Abstract

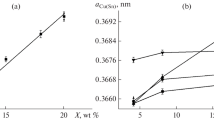

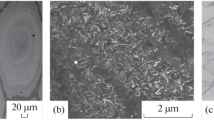

The evolution of the structure of tin bronze under the room-temperature high-pressure torsion with different degrees of deformation and the subsequent annealing has been investigated. The thermal stability of the structure formed, namely, its behavior upon annealing in the temperature range of 150–400°C has been studied. The possibility of alloying copper with tin has been analyzed with the purpose of obtaining a thermally stable nanostructure with high strength characteristics.

Similar content being viewed by others

References

R. Z. Valiev, “Nanostructuring of metals by severe plastic deformation for advanced properties,” Nature Mater. 3, 511–516 (2004).

R. Z. Valiev, Y. Estrin, Z. Horita, T. G. Langdon, M. J. Zehetbauer, and Y. T. Zhu, “Producing bulk ultrafine-grained materials by severe plastic deformation,” JOM 58, 33–39 (2006).

S. Qu, X. H. An, H. J. Yang, C. X. Huang, G. Yang, Q. S. Zang, Z. G. Wang, S. D. Wu, and Z. F. Zhang, “Microstructural evolution and mechanical properties of Cu–Al alloys subjected to equal-channel angular pressing,” Acta Mater. 57, 1586–1601 (2009).

Y. Estrin and A. Vinogradov, “Extreme grain refinement by severe plastic deformation: A wealth of challenging science,” Acta Mater. 61, 782–817 (2013).

M. Kawasaki and T. G. Langdon, “Principles of superplasticity in ultrafine-grained materials,” J. Mater. Sci. 42, 1782–1796 (2007).

A. Hohenwarter, C. Kammerhofer, and R. Pippan, “The ductile to brittle transition of ultrafine-grained armco iron: an experimental study,” J. Mater. Sci. 45, 4805–4812 (2010).

S. O. Rogachev, A. B. Rozhnov, S. A. Nikulin, O. V. Rybal’chenko, M. V. Gorshenkov, V. G. Chzhen, and S. V. Dobatkin, “Effect of torsion conditions under high pressure on the structure and strengthening of the Zr–1% Nb alloy,” Phys. Met. Metallogr. 117, 371–377 (2016).

A. P. Zhilyaev and T. G. Langdon, “Using high-pressure torsion for metal processing: fundamentals and applications,” Prog. Mater. Sci. 53, 893–979 (2008).

R. Pippan, S. Scheriau, A. Hohenwarte, and M. Hafok, “Advantages and limitations of HPT: A review,” Mater. Sci. Forum 584–586, 16–21 (2008).

D. K. Orlova, T. I. Chashchukhina, L. M. Voronova, and M. V. Degtyarev, “Effect of temperature–strainrate conditions of deformation on structure formation in commercially pure copper deformed in Bridgman anvils,” Phys. Met. Metallogr. 116, 951–958 (2015).

V. V. Sagaradze, V. A. Shabashov, K. A. Kozlov, N. V. Kataeva, V. A. Zavalishin, S. V. Afanas’ev, A. E. Zamatovskii, A. V. Litvinov, and K. A. Lyashkov, “Intensification of deformation-induced diffusion processes of the dissolution of intermetallic compounds in iron-based alloys at cryogenic temperatures,” Phys. Met. Metallogr., 116, 1002–1014 (2015).

A. Vorhauer and R. Pippan, “Microstructure and thermal stability of tungsten based materials processed by means of severe plastic deformation,” Mater. Sci. Forum 426–432, 2747–2752 (2003).

V. V. Popov, R. Z. Valiev, E. N. Popova, A. V. Sergeev, A. V. Stolbovsky, and V. U. Kazikhanov, “Structure and properties of grain boundaries in submicrocrystalline W obtained by severe plastic deformation,” Defect Diffus. Forum 283–286, 629–638 (2009).

V. V. Popov, G. P. Grabovetskaya, A. V. Sergeev, I. P. Mishin, A. N. Timofeev, and E. V. Kovalenko, “Structure and properties of grain boundaries in submicrocrystalline molybdenum prepared by high-pressure torsion,” Phys. Met. Metallogr. 109, 556–562 (2010).

