Abstract

The effects of Ag15+ (120 MeV) swift heavy ion (SHI) irradiation on the structural and morphological properties of epitaxial La0.25Pr0.375Ca0.375MnO3 (LPCMO) thin films were investigated by x-ray scattering and atomic force microscopy (AFM) techniques. LPCMO films of thickness ∼ 280 Å were irradiated with an Ag15+ ion beam at different fluences of 1 × 1011, 5 × 1011, and 1 × 1012 ions cm−2. XRD results suggested the development of the tensile stress along the out-of-plane direction of the LPCMO film upon ion irradiation, which increases on increasing the ion fluence. The morphology of the film was also modified with the irradiation and an increase in the fluence of the ion beam enhanced the in-plane height-height correlation length scale (grain size) with a loss of the fractal behaviours. The linear variation of microstrain with ion irradiation fluence in thin LPCMO film can be considered for a possible strain-driven application in modifying functional properties of such a phase separated complex oxide.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 4.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

Introduction

Manganite-based complex oxides are strongly correlated electronic systems which exhibit magnetoelectronic phase separation that gives rise to properties like colossal magnetoresistance (CMR), metal-to-insulator transition (MIT), colossal electroresistance (CER) and colossal piezoresistance (CPR) [1–5]. The competition and interplay among charge, spin, orbital, and lattice degrees of freedom lead to the coexistence of multiple phases and related electronic and magnetic properties in manganite oxides [1, 6]. Mixed valance bulk (La1-y Pry )1-x Cax MnO3 manganite, a prototypical electronic phase-separated system, has been studied extensively and it shows a phase separation of nanometer and micron length scale [5–11]. However thin films of (La1-y Pry )1-x Cax MnO3 have exhibited properties different from bulk behaviour because of the additional knob (strain) accessible in the case of thin films, suggesting that the strain field can tune the transport and magnetic properties as well as the phase coexistence [7, 12–20]. In the bulk phase, a nanometer and micron length scale phase separation has been observed for two manganites with slightly different compositions i.e. (La1-y Pry )1-x Cax MnO3 (y = 0.6) with x = 0.33 and x = 0.375 [7, 9]. Different phenomena, like magnetic anisotropy driven single to multi-domain transition [12], electronic phase separation (EPS) [13–18], correlation of electronic and magnetic phases [16, 17], coupling of bending strain and magnetism [13, 14, 19, 20], and electric field-driven phase separation [3, 21] have been reported for the thin film of (La1-y Pry )1-x Cax MnO3 with x = 0.33 and y = 0.6. However, the (La1-y Pry )1-x Cax MnO3 film with x = 0.375 and y = 0.6 has been studied rarely even though a larger phase separation (length ∼ micron) was suggested for this system in their bulk form [9].

Strain and related structural disorders can influence the competing interactions between different degrees of freedom and phase coexistence in the manganite films by modifying the structure and morphology. The effect of strain in manganite films is studied in both ways by applying strain (i) directly for substrate-induced strain [22–26], bending strain [4, 13, 14, 19, 20], and (ii) indirectly i.e. ion implantation [27–29] and swift heavy ion (SHI) irradiation [30–35]. The SHI irradiation using 100 MeV O7+ ions with different fluences of LaMnO3/Nd0.7Sr0.3MnO3/STO heterostructure showed a change in strain field across interfaces [35]. The influence of SHI irradiation on the magnetic proximity effect in oxide-based manganite/superconductor heterostructure has also been demonstrated as a modification in structure, magnetic, and superconducting properties upon irradiation [36]. Recently, Matthews et al [34] observed the formation and percolation of a network of disorder in the LaMnO3/SrTiO3 heterostructures on ion irradiation, which led to a change in structural and morphological properties at interfaces. Using x-ray resonant magnetic scattering (XRMS), Singh et al [16, 17] correlated the electronic and magnetic phases across MIT temperature of the (La1-y Pry )1-x Cax MnO3 thin film with x = 0.375 and y = 0.6 and found that these properties are highly dependent on the morphology of the interfaces.

There are several ways to control the structure and morphology of the surfaces and interfaces of thin film and a suitable characterization in this respect is required to study its influence on macroscopic properties. Thin films, grown by physical vapour deposition techniques like thermal evaporation [37], sputtering [38], and pulsed laser deposition (PLD) [12, 19, 39] have shown great structural and compositional stabilities. The PLD is an ideal and preferred technique for the deposition of compound oxide films because it maintains the stoichiometry of the target compound. The SHI irradiation [37], as well as low energy ion irradiation [38] of the thin films, have shown modification in microstructure (change in microstrain and crystallite size) and morphology without changing the crystalline structure (atomic length scale) even on varying the fluence of ion by an order of three [40]. Here, we report the evolution of structure and morphology upon ion irradiation of the (La1-y Pry )1-x Cax MnO3 film with x = 0.375 and y = 0.6 (i.e. La0.25Pr0.375Ca0.375MnO3 film) (LPCMO) grown on single crystal (110) NdGaO3 (NGO) substrate. Combining the x-ray scattering and atomic force microscope (AFM) measurements we have investigated the structural and morphological properties of the LPCMO film upon ion irradiation with different influences. These results suggest a strong modification in the microstrain and morphology of LPCMO film upon ion irradiation and parameters describing the depth-dependent structure and morphology are strongly correlated. The surface shows self-affine fractal behaviours which reduces upon irradiating the LPCMO film with a high ion fluence. We found a linear increase in the out-of-plane lattice constant (tensile strain) on increasing the fluence of SHI ion, suggesting that a controlled strain can be applied in oxide films using ion irradiation for studying the strain-field dependent properties.

Experimental details

Sample growth, swift heavy ion irradiation and structural characterization

The LPCMO thin film of thickness ∼300 Å was deposited from a high-density bulk target on a single crystal (110) NGO substrate using the PLD technique [39]. Extensive studies related to the structure and magnetic properties of manganite films have been reported earlier on similar thicknesses of the film [11, 16, 17]. The exact thickness of the film was estimated to ∼ 280 Å using x-ray reflectivity (XRR) measurements (discussed later). A KrF excimer laser (λ = 248 nm, pulse width = 20 ns) with an energy density of ∼4 J cm−2 was used to ablate the high-density LPCMO target. The PLD chamber was evacuated to a pressure of 10−6 mbar before the deposition to avoid any impurities. The oxide film was grown in an oxygen environment. During the deposition oxygen partial pressure of 0.2 mbar and a substrate temperature of 750 ◦C were maintained. Annealing of the thin film was carried out at the same substrate temperature after deposition for 30 min in a 1000 mbar oxygen environment after which the film was allowed to cool naturally in the same oxygen environment. The pristine LPCMO thin film (10 mm × 10 mm) was cut into four equal pieces (5 mm × 5 mm) and three pieces of the sample were irradiated at room temperature using 120 MeV Ag15+ ions at a fluence of 1 × 1011, 5 × 1011, and 1 × 1012 ions cm−2. Thus, for the present study, we have a pristine LPCMO film and three ion-irradiated LPCMO films with different fluences mentioned above. The ion-irradiation experiment was carried out at the Inter University Accelerator Centre (IUAC), New Delhi using the 15UD tandem accelerator under high vacuum conditions.

Depth-dependent structure analysis using ex situ XRR measurements (discussed later) suggested the growth of high-quality film with very small substrate-film roughness of ∼3 Å. The compositional analysis of the pristine film is carried out using energy-dispersive x-ray (EDX) analysis. Scanning electron microscopy (SEM) image of the pristine film was recorded using SERON Technologies Inc. (Model: AIS 2100) operating at 20 keV. The EDX measurements were carried out using Oxford Instruments (Model: INCA E350) coupled to the Vega MV2300t/40 scanning electron microscope. Structural characterization of the pristine and irradiated films was carried out using x-ray scattering with Cu Kα radiation from a rotating anode source, where x-ray diffraction (XRD) was used to investigate the atomic structure (strain) and XRR was used to investigate the depth-dependent structure.

