Abstract

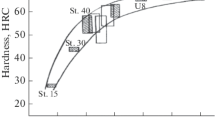

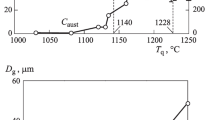

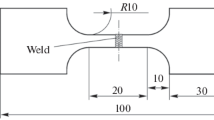

The martensite-austenite structures that are formed under the action of continuous laser irradiation in the 20KhN3A steel subjected to various regimes of cementation have been studied by metallography, electron microscopy, and X-ray diffraction. It has been established that a decrease in the amount of retained austenite in the laser-quenched structures from 40–90 to 5–35 vol % resulted from cold treatment at −196°C exerts only a small (within 10%) effect on the abrasive wear resistance of the cemented steel; the effect is negative upon microcutting and positive upon microscratching. An increase in the carbon concentration from 0.8 to 1.2 wt % in the martensite-austenite structures that are formed in the cemented steel under the action of laser irradiation and upon cold treatment leads to changes in the abrasive wear resistance by no more than 10–13%. The presence of 20–40 vol % metastable retained austenite retards the decrease in the abrasive wear resistance of the quenched steel upon subsequent low-temperature tempering. It has been shown that the laser quenching and additional cold treatment positively affect the resistance of rolling bearing units of drill bits to contact-fatigue fracture.

Similar content being viewed by others

References

A. V. Makarov, L. G. Korshunov, N. L. Chernenko, et al., “Structure and Wear Resistance of 20KhN3A Cemented Steel after Electron-Beam and Laser Treatment,” Fiz. Met. Metalloved. 68(1), 126–132 (1989).

M. N. Kryanina, S. D. Prokoshkin, A. M. Bernshtein, et al., “Laser Quenching of Cemented Structural Steels,” Izv. Vyssh. Uchebn. Zaved., Chern. Metall., No. 5, 115–119 (1989).

V. M. Goritskii, D. P. Khromov, K. B. Botvinnikova, et al., “Influence of Laser Heat Treatment on the Mechanical Properties and Fracture of Cemented Steel,” Metalloved. Term. Obrab. Met., No. 8, 37–39 (1991).

V. N. Vinogradov, G. M. Sorokin, A. N. Pashkov, and V. M. Rubarkh, Durability of Bore Bits (Nedra, Moscow, 1977) [in Russian].

V. I. Shapochkin, I. D. Zaitseva, O. S. Burenkova, and F. M. Chebotarev, “Contact Fatigue Resistance of Heavy-Loaded Toothed Wheels Made of 20KhN3A Steel Hardened by Chemical and Heat Treatment,” Metalloved. Term. Obrab. Met., No. 5, 12–17 (1987).

A. V. Makarov, L. G. Korshunov, and A. L. Osintseva, “Influence of Tempering and Friction Heating on the Wear Resistance of Laser-Quenched U8 Steel,” Trenie Iznos 12(5), 870–878 (1991).

A. V. Makarov and L. G. Korshunov, “Increasing the Hardness and Wear Resistance of Laser-Quenched Steel Surfaces with the Help of Friction Treatment,” Trenie Iznos 24(3), 301–306 (2003).

B. L. Mordike and H. W. Bergmann, “Laser Melting and Surface Alloying,” in Symp. on Rapidly Solidified Metastable Materials, Boston, Mass., 14–17 Nov., 1983, New York, 1984, pp. 45–64.

A. G. Grigor’yants and A. N. Safonov, Foundations of Laser Thermal Hardening of Alloys (Vysshaya Shkola, Moscow, 1988) [in Russian].

V. S. Velikikh, V. P. Goncharenko, V. S. Kartavtsev, and A. V. Romanenko, “Influence of Laser Treatment on the Wear Resistance and Thermal Resistance of Tool Steels,” Tekhnol. Organiz. Proizv., No. 4, 52–53 (1978).

V. P. Polukhin, M. L. Bernshtein, A. N. Veremeevich, et al., “On the Effect of Continuous Laser Irradiation on the Structure and Properties of 9Kh Steel,” Poverkhnost, No. 12, 119–123 (1987).

G. I. Brover, V. N. Varavka, and A. P. Rusin, “Peculiarities of the Structure and Properties of Tool Steels after Treatment by Highly Concentrated Heat Fluxes and Tempering,” Fiz. Khim. Obrab. Mater., No. 5, 107–113 (1988).

M. L. Bernshtein, S. D. Prokoshkin, L. M. Kaputkina, et al., “X-ray Study of Carbon Steel Structure after Laser Heat Treatment,” Fiz. Met. Metalloved. 67(5), 964–971 (1989).

B. Winderlich, D. Pollack, and D. Schneider, “Untersuchungen zum Anlaßverhalten des lasergehärteten Stahls 90SiCr5,” Neue Hütte 31(11), 418–423 (1986).

H. Jiandong, L. Zhang, W. Yufeng, and B. Xiangzhang, “Wear Resistance of Laser Processed 1.0%C Tool Steel,” Mater.Sci.Technol. 8(9), 796–798 (1992).

A. V. Makarov and L. G. Korshunov, “Effect of Laser Quenching on the Wear Resistance of Steels with Different Carbon Concentrations,” in Topical Problems of Laser Treatment of Steels and Alloys (Tekhnologiya, Ufa, 1994), Chapt. 2, pp. 30–57 [in Russian].

