Abstract

Magnetization orientation in thin films is intricately influenced by multiple anisotropy components, with the dominant anisotropy serving as a key determinant. This complexity becomes particularly intriguing when considering thin films composed of subnanometer-scale heterogeneous amorphous structures. Our investigation builds upon this foundation, specifically focusing on the Fe–Ni–B–Nb alloy system, known for its moderate glass-forming ability and susceptibility to nanocrystallization. In this study, we present thickness- and temperature-driven spin-reorientation (SRT) transition, attributed to competing magnetic anisotropy energies in thin films featuring a heterogeneous amorphous structure. Thermogravimetric investigations unveiled a unique heterogeneous amorphous structure, a revelation unattainable through conventional structural analysis methods. The observed spontaneous perpendicular magnetization in amorphous films, as evidenced by transcritical hysteresis loops and magnetic stripe domains, is ascribed to the pronounced residual stress arising from the substantial magnetostriction of the alloy system. The temperature-driven SRT is correlated to the order-disorder magnetic transition of the heterogeneous amorphous phase, characterized by a Curie temperature of ∼225 K. This transformative magnetic state of the heterogeneous amorphous matrix limits the exchange interaction among the densely distributed α-Fe nuclei regions, ultimately governing the dynamic magnetic responses with varying temperature. This work provides valuable insights into the dynamic magnetic orientation of thin films, especially those with heterogeneous amorphous structures, contributing to the broader understanding of the underlying mechanisms of magnetization reversals.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 4.0 license. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

The magnetic properties of materials are fundamentally influenced by the electron's spin-orbit coupling, leading to the emergence of magnetic anisotropy, a crucial factor governing magnetization orientation [1]. Effective magnetic anisotropy comprises various components, such as magnetocrystalline, magnetoelastic, surface, and shape anisotropy energies [2]. Nonetheless, it is the dominant anisotropy that ultimately defines the magnetization orientation [2]. In the context of epitaxially grown thin-film crystalline materials, unique characteristics emerge due to missing bonds and incomplete quenched orbital moments, leading to magnetic anisotropy that significantly differs from bulk ferromagnetic materials, particularly at the surface [1, 3]. Notably, when surface anisotropy prevails over weak shape anisotropy, magnetic spins align perpendicularly to the surface in thin films [4, 5]. This perpendicular magnetization phenomenon has been observed in numerous monolayer systems on a diverse range of substrates, where the film-substrate interface plays a pivotal role [6–8]. However, as the film thickness increases from a few monolayers to the micron scale, the interface's influence diminishes, and shape anisotropy becomes dominant [6–8]. When shape anisotropy overtakes perpendicular anisotropy, magnetic spins reorient from out-of-plane to in-plane configuration, a well-documented occurrence known as spin-reorientation transition (SRT), extensively reported in thin-film crystalline systems [9–11]. Intriguingly, contrary to thickness-driven SRT, an inverse-SRT has been observed in thin films, where magnetic spins transform from in-plane to out-of-plane alignment as a function of film thickness, exemplified by the classic case of Ni on a Cu (001) substrate [9, 11–15]. This inverse-SRT has been attributed to structural evolution, changes in anisotropy energy resulting from structural relaxations, or variations in broken symmetry at the film-substrate interface. [11–15]

In contrast to epitaxially grown ultra-thin film systems, amorphous materials offer a distinctive atomic structural configuration. The disordered atomic structure in amorphous materials presents an opportunity to manipulate magnetic exchange interactions by regulating the inter-atomic distance and degree of atomic randomness, thereby impacting magnetization reversal behaviors [16, 17]. Recently, there has been a notable increase in interest surrounding amorphous magnetic films [17–20]. The investigation into perpendicular magnetization in amorphous films holds particular significance for a broad spectrum of applications, especially within the domain of high-density magnetic storage [19, 21, 22]. Interestingly, the intriguing phenomenon of thickness-driven inverse SRT has also been observed in amorphous [21, 22] and two-phase nanocrystalline thin film materials [23]. This occurrence is attributed to the high degree of atomic disorder present within the amorphous structure and the significant residual stress/strain induced during the film deposition process [18, 21–24]. In addition, there have been reports documenting the emergence of perpendicular magnetic anisotropy (PMA) attributed to the columnar growth of thin films [17]. In this context, the prevailing factor is the microscopic shape anisotropy of nano size high aspect ratio columns, which dictates the orientation of magnetization towards out-of-plane orientations. Furthermore, it is noteworthy that amorphous/nanocrystalline films have demonstrated temperature-driven SRT in the temperature range of 100–300 K, a phenomenon that is not commonly observed in polycrystalline thin films [18, 21–24]. However, the origin of temperature-driven SRT in amorphous thin films, why spins reorient from in-plane to out-of-plane configuration as a function of temperature, remains inadequately understood and requires further investigation.

