Abstract

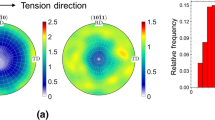

The Young’s modulus and the internal friction of beryllium polycrystals (size grain from 6 to 60 μm) prepared by the powder metallurgy method have been studied as functions of the amplitude and temperature in the range from 100 to 873 K. The measurements have been performed using the composite piezoelectric vibrator method for longitudinal vibrations at frequencies about 100 kHz. Based on the acoustic measurements, the data have been obtained on the elastic and inelastic (microplastic) properties as functions of vibration stress amplitudes within the limits from 0.2 to 30–60 MPa. The microplastic deformation diagram is shown to become nonlinear at the amplitudes higher than 5 MPa. The beryllium mechanical characteristics (the yield strength σ 0.2, the ultimate strength σ u , and the conventional microscopic yield strength σ y ) obtained with various grain sizes are compared. At room temperature, all the parameters satisfactorily obey the Hall-Petch relationship, although there is no complete similarity. The temperature dependences are quite different, namely: σ 0.2(T) and σ u (T) decrease monotonically during heating from room temperature to higher temperatures; however, σ y (T) behaves unusually, and it has a minimum near 400 K. The different levels of stresses and the absence of similarity indicate that the scattering of the ultrasound energy and the formation of a level of the macroscopic flow stresses in beryllium occur on dislocation motion obstacles of different origins.

Similar content being viewed by others

References

T. A. Read, Phys. Rev. 58(4), 371 (1940).

G. S. Baker, J. Appl. Phys. 33(5), 1730 (1962).

B. K. Kardashev, Sov. Phys. Solid State 19(8), 1459 (1977).

S. P. Nikanorov and B. K. Kardashev, Elasticity and Dislocation Inelasticity of Crystals (Nauka, Moscow, 1985) [in Russian].

A. B. Lebedev and S. B. Kustov, Sov. Phys. Solid State 29(3), 524 (1987).

A. B. Lebedev, J. Phys. IV 06(C8), C8–255 (1996).

B. K. Kardashev, A. S. Nefagin, G. N. Ermolaev, M. V. Leont’eva-Smirnova, M. M. Potapenko, and V. M. Chernov, Tech. Phys. Lett. 32(9), 799 (2006).

B. K. Kardashev and V. M. Chernov, Phys. Solid State 50(5), 854 (2008).

B. K. Kardashev and V. M. Chernov, Mater. Sci. Eng., A 521–522, 329 (2009).

V. L. Indenbom and V. M. Chernov, in Elastic Strain Fields and Dislocation Mobility, Ed. by V. L. Indenbom and J. Lothe (North-Holland, Amsterdam, 1992), p. 517.

G. Gremaud, Mater. Sci. Forum. 366–368, 178 (2001).

R. Honeycombe, The Plastic Deformation of Metals (Cambridge University Press, Cambridge, 1968; Mir, Moscow, 1972).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © B.K. Kardashev, I.B. Kupriyanov, 2011, published in Fizika Tverdogo Tela, 2011, Vol. 53, No. 12, pp. 2356–2361.

Rights and permissions

About this article

Cite this article

Kardashev, B.K., Kupriyanov, I.B. Elastic, micro- and macroplastic properties of polycrystalline beryllium. Phys. Solid State 53, 2480–2485 (2011). https://doi.org/10.1134/S1063783411120080

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063783411120080