Abstract

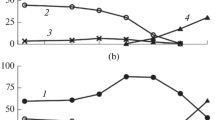

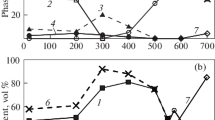

X-ray diffraction, Mössbauer spectroscopy, and magnetic measurements have been used to study the phase formation in (Fe1–xNix) (with х = 0–0.20) nanocomposites upon severe plastic deformation in a planetary ball mill and subsequent annealings. It has been shown that the mechanical synthesis results in the formation of mainly a nickel-alloyed nanocrystalline (Fe, Ni)3C cementite with a distorted crystal lattice and an amorphous Fe–Ni–C phase. During heating above 300°С, the amorphous phase crystallizes with the formation of cementite, which is characterized by a higher Ni content compared to that in mechanically synthesized cementite. The mechanically synthesized samples exhibit low coercive force (equal to several tens ampere per centimeter). In the course of annealing at temperatures of up to 500–550°С, crystal lattice distortions are removed; this results in reliving the magnetic anisotropy constant and high-coercivity state of cementite. At the same time, Ni-rich cementite areas decompose with the formation of γ-(Fe, Ni, C) phase (austenite); as a result, the average nickel content in the cementite substantially decreases. Annealings at higher temperatures cause the complete decomposition of cementite and lead to an abrupt decrease in the coercive force (Н с) of samples. Alloying with nickel leads to an increase in the Curie temperature of cementite and a decrease in its specific saturation magnetization, coercive force, and thermal stability.

Similar content being viewed by others

References

M. Umemoto, Z. G. Liu, K. Masuyama, and K. Tsuchiya, “Influence of alloy additions on production and properties of bulk cementite,” Scr. Mater. 45, 391–397 (2001).

E. P. Yelsukov, A. I. Ulyanov, A. V. Zagainov, and N. B. Arsentyeva, “Hysteresis magnetic properties of the Fe(100–x)Cx; x = 5–25 at % nanocomposites asmechanically alloyed and after annealing,” J. Magn. Magn. Mater. 258–259, 513–515 (2003).

A. I. Ul’yanov, E. P. Elsukov, A. A. Chulkina, A. V. Zagainov, N. B. Arsent’eva, G. N. Konygin, V. F. Novikov, and V. V. Isakov, “The role of cementite in the formation of magnetic hysteresis properties of plastically deformed high-carbon steels: I. Magnetic properties and structural state of cementite,” Russ. J. Nondestr. Testing 42 (7), 452–459 (2006).

A. A. Chulkina, A. I. Ul’yanov, N. B. Arsent’eva, A. V. Zagainov, E. S. Gorkunov, S. M. Zadvorkin, and V. M. Somova, “The role of cementite in the formation of magnetic hysteresis properties of plastically deformed high-carbon steels: II. Magnetic properties of patented wire made of steel 70,” Russ. J. Nondestr. Testing 42 (7), 460–467 (2006).

A. A. Chulkina and A. I., Ul’yanov, “Effect of the magnetic properties of cementite on the coercive force of high-carbon steels after quenching and tempering,” Phys. Met. Metallogr. 108 (6), 548–555 (2009).

A. I. Ul’yanov, A. A. Chulkina, V. A. Volkov, E. P. Elsukov, A. V. Zagainov, A. V. Protasov, and I. A. Zykina, “Structural state and magnetic properties of cementite alloyed with manganese,” Phys. Met. Metallogr. 113 (12), 1134–1145 (2012).

A. A. Chulkina, A. I. Ulyanov, A. L. Ulyanov, I. A. Baranova, A. V. Zagainov, and E. P. Yelsukov, “Phase composition, structural state, amd magnetic properties of nanocomposites of composition (Fe,Cr)75C25: Mechanosynthesis and isochronous annealings,” Phys. Met. Metallogr. 116 (1), 19–28 (2015).

E. Houdremont, Handbuch der Sonderstahlkunde (Springer-Verlag, Berlin, 1956; Metallurgiya, Moscow, 1966).

T. Shigematsu, “Magnetic properties of cementite (Fe(1–x) Me x)3C, (Me: Cr or Ni),” J. Phys. Soc. Jap. 37 (4), 940–946 (1974).

M. A. Smirnov, V. M Schastlivtsev, and L. G. Zhuravlev, Foundations of Heat Treatment of Steel (Inst. Fiz. Met., Ural. Otd. Ross. Akad. Nauk, Ekaterinburg, 1999) [in Russian].

A. Z. Men’shikov and E. E. Yurchikov, “Mössbauer effect in fcc Fe–Ni alloys,” Zh. Eksp. Teor. Fiz. 63, 190–198 (1971).

V. V. Sagaradze, V. A. Shabashov, and E. E. Yurchikov, “Mössbauer studies of homogenization of Fe–Ni alloy at a α → γ transformation,” Fiz. Met. Metalloved. 47, 663–665 (1979).

A. K. Arzhnikov, L. V. Dobysheva, and C. Demmangeat, “Structural peculiarities of cementite and their influence on magnetic characteristics,” J. Phys: Condens. Mater. 19, 196–214 (2007).

A. A. Chulkina, A. I. Ul’yanov, and A. V. Zagainov, “On the causes of the formation of a maximum in the dependencies of the coercive force of simple carbon steels on the tempering temperature,” Russ. J. Nondestr. Testing 46, 829–835 (2010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.I. Ul’yanov, A.A. Chulkina, V.A. Volkov, A.L. Ul’yanov, A.V. Zagainov, 2017, published in Fizika Metallov i Metallovedenie, 2017, Vol. 118, No. 7, pp. 725–734.

Rights and permissions

About this article

Cite this article

Ul’yanov, A.I., Chulkina, A.A., Volkov, V.A. et al. Structure and magnetic properties of mechanically synthesized (Fe1–x Ni x )75C25 nanocomposites. Phys. Metals Metallogr. 118, 691–699 (2017). https://doi.org/10.1134/S0031918X17050143

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X17050143