Morphological analysis using AFM

The surface topographic measurements were carried out using NT-MDT's solver-P47H ambient-based multimode AFM in intermittent-contact mode. A silicon cantilever (NT-MDT model: NSG30) with a radius of curvature of cantilever tip <10 nm, force constant of ∼30 N m−1, and resonance frequency of oscillation ∼320 kHz was used for AFM measurements over a scan area of 10 μm × 10 μm and 5 μm × 5 μm with the resolution of 256 pixels × 256 pixels for each scan. The surface morphology recorded by AFM can be analyzed by considering either the height-height autocorrelation function,  where Z denotes the height at the interface/surface and r is the spatial distance between two points (x1,y1) and (x2, y2) on the surface; or a height difference correlation function [41]:

where Z denotes the height at the interface/surface and r is the spatial distance between two points (x1,y1) and (x2, y2) on the surface; or a height difference correlation function [41]: ![$g\left(r\right)\,=\left\langle {[Z\left(x2,y2\right)-Z(x1,y1)]}^{2}\right\rangle ,$](https://content.cld.iop.org/journals/2051-672X/12/1/015022/revision2/stmpad331dieqn2.gif) where symbol

where symbol  denotes the spatial average over the whole scan area. AFM data over a scan area of 5 μm × 5 μm was used to calculate the experimental data for g(r). The nucleation and growth of thin films by physical vapour deposition usually develop self-affine surfaces [18] and the average height difference correlation function for self-affine surfaces is described by the phenomenological function defined as [42–44]:

denotes the spatial average over the whole scan area. AFM data over a scan area of 5 μm × 5 μm was used to calculate the experimental data for g(r). The nucleation and growth of thin films by physical vapour deposition usually develop self-affine surfaces [18] and the average height difference correlation function for self-affine surfaces is described by the phenomenological function defined as [42–44]:

where σ, ξ, and h are the root mean square (RMS) surface roughness, the correlation length (i.e. a measure of the lateral length scale of roughness), and the Hurst parameter (or roughness exponent), respectively. The Hurst parameter describes the texture of roughness of the interface/surface and varies as 0 < h < 1. For a self-affine morphology, the h is related to the fractal dimension (D) by a relation: D = 3 − h.

In general, the fractal analysis of the roughness is carried out more precisely using a power spectral density (PSD) function, which is based on the fast Fourier transform (FFT) of autocorrelation function to determine surface morphology over different spatial frequencies. The PSD spectrum as a function of spatial frequency from AFM images can be calculated by the FFT algorithms given elsewhere [45, 46] and we have adopted a similar approach to generate PSD profiles from AFM data. However, to interpret and understand the PSD information quantitatively more appropriate analytical models are needed and there are several models used to explain the data in the different spatial frequency ranges [45, 46]. We have fitted the PSD data using a combination of three models which define PSD data in different frequency ranges [45, 46] and these three models are (i) inverse power law ( ), (ii) the k-correlation or ABC model (

), (ii) the k-correlation or ABC model ( ), and (iii) the Gaussian function (

), and (iii) the Gaussian function ( The resultant PSD model (

The resultant PSD model ( ) over the whole spatial frequency range is given below [45, 46]:

) over the whole spatial frequency range is given below [45, 46]:

where K, f, and υ are the spectral strength of fractal, spatial frequency, and fractal spectral indices, respectively. The A, B, and C in  are model parameters and depend on the specific surface structure, which can be correlated to the intrinsic roughness parameters like RMS roughness (

are model parameters and depend on the specific surface structure, which can be correlated to the intrinsic roughness parameters like RMS roughness ( ) and in-plane (lateral) correlation length (

) and in-plane (lateral) correlation length ( ) using [45, 46]:

) using [45, 46]:  and

and  In the case of

In the case of  model, the

model, the  and

and  correspond to the size and height of the superstructures on the surface and summation is used for considering more than one length scale for superstructures over the scan area.

correspond to the size and height of the superstructures on the surface and summation is used for considering more than one length scale for superstructures over the scan area.

Results and discussion

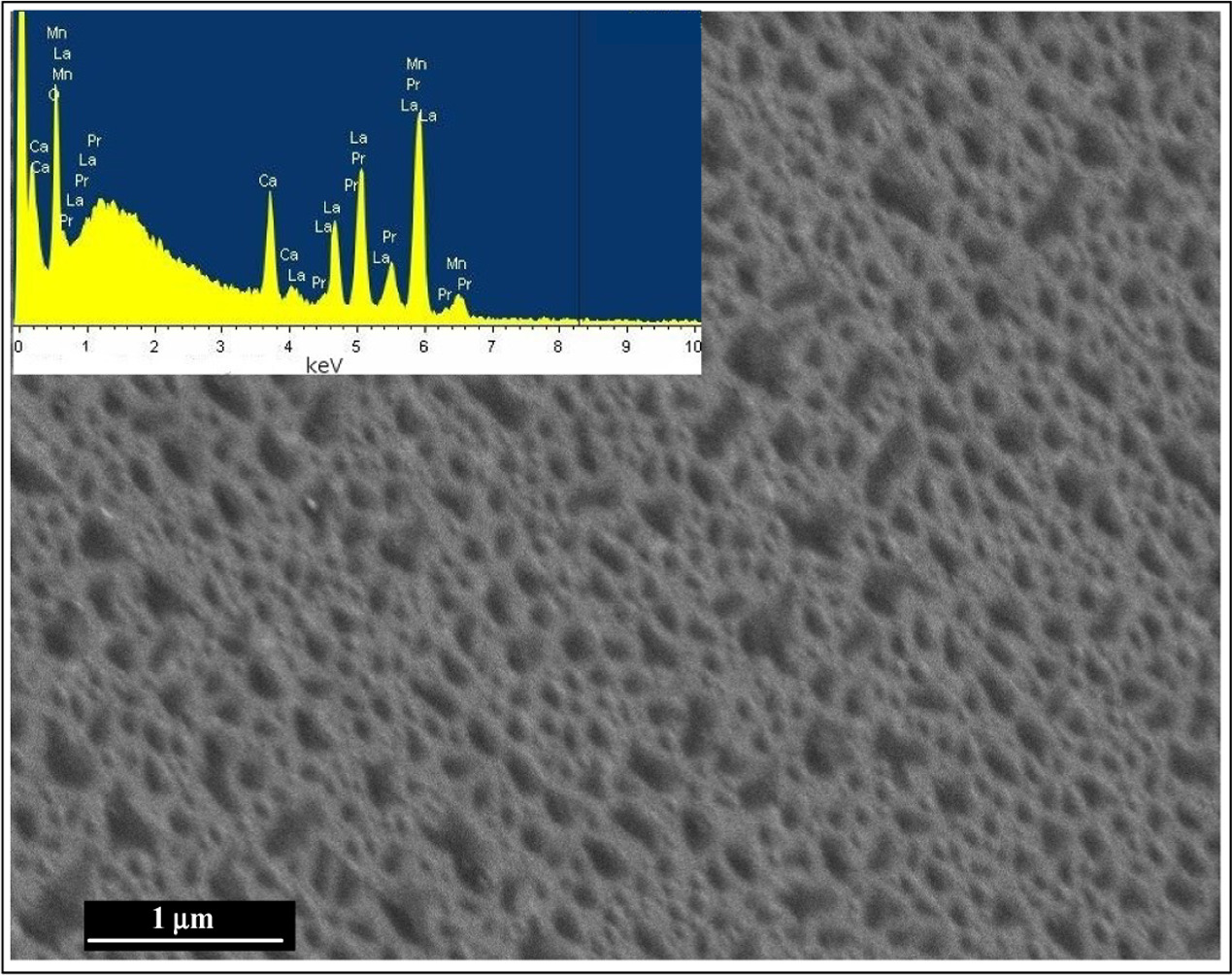

Pristine LPCMO film grown by PLD in the present study was investigated using SEM/EDX for surface morphology and compositional distribution. Figure 1 shows the recorded SEM image of pristine LPCMO film suggesting regular-shaped particles with a homogeneous distribution. The EDX spectrum of the pristine film is shown in the inset of figure 1. The characteristic x-ray peaks of different elements are indexed in the spectrum and the composition of the compound can be estimated from the comparison of the intensity of different elements. The similar energy for La and Pr suggested that the exact content determination of these elements cannot be estimated individually. However, using EDX data we found a ratio of (La+Pr)/Ca atoms to be ∼1.65, which is in good agreement with expected values of 1.66 for desired composition. This suggests that the sample has the desired composition of La0.25Pr0.375Ca0.375MnO3, which remains similar upon ion irradiation with different fluences. Using x-ray scattering (discussed later) we also observed modification in the microstrain of the film on ion irradiation but the crystalline structure remains integral even on varying the ion fluence from 1 × 1011 to 1 × 1012 ions cm−2.

Figure 1. The scanning electron microscope image of the pristine LPCMO film grown on NGO substrate. Inset shows the EDX spectrum.

