enabling ductile fracture arrest in high strength pipeline steel,” Mater. Sci. Forum 702–703, 770–773 (2012).

V. M. Farber, I. Yu. Pyshmintsev, A. B. Arabei, V. A. Khotinov, N. V. Lezhnin, and A. M. Mal’tseva, “Model of Cleavage,” Steel in Translation 42, 393–398 (2012).

V. M. Schastlivtsev, D. A. Mirzaev, I. L. Yakovleva, N. A. Tereshchenko, and T. I. Tabatchikova, “Effect of increasing impact toughness on the formation of a lay-ered structure upon hot rolling of a ferritic steel,” Dokl.-Phys. 55, 334–337 (2010).

D. A. Mirzaev, I. L. Yakovleva, N. A. Tereshchenko, I. V. Gervas’eva, D. V. Shaburov, and A. V. Panov, “Structural aspect of delamination crack formation during the HTMT of steels with a ferritic structure,” Phys. Met. Metallogr. 106, 186–195 (2008).

L. I. Gladshtein, P. D. Odesskii, and I. I. Vedyakov, Layered Destruction of Steels and Welded Joints (Inter-met Inzhiniring, Moscow, 2009) [in Russian].

G. Manucci and G. Demofonti, “Control of ductile fracture propagation in X80 gas linepipe,” in Proc. Int. Pipeline Tech. Conf., Beijing, 2010, pp. 86–115.

W. Guo, H. Dong, M. Lu, and X. Zhao, “The coupled effects of thickness and delamination on cracking resis-tance of X70 pipeline steel,” Int. J. Press. Vessels Pip. 79, 403–412 (2002).

C. Ruggieri and E. Hippert, Jr., “Delamination effects of fracture behavior of a pipeline steel: A numerical investigation of 3-D crack front fields and constraint,” Int. J. Press. Vessels Pip. 128, 18–35 (2015).

M. S. Joo, D.-W. Suh, J. H. Bae, and H. K. D. H. Bhadeshia, “Role of delamination and crystallography on anisotropy of Charpy toughness in API-X80 steel,” Mater. Sci. Eng., A 546, 314–322 (2012).

T. Inoue, F. Yin, Y. Kimura, K. Tsuzaki, and S. Ochiai, “Delamination effect on impact properties of ultra fine-grained low-carbon steel processed by warm cali-ber rolling,” Metall. Mater. Trans. A 41, 341–355 (2010).

S.-Y. Shin, S. Hong, J. -H. Bae, K. Kim, and S. Lee, “Separation phenomenon occurring during the Charpy impact test of API X80 pipeline steels,” Metall. Mater. Trans. A 40, 2333–2349 (2009).

A. B. Arabei, I. Yu. Pyshmintsev, M. A. Shtremel’, A. G. Glebov, A. O. Struin, and A. M. Gervas’ev, “Resistance of X80 steel to ductile-crack propagation in major gas lines,” Steel in Translation, 39, 715–724 (2009).

V. M. Schastlivtsev, T. I. Tabatchikova, I. L. Yakovleva, I. V. Gervas’eva, and L. Yu. Egorova, “Texture effect on cold resistance of the welded steel subjected to thermo-chemical treatment,” Deform. Razrush. Mater., No. 1, 34–40 (2010).

Yu. D. Morozov, M. Yu. Matrosov, S. Yu. Nastich, and A. B. Arabei, “New generation of high-strength tube steels with a ferrite-bainite structure,” Metallurgist 52, 450–456 (2008).

V. M. Farber, A. B. Arabei, I. Yu. Pyshmintsev, and V. A. Khotinov, “Fractographycal criteria of cold resis-tance of X80 strength group tubes,” Proizvodstvo Prokata, No. 1, 7–11 (2011).

I. Yu. Pyshmintsev, A. B. Arabei, V. M. Farber, V. A. Khotinov, N. V. Lezhnin, “Laboratory criteria of crack resistance of high-strength steels for gas main pipelines,” Phys. Met. Metallogr. 113, 411–417 (2012).

I. I. Vedyakov, D. V. Konin, and P. D. Odesskii, Steel Constructions of Scyscrapers (ASV, Moscow, 2014) [in Russian].

V. M. Schastlivtsev, T. I. Tabatchikova, I. L. Yakovleva, L. Yu. Egorova, I. V. Gervas’eva, A. A. Kruglova, E. I. Khlusova, and V. V. Orlov, “Effect of thermome-chanical treatment on the cold resistance of low-carbon low-alloy welding steel,” Phys. Met. Metallogr. 109, 289–299 (2010).

S.-Y. Shin, “Effects of microstructure on tensile, Charpy impact, and crack tip opening displacement properties of two API X80 pipeline steels,” Metall. Mater. Trans. A 44, 2613–2624 (2013).