The present work demonstrates the thickness- and temperature-driven SRT in Fe–Ni–B–Nb heterogeneous amorphous thin films obtained by pulsed laser deposition (PLD) and offers valuable insights into the intricate interplay of anisotropy energies that define the orientations of magnetization. The spontaneous perpendicular magnetization in these films, as manifested by transcritical hysteresis loops and magnetic stripe domains, founds origin in dominant magnetoelastic anisotropy energy, primarily induced by residual stress resulting from the high magnetostriction (λs) of the alloy system. The temperature-driven SRT, on the other hand, arises from the dynamic magnetic state of the heterogeneous amorphous phase, undergoing an order/disorder magnetic phase transition as a function of temperature.

2. Experimental methods

The Fe66Ni6B24Nb4 (atomic %) alloy was fabricated into a solid cylindrical shape using an induction furnace under a controlled Ar-atmosphere, with the chamber evacuated to ultra-high vacuum conditions. High-purity (99.99%) elements were employed to ensure the absence of impurities in the samples. To achieve homogenous alloying, the alloy was melted five times in an alumina crucible, with careful monitoring of the alloy melt temperature to prevent premature evaporation of boron. Following the homogenous melting process, the alloy melt was cast into an oxygen-free cylindrical copper mold. Subsequently, a 3 mm thick disk-shaped alloy was machined and polished to a mirror-like finish, serving as the target material for film deposition.

Thin films were fabricated on Si substrates through PLD using a Nd-YAG laser (Continuum NY 81C-10) with a wavelength (λ) of 355 nm. The laser operated with a pulse duration of 30 ns and a repetition rate of 10 Hz. The target alloy was ultrasonically cleaned using acetone to avoid further contamination. The laser energy was precisely set at 100 mJ per pulse. The laser beam was focused on the target alloy using a 45 cm focal length lens at an incident angle of 45 degrees. Maintaining a fixed distance (5 cm) between the target and the substrate enabled a deposition rate of 0.2 nm s−1. The target alloy was continuously rotated to prevent excessive material removal. Film deposition took place under a base pressure of 1 microbar, with substrate temperature deliberately kept at room temperature to prevent crystallization during deposition. Pre-ablation of the target alloy was conducted for 120 s before each deposition to prevent the contamination of surface impurities. The film thicknesses 27 nm, 258 nm, and 408 nm were regulated by adjusting the deposition time as the sole variable while maintaining all other deposition parameters at a constant value.

The atomic structure of the films was assessed using x-ray diffraction (XRD) with Cu–Kα radiation (Siemens D5000, λ = 1.54 Å) and a monochromatic detector using theta-2theta scan for examining intricate details of thin film crystal structure. Furthermore, to minimize substrate interference, a grazing angle configuration was employed with a source angle (θ) of 1.5. Surface morphology analysis of the films was conducted via scanning electron microscopy (SEM). Film thickness was determined using a dual-beam Focused Ion Beam system (FIB, Nova 600 Nano lab by FEI Co.).

High-temperature temperature dependent magnetization M(T), Curie points (TC), and structural anomalies in the films were investigated using magneto-thermo-gravimetry (MTG, Perkin Elmer). The TC was derived through the steepest temperature derivative, dM(T)/d(T), of the M(T) curve, detailed procedure is described elsewhere [25].

In-plane magnetic hysteresis loops were measured using a superconducting quantum interference device (SQUID) magnetometer (quantum design, MPMS2) from liquid helium to room temperature, with a maximum field strength of 10 kOe, using 4 mm × 4 mm samples. The films underwent one-hour annealing in a high vacuum furnace. Temperature-dependent magnetization M(T), both zero-field-cooled (ZFC) and field-cooled (FC), were measured using SQUID at different probe fields (5–20 Oe). Melt-spun amorphous ribbon (6 mm length × 2 mm width × 20 μm thickness) was evaluated using a vibrating sample magnetometer to study the M(H) behavior. Magnetic force microscopy (MFM) was employed to investigate magnetic domains within the films. Low-temperature AC susceptibility was assessed with a custom-designed setup.

3. Results and discussion

3.1. Surface morphology and structural investigations

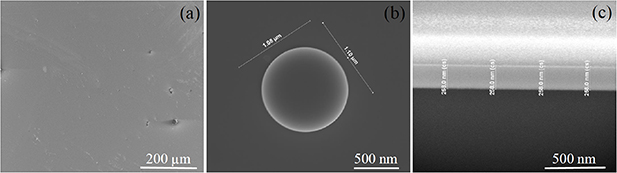

The examination of the surface morphology of the films was carried out through high-resolution SEM, as shown in figure 1. A low-magnification SEM image, figure 1(a), reveals the dispersion of laser droplets distributed across the film's surface. Additionally, figure 1(b) presents the high-resolution SEM image which highlights the spherical characteristics of these laser droplets. For a more detailed view of the film's structure, figure 1(c) presents a cross-sectional image obtained through FIB technique. This image reveals a continuous, rigid film surface characterized by smoothness, without any distinct texture, grains, or grain boundaries. This observation is consistent with the typical characteristics reported for amorphous thin film systems [26].