Download figure:

Standard image High-resolution imageIt is well known that the defects induced by SHI irradiation provide additional stress in the material and for thin films, the overall strain (due to substrate and irradiation) gets modified [30–34, 40, 47, 48]. Thus, it is believed that SHI irradiation can generate strain, release strain, anneal or create defects depending upon the initial state (relaxed and strained) of the thin film [32]. Various kinds of defects (columnar and point) can be produced in the material when an energetic ion is incident on it, which consequently modifies the local strain. The formation of defects leads to modification of the morphology of the film. The ion fluence of SHI irradiation plays an important role in modifying the properties (structure, magnetic and morphological) of the film [27, 32]. Earlier results on manganite [27] and another magnetic film [32] suggested that low fluence of ions modifies the strain states, whereas high fluence (>1 × 1013) introduces more structural disorder resulting in phase changes. In this study, our focus is to investigate the changes in strain states and associated morphological variance in LPCMO film using low ion fluence (<1 × 1013 ). When high-energy ions pass through a medium they lose energy ( mainly via two processes [32], i.e., (i) nuclear energy loss,

mainly via two processes [32], i.e., (i) nuclear energy loss,  (elastic scattering) and (ii) electronic energy loss,

(elastic scattering) and (ii) electronic energy loss,  (inelastic scattering). The total energy loss of ions is defined as:

(inelastic scattering). The total energy loss of ions is defined as:  However,

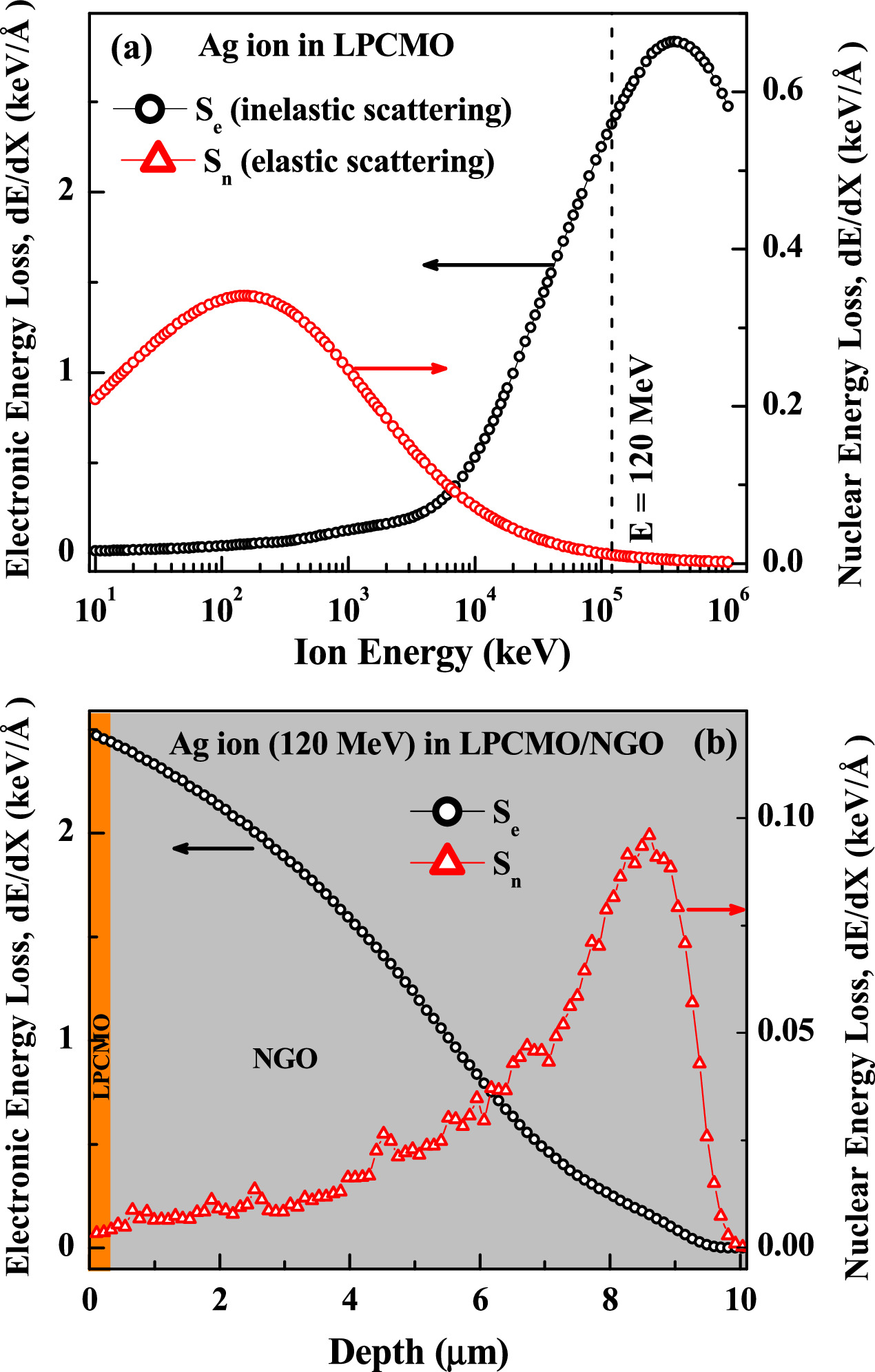

However,  energy loss is predominant in SHI irradiation. Using the Stopping and Range of Ions in Matter (SRIM-2013) code [49], we have simulated the energy loss for Ag ions in the LPCMO medium (figure 2(a)) as a function of the energy of the incident Ag ions. It is apparent from figure 2(a) that for 120 MeV Ag15+ ions the values of

energy loss is predominant in SHI irradiation. Using the Stopping and Range of Ions in Matter (SRIM-2013) code [49], we have simulated the energy loss for Ag ions in the LPCMO medium (figure 2(a)) as a function of the energy of the incident Ag ions. It is apparent from figure 2(a) that for 120 MeV Ag15+ ions the values of

and range in the LPCMO are 2.376 keV Å−1, 0.011 keV Å−1 and 8.8 μm, respectively. Figure 2(b) shows the depth profiling of energy loss (

and range in the LPCMO are 2.376 keV Å−1, 0.011 keV Å−1 and 8.8 μm, respectively. Figure 2(b) shows the depth profiling of energy loss ( and

and  ) in the LPCMO/NGO thin film. This estimation of energy loss and range of ions in the LPCMO material suggests that Ag ions lose energy mostly for electron excitation (

) in the LPCMO/NGO thin film. This estimation of energy loss and range of ions in the LPCMO material suggests that Ag ions lose energy mostly for electron excitation ( is more than two orders of magnitude as compared to

is more than two orders of magnitude as compared to  ) and it will pass through the film (thickness ∼ 280 Å ≪ range) without being implanted. It is noted that the energy (

) and it will pass through the film (thickness ∼ 280 Å ≪ range) without being implanted. It is noted that the energy ( = 2.376 keV Å−1) deposited in the LPCMO layer on Ag15+ ion irradiation is large enough to modify the properties of the film and using different fluences of the ions will result in different structural and morphological properties. Various models have been proposed to interpret the high energy SHI-induced modification in the materials e.g. thermal spike model [50], lattice instability model [51] and coulomb explosion model [52]. In the case of the thermal spike, an increase of the local temperature in the target material and formation of a latent track takes place because of strong electron–phonon coupling due to the interaction of high energy ion beam with the electronic system at the local site in the target material [50]. All three models are complementary to each other for producing radiation damage due to SHI irradiation in the material [53]. These mechanisms are responsible either for producing defects/distortion or annealing these if already present in the material. In the present case the thickness of the LPCMO thin film is very small as compared to the range of high-energy Ag ions, and thus we expect a huge electronic energy loss (

= 2.376 keV Å−1) deposited in the LPCMO layer on Ag15+ ion irradiation is large enough to modify the properties of the film and using different fluences of the ions will result in different structural and morphological properties. Various models have been proposed to interpret the high energy SHI-induced modification in the materials e.g. thermal spike model [50], lattice instability model [51] and coulomb explosion model [52]. In the case of the thermal spike, an increase of the local temperature in the target material and formation of a latent track takes place because of strong electron–phonon coupling due to the interaction of high energy ion beam with the electronic system at the local site in the target material [50]. All three models are complementary to each other for producing radiation damage due to SHI irradiation in the material [53]. These mechanisms are responsible either for producing defects/distortion or annealing these if already present in the material. In the present case the thickness of the LPCMO thin film is very small as compared to the range of high-energy Ag ions, and thus we expect a huge electronic energy loss ( = 2.376 keV Å−1) producing ionized zones and creating distortions in the materials (with

= 2.376 keV Å−1) producing ionized zones and creating distortions in the materials (with  ) in accordance with the coulomb explosion model [32]. The distortion in the material may further alter the morphology of the film significantly.