E. N. Popova, V. V. Popov, E. P. Romanov, and V. P. Pilyugin, “Thermal stability of nanocrystalline Nb produced by severe plastic deformation,” Phys. Met. Metallogr. 101, 52–57 (2006).

E. N. Popova, V. V. Popov, E. P. Romanov, and V. P. Pilyugin, “Effect of the degree of deformation on the structure and thermal stability of nanocrystalline niobium produced by high-pressure torsion,” Phys. Met. Metallogr. 103, 407–413 (2007).

V. V. Popov, E. N. Popova, and A. V. Stolbovskiy, “Nanostructuring Nb by various techniques of severe plastic deformation,” Mater. Sci. Eng., A 539, 22–29 (2012).

T. M. Gapontseva, M. V. Degtyarev, V. P. Pilyugin, T. I. Chashchukhina, L. M. Voronova, and A. M. Patselov, “Effect of temperature of HPT deformation and the initial orientation on the structural evolution in single-crystal niobium,” Phys. Met. Metallogr. 117, 336–347 (2016).

H. W. Zhang and X. Huang, and N. Hansen, “Evolution of microstructural parameters and flow stresses toward limits in nickel deformed to ultra-high strains,” Acta Mater. 56, 5451–5465 (2008).

H. W. Zhang, X. Huang, R. Pippan, and N. Hansen, “Thermal behavior of Ni (99.967% and 99.5% purity) deformed to an ultra-high strain by high pressure torsion,” Acta Mater. 58, 1698–1707 (2010).

Yu. G. Krasnoperova, L. M. Voronova, M. V. Degtyarev, T. I. Chashchukhina, and N. N. Resnina, “Recrystallization of nickel upon heating below the temperature of thermoactivated nucleation,” Phys. Met. Metallogr. 116, 79–86 (2015).

Yu. G. Krasnoperova, M. V. Degtyarev, L. M. Voronova, and T. I. Chashchukhina, “Effect of annealing temperature on the recrystallization of nickel with different ultradisperse structures,” Phys. Met. Metallogr. 117, 267–274 (2016).

V. V. Popov, E. N. Popova, A. V. Stolbovskii, V. P. Pilyugin, and N. K. Arkhipova, “Nanostructurization of Nb by High-Pressure Torsion in Liquid Nitrogen and the Thermal Stability of the Structure Obtained,” Phys. Met. Metallogr. 113, 295–301 (2012).

V. V. Popov, E. N. Popova, A. V. Stolbovskiy, and V. P. Pilyugin, “Thermal Stability of Nanocrystalline Structure in Niobium Processed by High Pressure Torsion at Cryogenic Temperatures,” Mater. Sci. Eng., A 528, 1491–1496 (2011).

G. B. Rathmayr and R. Pippan, “Influence of impurities and deformation temperature on the saturation microstructure and ductility of HPT-deformed nickel,” Acta Mater. 59, 7228–7240 (2011).

V. V. Popov, E. N. Popova, D. D. Kuznetsov, A. V. Stolbovskii, and V. P. Pilyugin, “Thermal stability of nickel structure obtained by high-pressure torsion in liquid nitrogen”, Phys. Met. Metallogr. 115, 682–691 (2015).

V. V. Popov, A. V. Stolbovsky, E. N. Popova, and V. P. Pilyugin, “Structure and thermal stability of Cu after severe plastic deformation,” Defect Diffus. Forum 297–301, 1312–1321 (2010).

A. V. Stolbovsky, V. V. Popov, E. N. Popova, and V. P. Pilyugin, “Structure, thermal stability, and state of grain boundaries of copper subjected to high-pressure torsion at cryogenic temperatures,” Bull. Russ. Acad. Sci.: Phys. 78, 908–916 (2014).

V. V. Popov, E. N. Popova, V. P. Pilyugin, D. D. Kuznetsov, and A. V. Stolbovsky, “Nanostructuring of pure metals by severe plastic deformation at cryogenic temperatures,” IOP Conf. Ser.: Mater. Sci. Eng. 63, 012096 (2014).