Figure 1. (a) A typical SEM image at low magnification depicting the inhomogeneous distribution of laser droplets on the 258 nm film's surface. (b) A high-resolution SEM image showcasing the spherical nature of a laser droplet. (c) A cross-sectional image of the 258 nm film obtained through FIB.

Download figure:

Standard image High-resolution imageThe phenomenon of spherical particle growth, specifically laser droplets, has been widely documented in thin films generated through the PLD technique [19, 27]. The growth process of these laser droplets is comprehensively explained by considering the mechanical forces exerted on the target [27]. It is worth noting that techniques such as employing the slit and filter method or precise control over the target and substrate configurations have proven effective in avoiding the occurrence of laser droplets [28, 29].

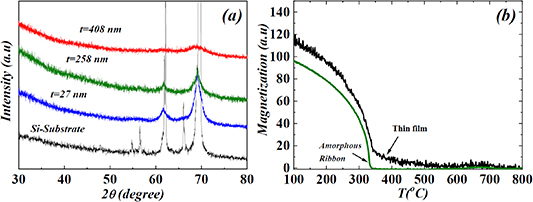

XRD pattern of all investigated samples and Si-substrate is presented in figure 2(a). Notably, no discernible Bragg's peaks were detected; instead, a broad maximum within the 2θ range of 35–50° was evident. This absence of Bragg's peaks and the presence of this broad maximum, which signifies the statistical distribution of the short-range ordered atomic structure, supports the overall amorphous nature of the films on a macroscopic scale. Nevertheless, it is widely acknowledged that the broad maximum in XRD pattern does not rule out the possibility of minute sub-nanometer scale crystallites within the amorphous matrix [30], primarily attributed to the inherent lower detection limit (i.e. 1%–2%) of the investigating technique [31].

Figure 2. (a) X-ray diffraction (XRD) of 27 nm–408 nm films in as-deposited state. The XRD of the Si-substrate is presented for comparison, (b) the temperature dependence of magnetization, M(T), of 408 nm film measured by magneto-thermo-gravimetry (MTG). The M(T) of melt-spun amorphous ribbon is presented for comparison.

Download figure:

Standard image High-resolution imageThe M(T) of the 408 nm film and a melt-spun amorphous ribbon (both composed of the same alloy) are illustrated in figure 2(b). In the case of 408 nm film, the magnetization decay towards the Curie point of the amorphous phase is denoted as TC(am)= 330 °C. However, it is noteworthy that the magnetization did not reach absolute zero at what is referred to as TC(am) for the amorphous phase. Instead, it extended towards the crystallization temperature (605 °C) of the alloy. Interestingly, the M(T) of the ribbon approached the absolute zero magnetization at the Curie point (320 °C). The observed increase in magnetization for both the film and ribbon at 605 °C is attributed to the precipitation of crystalline phases. The presence of a non-zero magnetization of the film in the 330 °C–550 °C temperature range suggests the existence of magnetic entities with a Curie point >330 °C (TC(am)), even though these entities remained obscured through XRD analysis. It is worth noting that the magnetization reached absolute zero at ⩾750 °C (i.e. ≈TC(Fe)), confirming that the non-zero magnetization observed above TC(am) is not an artifact but rather represents a genuine magnetic entity with a higher Curie point. Nevertheless, accurately quantifying the nature and magnitude of this magnetic entity in amorphous films remains challenging using conventional techniques [16, 32]. We propose that this magnetic entity in the amorphous film corresponds to highly disordered Fe-nuclei, given its Curie point (i.e. ⩾750 °C ≈TC(Fe))), which bears similarity to α-Fe.

The presence of the magnetic entity within the amorphous matrix could be associated with the nucleation of nanocrystalline seeds and the subsequent growth of primary nanograins. One could propose that there may be the precipitation of heterogeneous chemical structures or regions with dense α-Fe nuclei at the sub-nanometre scale, even though these are not detectable through XRD analysis. The agglomeration of Fe-nuclei could be anticipated due to the low glass-forming ability (GFA) of Fe–Ni–B–Nb alloy [33, 34].

The formation of homogeneous/heterogeneous amorphous alloys depends on the GFA, i.e. the ease of forming the disordered atomic structure of the alloy system [35]. The higher the GFA, the lower the cooling rates required to retain the homogeneous amorphous structure. GFA is intricately tied to several factors, including the number of constituent elements (the higher, the better), atomic size mismatch (at least 12%), and the enthalpy of mixing between the constituents (negative enthalpy is ideal), as outlined in Inoue's empirical rules [36]. In the case of the Fe–Ni–B–Nb system, it exhibits a moderate GFA [33, 34], primarily due to its relatively small number of constituents and a high proportion of metallic content (72 atomic % Fe + Ni), though other GFA criteria remain satisfied. The relatively low GFA of the alloy plays a significant role in the agglomeration of localized regions with dense Fe-nuclei in the amorphous films. The fact that XRD cannot reveal the infinitesimal magnetic entities is not staggering; rather, it is anticipated. The primary nanocrystallization in Fe-based alloys leads to the precipitation of highly disordered regions of Fe nuclei, which results in broad diffraction peaks that are eventually concealed by the dominant amorphous matrix. These nanoscale entities within the amorphous matrix are particularly challenging to detect even with advanced techniques such as XRD, transmission electron microscopy, x-ray absorption fine-structure spectroscopy, and ferromagnetic resonance [16, 32].