L. G. Korshunov, A. V. Makarov, V. M. Schastlivtsev, et al., “Structure and Wear Resistance of Laser-Treated U8 Steel,” Fiz. Met. Metalloved. 66(5), 948–957 (1988).

U. Bernini, U. B. Vetrella, A. Cutoto, et al., “Absorptance Enhancement for Laser Metal Processing: Application to Steel Samples,” Appl. Opt. 26(22), 4722–4730 (1987).

H. Masayesi, Method of Hardening of Surfaces of Small Products by Laser Heating, JP Appl. No. 59-116316.

D. P. Koistinen and R. E. Marburger, “A General Equation Prescribing the Extent of the Austenite-Martensite Transformation in Pure Iron-Carbon Alloys and Plain Carbon Steels,” Acta Metall. 7(1), 59–60 (1959).

A. A. Popov and N. P. Nagornov, “Structural Transformations and Mechanical Properties of Chromium-Nickel-Molibdenum Steels,” in Problems of Structural Steel (Mashgiz, Moscow, 1949), pp. 187–203 [in Russian].

M. Carbucicchio, G. Sambogna, and G. Palombarini, “Some Effects of Laser Treatments on Medium Carbon Steels,” Hyperfine Interact. 28(1–4), 1021–1024 (1986).

F. Lecroisey and A. Pineau, “Martensitic Transformations Induced by Plastic Deformation in the Fe-Ni-Cr-C System,” Metall. Trans. 3(2), 387–396 (1972).

P. C. Maxwell, A. Goldberg, and J. C. Shyne, “Stress-Assisted and Strain-Induced Martensites in Fe-Ni-C Alloys,” Metall. Trans. 5(6), 1305–1318 (1974).

M. L. Bernshtein, L. M. Kaputkina, A. M. Glushets, and E. D. Panov, “Structure of the Crystal Lattice of Martensite Obtained by the Deformation of Metastable Austenite Steel 70Kh5G4,” Fiz. Met. Metalloved. 46(1), 121–131 (1978).

A. V. Makarov, L. G. Korshunov, V. M. Schastlivtsev, et al., “Structure and Abrasive Wear Resistance of Quenched and Tempered Hypereutectoid Carbon Steels,” Fiz. Met. Metalloved. 98(4), 96–112 (2004) [Phys. Met. Metallogr. 98 (4), 428–443 (2004)].

V. S. Popov, N. N. Brykov, M. I. Andrushchenko, et al., “Resistance to Abrasive Wear of Alloys with a Metastable Austenite Structure Depending on Their Chemical Composition,” Trenie Iznos 12(1), 163–170 (1991).

L. G. Korshunov, “Structural Transformations during Friction and Wear Resistance of Austenitic Steel,” Fiz. Met. Metalloved. 74(2), 3–21 (1992) [Phys. Met. Metallogr. 74 (2), 150–161 (1992)].

L. G. Korshunov, A. V. Makarov, and N. L. Chernenko, “Structural Aspects of Wear Resistance of Martensitic Steels,” Fiz. Met. Metalloved. 78(4), 128–146 (1994) [Phys. Met. Metallogr. 78 (4), 442–453 (1994)].

M. M. Khrushchov and M. A. Babichev, Abrasive Wear (Nauka, Moscow, 1970) [in Russian].

K.-H. Zum Gahr, “The Influence of Thermal Treatment on Abrasive Wear Resistance of Tool Steels,” Z. Metallkd. 68(12), 783–792 (1977).

E. Hornbogen, “Microstructure and Wear,” in Metallurgical Aspects of Wear (Bad Pyrmont, Obernsel, 1979), pp. 23–49.

A. V. Makarov and L. G. Korshunov, “Hardness and Wear Resistance of Nanocrystalline Structures of Friction Surfaces of Steels with a Martensite Base,” Izv. Vyssh. Uchebn. Zaved., Fiz., No. 8, 65–80 (2004).

A. V. Makarov, L. Kh. Kogan, E. S. Gorkunov, and Yu. M. Kolobylin, “Eddy-Current Control of Wear Resistance of Cemented Chromium-Nickel 20KhN3A Steel,” Defektoskopiya, No. 2, 67–78 (2001) [Rus. J. Nondest. Test. 37 (2), 136–144 (2001)].

A. L. Geller and V. N. Yurko, “Retained Austenite and Wear Resistance of Alloy Cemented Steels,” Izv. Vyssh. Uchebn. Zaved., Chern. Metall., No. 6, 66–69 (1991).

E. I. Tesker, “Formation of Contact Destruction of Laser-Hardened Cylindrical Surfaces of Frictionless Bearings,” Vestn. Mashinostr., No. 8, 3–8 (1988).

Author information

Authors and Affiliations

Additional information

Original Russian Text © A.V. Makarov, L.G. Korshunov, I.Yu. Malygina, A.L. Osintseva, 2007, published in Fizika Metallov i Metallovedenie, 2007, Vol. 103, No. 5, pp. 536–548.

Rights and permissions

About this article

Cite this article

Makarov, A.V., Korshunov, L.G., Malygina, I.Y. et al. Effect of laser quenching and subsequent heat treatment on the structure and wear resistance of a cemented steel 20KhN3A. Phys. Metals Metallogr. 103, 507–518 (2007). https://doi.org/10.1134/S0031918X07050110

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X07050110