Abstract

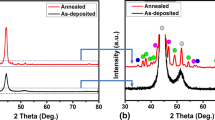

In this study, the surface of AISI D2 steel, which has the most common usage area among cold work tool steels, was coated with boride, vanadium carbide and boron-vanadium carbide layer by thermo-reactive deposition method. Characterization of obtained coatings was determined by scanning electron microscopy with energy dispersive spectroscopy (SEM-EDS), X-ray diffraction (XRD), two-dimensional (2D) surface roughness, microhardness, nanoindentation, and wear tests. Wear tests were carried out in an open-air and 3.5 wt % NaCl environment, taking into account the working conditions of AISI D2 steel, by using a ball-on-disc type tribometer with 10 N applying load and 250 m sliding distance. Characterization results revealed that, boride, carbide, and complex borocarbide coating layers were achieved. The thickness, hardness and elasticity of the obtained coating for boronizing, vanadinizing and borovanadinizing were respectively 124, 20, 98 µm thicknesses, 2176, 2250, 2338 HV hardness and 219, 169, 141 GPa elasticity modules. Depending on improving microhardness and elasticity modulus higher wear resistances were found in both open-air environments and 3.5 wt % NaCl environment than untreated AISI D2 steel. The wear environment is effective on the wear type. A lower friction coefficient and reduced wear rates occurred in 3.5 wt % NaCl environment compared to the open-air environment. In addition, while delamination and oxidative wear mechanisms were observed for coated samples in the open-air environment, delamination and pitting erosion mechanisms were observed in 3.5 wt % NaCl environment.

Similar content being viewed by others

REFERENCES

Sista, V., Kahvecioglu, O., Yilmaz, O.L., Erdemir, A., and Timur, S., Thin Solid Films, 2011, vol. 520, no. 5, p. 1582.

Tang, L., Gao, C. Huang, J., Zhang, H., and Chang, W., Tribol. Int., 2013, vol. 66, p. 165.

Karakaş, M.S., Surf. Coat. Technol., 2020, vol. 394, p. 125884.

Mallick, R., Kumar, R., Panda, A., and Sahoo, A.K., Mater. Today, 2020, vol. 26, p. 2685.

Oliveira, C.K.N., Casteletti, L.C., Neto, A.L., Totten, G.E., and Heck, S.C., Vacuum, 2010, vol. 84, p. 792.

Yapici, A., Aydin, S.E., Koc, V., Kanca, E., and Yildiz, M., Prot. Met. Phys. Chem. Surf., 2019, vol. 55, no. 2, p. 341.

Kurt, B., Gunen, A., Kanca, Y., Koc, V., Gok, M.S., Kirar, E., and Askerov, K., JOM, 2018, vol. 70, no. 11, p. 2650.

Nanesa, H.G. and Jahazi, M., Mater. Sci. Eng., A, 2015, vol. 634, p. 32.

Nanesa, H.G., Touazine, H., and Jahazi, M., Int. J. Adv. Manuf. Technol., 2016, vol. 85, no. 1, p. 881.

Günen, A., Kurt, B., Milner, P., and Gök, M.S., Int. J. Refract. Met. Hard Met., 2019, vol. 81, p. 333.

Farrahi, G.H. and Ghadbeigi, H., J. Mater. Process. Technol., 2006, vol. 174, p. 318.

Cho, K.T., Lee, Y.K., and Lee, W.B., Tribol. Int., 2015, vol. 87, p. 82.

Bayoumi, M.R. and Abdellatif, A.K., Eng. Fract. Mech., 1995, vol. 51, no. 5, p. 861.

Budynas, R. and Nisbett, K., Shigley’s Mechanical Engineering Design, New York: McGraw-Hill, 2014.

Mittemeijer, E.J. and Somers, M.A.J., Thermochemical Surface Engineering of Steels: Improving Materials Performance, book 62 of Woodhead Publishing Series in Metals and Surface Engineering, Woodhead Publ., 2014.

Davis, J.R., Surface Engineering for Corrosion and Wear Resistance, ASM Int., 2001.

Lemm, J.D., Warmuth, A.R., Pearson, S.R., and Shipway, P.H., Tribol. Int., 2015, vol. 81, p. 258.

Takeya, G., Mariani, F., Neto, A., Totten, G., and Casteletti, L., Mater. Perform. Charact., 2016, vol. 5, no. 4, p. 396.

Castillejo, F., Olaya, J.J., and Alfonso, J.E., Coatings, 2019, vol. 9, p. 1.

Park, K., Kim, J.H., Kim, S., and Kang, N., Metals, 2018, vol. 8, no. 6, p. 400.