) in accordance with the coulomb explosion model [32]. The distortion in the material may further alter the morphology of the film significantly.

Figure 2. (a) Energy loss (electronic and nuclear contribution) of Ag15+ ions in LPCMO as a function of the energy of incident ions. (b) Depth-dependent nuclear and electronic energy loss profile of 120 MeV Ag15+ ions in an LPCMO (280 Å)/NGO film.

Download figure:

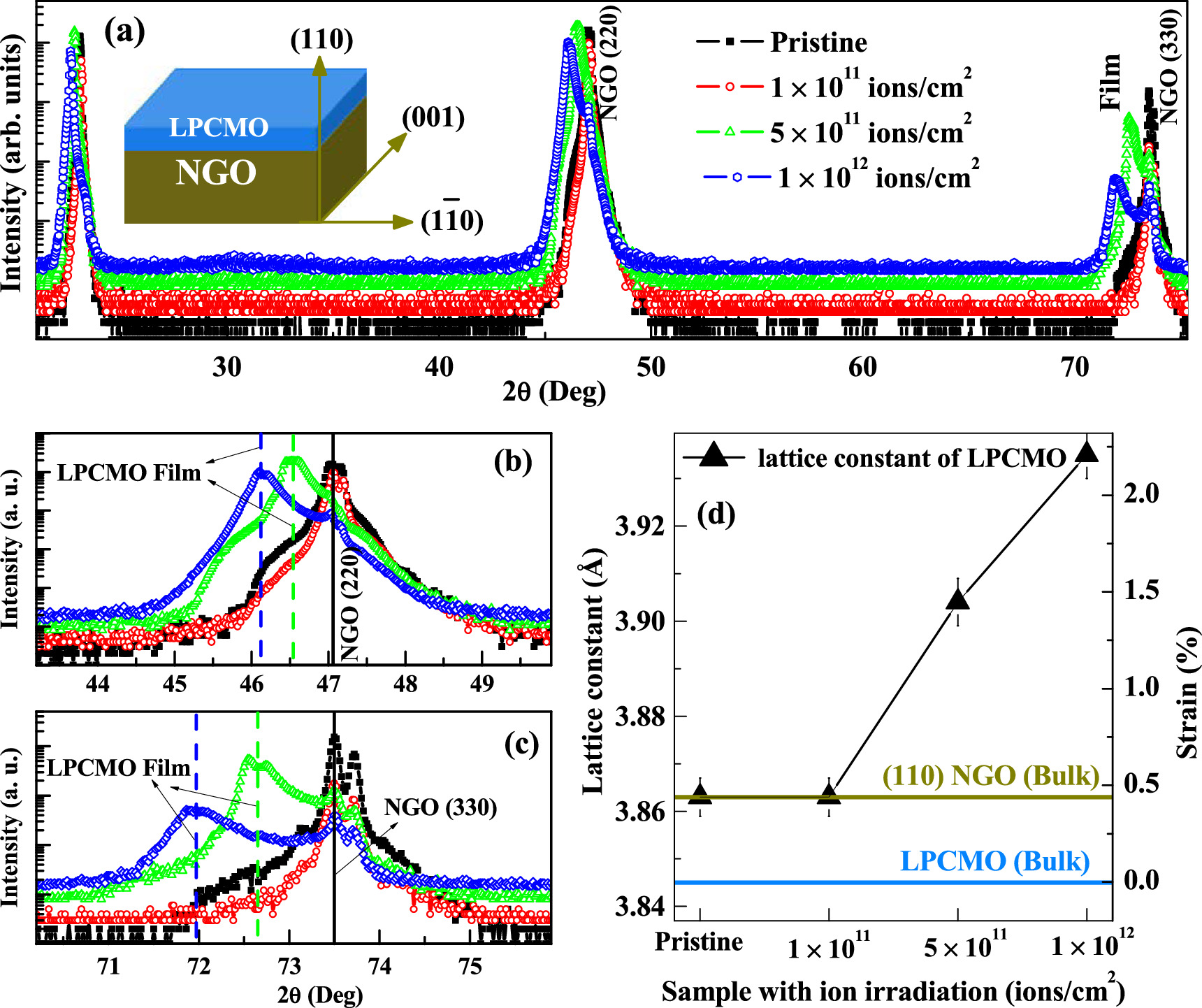

Standard image High-resolution imageThe SHI irradiation-induced structural modifications were studied using XRD measurements. Figure 3(a) shows the XRD data for pristine LPCMO film as well as irradiated films with different fluences. The magnified version of Bragg peaks around (220) and (330) reflection of NGO is shown in figures 3(b) and (c), respectively, for pristine and irradiated samples. Inset of figure 3(a) shows the schematic of the structure of the LPCMO film grown on orthorhombic NGO substrates along with three mutually perpendicular directions of NGO substrate, with (001) and (1  0) as in-plane directions, and (110) as an out-of-plane (c) direction. The orthorhombic lattice of the NGO crystal can be represented as a distorted perovskite cube with its base inscribed in a slightly distorted square [54], i.e., the in-plane lattice parameters of NGO substrate are

0) as in-plane directions, and (110) as an out-of-plane (c) direction. The orthorhombic lattice of the NGO crystal can be represented as a distorted perovskite cube with its base inscribed in a slightly distorted square [54], i.e., the in-plane lattice parameters of NGO substrate are  = 3.854 Å and

= 3.854 Å and  = 3.863 Å. Whereas the bulk LPCMO is a pseudo-cubic perovskite at room temperature with a lattice parameter (

= 3.863 Å. Whereas the bulk LPCMO is a pseudo-cubic perovskite at room temperature with a lattice parameter ( of 3.845 Å [55]. Therefore, different in-plane lattice parameters of the NGO substrate contribute to the tensile lattice mismatch strains in the two in-plane directions of LPCMO thin film, which can be calculated using

of 3.845 Å [55]. Therefore, different in-plane lattice parameters of the NGO substrate contribute to the tensile lattice mismatch strains in the two in-plane directions of LPCMO thin film, which can be calculated using  and are

and are  = 0.26% and

= 0.26% and  = 0.49%. This suggests that the c lattice parameter for LPCMO film on (110) NGO substrate should compress due to this lattice mismatch. However, XRD data from pristine film suggested a small increase in the c lattice parameter of LPCMO film and matching with that of NGO. Earlier studies [3, 4, 12] also suggested similar results where a perfect match for the c lattice parameter for LPCMO film with NGO was observed, however, the lattice mismatch strain highly depends on the thickness of the film. XRD data from ion irradiated films show a systematic shift in the Bragg peak positions to a lower angle except at the first ion irradiation with a fluence of 1 × 1011 ions cm−2. There is a significant separation between the Bragg peaks of NGO substrate and LPCMO film near the (330) NGO reflection (corresponding 2θ ∼ 73.5°) and thus it is used for estimation of the lattice parameter for the film upon ion irradiation. The estimated lattice parameter, c, of the film on ion irradiation, are plotted in figure 3(d) along with the bulk value of lattice constant for (110) NGO and LPCMO (horizontal lines in figure 3 (d)). Figure 3(d) also depicts the corresponding out-of-plane strain values as a function of ion fluence for LPCMO film with respect to its bulk lattice parameter. It is evident from figure 3(d) that the c lattice parameter increases on irradiation for the higher fluences of 5 × 1011 and 1 × 1012 ions cm−2 with the c lattice parameter of 3.936 Å for a fluence of 1 × 1012 ions cm−2. This change in lattice parameter suggests the advancement of a strong tensile strain along the normal of the film upon ion irradiation with a fluence >1011 ions cm−2. On comparing the shift in Bragg peaks of LPCMO films upon irradiation and pristine conditions, we have estimated an increase in a tensile strain of ∼ 1.06% and 1.86% for LPCMO films irradiated at ion influences of 5 × 1011 and 1 × 1012 ions cm−2, respectively.

