Abstract

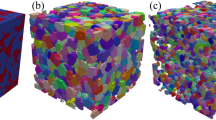

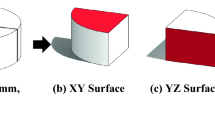

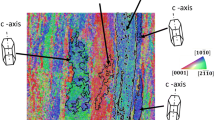

In order to describe irreversible deformation during metal forming processes, the yield surface is one of the most important criteria. Because of their simplicity and efficiency, analytical yield functions along with experimental guidelines for parameterization become increasingly important for engineering applications. However, the relationship between most of these models and microstructural features are still limited. Hence, we propose to use micromechanical modeling, which considers important microstructural features, as a part of the solution to this missing link. This study aims at the development of a micromechanical modeling strategy to calibrate material parameters for the advanced analytical initial yield function Barlat YLD 2004-18p. To accomplish this, the representative volume element is firstly created based on a method making use of the statistical description of microstructure morphology as input parameter. Such method couples particle simulations to radical Voronoi tessellations to generate realistic virtual microstructures as representative volume elements. Afterwards, a nonlocal crystal plasticity model is applied to describe the plastic deformation of the representative volume element by crystal plasticity finite element simulation. Subsequently, an algorithm to construct the yield surface based on the crystal plasticity finite element simulation is developed. The primary objectives of this proposed algorithm are to automatically capture and extract the yield loci under various loading conditions. Finally, a nonlinear least square optimization is applied to determine the material parameters of Barlat YLD 2004-18p initial yield function of representative volume element, mimicking generic properties of bcc and fcc steels from the numerical simulations.

Similar content being viewed by others

References

Zhang, H., Diehl, M., Roters, F., and Raabe, D., A Virtual Laboratory Using High Resolution Crystal Plasticity Simulations to Determine the Initial Yield Surface for Sheet Metal Forming Operations, Int. J. Plasticity, 2016, vol. 80, pp. 111–138.

von Mises, R., Mechanik der Plastischen Formanderung von Kristallen, Z. Angew. Math. Mech., 1928, vol. 8, pp. 161–185.

Hill, R., A Theory of the Yielding and Plastic Flow of Anisotropic Metals, Proc. R. Soc. A. Math. Phys. Eng. Sci., 1948, vol. 193, pp. 281–297.

Hosford, W.F., Limitations of Non-Quadratic Anisotropic Yield Criteria and Their Use in Analysis of Sheet Forming, Proc. of 15th Congress of Int. Deep Drawing Research Group, Materials Park: ASM Int., 1988, pp. 163–170.

Hill, R., Theoretical Plasticity of Textured Aggregates, Math. Proc. Cambridge Philos. Soc., 1979, vol. 85, no. 1, pp. 179–191.

Hosford, W.F., Comments on Anisotropic Yield Criteria, Int. J. Mech. Sci., 1985, vol. 27, no. 7-8, pp. 423–427.

Barlat, F., and Lian, K., Plastic Behavior and Stretchability of Sheet Metals. Part I: A Yield Function for Crthotropic Sheets under Plane Stress Conditions, Int. J. Plasticity, 1989, vol. 5, no. 1, pp. 51–66.

Barlat, F., Aretz, H., Yoon, J.W., Karabin, M.E., Brem, J.C., and Dick, R.E., Linear Transformation-Based Anisotropic Yield Functions, Int. J. Plasticity, 2005, vol. 21, no. 5, pp. 1009–1039.

Karafillis, A.P. and Boyce, M.C., A General Anisotropic Anisotropic Yield Criterion Using Bounds and a Transformation Weighting Tensor, J. Mech. Phys. Solids, 1993, vol. 41, no. 12, pp. 1859–1886.

Banabic, D., Kuwabara, T., Balan, T., Comsa, D.S., and Julean, D., Nonquadratic Yield Criterion for Orthotropic Sheet Metals under Plane Stress Conditions, Int. J. Mech. Sci., 2003, vol. 45, no. 5, pp. 797–811.

Lademo, O.G., Hopperstad, O.S., and Langseth, M., An Evaluation of Yield Criteria and Flow Rules for Aluminum Alloys, Int. J. Plasticity, 1999, vol. 15, no. 2, pp. 191–208.

Vajragupta, N., Wechsuwanmanee, P., Lian, J., Sharaf, M., Munstermann, S., Ma, A., Hartmaier, A., and Bleck, W., The Modelling Scheme to Evaluate the Influence of Microstructure Features on Microcrack Formation in DP-Steel: The Artificial Microstructure Model and Its Applications to Predict the Strain Hardening Behaviour, Comp. Mater. Sci., 2014, vol. 94, pp. 198–213.

Regener, B., Krempaszky, C., Werner, E., and Stockinger, M., Modelling the Micromorphology of Heat Treated Ti6Al4V Forgings by Means of Spatial Tessellations Feasible for FEM Analyses of Microscale Residual Stresses, Comp. Mater. Sci., 2012, vol. 52, pp. 77–81.

Wu, Y., Zhou, W., Wang, B., and Yang, F., Modeling and Characterization of Two-Phase Composites by Voronoi Diagram in the Laguerre Geometry Based on Random Close Packing of Spheres, Comp. Mater. Sci., 2010, vol. 47, no. 4, pp. 951–961.