Günen, A., Kalkandelen, M., Gök, M.S., Kanca, E., Kurt, B., Karakaş, M.S., Karahan, İ.H., and Çetin, M., Surf. Coat. Technol., 2020, vol. 402, p. 126402.

Günen, A., Kanca, E., Karakaş, M.S., Koç, V., Gök, M.S., Kanca, Y., Çürük, A., and Demir, M., Surf. Coat. Technol., 2018, vol. 348, p. 130.

Arai, T. and Harper, S., in Steel Heat Treating, Fundamentals and Processes, vol. 4 of ASM Handbook, Materials Park, OH: ASM Int., 1991.

Kılınç, B., Cegil, O., Sen, S., and Sen, U., Acta Phys. Pol., A, 2014, vol. 125, no. 2, p. 362.

Castillejo-Nieto, F.E., Olaya-Florez, J.J., and Alfonso, J.E., DYNA, 2015, vol. 82, no. 193, p. 104.

Shirinbayan, M., Shafyei, A., and Aboutalebi, M.R., Russ. J. Appl. Chem., 2014, vol. 87, no. 12, p. 1930.

Kurt, B., Onder, E., Carboga, C., and Demirel, B., Pract. Metallogr., 2014, vol. 51, no. 1, p. 32.

Vadivel, K. and Rudramoorthy, R., Int. J. Adv. Manuf. Technol., 2009, vol. 42, nos. 3–4, p. 222.

Çiçek, A., Ekici, E., Uygur, İ., Akıncıoğlu, S., and Kıvak, T., Uluslararasi Teknol. Bilimler Derg., 2012, vol. 4, no. 1, p. 1.

Ay, G.M. and Celik, O.N., Ind. Lubr. Tribol., 2019, vol. 71, no. 4, p. 548.

Topuz, P., Aydoğmuş, T., and Aydın, Ö., Int. J. Eng. Sci., 2019, vol. 2, no. 1, p. 17.

Bican, O., Bayca, S.U., Ocak-Araz, S., Yamanel, B., and Tanis, N.A., Surf. Rev. Lett., 2020, vol. 27, no. 06, p. 1950157.

Turgut, S. and Günen, A., J. Mater. Eng. Perform., 2020, vol. 29, no. 11, p. 6997.

Woydt, M. and Habig, K.H., Tribol. Int., 1989, vol. 22, p. 75.

Campos, I., Palomar, M., Amador, A., Ganem, R., and Martinez, J., Surf. Coat. Technol., 2006, vol. 201, p. 2438.

Batista, J.C.A., Matthews, A., and Godoy, C., Surf. Coat. Technol., 2001, vol. 142, p. 1137.

Günen, A., Kanca, E., Demir, M., Er, Y., Sağlam, G., and Gök, M. S., Tribol. Trans., 2017, vol. 60, no. 2, p. 267.

Gök, M.S., Küçük, Y., Gencel, O., Koç, V., and Brostow, W., Mech. Adv. Mater. Struct., 2011, vol. 18, no. 6, p. 389.

Panda, J.N., Wong, B.C., Medvedovski, E., and Egberts, P., Tribol. Int., 2021, vol. 153, p. 106666.

Wang, Y., Yang, Y., Yang, H., Zhang, M., and Qiao, J., J. Alloys Compd., 2017, vol. 725, p. 365.

Günen, A., Metall. Mater. Trans. A, 2020, vol. 51, no. 2, p. 927.

Strahin, B.L., Shreeram, D.D., and Doll, G.L., JOM, 2017, vol. 69, no. 7, p. 1160.

Trevisiol, C., Jourani, A., and Bouvier, S.E., Wear, 2017, vol. 388, p. 101.

Wu, L., Guo, X., and Zhang, J., Lubricants, 2014, vol. 2, no. 2, p. 66.

Kurt, B., Günen, A., Kanca, Y., Koç, V., Gök, M.S., Kırar, E., and Askerov, K., JOM, 2018, vol. 70, no. 11, p. 2650.

Hutchings, I. and Shipway, P., Tribology: Friction and Wear of Engineering Materials, Butterworth-Heinemann, 2017.

Enayati, K. and Sayyedan, F.S., Tribol.-Mater., Surf. Interfaces, 2021, vol. 1, p. 1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Çakir, M.V. A Comparative Study on Tribocorrosion Wear Behavior of Boride and Vanadium Carbide Coatings Produced by TRD on AISI D2 Steel. Prot Met Phys Chem Surf 58, 562–573 (2022). https://doi.org/10.1134/S2070205122030042

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205122030042