= 0.49%. This suggests that the c lattice parameter for LPCMO film on (110) NGO substrate should compress due to this lattice mismatch. However, XRD data from pristine film suggested a small increase in the c lattice parameter of LPCMO film and matching with that of NGO. Earlier studies [3, 4, 12] also suggested similar results where a perfect match for the c lattice parameter for LPCMO film with NGO was observed, however, the lattice mismatch strain highly depends on the thickness of the film. XRD data from ion irradiated films show a systematic shift in the Bragg peak positions to a lower angle except at the first ion irradiation with a fluence of 1 × 1011 ions cm−2. There is a significant separation between the Bragg peaks of NGO substrate and LPCMO film near the (330) NGO reflection (corresponding 2θ ∼ 73.5°) and thus it is used for estimation of the lattice parameter for the film upon ion irradiation. The estimated lattice parameter, c, of the film on ion irradiation, are plotted in figure 3(d) along with the bulk value of lattice constant for (110) NGO and LPCMO (horizontal lines in figure 3 (d)). Figure 3(d) also depicts the corresponding out-of-plane strain values as a function of ion fluence for LPCMO film with respect to its bulk lattice parameter. It is evident from figure 3(d) that the c lattice parameter increases on irradiation for the higher fluences of 5 × 1011 and 1 × 1012 ions cm−2 with the c lattice parameter of 3.936 Å for a fluence of 1 × 1012 ions cm−2. This change in lattice parameter suggests the advancement of a strong tensile strain along the normal of the film upon ion irradiation with a fluence >1011 ions cm−2. On comparing the shift in Bragg peaks of LPCMO films upon irradiation and pristine conditions, we have estimated an increase in a tensile strain of ∼ 1.06% and 1.86% for LPCMO films irradiated at ion influences of 5 × 1011 and 1 × 1012 ions cm−2, respectively.

Figure 3. XRD pattern for pristine LPCMO film grown on NGO substrate and ion irradiated LPCMO films at different fluences of 1 × 1011, 5 × 1011, and 1 × 1012 ions cm−2. The inset shows the schematic of the structure of the LPCMO film on NGO substrate with three mutually perpendicular directions of NGO substrate. The magnified version of the XRD pattern near (b) (220) and (c) (330) Bragg peaks of NGO substrate, highlighting the shift of Bragg peak (vertical dashed lines) for a film to a lower angle on increasing the fluence of ion irradiation. (d) estimated out-of-plane, c, the lattice parameter of the film at different ion fluences.

Download figure:

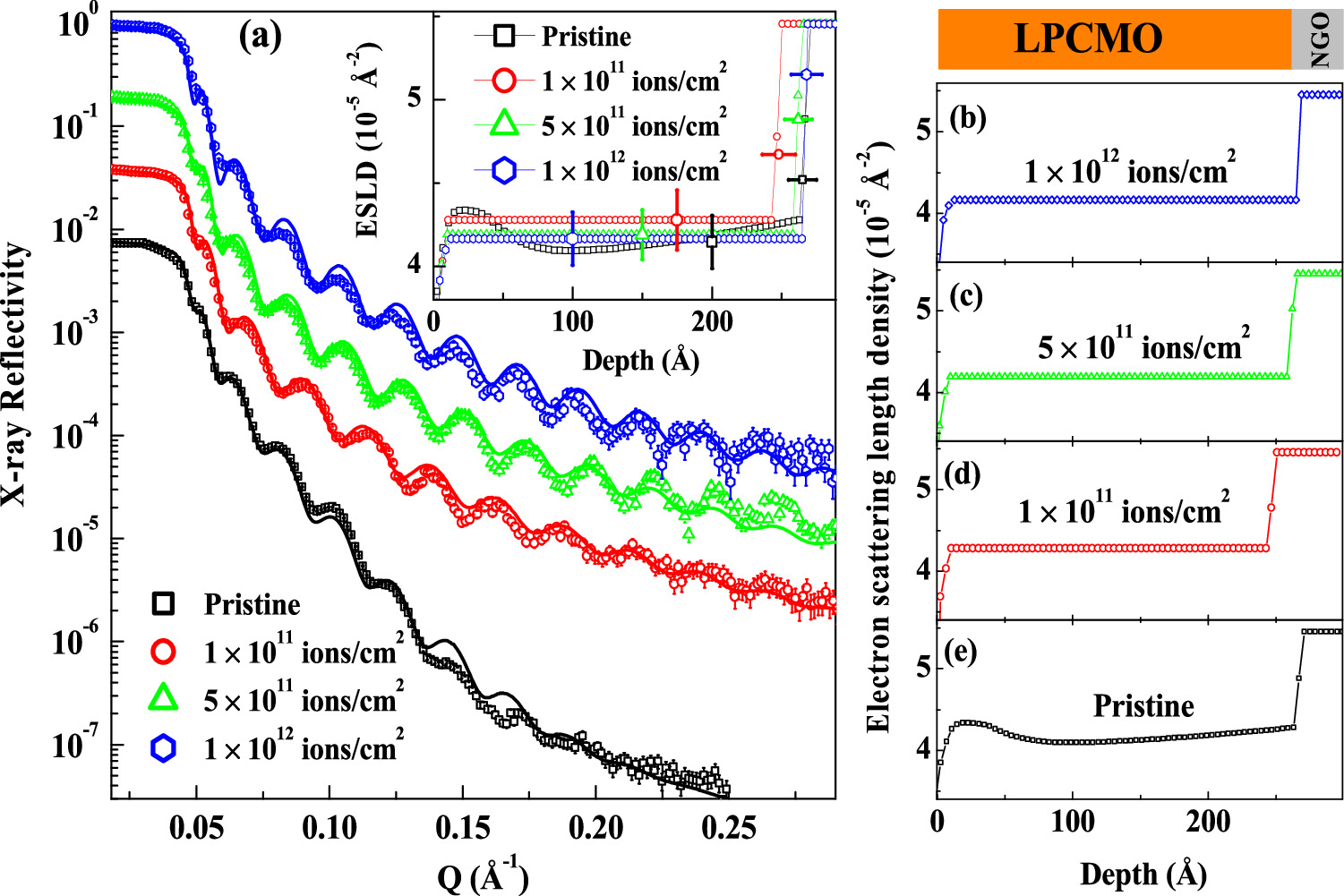

Standard image High-resolution imageTo study the influence of ion irradiation on the depth-dependent structure of LPCMO film, we have carried out specular (angle of incidence = angle of reflection) XRR measurements [56, 57]. Experimental specular XRR data (symbols) with corresponding fits (solid lines) as a function of wave-vector transfer, Q = 4π (sin θ)/λ (where λ is the wavelength of x-ray and θ is the angle of incidence) for pristine and irradiated LPCMO films, which are sifted vertically for better visualization, are shown in figure 4(a). XRR is qualitatively related to the Fourier transform of the electron scattering length density (ESLD) depth profile averaged over the whole sample area [56, 57]. To confirm the uniformity of the pristine LPCMO film, we performed XRR measurements from different regions (in-plane area) of the film using small beam sizes and observed similar XRR profiles suggesting a uniform growth of the film. In addition, the XRR data measured from small (5 mm × 5 mm) pristine samples (used for ion irradiation) showed similar profiles. The best-fitted reflectivity curves for different samples are shown as a solid line in figure 4(a) and the corresponding ESLD depth profiles are shown in figures 4(b) to (e). The ESLD depth profile consists of structural parameters, ESLD value for each layer, layer thickness and interface (or surface) roughness. Different structural parameters obtained from XRR data for pristine and irradiated LPCMO films are given in table 1. The inset of figure 4(a) shows the comparison of ESLD profiles for pristine and irradiated films. We have also shown the error in the ESLD value (vertical lines) and thickness (horizontal lines) of each sample. XRR results suggested that the variance in the ESLD and thickness parameters of the film upon ion irradiation are well within the error values (<5%) on different parameters obtained from XRR. The thickness of pristine LPCMO film was found to be ∼270 Å with a surface roughness of ∼9 Å. XRR results from pristine LPCMO film also suggested a small increase in the ESLD value at both interfaces (substrate/film and film/air). However, a higher value of ESLD was observed towards the surface (film/air interface) region. Enhanced values of ESLD at interfaces in LPCMO films grown on NGO substrate were also observed earlier [19, 20], and were attributed to the different stoichiometry of the film at these regions. XRR results also revealed a smaller roughness (∼3 Å) for substrate/film (buried) interfaces for all the samples, suggesting negligible contamination during the growth of the film, which is a general case for the deposition of high-quality oxide films using PLD at elevated substrate temperature. Upon first ion irradiation of the LPCMO film with a fluence of 1 × 1011 ions cm−2, we find a small increase in the ESLD and a drastic reduction in the surface roughness. This may be a result of the annealing of the defects from the film upon ion irradiation at a lower fluence value [47]. However, a decrease in ESLD was observed on irradiating the LPCMO film with higher ion fluence (figures 4(b) and (c)). Therefore, XRR in combination with XRD suggests a significant modification in the microstructural properties both at layer structure length (with sub-nanometer depth resolution) and atomic (XRD) length scale (microstrain growth) due to SHI irradiation. However, the crystalline structure (pseudo-cubic perovskite) of the LPCMO films remains integral to ion irradiation, which is consistent with other studies [30–34].

