Abstract

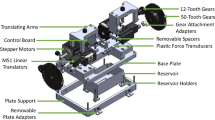

In-situ testing methods are used to investigate the real-time changing process of materials under different mechanical tests. This paper describes a miniature in-situ three-point bending device, which is compatible with the laser scanning confocal microscope. This device integrates a servo motor, a two-stage worm gears reducer with large reduction ratio and two small lead ball screws. It can realize quasi-static loading mode with a wide rate range from 0.1 µm/s to 0.1 mm/s. The microstructure of the specimen can be observed dynamically during the three-point bending test combined with the force-deflection curve. A calibration method was introduced to calibrate the flexibility of the developed device. The bending experiments were carried out for several different materials with known elastic modulus to verify the feasibility of the calibration method. Finally, the in-situ three-point bending test of red copper was performed to verify the function of the device.

Similar content being viewed by others

References

Huang, J.G., Wang, X.S., and Meng, X.K., Mater. Trans., 2007, vol. 48, no. 10, p. 2795. doi 10.2320/matertrans.MRP2007069

Malachevsky, M.T., D’Ovidio, C.A., and Esparza, D.A., Physica C, 2002, vol. 372–376, Part 2, p. 935. doi 10.1016/S0921-4534(02)00937-1

Jiang, Z., Lu, F.X., Tang, W.Z., Wang, S.G., Tong, Y.M., Huang, T.B., and Liu, J.M., Diam. Relat. Mater., 2000, vol. 9, nos. 9–10, p. 1734. doi 10.1016/S0925-9635(00)00290-9

Zhang, H. and Li, D.Y., Surf. Coat. Tech., 2002, vol. 155, nos. 2–3, p. 190. doi 10.1016/S0257-8972(02)00059-2

Boucher, E., Folkers, J.P., Hervet, H., Leger, L., and Creton, C., Macromolecules, 1996, vol. 29, no. 2, p. 774. doi 10.1021/ma9509422

Wang, M., Wang, J., Feng, H., and Ke, W., Mat. Sci. Eng. A, 2012, vol. 558, p. 649. doi 10.1016/j.msea. 2012.08.069

Lin, T., Jia, D., He, P., and Wang, M., Mat. Sci. Eng. A, 2010, vol. 527, no. 9, p. 2404. doi 10.1016/j.msea. 2009.12.004

Mao, S.C., Han, X.D., Tian, Y.B., Luo, J.F., Zhang, Z., Ji, Y., and Wu, M.H., Mat. Sci. Eng. A, 2008, vol. 498, nos. 1–2, p. 278. doi 10.1016/j.msea.2008.07.072

Sha, J.B. and Yip, T.H., Mat. Sci. Eng. A, 2004, vol. 386, nos. 1–2, p. 91. doi 10.1016/j.msea.2004.07.034

Fist, N., Dinan, J., Stadelmann, R., and Orlovskaya, N., Adv. Appl. Ceram., 2012, vol. 111, no. 7, p. 433. doi 10.1179/1743676111Y.0000000069

Chen, Y., Xu, H., Kibble, K.A., and Hall, R., Mater. Design., 2000, vol. 21, no. 5, p. 453. doi 10.1016/S0261-3069(00)00034-0

Mušálek, R., Kovárík, O., and Matejícek, J., Surf. Coat. Tech., 2010, vol. 205, no. 7, p. 1807. doi 10.1016/j.surfcoat. 2010.03.064

Baird, J.C., Li, B., Parast, S.Y., Horstemeyer, S.J., Hector, L.G., Wang, P.T., and Horstemeyer, M.F., Scr. Mater., 2012, vol. 67, no. 5, p. 471. doi 10.1016/j.scriptamat. 2012.06.007

Zhang, Y., Yang, R., George, S.M., and Lee, Y.C., Thin Solid Films, 2011, vol. 520, no. 1, p. 251. doi 10.1016/j.tsf.2011.07.056

Zu, G., Song, B., Zhong, Z., Li, X., Mu, Y., and Yao, G., J. Alloy. Compd., 2012, vol. 540, p. 275. doi 10.1016/j.jallcom.2012.06.079

Davidkov, A., Jain, M.K., Petrov, R.H., Wilkinson, D.S., and Mishra, R.K., Mat. Sci. Eng. A, 2012, vol. 550, p. 395. doi 10.1016/j.msea.2012.04.093

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Li, J., Zhao, H., Hu, X. et al. A compact bending device for in-situ three-point bending tests under laser scanning confocal microscope. Instrum Exp Tech 59, 762–767 (2016). https://doi.org/10.1134/S0020441216040060

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020441216040060