Abstract

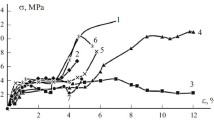

The strength and resistance of epoxide (ED20 + polyethylenepolyamine)–micronanoiron (R10 or R20) composite systems, which are of interest for machine-building, instrument-making, and aerospace industry, were studied. Introduction of micronanoiron into the epoxy resin allows preparation of iron–epoxy composites without significant changes in the adhesion to steel and in the bending modulus, with only a slight (10–15%) decrease in the compression strength. Filling does not affect the heat resistance of the components (thermal gravimetric analysis) and enhances the flame resistance. The morphology of the composites is characterized by aggregative, relatively uniform distribution of iron particles in the resin. The compression strength increases after heating to 250°С (in contrast to the unfilled polymer). On the other hand, filling slightly weakens the resistance of iron–epoxy composites to aggressive media (with acetone–ethyl acetate mixture and 25% HNO3 as examples). Surface modification of iron particles with acrylic varnish in some cases enhanced both the swelling resistance (with 10% modified R10 iron in contact with water and 25% HNO3 as example) and the strength characteristics (with the bending modulus and compression strength after heating to 250°С as example).

Similar content being viewed by others

References

Shandruk, M.I., Mamunya, E.P., Zinchenko, O.V., et al., Polim. Zh., 2006, vol. 28, no. 2, pp. 112–116.

Ishchenko, A.A., Tekhnologicheskie osnovy vosstanovleniya promyshlennogo oborudovaniya sovremennymi polimernymi materialami (Technological Principles of Restoration of Industrial Equipment Using Modern Polymer Materials), Mariupol: Priazovskii Gos. Tekh. Univ., 2007.

Demchenko, V. and Riabov, S., Eur. Polym. J., 2016, vol. 75, pp. 310–316.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © D.L. Starokadomskii, 2017, published in Zhurnal Prikladnoi Khimii, 2017, Vol. 90, No. 8, pp. 1074−1082.

Rights and permissions

About this article

Cite this article

Starokadomskii, D.L. Epoxy composites with 10 and 50 wt % micronanoiron: strength, microstructure, and chemical and thermal resistance. Russ J Appl Chem 90, 1337–1345 (2017). https://doi.org/10.1134/S1070427217080249

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070427217080249