Figure 4. (a) XRR data (symbol) and corresponding fits (solid lines) for pristine and irradiated LPCMO films, which are shifted vertically for better visualization. (b) to (e): Electron scattering length density depth profiles obtained from XRR data for pristine and irradiated samples at different fluences. Inset of (a) shows the comparison of the ESLD profiles for different conditions, the error on the thickness and ESLD values are shown as horizontal and vertical lines.

Download figure:

Standard image High-resolution imageTable 1. Structural parameters obtained from x-ray scattering measurements.

| Samples → | Pristine | Irradiated with 120 MeV Ag15+ ions with different fluences | ||

|---|---|---|---|---|

| 1 × 1011 ions cm−2 | 5 × 1011 ions cm−2 | 1 × 1012 ions cm−2 | ||

| Thickness (Å) | 270 ± 8 | 248 ± 12 | 265 ± 9 | 266 ± 8 |

| Roughness (Å) | 9 ± 3 | 3 ± 2 | 3 ± 2 | 4 ± 2 |

| ESLD (10−5 Å−2) | 4.14 ± 0.15 | 4.28 ± 0.18 | 4.20 ± 0.15 | 4.18 ± 0.14 |

| c lattice parameter (Å) | 3.86 ± 0.01 | 3.86 ± 0.01 | 3.90 ± 0.01 | 3.93 ± 0.01 |

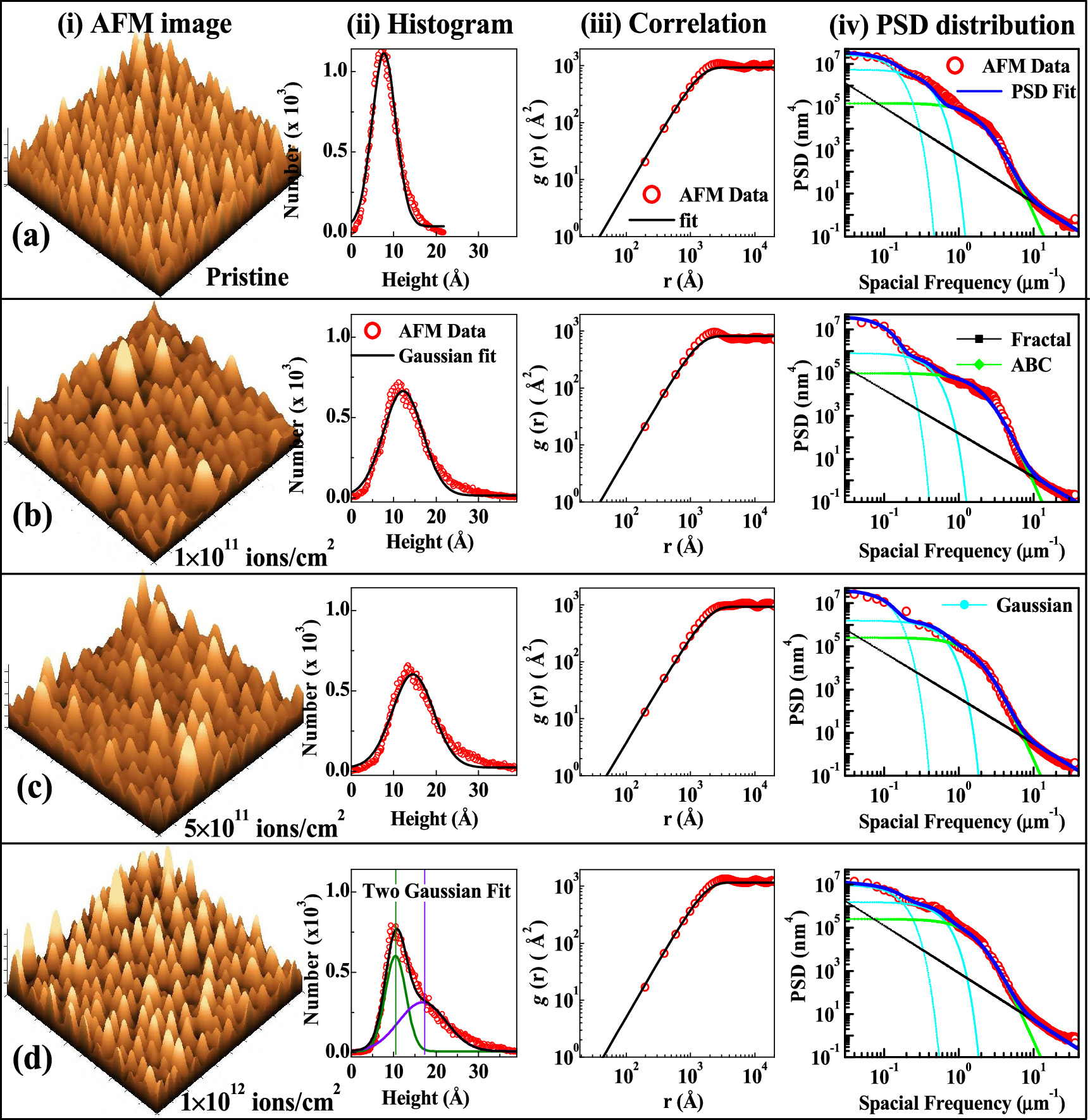

Further to investigate the irradiation-induced morphology in the LPCMO film we carried out AFM measurements for the pristine and irradiated films. Figure 5 shows the AFM results from the pristine and irradiated samples. AFM is a valuable tool to extract the microstructure/microroughness/morphological information of surfaces with high vertical and spatial resolution [58]. Although the RMS roughness estimated from the AFM technique is highly local and dependent on the scan area, it provides a complete height-height morphology for describing the fractal geometry and scaling concepts [39, 41, 44–46], which are important factors for influencing the interactions and macroscopic properties of a thin film. Column (i) of figures 5(a)–(d) shows the 3D-AFM images of pristine and irradiated LPCMO films recorded over a scan area of 5.0 μm × 5.0 μm. Visually, AFM images indicate a modification in the morphology of the film upon ion irradiation and suggest a distribution in LPCMO islands in both out-of-plane and in-plane directions. Therefore, a comparison of the surface topography of pristine and irradiated LPCMO films suggests the presence of grains of similar sizes on the substrate for pristine film, which is distributed densely over the substrate. Whereas the topography of the irradiated film depicts grains of different sizes, which are larger in size compared to the pristine film. More qualitative information has been obtained from the PSD function of these surfaces and their characteristic parameters described later. Further to analyze the distribution of these islands (grains), we have calculated the topographical histogram data from AFM images and plotted the histograms (symbols) and the corresponding Gaussian fits (solid black lines) to histogram data for pristine and irradiated films in column (ii) of figures 5(a)–(d). A single Gaussian function fits well to the histogram profile of pristine film suggesting that the surface topographies are distributed evenly about a mean surface profile. While the single Gaussian function also fits the histogram for irradiated LPCMO film with the lowest ion fluence of 1 × 1011 ions cm−2, the increase in ion fluence modifies the height-height distribution. The deviation of a single Gaussian fit was observed for irradiated films with an ion fluence greater than 1 × 1011 ions cm−2, suggesting that the surface features are distributed around more than one mean surface profile, i.e. distribution of grains at different length scales. The sum of two Gaussian functions provided a good fit to the height-height distribution function (second column of figure 5(d)) for LPCMO film irradiated with ion fluence of 1 × 1012 ions cm−2, suggesting the combination of two surface features around 10 and 17 Å.