Electron Backscatter Diffraction in Materials Science, Ed. by A. J. Schwartz, M. Kumar, B. L. Adams, and D. P. Field (Springer Science, LLC, 2009).

A. B. Arabei, V. M. Farber, N. V. Lezhnin, I. Yu. Pysh-mintsev, O. V. Selivanova, A. G. Glebov, and V. E. Bazhenov, “Microstructure and disperse phases of X80 pipe steel for gas pipelines,” Steel in Translation 42, 14–21 (2012).

V. M. Farber, A. B. Arabei, I. Yu. Pyshmintsev, O. V. Selivanova, V. A. Khotinov, A. O. Struin, and N. V. Lezhnin, “Disperse phase contribution to the for-mation of structure and properties of high-strength tube steels,” Proizvodstvo Prokata, No. 1, 14–21 (2011).

M. I. Gol’dshtein and M. V. Farber, Disperse Hardening of Steel (Metallurgiya, Moscow, 1979) [in Russian].

V. M. Farber, A. B. Arabei, I. Yu. Pyshmintsev, O. V. Selivanova, V. A. Khotinov, N. V. Lezhnin, and M. A. Valov, “Effect of low-temperature heating on mechanical properties of tube steels of K65 (X80) strength category,” Proizvodstvo Prokata, No. 1, 35–39 (2012).

Yu. A. Skakov, “Natural and artificial aging of technical iron,” in Proc. Sci.-Pract. Semin. “Aging Problems of Main Pipeline Steels” (Univers. Kniga, Nizhny Novgorod, 2006), pp. 86–94 [in Russian].

V. M. Farber, V. A. Khotinov, A. N. Morozova, N. V. Lezhnin, and T. Martin, “Diagnosis of the frac-ture and fracture energy of high-ductility steels in instrumented impact-bending tests,” Metal Sci. Heat Treat. 57, 329–333 (2015).

L. R. Botvina, Fracture: Kinetics, Mechanisms, General Laws (Nauka, Moscow, 2008) [in Russian].

Ya. B. Fridman, Mechanical Properties of Metals. Ch. 1. Deformation and Fracture (Mashinostroenie, Moscow, 1979) [in Russian].

M. A. Shtremel’, Alloy Strength. Part 1. Lattice Defects (MISiS, Moscow, 1989) [in Russian].

R. W. Hertzberg, Deformation and Fracture Mechanics of Engineering Materials (Wiley, 1996).

I. M. Safarov, A. V. Korznikov, R. M. Galeev, S. N. Sergeev, S. V. Gladkovskii, E. M. Borodin, and I. Yu. Pyshmint-sev, “Strength and impact toughness of low-carbon steel with fibrous ultrafine-grained structure,” Phys. Met. Metallogr. 115, 295–302 (2014).

V. E. Panin, Yu. V. Grinyaev, V. I. Danilov, L. B. Zuev, V. E. Egorushkin, T. F. Elsukova, N. A. Koneva, E. V. Kozlov, T. M. Poletika, S. N. Kul’kov, S. G. Psakh’e, S. Yu. Korostelev, and N. V. Chertova, Structural Levels of Plastic Deformation and Destruction (Nauka, Novosibirsk, 1990) [in Russian].

V. M. Farber, A. B. Arabei, I. Yu. Pyshmintsev, O. V. Selivanova, V. A. Khotinov, A. S. Yurovskikh, and N. V. Lezhnin, “Disperse phases in high-tensile low-carbon micro-alloyed steels for welded constructions,” Materialovedenie, No. 1, 11–16 (2012).

V. M. Farber and O. V. Selivanova, “Classification of stress relaxation processes and their development upon plastic deformation of metals,” Russ. Metall. (Metally) 2001, 101–105 (2001).

V. M. Farber, O. V. Selivanova, O. N. Polukhina, I. Yu. Pyshmintsev, and A. B. Arabei, “Contributions of structural factors to the strength of K65 steels,” Steel in Translation 42, 687–690 (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.M. Farber, V.A. Khotinov, S.V. Belikov, O.V. Selivanova, N.V. Lezhnin, A.N. Morozova, M.S. Karabonalov, A.Yu. Zhilyakov, 2016, published in Fizika Metallov i Metallovedenie, 2016, Vol. 117, No. 4, pp. 422–436.

An erratum to this article is available at http://dx.doi.org/10.1134/S0031918X1702017X.

Rights and permissions

About this article

Cite this article

Farber, V.M., Khotinov, V.A., Belikov, S.V. et al. Separations in steels subjected to controlled rolling, followed by accelerated cooling. Phys. Metals Metallogr. 117, 407–421 (2016). https://doi.org/10.1134/S0031918X16040050

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X16040050