Additionally, it is essential to consider that the high energies involved during the film deposition process using PLD may lead to a miscibility gap between the alloy constituents. This becomes particularly significant when the GFA is low. For instance, the heat energy generated during the synthesis of PLD-based Fe–B–Si amorphous films eventually initiated the nucleation and growth of undesired crystallites.

Recent research by the authors involved the quantification of structural anomalies in melt-spun Fe–B–Si–P–Cu amorphous ribbons [30], Fe–B–Nb thin films [37] and gas-atomized Fe–B–Si–Nb–Cu amorphous powders [38] using MTG, a technique capable of detecting minimal phase heterogeneity (ca ⩽1%) [30]. This kind of heterogeneity is typically difficult to identify using conventional techniques. The structural anomalies in the melt-spun amorphous alloys were attributed to the lower amorphization capability of the alloy [30]. In conclusion, the combined effects of low GFA and the nature of the film deposition process contribute to the agglomeration of Fe-nuclei in amorphous films. In the present case, we propose that the magnetic entity in the films is heterogeneously dispersed α-Fe nuclei within an amorphous matrix.

3.2. Room-temperature magnetization behaviours

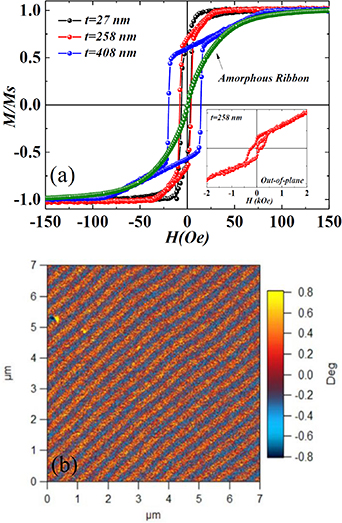

Figure 3 presents the in-plane hysteresis loops of the films at room temperature. Notably, the hysteresis loop for the 27 nm film exhibits a 'square-type' shape with a relatively small coercivity (HC) value. In contrast, the hysteresis loop of the 258 nm film undergoes a transformation into a 'transcritical-type' with HC (4.2 Oe) and HK (29 Oe). The inset in figure 3 provides insight into the out-of-plane hysteresis of the 258 nm film. The transcritical hysteresis pattern further evolves in the case of the 408 nm film, resulting in an increase in HC (14 Oe) and HK (82 Oe). This systematic change in hysteresis loop shape, HC, and HK as a function of film thickness signifies an alteration in the competing magnetic anisotropies that define the magnetization reversal behaviors. The hysteresis loop of the melt-spun amorphous ribbon composed of the same alloy is shown for comparison. The ribbon's hysteresis behavior conforms to the typical characteristics exhibited by soft magnetic amorphous materials. Figure 3(b) illustrates the magnetic domain pattern at the remanent state (MR) of magnetization of 408 nm film. This pattern consists of periodic stripe domains with distinct dark and bright contrasts, illustrating the magnetic orientation of spins in either the 'up' or 'down' configuration.

Figure 3. (a) In-plane magnetic hysteresis loops of 27–408 nm films. The inset shows the out-of-plane hysteresis of 258 nm film. The hysteresis of a melt-spun amorphous ribbon of the same alloy is presented for comparison, (b) The MFM image of the 408 nm film carried out at the remanent-state of magnetization (MR).

Download figure:

Standard image High-resolution imageThe conventional square-type hysteresis pattern is widely recognized in cases of in-plane magnetization, indicating that the spins align parallel to the film's surface [17]. Conversely, the presence of transcritical hysteresis loops is a well-established phenomenon when dealing with perpendicular magnetization [21, 22]. The observation of transcritical hysteresis loops and accompanying stripe domain patterns serves as compelling evidence that the magnetic orientation undergoes a transition from in-plane to out-of-plane as the film thickness extends to ⩾258 nm [21, 22].

A systematic elevation in the values of perpendicular anisotropy energy ( ) corresponding to variations in film thickness establishes a direct and discernible correlation between the two parameters, as elucidated by numerous studies [18, 21, 22]. The lower slope observed in the transcritical loops, which manifest prior to reaching saturation magnetization (MS), serves as a direct metric for uniaxial out-of-plane anisotropy (

) corresponding to variations in film thickness establishes a direct and discernible correlation between the two parameters, as elucidated by numerous studies [18, 21, 22]. The lower slope observed in the transcritical loops, which manifest prior to reaching saturation magnetization (MS), serves as a direct metric for uniaxial out-of-plane anisotropy ( ) represented by

) represented by

, where µo

MS denotes saturation magnetization [18]. This correlated phenomenon is crucial for understanding the material's magnetic behavior.

, where µo

MS denotes saturation magnetization [18]. This correlated phenomenon is crucial for understanding the material's magnetic behavior.

