Abstract

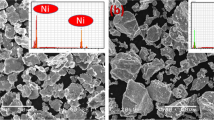

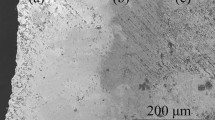

The erosion-resistant ZrN and Cr3C2 coatings intended for the protection of the titanium and steel blades in a GTE compressor are studied. The erosion resistance of the substrate–coating composition is shown to depend on the coating thickness, the deposition conditions, and the coating texture. Ion-assisted deposition changes the structure–phase state of a coating and substantially increases its erosion resistance. It is found that a nanolayer 2D TiN/CrN coating with an average nanolayer thickness of ~60 nm is the best erosion- corrosion-resistant coating for titanium alloys and that a (NiCrTiAlHf)C + CrC coating formed by ionassisted deposition is the best coating for steels. The testing of alloy VT8 compressor blades in an engine supported high protective properties of the nanolayer TiN/CrN coating.

Similar content being viewed by others

References

D. V. Ivchenko, P. K. Shtan’ko, N. V. Isaev, and I. Yu. Pavlov, “Erosion strength of the parts in the gas–air conduit of helicopter gas turbine engines during operation under air dustiness conditions. State of the art of the problem and a possible way of its solution,” Aviats.-Kosm. Tekh. Tekhnol., No. 7(15), 135–139 (2004).

J. H. Richardson, G. P. Sallee, and F. K. Smakula, “Causes of high temperature compressor deterioration in service,” in Proceedings of 15th Joint Propulsion Conference (Las Vegas, 19789), pp. AIAA-79–1234.

E. N. Kablov, S. A. Muboyadzhyan, S. A. Budinovskii, and A. N. Lutsenko, “Ion-Plasma protective coatings for gas-turbine engine blades,” Russian Metallurgy (Metally), No. 5, 413–424 (2007).

E. N. Kablov, S. A. Muboyadzhyan, and A. N. Lutsenko, “Nanostructured ion-plasma protective and hardening coatings for gas turbine engine blades,” Vopr. Materialoved., No. 2, 175–180 (2008).

S. A. Muboyadzhyan and Ya. A. Pomelov, “Erosion resistance of coatings deposited by high-energy plasmochemistry,” Vopr. Aviats. Nauki Tekhn., No. 1, 58–66 (1992).

S. A. Muboyadzhyan and Ya. A. Pomelov, “Protective coatings for GTE compressor blades,” in Problems of Aviation Science and Engineering. Aviation Materials and Technologies. Ser. Ultrahigh-Temperature Materials for Modern and Promising Gas-Turbine Engines and Progressive Processes of Their Production (VIAM, Moscow, 2003), pp. 116–131.

S. A. Muboyadzhyan, “Erosion-resistant coatings for gas turbine compressor blades,” Russ. Metall. (Metally), No. 3, 193–210 (2009).

S. A. Muboyadzhyan, D. A. Aleksandrov, and D. S. Gorelov, “Ion–plasma erosion-resistant nanocoatings based on metal carbides and nitrides,” Russ. Metall. (Metally), No. 9, 719–731 (2010).

S. A. Muboyadzhyan, A. N. Lutsneko, D. A. Aleksandrov, D. S. Gorlov, and P. L. Zhuravleva, “Properties of nanolayer erosion-resistant coatings based on metal carbides and nitrides,” Russ. Metall. (Metally), No. 7, 601–611 (2011).

E. N. Kablov, “Innovative solutions of FGUP VIAM GNTs RF for “Strategic Directions of Designing Materials and Technologies of Their Processing up to 2030,”” Aviats. Mater. Tekhnol., No. 1(34), 3–33 (2015).

S. A. Muboyadzhyan, S. A. Budinovskii, Yu. D. Yagodkin, et al., “Effect of the technological parameters of deposition on the structure of ion-plasma coatings,” in Proceedings of the III Conference on the Modification of the Properties of Structural Materials by Charged-Particle Fluxes (ISE SO RAN, Tomsk, 1994), Vol. 2, pp. 146–149.

J. A. Sue and H. H. Troue, “Union carbide coating service technology corporation. Zirconium nitride coating and a method for its deposition,” US Patent 4839245, 1989.

J. A. Sue and H. H. Troue, “Union carbide coating service technology corporation. Multilayer coating of a nitride-containing composite material and a method for its deposition,” US Patent 5071693, 1991.

S. A. Muboyadzhyan, D. A. Aleksandrov, and D. S. Gorlov, “Nanolayer hardening coatings for protecting steel and titanium GTE compressor blades,” Aviats. Mater. Tekhnol., No. 3, 3–8 (2011).

E. N. Azarovskii and S. A. Muboyadzhyan, “Surface modification of parts made of structural steels in the vacuum–arc plasma of titanium. Part 1,” Aviats. Mater. Tekhnol., No. 3, 20–25 (2013).

S. A. Muboyadzhyan, D. A. Aleksandrov, D. S. Gorlov, L. P. Egorova, and E. E. Bulavintseva, “Protective and hardening ion–plasma coatings for blades and other important parts of a GTE compressor,” Aviats. Mater. Tekhnol., No. S, 71–81 (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © E.N. Kablov, S.A. Muboyadzhyan, 2016, published in Elektrometallurgiya, 2016, No. 10, pp. 23–38.

Rights and permissions

About this article

Cite this article

Kablov, E.N., Muboyadzhyan, S.A. Erosion-resistant coatings for gas turbine engine compressor blades. Russ. Metall. 2017, 494–504 (2017). https://doi.org/10.1134/S0036029517060118

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029517060118