Figure 5. Comparison of AFM measurements from (a) pristine and ion irradiated LPCMO films at different fluences of (b) 1 × 1011 ions cm−2, (c) 5 × 1011 ions cm−2, and (d) 1 × 1012 ions cm−2. Columns (i), (ii), (iii), and (iv) in each case (a to d) show the 3D-AFM images of size 5μm × 5μm, histogram, height-height correlation function, and PSD distribution function, respectively for pristine and irradiated LPCMO films. Column (ii) of (d) shows the fitting of histogram profiles using two Gaussian functions, suggesting two length scales for the surface.

Download figure:

Standard image High-resolution imageColumn (iii) of figures 5(a) to (d) show the experimental height difference correlation function [g (r)] data (symbol) extracted from height-height information of the AFM image of scan area of 5.0 μm × 5.0 μm and the corresponding fits (solid black line) assuming self-affine surface described in equation (1) for pristine and irradiated LPCMO films. We find small changes in morphological parameters (σ, ξ and h) of LPCMO film on irradiation with different fluences and parameters σ, ξ and h showed a variation within the range of 13 ± 5 Å, 2500 ± 400 and 0.90 ± 0.05, respectively. Thus, using the height-height correlation function (equation (1)), the surface morphology for all the films indicates a fractal dimension (D = 3- h) of ∼2.1. While the self-affine fractal nature studied using the height-height difference function indicated modification in surface morphology upon ion irradiation, we further studied the evolution in surface topography using PSD analysis [41, 45, 46], which correlated the amplitude of surface roughness to the spatial frequencies and revealed the statistical properties of surfaces. Column (iv) of figures 5(a) to (d) show the experimental PSD spectrums as a function of spatial frequency from AFM images of pristine and irradiated samples. The PSD data for different samples clearly show a variation over the frequency ranges and thus need a careful analysis for the interpretation of data over the entire frequency range. We have used different PSD models given in equation (2) for analyzing the PSD data.

The self-affine fractal surfaces, which follow the inverse power law ( are important characteristics of the roughness morphology of the film and thus it is one of the standard models to fit PSD data. We have fitted the PSD data considering three contributions for the PSD model as given in equation (2) and also assumed the summation of two Gaussian functions to get the best fit to PSD data. Different contributions to the PSD model and best fit (

are important characteristics of the roughness morphology of the film and thus it is one of the standard models to fit PSD data. We have fitted the PSD data considering three contributions for the PSD model as given in equation (2) and also assumed the summation of two Gaussian functions to get the best fit to PSD data. Different contributions to the PSD model and best fit ( given in equation (2)) are also shown in column (iv) of figures 5(a) to (d) for pristine and irradiated films. The PSD model characteristics parameters obtained from the fit to PSD data for pristine and irradiated films are given in table 2. The PSDs of the LPCMO films under different conditions (pristine and irradiated) exhibit inverse power law variation at the high spatial frequency region confirming the presence of fractal components in the surface topographies. The spectral indices (υ) for all the films, which is a measure of slopes of the PSD curve at the high-frequency region, are almost the same (see table 2), with a value of 2.1 to 2.25. Using the spectral indices (υ) one can estimate the fractal dimension (D) using

given in equation (2)) are also shown in column (iv) of figures 5(a) to (d) for pristine and irradiated films. The PSD model characteristics parameters obtained from the fit to PSD data for pristine and irradiated films are given in table 2. The PSDs of the LPCMO films under different conditions (pristine and irradiated) exhibit inverse power law variation at the high spatial frequency region confirming the presence of fractal components in the surface topographies. The spectral indices (υ) for all the films, which is a measure of slopes of the PSD curve at the high-frequency region, are almost the same (see table 2), with a value of 2.1 to 2.25. Using the spectral indices (υ) one can estimate the fractal dimension (D) using  for

for  [41]. We obtained a fractal dimension of ∼ 2.4 (for υ = 2), which is close to the value estimated (D ∼ 2.1) from the height-height difference function for self-affine surfaces. In contrast, we found a decrease in the value of the spectral strength (K) (table 2) on increasing the ion fluence for irradiation of the film, indicating that upon ion irradiation, the film loses the fractal behaviours. Similarly, best-fit parameters (table 2) obtained from the ABC model (

[41]. We obtained a fractal dimension of ∼ 2.4 (for υ = 2), which is close to the value estimated (D ∼ 2.1) from the height-height difference function for self-affine surfaces. In contrast, we found a decrease in the value of the spectral strength (K) (table 2) on increasing the ion fluence for irradiation of the film, indicating that upon ion irradiation, the film loses the fractal behaviours. Similarly, best-fit parameters (table 2) obtained from the ABC model ( ) of PSD function show the variation and suggest a change in surface RMS roughness and in-plane correlation length upon ion irradiation. The parameters obtained from the best fit of the Gaussian model (

) of PSD function show the variation and suggest a change in surface RMS roughness and in-plane correlation length upon ion irradiation. The parameters obtained from the best fit of the Gaussian model ( ) for different samples (table 2) does not show significant variation but it needed two Gaussians to fit the PSD data, suggesting the distribution of grains at lower spatial frequency remains similar.

) for different samples (table 2) does not show significant variation but it needed two Gaussians to fit the PSD data, suggesting the distribution of grains at lower spatial frequency remains similar.

Table 2. Different parameters describing a PSD model are fitted to experimental PSD data for pristine and irradiated LPCMO films.

| Samples (LPCMO film) | Fractal | k-Correlation | Shifted Gaussians | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Guassian1 | Gaussian2 | ||||||||||

| K (10−3 nm) | υ | A (104 nm) | B (nm) | C | σ1 (nm) | τ1 (nm) | x1 (μm−1) | σ2 (nm) | τ2 (nm) | x2 (μm−1) | |

| Pristine | 15 | 2.1 | 15 | 425 | 7 | 1.0 | 3200 | 0.8 | 0.8 | 1100 | 3 |

| 1 × 1011 ions cm−2 | 13 | 2.15 | 9.2 | 400 | 7.25 | 1.0 | 3500 | 0.7 | 0.7 | 1000 | 1.5 |

| 5 × 1011 ions cm−2 | 2 | 2.2 | 25 | 500 | 7 | 1.2 | 3500 | 0.7 | 1.2 | 700 | 1.5 |

| 1 × 1012 ions cm−2 | 2 | 2.25 | 27 | 510 | 7 | 1.3 | 3000 | 0.7 | 1.1 | 700 | 1.5 |

