Abstract

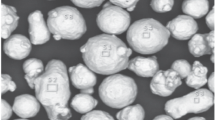

Advantages of direct laser deposition of metal providing the directional crystallization of 316L stainless steel specimens are shown. It is found that direct laser deposition of metal offers exciting possibilities for obtaining monocrystalline structures by directional crystallization of the deposited metal. The metal structure of the obtained specimens is represented by dendritic crystals oriented toward the thermal center. The cross-section view of the structure, formed by the crystal axes of the first order, is of the form of honeycombs. The thickness of the applied layer (200 µm) in the central part of the specimen does not prevent the development of the dendrite structure and it contributes to the formation of the monocrystalline structures (having no pores and cracks). It was stated that the growth orientation of dendritic crystals is driven by the thermal center determined by the position of the laser spot. A technique of manufacturing stainless steel products by direct laser deposition using the developed algorithm which allowed connecting the movement of the robotic center and specimen, laser switching, and feeding of the gas-powder mixture was presented. The possibilities of estimating the inclination angle of dendritic crystals in the metal relative to the symmetry axis of the specimen using a metallographic software package for analysis of digital images of the microstructures, as well as the quality control of the items obtained by the X-ray tomographic quality control, determination of the parameters of the laser spot on the substrate surface using high-speed photography, and estimation of the phase composition of the deposited metal using X-ray diffraction analysis, are shown. In such a case, the roughness of the specimens determined by the size of the powder particles may be removed by mechanical treatment.

Similar content being viewed by others

REFERENCES

Kablov, E.N., Additive technologies as the dominant of the national technological initiative, Intell. Tekhnol., 2015, no. 2 (11), pp. 52–55.

Grigor’ev, S.N. and Smurov, I.Yu., Prospective development of innovative additive production in Russia and abroad, Innovatsii, 2013, no. 10, pp. 76–82.

Kablov, E.N., Strategic development of the materials and technologies for their recycling until 2030, Aviats. Mater. Tekhnol., 2012, no. 5, pp. 7–17.

Grigor’yants, A.G., Shiganov, I.N., and Misyurov, A.I., Tekhnologicheskie protsessy lazernoi obrabotki (Technological Processes of Laser Treatment), Moscow: Mosk. Gos. Tekh. Univ. im. N.E. Baumana, 2006.

Turichin, G.A., Zemlyakov, E.V., Pozdeeva, E.Yu., Tuominen, J., and Vuoristo, P., Technological possibilities of laser cladding with the help of powerful fiber lasers, Met. Sci. Heat Treat., 2012, vol. 54, nos. 3–4, pp. 139–144.

Gorynin, I.V., Oryshchenko, A.S., Malyshevskii, V.A., Farmakovskii, B.V., and Kuznetsov, P.A., Additive technologies based on composite powder nanomaterials, Met. Sci. Heat Treat., 2015, vol. 56, nos. 9–10, pp. 519–524.

Sova, A., Grigoriev, S., Okunkova, A., and Smurov, I., Cold spray deposition of 316L stainless steel coatings on aluminum surface with following laser post-treatment, Surf. Coat. Technol., 2013, vol. 235, pp. 283–289.

Gorunov, A.I., Fabrication of coatings and bulk products made of a nickel-based material by additive technology laser metal deposition, Russ. Metall. (Engl. Transl.), 2016, vol. 2016, no. 1, pp. 91–94.

Gorunov, A.I. and Gilmutdinov, A.Kh., Study of the effect of heat treatment on the structure and properties of the specimens obtained by the method of direct metal deposition, Int. J. Adv. Manuf. Technol., 2016, vol. 86, no. 9, pp. 2567–2574.

Luo, K.Y., Jing, X., Sheng, J., Sun, G.F., Yan, Z., and Lu, J.Z., Characterization and analyses on micro-hardness, residual stress and microstructure in laser cladding coating of 316L stainless steel subjected to massive LSP treatment, J. Alloys Compd., 2016, vol. 673, no. 15, pp. 158–169.

Gorunov, A.I. and Gilmutdinov, A.Kh., Investigation of coatings of austenitic steels produced by supersonic laser deposition, Opt. Laser Technol., 2017, vol. 88, pp. 157–160.

Guo, P., Zou, B., Huang, C., and Gao, H., Study on microstructure, mechanical properties and machinability of efficiently additive manufactured AISI 316L stainless steel by high-power direct laser deposition, J. Mater. Process. Technol., 2017, vol. 240, pp. 12–22.

Kuznetsov, P.A., Zisman, A.A., Petrov, S.N., and Goncharov, I.S., Structure and mechanical properties of austenitic 316L steel produced by selective laser melting, Russ. Metall. (Engl. Transl.), 2016, vol. 2016, no. 10, pp. 930–934.

Wang, D., Song, C., Yang, Y., and Bai, Y., Investigation of crystal growth mechanism during selective laser melting and mechanical property characterization of 316L stainless steel parts, Mater. Des., 2016, vol. 100, pp. 291–299.

Ma, M., Wang, Z., Wang, D., and Zeng, X., Control of shape and performance for direct laser fabrication of precision large-scale metal parts with 316L stainless steel, Opt. Laser Technol., 2013, vol. 45, pp. 209–216.

Gorunov, A.I., RF Inventor’s Certificate no. 2016660262, 2016.

Gryaznov, M.Yu., Shotin, S.V., and Chuvil’deev, V.N., The effect of mesostructural hardening of 316L steel with layer-by-layer laser fusion, Vestn. Nizhegorodsk. Univ. im. N.I. Lobachevskogo, 2012, no. 5 (1), pp. 45–50.

Gorunov, A.I., The influence of heat treatment on the structure and properties of samples obtained by direct laser deposition, Tsvetn. Met., 2016, no. 5 (881), pp. 69–74.

Liu, Y., Yang, Y., Mai, S., Wang, D., and Song, C., Investigation into spatter behavior during selective laser melting of AISI 316L stainless steel powder, Mater. Des., 2015, vol. 87, pp. 797–806.

Gorunov, A.I., The structure and mechanical properties of corrosion-resistant steel coating formed by gas-dynamic sputtering method with process activation by laser emission, Deform. Razrushenie Mater., 2016, no. 9, pp. 2–7.

21. GOST (State Standard) 2789-73: Surface Roughness, Parameters and Characteristics, Moscow: Standartinform, 2006.

Funding

The work was performed within the framework of the state task of the Ministry of Education and Science of the Russian Federation (task no. 9.3236.2017/4.6).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Grishina

Rights and permissions

About this article

Cite this article

Gorunov, A.I. Directional Crystallization of 316L Stainless Steel Specimens by Direct Laser Deposition. Inorg Mater 55, 1439–1444 (2019). https://doi.org/10.1134/S002016851915007X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S002016851915007X