The emergence of transcritical loops and the intriguing manifestation of stripe domains are intricately linked to the Q-factor ( / Kd), where Kd

/ Kd), where Kd

signifies in-plane magnetostatic anisotropy. The spontaneous appearance of stripe domains becomes evident when Q > 1 [2, 18]. Calculated Q-factors for films within the thickness range of 258 nm–408 nm, with µo

MS set to 1 Tesla as measured from hysteresis loops, fall within the range of (2.9–8.2) × 10−3, indicating an unusually low value that accounts for the observed stripe domain formation [2, 18].

signifies in-plane magnetostatic anisotropy. The spontaneous appearance of stripe domains becomes evident when Q > 1 [2, 18]. Calculated Q-factors for films within the thickness range of 258 nm–408 nm, with µo

MS set to 1 Tesla as measured from hysteresis loops, fall within the range of (2.9–8.2) × 10−3, indicating an unusually low value that accounts for the observed stripe domain formation [2, 18].

However, a deeper exploration into the critical thickness (Tcr) of the films, leading to the emergence of transcritical loops and stripe domains, was calculated using Tcr

with A set to 10−11 J m−1 as the exchange stiffness constant, reveals a critical value of 186 nm, which closely corresponds to the critical thickness derived from our experimental findings [18, 39].

with A set to 10−11 J m−1 as the exchange stiffness constant, reveals a critical value of 186 nm, which closely corresponds to the critical thickness derived from our experimental findings [18, 39].

Furthermore, assuming a Landau domain-type structure, specifically an in-plane closure domain for the 408 nm films, we extend our analysis to calculate the stripe domain width (W) using equation (1) [18, 40]:

Here, 't' represents the thickness of the film. The calculated stripe domain width (425 nm) for 408 nm film closely corresponds to the width measured through MFM, providing additional validation for our experimental observations [18, 41].

The experimental findings offer profound insights into the magnetic characteristics of amorphous thin films, specifically revealing the intricate interplay between PMA and shape anisotropy phenomena. These two anisotropies, stemming from distinct mechanisms, contribute synergistically to the overall magnetization dynamics of the thin films. From the meticulous analysis of hysteresis loops and magnetic domain patterns, a detailed phenomenological description emerges, offering a deeper understanding of the magnetic dynamics at play.

In the 27 nm film, the presence of a square-type hysteresis loop suggests a magnetic orientation predominantly in-plane, with a relatively small coercivity. This aligns seamlessly with expectations of shape anisotropy dominance, particularly in films with reduced dimensions, where the impact of demagnetizing energy from shape effects becomes more pronounced. Conversely, the appearance of a transcritical-type hysteresis loop in the 258 nm film indicates a captivating transition in magnetic behaviour, suggesting a dynamic competition between perpendicular and shape anisotropy. As the film thickness increases, the growing influence of perpendicular anisotropy becomes evident, resulting in a discernible change in the shape of the hysteresis loop. This evolution is notably observed in the 408 nm film, emphasizing a thickness-dependent alteration in the equilibrium between competing anisotropies, thus influencing the dynamics of magnetization reversal.

The magnetic domain pattern observed in the 408 nm film, characterized by periodic stripe domains with distinct dark and bright contrasts, adds an additional layer of insight. This intricate pattern suggests that the interplay between competing anisotropies leads to a modulation of magnetic domains, with different regions exhibiting diverse magnetic orientations. Such stripe domains, commonly associated with PMA, are shown to be influenced by the thickness of the film [21, 23].

In highlighting the uniqueness of thin film geometry, a comparison with a melt-spun amorphous ribbon of the same alloy underscores that observed variations in hysteresis loops are not generic to the alloy composition but rather are intricately linked to the distinctive characteristics of thin film geometry.

Several mechanisms have been proposed to explain the origin of PMA and hence, the emergence of thickness-dependent SRT in amorphous thin films [2, 17, 18, 21, 22]. Fe-based amorphous alloys are characterized by elevated λs values [42], thus underscoring the significant role of intrinsic residual stress, and consequently magnetoelastic energy (Ku ), in dictating the magnetization reversal and orientation in these materials [18]. Additionally, the degree of atomic disorder (i.e. state of the dense atomic packing) and the quality of the amorphous structure (i.e. homogeneous vs. heterogeneous chemical structure) [16] are contingent upon the specific fabrication process (e.g. magnetron sputtering, PLD) employed in film production and act as a source of macroscopic induced stress [17]. Various deposition parameters, including deposition power, pressure, the geometry of the deposition chamber, the distance between the target and substrate, the angle at which atomic flux reaches the substrate, and the substrate's temperature, exert a significant influence over the thin film growth process and the degree of atomic disorder present in amorphous films [16, 17]. Consequently, these factors play a pivotal role in determining the magnetization state and the behaviors associated with magnetization reversal. A pertinent recent illustration of this phenomenon is observed in the Fe–Zr amorphous system [16], where differing degrees of atomic disorder lead to a transformation in the magnetization reversal, shifting from superparamagnetic behavior to a spin-glass-like pattern. Both, intrinsic residual stress due to large λs of the alloy and induced macroscopic stress could be the potential source of perpendicular magnetization in thicker films.

