Abstract

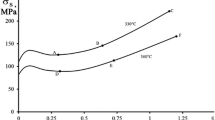

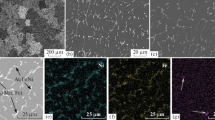

The microstructure and acting superplastic deformation mechanisms in the high-strength Al–7.0% Zn–2.7% Mg–1.0% Ni–0.9% Fe alloy low-doped with Sc and Zr upon deformation at a temperature of 480°С and a strain rate of 1 × 10–2 s–1 at a stable flow stage in a true strain range of 1.1 to 1.6 have been investigated. To evaluate the contributions of superplastic deformation mechanisms to the total elongation, marker grids have been applied on the surface by ion etching, and microstructural changes of the surface have been analyzed. Grain boundary sliding and intragranular deformation play dominant roles. The contribution of each mechanism is 35–40%. The remaining 25% belongs to the diffusional creep mechanism, which is determined from the size of striated zones formed at the transverse grain boundaries on the surface of a deformed sample.

Similar content being viewed by others

REFERENCES

J. Pilling and N. Ridley, Superplasticity in Crystalline Solids (The Institute of Metals, London, 1989).

T. G. Nieh, J. Wadsworth, and O. D. Sherby, Superplasticity in Metals and Ceramics (Cambridge, New York, 1997).

R. D. Wood and J. Bonet, “A review of the numerical analysis of superplastic forming,” J. Mater. Process. Technol. 60, 45–53 (1996).

K. H. J. Buschow, R. W. Cahn, M. C. Flemings, B. Ilschner, E. J. Kramer, S. Mahajan, and P. Veyssière, Encyclopedia of Materials: Science and Technology (Second Edition), Chapter: W. Koehler, B. Plege, and K. F. Sahm, Metal Forming: Specialized Procedures for the Aircraft Industry (Elsevier, Oxford, 2001) 10388 (5427–5433).

M. A. Rust and R. I. Todd, “Surface studies of Region II superplasticity of AA5083 in shear: Confirmation of diffusion creep, grain neighbor switching and absence of dislocation activity,” Acta Mater. 59, 5159–5170 (2011).

D. V. Dudina, R. S. Mishra, and A. K. Mukherjee, “Superplasticity: Where the Deformation mechanism is also an industry,” in Reference Module in Materials Science and Materials Engineering, Ed. by S. Hashmi (Elsevier, Oxford, 2016), pp. 1–8.

O. A. Kaibyshev, Superplasticity of Industrial Alloys (Metallurgiya, Moscow, 1984) [in Russian].

O. A. Kaibyshev, Plasticity and Superplasticity of Metals (Metallurgiya, Moscow, 1975) [in Russian].

I. I. Novikov and V. K. Portnoi, “Features of superplastic deformation of some aluminum alloys,” Izv. Vyssh. Uchebn. Zaved., Tsvetn. Metall., No. 4, 4–11 (2001).

P. S. Bate, F. J. Humphreys, N. Ridley, and B. Zhang, “Microstructure and texture evolution in the tension of superplastic Al–6Cu–0.4Zr,” Acta Mater. 53, 3059–3069 (2005).

F. Musin, R. Kaibyshev, Y. Motohashi, and G. Itoh, “High strain rate superplasticity in a commercial Al–Mg–Sc alloy,” Scr. Mater. 50, 511–516 (2004).

K. Sotoudeh and P. S. Bate, “Diffusion creep and superplasticity in aluminium alloys,” Acta Mater. 58, 1909–1920 (2010).

M. F. Ashby and R. A. Verrall, “Diffusion accommodated flow and superplasticity,” Acta Metall. 21, 149–163 (1973).

A. K. Mukherjee, “The rate controlling mechanism in superplasticity,” Mater. Sci. Eng. 8, 83–89 (1971).

A. V. Mikhaylovskaya, O. A. Yakovtseva, I. S. Golovin, A. V. Pozdniakov, and V. K. Portnoy, “Superplastic deformation mechanisms in fine-grained Al–Mg based alloys,” Mater. Sci. Eng., A 627, 31–41 (2015).