R. Pippan, S. Scheriau, A. Taylor, M. Hafok, A. Hohenwarter, and A. Bachmaier, “Saturation of fragmentation during severe plastic deformation,” Ann. Rev. Mater. Res. 40, 319–343 (2010).

K. Oh-ishi, Z. Horita, D. J. Smith, R. Z. Valiev, and M. Nemoto, T. G. Langdon, “Fabrication and thermal stability of a nanocrystalline Ni–Al–Cr alloy: Comparison with pure Cu and Ni,” J. Mater. Res. 14, 4200–4207 (1999).

P. V. Kuznetsov, T. V. Rakhmatulina, I. V. Belyaeva and A. V. Korznikov, “Energy of Internal Interfaces as a Characteristic of the Structural Evolution of Ultrafine-Grained Copper and Nickel after Annealing,” Phys. Met. Metallogr. 118, 241–248 (2017).

T. N. Kon’kova, S. Yu. Mironov, and A. V. Korznikov, “Anomalous Growth of Grain Size in Criogenicdeformed Copper,” Fiz. Mezomekh. 14, 29–37 (2011).

T. N. Kon’kova, S. Yu. Mironov, and A. V. Korznikov, “Room-temperature instability of the structure of copper deformed at a cryogenic temperature,” Russian Metallurgy (Metally) 2011, 689–698 (2011).

H. W. Zhang, K. Lu, R. Pippan, X. Huang, N. Hansen, “Enhancement of Strength and Stability of Nanostructured Ni by Small Amounts of Solutes,” Scr. Mater. 65, 481–484 (2011).

V. V. Rybin, N. Yu. Zolotorevskii, and E. A. Ushanova, “Fragmentation of Crystals upon Deformation Twinning and Dynamic Recrystallization”, Phys. Met. Metallogr., 116, 730–744 (2015).

A. V. Stolbovskii, V. V. Popov, and E. N. Popova, “Structure and Thermal Stability of Tin Bronze, Nanostructured by High-pressure Torsion,” Diagnostics, Resource and Mechanics of Materials and Structure, No. 5, 118–132 (2015).

A. P. Zhilyaev, S. Lee, G. V. Nurislamova, R. Z. Valiev, and T. G. Langton, “Microhardness and Microstructural Evolution in Pure Nickel During High Pressure Torsion,” Scr. Mater. 44, 2753–2758 (2001).

A. N. Tyumentsev, I. A. Ditenberg, Yu. P. Pinzhin, A. D. Korotaev, and R. Z. Valiev, “Microstructure and Mechanisms of Its Formation in Submicrocrystalline Copper Produced by Severe Plastic Deformation,” Phys. Met. Metallogr. 96, 378 (2003).

T. Hebesberger, H. P. Stuwe, A. Vorhauer, F. Wetscher, and R. Pippan, “Structure of Cu Deformed by High Pressure Torsion,” Acta Mater. 53, 393–402 (2005).

V. V. Popov, A. V. Sergeev, G. P. Grabovetskaya, and I. P. Mishin, “Structure, Thermal Stability and Properties of Grain Boundaries of Submicrocrystalline Mo Obtained by Severe Plastic Deformation,” Defect Diffus. Forum 326–328, 674–681 (2012).

R. Wadsack, R. Pippan, and B. Schedler, “Structural Refinement of Chromium by Severe Plastic Deformation,” Fusion Eng. Des. 66–68, 265–269 (2003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.V. Popov, E.N. Popova, A.V. Stolbovsky, R.M. Falahutdinov, 2018, published in Fizika Metallov i Metallovedenie, 2018, Vol. 119, No. 4, pp. 377–386.

Rights and permissions

About this article

Cite this article

Popov, V.V., Popova, E.N., Stolbovsky, A.V. et al. Evolution of the Structure of Cu–1% Sn Bronze under High Pressure Torsion and Subsequent Annealing. Phys. Metals Metallogr. 119, 358–367 (2018). https://doi.org/10.1134/S0031918X18040154

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X18040154