Abstract

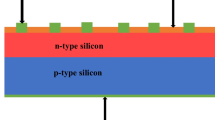

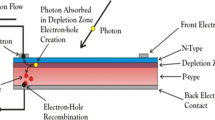

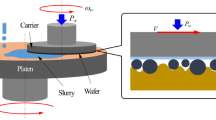

Porous silicon (PS) with high porosity is used in energy storage, solar photovoltaics, and sensing applications. The anodization method is the most widely used fabrication method since it is easy and economical. However, the method has various interdependent controlling parameters to fabricate PS, such as wafer resistivity, current density, hydrofluoric acid concentration, and anodization time. The parameters need to be optimized for a particular application to achieve the optimum porosity with fewer accouterments and time. The optimization can be carried out using the Taguchi design of experiment, which is based on the fractional factorial orthogonal array (OA). Mean output parameter graph, Signal to noise ratio, and interaction plot help to decide the interdependency and the optimized parameter for the desired output. The optimization achieved is validated by the factorial design of experiments.

Similar content being viewed by others

REFERENCES

K. A. Salman, K. Omar, and Z. Hassan, Superlatt. Microstruct. 50, 647 (2011).

A. Vu, Y. Qian, and A. Stein, Adv. Energy Mater. 2, 1056 (2012).

J. H. Park, L. Gu, G. von Maltzahn, et al., Nat. Mater. 2009 (8), 331 (2009).

Y. Liu, T. Lai, H. Li, et al., Small 8, 1392 (2012).

P. Biswas, A. K. Karn, P. Balasubramanian, and P. G. Kale, Biosens. Bioelectron. 94, 589 (2017).

C. W. Jang, D. H. Shin, and S.-H. Choi, J. Alloys Compd. 877, 160311 (2021).

R. Fopase, S. Paramasivam, P. Kale, and B. Paramasivan, J. Environ. Chem. Eng. 8, 104266 (2020).

N. Zilony-Hanin, M. Rosenberg, M. Richman, et al., Small 15, e1904203 (2019).

R. Vercauteren, G. Scheen, J.-P. Raskin, and L. A. Francis, Sens. Actuat., A 318, 112486 (2021).

P. G. Kale and C. S. Solanki, in Proceedings of the IEEE Photovoltaic Specialists Conference (IEEE, 2010), p. 3692.

Y. Lai, J. R. Thompson, and M. Dasog, Chem. - Eur. J. 24, 7913 (2018).

H. Jia, J. Zheng, J. Song, et al., Nano Energy 50, 589 (2018).

F. Wang, L. Sun, W. Zi, et al., Chem. - Eur. J. 25, 9071 (2019).

P. G. Kale, P. Sharma, and C. S. Solanki, J. Nano Res. 17, 13 (2012).

E. Barsotti, S. P. Tan, S. Saraji, et al., Fuel 184, 344 (2016).

M. K. Sahoo and P. Kale, Thin Solid Films 698, 137866 (2020).

T. Kıvak, Measurement 50, 19 (2014).

J. S. Oakland, Total Quality Management and Operational Excellence (Routledge, London, 2014).

Y.-D. Chiang, H.-Y. Lian, S.-Y. Leo, et al., J. Phys. Chem. C 115, 13158 (2011).

A.-H. Chiou, W.-F. Wu, D.-Y. Chen, and C.-Y. Hsu, J. Nanopart. Res. 15, (2013).

S. Song, H. B. Cho, and H. T. Kim, J. Ind. Eng. Chem. 61, 281 (2018).

H. Kim, J. Yun, M. Gao, et al., ACS Appl. Mater. Interfaces 12, 43614 (2020).

R. A. Ismail, A. M. Alwan, and A. S. Ahmed, Appl. Nanosci. (Switzerland) 7, 9 (2017).

ACKNOWLEDGMENTS

The research is part of a project funded by DST-IIT Bombay Energy Storage Platform on Hydrogen (DST/TMD/MECSP/2K17/14 (G), 14-Feb-2019). The authors thankfully acknowledge the financial support extended by DST, Govt. of India.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Maurya, S., Muduli, S.P., Nayak, S. et al. Optimization of Controlling Parameters of Porous Silicon Synthesis Using Taguchi Design of Experiment. Russ. J. Phys. Chem. 97, 749–755 (2023). https://doi.org/10.1134/S0036024423040295

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036024423040295