O. A. Yakovtseva, A. V. Mikhaylovskaya, V. S. Levchenko, A. V. Irzhak, and V. K. Portnoi, “Study of the acting mechanisms of superplastic deformation in Al–Mg–Mn-based alloys,” Phys. Met. Metallogr. 116, 908–916 (2015).

A. V. Mikhaylovskaya, O. A. Yakovtseva, M. N. Sitkina, A. D. Kotov, A. V. Irzhak, S. V. Krymskiy, and V. K. Portnoy, “Comparison between superplastic deformation mechanisms at primary and steady stages of the fine grain AA7475 aluminium alloy,” Mater. Sci. Eng., A 718, 277–286 (2018).

G. T. Langdon, “Grain boundary sliding revisited: Developments in sliding over four decades,” J. Mater. Sci. 41, 597–609 (2006).

C. H. Hamilton, C. C. Bampton, and N. E. Paton, Superplasticity in high strength aluminium alloys, Proceedings of AIME Met. Soc. Conference on Superplastic Forming of Structural Alloys (San Diego, 1982).

T. Sahraoui, M. Hadji, N. Bacha, and R. Badji, “Superplastic deformation behavior of 7075 aluminum alloy,” J. Mater. Eng. Perform. 12, 398–401 (2003).

J. Liu and D. J. Chakrabarti, “Grain structure and microstructure evolution during superplastic forming of a high strength Al–Zn–Mg–Cu alloy,” Acta Mater. 44, 4641–4661 (1996).

H. E. Adabbo, G. Gonzalez-Doncel, O. A. Ruano, J. M. Belzunce, and O. D. Sherby, “Strain hardening during superplastic deformation of Al-7475 alloy,” Mater. Res. Soc. 3, 587–594 (1989).

Z. P. Chen and P. F. Thomson, “A study of post-form static and fatigue properties of superplastic 7475-SPF and 5083-SPF aluminum alloys,” J. Mater. Process. Technol. 148, 204–219 (2004).

C. Chen and M. Tan, “Cavity growth and filament formation of superplastically deformed Al 7475 alloy,” Mater. Sci. Eng., A 298, 235–244 (2001).

A. V. Mikhaylovskaya, A. D. Kotov, A. V. Pozdniakov, and V. K. Portnoy, “A high-strength aluminum-based alloy with advanced superplasticity,” J. Alloys Compd. 599, 139–144 (2014).

A. V. Mikhaylovskaya, O. A. Yakovtseva, V. V. Cheverikin, A. D. Kotov, and V. K. Portnoy, “Superplastic behaviour of Al–Mg–Zn–Zr–Sc-based alloys at high strain rates,” Mater. Sci. Eng., A 659, 225–233 (2016).

A. D. Kotov, A. V. Mikhaylovskaya, and V. K. Portnoy, “Effect of the solid-solution composition on the superplasticity characteristics of Al–Zn–Mg–Cu–Ni–Zr alloys,” Phys. Met. Metallogr. 115, 730–735 (2014).

A. D. Kotov, A. V. Mikhaylovskaya, A. A. Borisov, O. A. Yakovtseva, and V. K. Portnoy, “High-strain-rate superplasticity of the Al–Zn–Mg–Cu alloys with Fe and Ni,” Phys. Met. Metallogr. 118, 913–921 (2017).

V. V. Cheverikin, N. A. Belov, D. G. Eskin, and A. N. Turchin, “Effect of Al3Ni and Mg2Si eutectic phases on casting properties and hardening of an Al–7% Zn–3% Mg alloy,” Mater. Sci. Forum 519–521, 413–418 (2006).

V. K. Portnoy and I. I. Novikov, “Evaluation of grain boundary sliding contribution to the total strain during superplastic deformation,” Scr. Mater. 40, 39–43 (1998).

P. K. Rout, M. M. Ghosh, and K. S. Ghosh, “Microstructural, mechanical and electro-chemical behavior of a 7017Al–Zn–Mg alloy of different tempers,” Mater. Charact. 104, 49–60 (2015).

