Abstract

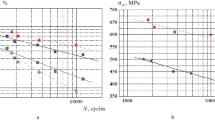

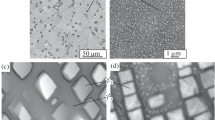

The processes of the fracture of 40Kh and U8 steels under cyclic dynamic compression are studied. It has been found that the main cause for the fracture of the cyclically compressed specimens is the propagation of cracks due to the effect of residual tensile stresses, which arise near the tips of the cracks at the stage of the unloading of the specimens. The growth rate of a crack has the maximum value at the initial stage of its propagation in the vicinity of the stress concentrator. As the crack propagates deep into the specimen, its growth rate decreases and depends only slightly on the real cross section of the specimen. The model of the process of the fatigue fracture of the steels under dynamic loading by a cyclically varied compressive force is proposed. It has been found that the high fatigue endurance is provided by tempering at 200°C for the 40Kh steel and at 300°C for the U8 steel.

Similar content being viewed by others

References

V. B. Sokolinskii, Machines for Impact Destruction (Foundations of Complex Design) (Mashinostroenie, Moscow, 1982) [in Russian].

U. Krupp, Fatigue Crack Propagation in Metals and Alloys. Microstructural Aspects and Modeling Concepts (Wiley-VCH, 2007).

V. M. Pestrikov and E. M. Morozov, Mechanics of Destruction of Solids (Professiya, St. Petersburg, 2002) [in Russian].

R. R. W. Hertzberg, Deformation and Fracture Mechanics of Engineering Materials (Wiley, New York, 1996, Fourth Edition; Metallurgiya, Moscow, 1989).

R. P. Habbard, “Crack Growth under Cyclic Compression,” J. Basic Eng. Transactions. ASME 91, 625–631 (1969).

C. N. Reid, K. Williams, and R. Hermann, “Fatigue in compression,” Fat. Engng. Mater. Struct. 1, 267–270 (1979).

D. K. Holm, A. F. Blom, and S. Suresh, “Growth of cracks under far-field cyclic compressive loads: Numerical and experimental results,” Eng. Fract. Mech. 23, 1097–1106 (1986).

T. Christman and S. Suresh, “Crack initiation under far-field cyclic compression and the study of short fatigue crack,” Eng. Fract. Mech. 23, 953–964 (1986).

S. Suresh, “Crack initiation in cyclic compression and its applications,” Eng. Fract. Mech. 21, 453–463 (1985).

Zhonghua Li, Jiaozhong Zhang, Jinghua Luo, and Zhongxin Feng, “An experimental and numerical study of the factors governing crack growth under cyclic compression,” Eng. Fract. Mech. 36, 1029–1035 (1990).

A. K. Vasudevan and K. Sadananda, “Analysis of fatigue crack growth under compression—Compression loading,” Int. J. Fatigue 23, Suppl. 1, 365–374 (2001).

Jianda Yang, Honguin Li, and Zhonghua Li, “A Plasticity-corrected stress intensity factor for fatigue crack growth in ductile materials under cyclic compression,” Int. J. Fatigue 59, 208–214 (2014).

J. C. Newman and Y. Yamada, Jr., “Compression precracking methods to generate near-threshold fatiguecrack-growth-rate data,” Int. J. Fatigue 32, 879–885 (2010).

V. M. Tikhomirov, “Crack growth under alternating loading,” J. Appl. Mech. Tech. Phys. 49, 864–871 (2008).

Y. N. Lenets, “Compression fatigue crack growth behavior of metallic alloys: Effect of environment,” Eng. Fract. Mech. 57, 527–539 (1997).

A. P. Shabanov, “Mechanism of fatigue-crack growth under compressive external stresses,” J. Appl. Mech. Tech. Phys. 46, 861–866 (2005).

A. P. Shabanov, “On fatigue crack formation in samples placed in a field of external compressive stresses,” Vestn. Sibir. Gos. Univ. Putei Soobshch., No. 12, 42–46 (2005).

A. A. Repin, S. E. Alekseev, and A. I. Popelyukh, “Enhancing reliability of parts of percussion machines,” J. Mining Sci. 48, 669–674 (2012).

L. I. Tushinskii, A. A. Bataev, V. A. Bataev, and A. I. Popelyukh, “Machines for testing materials for impact fatigue,” Ind. Lab. 62, 317–318 (1996).

D. Broek, Elementary Engineering Fracture Mechanics (Noordhoff Int., Leyden, 1974; Kluwer Academic, 1982, 1987; Vysshaya Shkola, Moscow, 1980).

O. N. Romaniv, S. Ya. Yarema, G. N. Nikiforchin, N. A. Makhutov, and M. M. Stadnik, Fatigue and Cyclic Crack-Resistance of Structural Materials. Mechanics of Fracture and Strength of Materials (Naukova Dumka, Kiev, 1990), Vol. 4 [in Russian].

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.I. Popelyukh, P.A. Popelyukh, A.A. Bataev, A.A. Nikulina, A.I. Smirnov, 2016, published in Fizika Metallov i Metallovedenie, 2016, Vol. 117, No. 3, pp. 291–299.

Rights and permissions

About this article

Cite this article

Popelyukh, A.I., Popelyukh, P.A., Bataev, A.A. et al. Specific Features of the Nucleation and Growth of Fatigue Cracks in Steel under Cyclic Dynamic Compression. Phys. Metals Metallogr. 117, 279–287 (2016). https://doi.org/10.1134/S0031918X1603011X

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X1603011X