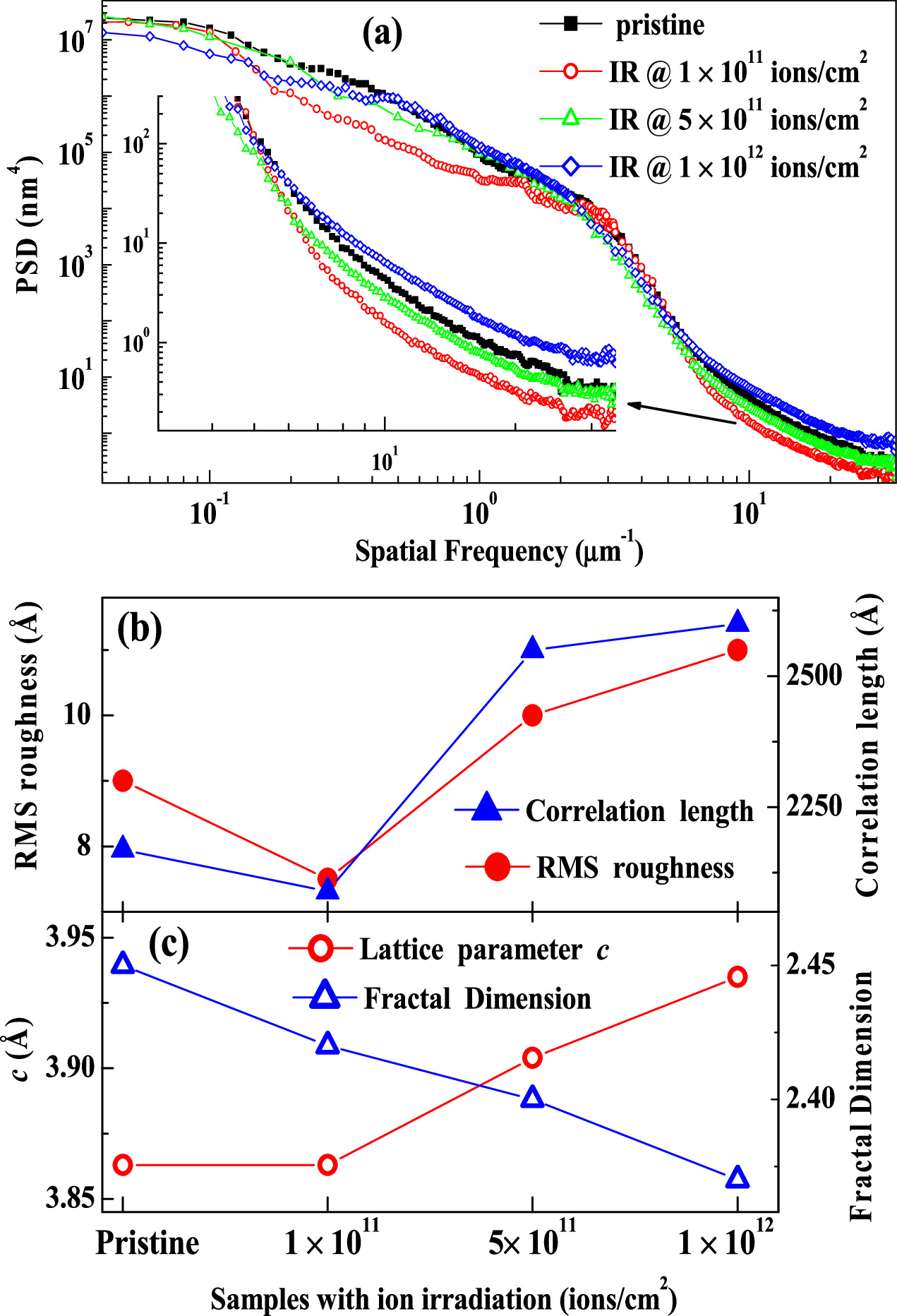

A comparison of experimental PSD profiles for pristine and irradiated LPCMO films is shown in figure 6(a). The inset shows the PSD function in the higher spatial frequency region. It is evident from figure 6(a) that a drastic change in the PSD profile over the whole frequency range is observed on the first ion irradiation of the film by an ion fluence of 1 × 1011 ions cm−2, this is consistent with the results from XRR measurements, which showed densification and reduction of the layer thickness. The reduction in PSD profiles in the intermediate frequency range for the irradiated sample at low fluence also suggests a reduction in the roughness parameter for this sample. While the fractal behaviours of these films show similar behaviours, the slower or faster variation of PSD over the spatial frequency suggests different topological behaviours upon ion irradiation. Upon ion irradiation of the film with the lowest value of fluence of 1 × 1011 ions cm−2, we observed that PSD falls faster in higher frequency regions as compared to other conditions (pristine and other fluence) suggesting modification in lateral structure (grain sizes). On increasing the fluence of ion irradiation, we observed slower variation in the PSD profiles, indicating the presence of a larger in-plane length scale (grain size) in the system. A similar variation of PSD profiles in the low and intermediate frequency range suggests the same roughness parameters for the films.

Figure 6. (a) The experimental PSD profiles of LPCMO film under different conditions of ion irradiations. The inset shows the magnified version of the PSD profile for a spatial frequency range of f > 3 μm−1. Evolution of (b) RMS roughness and lateral correlation length, and (c) lattice parameter and fractal dimension, upon ion irradiation with different fluence.

Download figure:

Standard image High-resolution imageIn addition, using the A, B, and C parameters from the ABC model ( ) of the PSD data, we have calculated characteristic parameters of film surfaces (i.e. RMS roughness (

) of the PSD data, we have calculated characteristic parameters of film surfaces (i.e. RMS roughness ( ) and lateral correlation length (

) and lateral correlation length ( ) ) and plotted them in figure 6(b) for pristine and irradiated LPCMO films. We find a small decrease in RMS roughness and correlation length of the first irradiated LPCMO film at a fluence of 1 × 1011 ions cm−2 as compared to pristine film. On further increase in ion fluence both these parameters increase. Figure 6(c) depicts the comparison of lattice parameter (c) and fractal dimension for LPCMO films under different conditions (pristine and ion irradiation at different fluence). Figures 6(b) and (c) illustrate the correlation between atomic structure and morphological properties of LPCMO films under ion irradiation with different fluences. A similar variation of RMS roughness, lateral correlation length, and out-of-plane lattice parameters (c) as a function of ion fluence clearly suggest a strong correlation in structural and morphological modifications due to ion irradiation. The study also suggests an increase in the in-plane grain size and a reduction in the fractal characteristics of the film surface upon ion irradiation with a fluence of larger than 1 × 1011 ions cm−2.

) ) and plotted them in figure 6(b) for pristine and irradiated LPCMO films. We find a small decrease in RMS roughness and correlation length of the first irradiated LPCMO film at a fluence of 1 × 1011 ions cm−2 as compared to pristine film. On further increase in ion fluence both these parameters increase. Figure 6(c) depicts the comparison of lattice parameter (c) and fractal dimension for LPCMO films under different conditions (pristine and ion irradiation at different fluence). Figures 6(b) and (c) illustrate the correlation between atomic structure and morphological properties of LPCMO films under ion irradiation with different fluences. A similar variation of RMS roughness, lateral correlation length, and out-of-plane lattice parameters (c) as a function of ion fluence clearly suggest a strong correlation in structural and morphological modifications due to ion irradiation. The study also suggests an increase in the in-plane grain size and a reduction in the fractal characteristics of the film surface upon ion irradiation with a fluence of larger than 1 × 1011 ions cm−2.

The strain and morphology of the LPCMO films play an important role in determining the macroscopic magnetic and transport properties [13–17, 20]. However, controlled application of strain and modification in the morphological parameters of LPCMO films grown on single crystal oxide substrates (e.g. NGO, LAO etc) are always challenging. The present study shows a strong correlation between the fluence of ion irradiation and corresponding modification in the strain and morphology of LPCMO films. Therefore, ion irradiation will provide an additional tool to understand the mechanism of interactions associated with strain/morphology and magnetic and transport properties in these phase-separated systems. In addition, the in-plane correlation length measured by AFM is equivalent to the charge-charge correlation length (electronic phase/domain) obtained from the off-specular x-ray reflectivity [16, 17, 44]. Earlier studies have suggested that different charge-charge correlation lengths correspond to different electronic phases, responsible for different macroscopic properties [16, 17, 44]. Therefore, an increase in the correlation length of LPCMO films upon ion irradiation with a fluence >1 × 1011 ions cm−2 clearly suggests an equivalent increase in charge-charge correlation length (or increase in electronic/conducting domain size) in this system, which will influence the magnetotransport and macroscopic magnetic properties of the films.

Conclusion

In summary, we have investigated the effect of SHI ion irradiation (Ag15+) on the structural and surface morphological properties of LPCMO thin films deposited on NGO substrate in the fluence range from 1 × 1011 to 1 × 1012 ions cm−2. EDX data from pristine film suggested that the film is grown with the desired composition. XRD measurements from irradiated LPCMO suggested an increase in the out-of-plane lattice parameter (tensile strained) on increasing the fluence of ions, i.e., a linear variation of microstrain with the ion irradiated fluence. In addition, XRD data also indicated that the crystalline nature of the film did not change on ion irradiation. AFM measurements were analyzed primarily through the PSD function and indicated the evolution of morphological properties at various fluences. The XRD and AFM data suggested that upon ion irradiation the surface structure and morphology of the films are modified significantly. All the LPCMO films (pristine as well as ion irradiated at different fluence) display a self-affine surface and the fractal dimension decreases with an increase of ion fluence. A comparison of structural and morphological parameters as a function of ion fluence suggested a strong correlation in atomic structure and morphology, where the lattice constant, surface roughness and in-plane correlation length increase on increasing the ion fluence of irradiation. Whereas the fractal behaviours of the film faded on increasing the ion fluence. Thus, the present study shows that SHI irradiation causes notable modifications in the structural and morphological properties of LPCMO thin films, which can be controlled by ion fluence. We believe the linear response of controlled ion irradiation fluence to microstrain in LPCMO film may be useful for studying the influence of strain field on the functional properties of phase-separated complex oxide systems.

Acknowledgments

One of the authors (YK) would like to thank the Department of Science and Technology (DST), India, for financial support via the DST INSPIRE faculty research Grant (No. DST/INSPIRE/04/2015/002938) and the Science and Engineering Research Board (SERB), India via research grant (No. SB/SRS/2021–22/65/PS).

Data availability statement

All data that support the findings of this study are included within the article (and any supplementary files).