Yu. A. Filatov, V. I. Yelagin, and V. V. Zakharov, “New Al–Mg–Sc alloys,” Mater. Sci. Eng., A 280, 97–101 (2000).

V. S. Zolotorevskiy, R. I. Dobrojinskaja, V. V. Cheverikin, E. A. Khamnagdaeva, A. V. Pozdniakov, V. S. Levchenko, and E. S. Besogonova, “Evolution of structure and mechanical properties of Al–4.7Mg–0.32Mn–0.21Sc–0.09Zr alloy sheets after accumulated deformation during rolling,” Phys. Met. Metallogr. 117, 1163–1169 (2016).

F. J. Humphreys, “Recrystallization mechanisms in two-phase alloys,” Met. Sci. 13, 136–145 (1979).

F. J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, 2nd ed. (Elsevier, Oxford, 2004).

A. V. Pozdniakov, S. V. Makhov, and V. I. Napalkov, “Effect of impurities of Fe and Si on the structure and strengthening upon annealing of the Al–0.2% Zr–0.1% Sc alloys with and without Y additive,” Phys. Met. Metallogr. 118, 479–484 (2017).

A. D. Kotov, A. V. Mikhaylovskaya, I. S. Golovin, and V. K. Portnoy, “Fine-grained structure and superplasticity of Al–Cu–Mg–Fe–Ni alloys,” Mater. Sci. Forum 735, 55–60 (2013).

M. E. Van Dalen, T. Gyger, D. C. Dunand, and D. N. Seidman, “Effects of Yb and Zr microalloying additions on the microstructure and mechanical properties of dilute Al–Sc alloys,” Acta Mater. 59, 7615–7626 (2011).

I. I. Novikov and V. K. Portnoi, Superplasticity of Alloys with Ultrafine Grains (Metallurgiya, Moscow, 1981) [in Russian].

C. L. Chen and M. J. Tan, “Effect of grain boundary character distribution (GBCD) on the cavitation behaviour during superplastic deformation of Al 7475,” Mater. Sci. Eng., A 338, 243–252 (2002).

H. Masuda, H. Tobe, T. Hara, and E. Sato, “Three-dimensional characterization of superplastic grain boundary sliding inside Al–Zn–Mg–Cu alloy sheet,” Scr. Mater. 164, 82–85 (2019).

J. M. Ford, J. Wheeler, and A. B. Movchan, “Computer simulation of grain-boundary diffusion creep,” Acta Mater. 50, 3941–3955 (2002).

P. L. Blackwell and P. S. Bate, “Superplastic deformation without relative grain translation,” Mater. Sci. Forum 304–306, 189–194 (1999).

J. C. Tan and M. J. Tan, “Superplasticity and grain boundary sliding characteristics in two stage deformation of Mg–3Al–1Zn alloy sheet,” Mater. Sci. Eng., A 339, 124–132 (2003).

V. K. Portnoy, D. S. Rylov, V. S. Levchenko, and A. V. Mikhaylovskaya, “The influence of chromium on the structure and superplasticity of Al–Mg–Mn alloys,” J. Alloys Compd. 581, 313–317 (2013).

A. A. Kishchik, A. V. Mikhaylovskaya, V. S. Levchenko, and V. K. Portnoy, “Formation of microstructure and the superplasticity of Al–Mg-based alloys,” Phys. Met. Metallogr. 118, 96–103 (2017).

Funding

This work was supported by the Russian Scientific Foundation (project no. 17-79-20426).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by T. Gapontseva

Rights and permissions

About this article

Cite this article

Yakovtseva, O.A., Kotov, A.D., Sitkina, M.N. et al. Mechanisms of Superplastic High-Rate Deformation in the Al–Mg–Zn–Fe–Ni–Zr–Sc Alloy. Phys. Metals Metallogr. 120, 1014–1020 (2019). https://doi.org/10.1134/S0031918X19100156

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X19100156