Okabe, A., Boots, B., Sugihara, K., and Chiu, S.N., Spatial Tessellations: Concepts and Applications ofVoronoi Diagrams, Chichester: John Wiley & Sons Ltd., 2000.

Boeff, M., Micromechanical Modelling of Fatigue Crack Initiation and Growth: PhD Thesis, Bochum: Ruhr-Universitat Bochum, 2016.

Roters, F., Overview of Constitutive Laws Kinematics Homogenization and Multiscale Methods in Crystal Plasticity Finite-Element Modeling: Theory, Experiments, Applications, Acta Mater., 2010, vol. 58, pp. 1152–1211.

Tikhovsky, I., Raabe, D., and Roters, F., Simulation of Earing of a 17% Cr Stainless Steel Considering Texture Gradients, Mat. Sci. Eng. A. Struct., 2008, vol. 488, pp. 482–490.

Wang, Y., Orientation Dependence of Nanoindentation Pile-up Patterns and of Nanoindentation Microtextures in Copper Single Crystals, Acta Mater., 2004, vol. 52, pp. 2229–2238.

Sachtleber, M., Zhao, Z., Raabe, D., Experimental Investigation of Plastic Grain Interaction, Mat. Sci. Eng. A, 2002, vol. 336, no. 1-2, pp. 81–87.

Stoelken, J. and Evans, A., A Microbend Test Method for Measuring the Plasticity Length Scale, Acta Mater., 1998, vol. 46, pp. 5109–5115.

Suzuki, K., Matsuki, Y., Masaki, K., Sato, M., and Kuroda, M., Tensile and Microbend Tests of Pure Aluminum Foils with Different Thicknesses, Mat. Sci. Eng. A, 2009, vol. 513, pp. 77–82.

Hayashi, I., Sato, M., and Kuroda, M., Stain Hardening in Bent Copper Foils, J. Mech. Phys. Solids, 2011, vol. 59, pp. 1731–1751.

Fleck, N.A., Muller, G.M., Ashby, M.F., and Hutchinson, J.W., Strain Gradient Plasticity: Theory and Experiment, Acta Metall. Mater., 1994, vol. 42, pp. 475–487.

Nye, J.F., Some Geometrical Relations in Dislocated Crystals, Acta Metall., 1953, vol. 1, pp. 153–162.

Tarjus, G., Schaaf, P., and Talbot, J., Random Sequential Addition: A Distribution Function Approach, JSP, 1991, vol. 63, pp. 167–202.

Plimpton, S., Fast Parallel Algorithms for Short-Range Molecular Dynamics, J. Comput. Phys., 1995, vol. 117, no. 1, pp. 1–19.

Plimpton, S., LAMMPS Molecular Dynamics Simulator. http://lammps.sandia.gov. Accessed: 2016-02-01.

Rycroft, C.H., Grest, G.S., Landry, J.W., and Bazant, M.Z., Analysis of Granular Flow in a Pebble-Bed Nuclear Reactor, Phys. Rev. E, 2006, vol. 74, p. 021306.

Sandia National Laboratories “CUBIT 13.2”. https://cubit.sandia.gov/. Accessed: 2016-05-04.

Ma, A. and Hartmaier, A., On the Influence of Isotropic and Kinematic Hardening Caused by Strain Gradients on the Deformation Behaviour of Polycrystals, Philos. Mag., 2014, vol. 94, no. 2, pp. 125–140.

Newville, M., Ingargiola, A., Stensitzki, T., and Allen, D.B., LMFT: Non-Linear Least-Square Minimization and Curve-Fitting for Python, Zenodo, 2014.

Vitek, V., Mrovec, M., and Bassani, J.L., Influence of Non-Glide Stresses on Plastic Flow: From Atomistic to Continuum Modeling, Mater. Sci. Eng. A, 2004, vol. 365, no. 1, pp. 31–37.

Koester, A., Ma, A., and Hartmaier, A., Atomistically Informed Crystal Plasticity Model for Body-Centered Cubic Iron, Acta Mater., 2012, vol. 60, pp. 3894–3901.

ABAQUS User Subroutine Reference Manual Version 6.7. Dassault Systems: 2007.

ABAQUS/Analysis User’s Manual. Version 6.12. ABAQUS Inc.

Smit, R., Brekelmans, W., and Meijer, H., Prediction of the Mechanical Behavior of Nonlinear Heterogeneous Systems by Multi-Level Finite Element Modeling, Comput. Method. Appl. Mech. Eng., 1998, vol. 155, no. 12, pp. 181–192.

Hosford, W.F., A Generalized Isotropic Yield Criterion, Int. J. Appl. Mech., 1972, vol. 39, no. 2, pp. 607–609.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Text © N. Vajragupta, S. Ahmed, M. Boeff, A. Ma, A. Hartmaier, 2017, published in Fizicheskaya Mezomekhanika, 2017, Vol. 20, No. 1, pp. 100–108.

Rights and permissions

About this article

Cite this article

Vajragupta, N., Ahmed, S., Boeff, M. et al. Micromechanical modeling approach to derive the yield surface for BCC and FCC steels using statistically informed microstructure models and nonlocal crystal plasticity. Phys Mesomech 20, 343–352 (2017). https://doi.org/10.1134/S1029959917030109

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1029959917030109