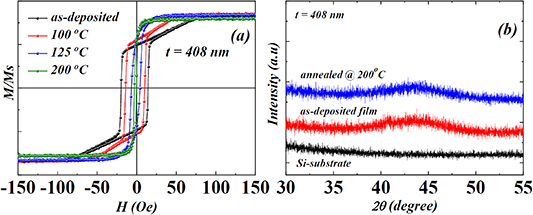

To evaluate the effect of residual stress/strain on the magnetic behaviours, the 408 nm film was subjected to annealing within the temperature range of 100 °C–200 °C for one hour. Figure 4(a) demonstrates the systematic alteration in the hysteresis shape in response to varying annealing temperatures. Specifically, as the annealing temperature increased, the lower slope of the transcritical hysteresis gradually decreased, resulting in reduced values of HK. Ultimately, at an annealing temperature of 200 °C, the transcritical hysteresis underwent a complete transformation into a square-type loop. It is worth mentioning that the HC values have also significantly decreased, resembling the soft magnetic nature commonly observed in amorphous alloys.

Figure 4. (a) Hysteresis loops for a 408 nm film annealed at temperatures ranging from 100 to 200 °C for one hour, (b) XRD pattern of 408 nm film before and after annealing at 200 °C for one hour measured using grazing incidence angle method.

Download figure:

Standard image High-resolution imageThe annealing process for amorphous films can yield two primary effects: it holds the potential to alleviate residual stress within the atomic structure [2], arising from the high λs of the alloy system as well as due to fabrication factors, and simultaneously, it can induce fundamental changes in the material's structural state through atomic diffusion [43]. Figure 4(b) illustrates the XRD pattern of the 408 nm film in both the as-deposited state and after annealing at 200 °C. The XRD pattern demonstrates that the amorphous structure of the film persists post-annealing. When subjected to annealing, the film may mitigate magnetoelastic effects either by reducing residual stress or by transforming into a zero/near-zero magnetostrictive film through the precipitation of a heterogeneous amorphous structure, although not evident from the diffraction pattern. In both scenarios, a weakened magnetoelastic anisotropy allows shape anisotropy to dominate, resulting in a transition of magnetization to an in-plane configuration. In conclusion, it becomes evident that elevated levels of residual stress significantly contribute to the development of perpendicular magnetization, especially when the film thickness exceeds 258 nm.

Similar observations have been reported in the literature, revealing SRT from out-of-plane magnetization to in-plane orientation subsequent to annealing [2, 21, 23, 24]. This phenomenon is linked to the structurally relaxed state of films originally characterized by a high degree of amorphous disorder induced by both intrinsic alloy characteristics (high λs) and extrinsic factors such as the fabrication process. These insights enhance our comprehension of SRT dynamics, particularly in the context of annealed samples, elucidating the intricate interplay involving the contributions of magnetoelastic anisotropy, coupled with residual stress and magnetization, and dominant shape anisotropy once the stress is released in the films. In a previous study by the authors, the research findings emphasized the intricate impact of residual stress—whether compressive or tensile—and its magnitude on the orientation of magnetization within multilayer amorphous systems [44]. The study's conclusion highlighted that the origin of PMA in amorphous films lies in the tensile nature of residual stress. Expanding on these insights, our current research adds further credence to the idea that residual stress, coupled with its consequential magnetoelastic anisotropy, decisively contributes to defining the PMA in thicker amorphous films.

In addition, conclusive findings from in-depth ab-initio calculations, exploring the influence of atomic relaxation on the magnetic characteristics of individual Co adatoms and clusters, reinforce the notion that a robust atomic relaxation of atoms significantly suppresses the emergence of perpendicular magnetization [45]. This highlights the critical role of the intricate interplay of atomic positions in modulating the magnetic behavior of the system, emphasizing the importance of considering the atomic relaxation state, particularly within the context of thin film magnetic systems [21, 45].

Moreover, PMA in amorphous thin films has also been attributed to the 'columnar growth' phenomenon, wherein the microscopic shape anisotropy of the vertical columns plays a decisive role in orienting the magnetization out-of-plane [17]. However, surface morphology and cross-sectional investigations (see figure 1(c)) of the investigated samples reveal a uniformly homogeneous growth pattern, devoid of evidence for columnar growth. This finding conclusively dismisses the possibility of contributions from microscopic shape effects to the observed PMA.

3.3. Low-temperature magnetization dynamics

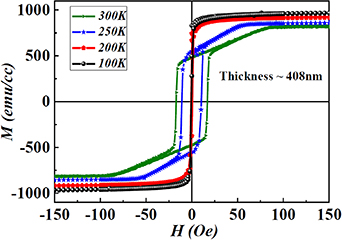

The magnetic hysteresis investigation conducted at low temperatures for the 408 nm film involved a comprehensive examination across the temperature range of 100–300 K, as depicted in figure 5. A systematic decrease in temperature from 300 K coincided with a gradual reduction in the intensity of the perpendicular magnetic component within the transcritical hysteresis loop. This progressive attenuation culminated in a discernible transformation, wherein the transcritical hysteresis loop transformed into simple square-type configurations, characterized by an exceptionally diminutive HC, particularly notable at temperatures ⩽225 K. The discerned temperature-dependent behaviors in both coercivity HC and HK distinctly point towards the discernible influence of a thermal activation mechanism defining the magnetization dynamics within the 408 nm film.

Figure 5. In-plane hysteresis loop of 408 nm film in the temperature range of 100–300 K. The sample was zero fields cooled for the measurements.

Download figure:

Standard image High-resolution imageThis detailed interplay between temperature and magnetic behavior yields valuable insights into the intricate thermomagnetic characteristics of the examined film, thereby prompting further investigation for a more comprehensive understanding of magnetic phenomena in thin film systems. A similar phenomenon was observed by Sharma et al [21] in Co–Fe–Ta–B amorphous thin films. However, the origin of temperature-driven SRT, why spins align in-plane configuration at lower temperatures and reorient in perpendicular configuration close to the room temperature, was not explicitly described by the authors.

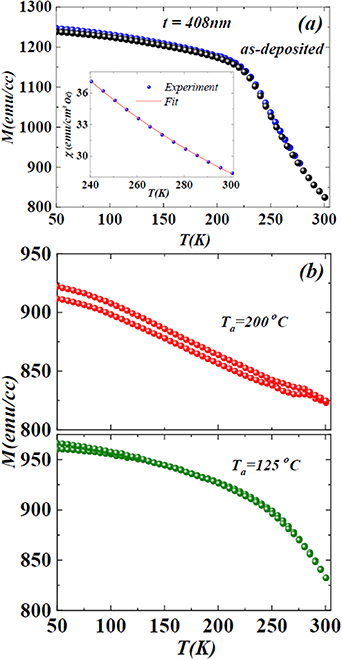

Figure 6 presents the low-temperature M(T) of a 408 nm film. The sample was subjected to cooling from 300 K to 50 K using two distinct modes of magnetization. In the first case, the film was cooled down under a zero magnetic field ZFC, while in the second case, the film was cooled with an applied magnetic field of 10 Oe FC. The M(T) curves for ZFC and FC overlapped across the entire temperature range of 50–300 K, as illustrated in figure 6(a). However, a distinctive two-slope behavior was observed in the M(T) response, which essentially divided the M(T) spectrum into two temperature ranges: (a) 50–225 K and (b) 225–300 K, with a sharp transition occurring at 225 K. This two-slope M(T) behavior indicates that the film experiences different magnetization states as a function of temperature. Figure 6(b) displays the FC-ZFC M(T) for samples that underwent annealing at 125 °C and 200 °C. Notably, the response of the FC-ZFC M(T) curves for annealed films was quite different from that of the as-deposited films. There was no sharp transition at 225 K in the annealed samples. Instead, a noticeable divergence between the ZFC and FC M(T) curves was observed, which became more pronounced for the film annealed at 200 °C.

Figure 6. (a) Temperature dependence of magnetization M (T) in field-cooled (FC) and zero-field-cooled (ZFC) state of magnetization in 10 Oe probe field of 408 nm film, (b) the FC/ZFC magnetization of 408 nm film annealed at 125 °C and 200 °C.

Download figure:

Standard image High-resolution imageThe smooth progression of ZFC and FC M(T) of 408 nm film within the temperature interval of 100–225 K affirms the film's ferromagnetic nature. Nevertheless, a sharp decay in ZFC/FC M(T) at 225 K, which is unexpected for typical soft magnetic amorphous materials, implies a transformation in the film's ferromagnetic state. To explore the nature of this decay in the temperature-dependent magnetization of the film, the Curie–Weiss law, expressed as χ = C/(T−θ), was effectively applied to fit the ZFC M(T), as shown in the inset of figure 6(a). This indicates a magnetic phase transition within the system, leading to a transition from a ferromagnetic state to a paramagnetic state at temperatures ⩾225 K.

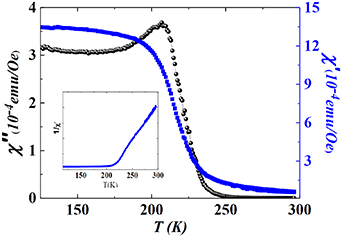

Figure 7 displays the temperature-dependent AC susceptibility of a 408 nm film, probed with a custom-designed susceptometer using a 2 Oe field oscillating at a frequency of 181 Hz. Notably, a sharp transition was observed at 225 K in both the real (χ') and imaginary (χ'') components of the susceptibility. The χ' component exhibited a thermal activation pattern similar to the ZFC/FC M(T) response presented in figure 5(a). The inverse of χ' as a function of temperature, presented as inset of figure 7, shows a sharp transition from a ferromagnetic state to a paramagnetic at 225 K. The real part of the AC susceptibility (χ') exhibited a temperature-dependent behavior similar to the thermal evolution seen in the ZFC and FC M(T) curves, displaying a seemingly uniform Curie–Weiss-type decay. However, χ'' exhibited a pronounced decline to zero at 225 K, manifesting a magnetic phase transition with a Curie temperature of ∼225 K.

Figure 7. Real (χ' ) and imaginary (χ'') AC susceptibility of the 408 nm thin film as a function of temperature performed by applying the oscillating magnetic field of 2 Oe at 181 Hz frequency. The inset represents the relation between 1/ χ' and temperature.

Download figure:

Standard image High-resolution imageThe emergence of temperature-dependent SRT is likely associated with the intrinsic ferromagnetic state within the heterogeneous amorphous films. This suggests that the thermal dynamics within the heterogeneous amorphous structure play a crucial role in driving the observed SRT, where changes in temperature trigger alterations in the magnetic configuration, thereby impacting the overall magnetic behavior of the films. Chien and Unruh [46] conducted an extensive examination into the impact of Boron on the TC of amorphous Fe–B thin films. Their findings led to a significant conclusion: when the atomic percentage of Fe content reaches the range of 40–45%, the amorphous phase of Fe–B undergoes a remarkable transformation, shifting from a ferromagnetic state to a paramagnetic one, with TC falling within the specific temperature range of 200–225 K. Similarly, we suggest that, in Fe–Ni–B–Nb thin film system, the pronounced magnetic transition at 225 K in the M(T) curve is due to the chemical composition of the amorphous phase, which closely approximates the 40%–45% threshold, causing it to become paramagnetic ⩾TC 225 K. However, the scenario becomes entirely different when the samples are annealed at elevated temperatures. The disparity observed between ZFC and FC M(T) indicates that thermal treatment significantly alters the overall structure of the films, resulting in an in-plane magnetization orientation after annealing at 200 °C.

In earlier studies, Alonso et al [47, 48] reported an analogous order-disorder magnetic phase transition within the amorphous matrix of nanograins in granular Fe–Ag thin films obtained through PLD, impacting magnetization reversal behavior based on the magnetic state of the amorphous matrix. This transition notably influenced magnetization reversal behavior, contingent upon the magnetic state of the amorphous matrix. Extending from these observations, we propose a similar origin for the low-temperature SRT in our study. This SRT is primarily driven by the temperature-dependent order-disorder transition occurring within the weakly ferromagnetic amorphous matrix between the densely packed α-Fe regions. The ferromagnetic amorphous matrix undergoes a dynamic magnetic ordering/disordering process as a function of temperature, acting as a decisive barrier for magnetic interactions and playing a pivotal role in shaping the overall magnetic reversal behaviors of the films. Below the critical transition temperature of 225 K, the amorphous matrix undergoes magnetic ordering, facilitating direct exchange interactions between α-Fe regions and resulting in a ferromagnetic-like behavior, as evidenced by a smooth and consistent M(T) curve shown in figure 6. Consequently, this state leads to the emergence of magnetic hysteresis loops with very low HC, characteristic of soft magnetic amorphous materials. Above the transition temperature (225 K), the amorphous matrix transitions into a paramagnetic state, leading to a decline in ferromagnetic exchange interactions between α-Fe regions and an overall decay in the magnetization of the system, as shown in figure 6. As the exchange coupling weakens, the magnetoelastic anisotropy energy emerges as the dominant force, prevailing over shape anisotropy and ultimately facilitating the promotion of perpendicular magnetization in the system.

4. Conclusions

In conclusion, thickness- and temperature-driven SRT in Fe–Ni–B–Nb thin films, featuring a heterogeneous amorphous structure achieved via PLD, provide valuable insights into the role of competing magnetic anisotropies in defining magnetization orientation. We explored a wide range of film thicknesses, spanning from 27 to 408 nm, and conducted a multifaceted analysis encompassing structural investigations, magnetic domain imaging, thickness- and temperature-dependent hysteretic loops, and low-temperature ZFC/FC M(T) and AC susceptibility investigations. The thermogravimetric investigations notably unveiled the heterogeneous amorphous nature of these films, a revelation that was unattainable through conventional structural analysis methods. The spontaneous perpendicular magnetization, evident through transcritical hysteresis loops and the presence of magnetic stripe domains, was attributed to the significant residual stress resulting from the substantial magnetostriction of the alloy system and the thin film deposition process. Additionally, the temperature-driven SRT was traced back to the order-disorder transition within the weak ferromagnetic amorphous phase, characterized by a Curie temperature of ∼225 K. We found that this dynamic state of the amorphous matrix limits the exchange interactions among the highly dense α-Fe regions and hence defines the magnetization reversal as a function of temperature.

Acknowledgments

The authors extend their appreciation to Akihiro Makino from Tohoku University for providing a fabrication facility in the production of alloy targets and Sandeep Nagar from KTH for their assistance in sample fabrication. This article is dedicated to the memory of the late Professor K V Rao, whose thoughtful insights and contributions greatly influenced the thought process behind this work.

Data availability statement

All data that support the findings of this study are included within the article (and any supplementary files).