Abstract

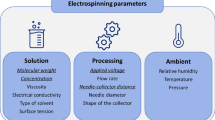

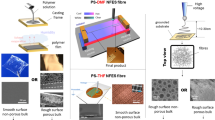

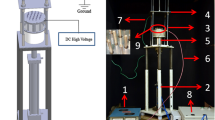

Electrospinning is used to fabricate microscale to nanoscale materials from polymeric solutions based on electrohydrodynamics. Material modifications are achieved through physical and chemical processes, producing diverse material architectures, from laboratory to industrial scales, for conventional and emerging applications. This Primer explains electrospinning technology, encompassing principles, methodologies, equipment, materials, applications, scalability and optimization. The article begins by elucidating the working principles, providing an overview of electrospinning methods and process parameters at laboratory and industrial scales, and discussing emerging equipment. Methods are described for tailoring the composition, architecture and properties of electrospun fibres and fibre assemblies. The versatility of these properties makes electrospun materials suitable for diverse applications spanning environmental, energy and medical applications, textiles, wearables, agriculture and advanced materials. The Primer concludes by discussing the constraints of current electrospinning techniques and offers a perspective on the field’s potential future trajectory.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 1 digital issues and online access to articles

$99.00 per year

only $99.00 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Reneker, D. H. & Chun, I. Nanometre diameter fibres of polymer, produced by electrospinning. Nanotechnology 7, 216 (1996).

Srinivasan, G. & Reneker, D. H. Structure and morphology of small diameter electrospun aramid fibers. Polym. Int. 36, 195–201 (1995).

Xue, J., Wu, T., Dai, Y. & Xia, Y. Electrospinning and electrospun nanofibers: methods, materials, and applications. Chem. Rev. 119, 5298–5415 (2019).

Doshi, J. & Reneker, D. H. Electrospinning process and applications of electrospun fibers. J. Electrost. 35, 151–160 (1995).

Ji, L. & Zhang, X. Generation of activated carbon nanofibers from electrospun polyacrylonitrile–zinc chloride composites for use as anodes in lithium-ion batteries. Electrochem. Commun. 11, 684–687 (2009).

Yu, Y. et al. Encapsulation of Sn@carbon nanoparticles in bamboo-like hollow carbon nanofibers as an anode material in lithium-based batteries. Angew. Chem. Int. Ed. 48, 6485–6489 (2009).

Yoshimoto, H., Shin, Y. M., Terai, H. & Vacanti, J. P. A biodegradable nanofiber scaffold by electrospinning and its potential for bone tissue engineering. Biomaterials 24, 2077–2082 (2003).

Chua, K.-N. et al. Stable immobilization of rat hepatocyte spheroids on galactosylated nanofiber scaffold. Biomaterials 26, 2537–2547 (2005).

Rogers, J. A., Someya, T. & Huang, Y. Materials and mechanics for stretchable electronics. Science 327, 1603–1607 (2010).

Miyamoto, A. et al. Inflammation-free, gas-permeable, lightweight, stretchable on-skin electronics with nanomeshes. Nat. Nanotechnol. 12, 907–913 (2017).

Huang, Z.-M., Zhang, Y.-Z., Kotaki, M. & Ramakrishna, S. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos. Sci. Technol. 63, 2223–2253 (2003).

Yang, F., Murugan, R., Wang, S. & Ramakrishna, S. Electrospinning of nano/micro scale poly(l-lactic acid) aligned fibers and their potential in neural tissue engineering. Biomaterials 26, 2603–2610 (2005).

Mo, X. M., Xu, C. Y., Kotaki, M. & Ramakrishna, S. Electrospun P(LLA-CL) nanofiber: a biomimetic extracellular matrix for smooth muscle cell and endothelial cell proliferation. Biomaterials 25, 1883–1890 (2004).

Khin, M. M., Nair, A. S., Babu, V. J., Murugan, R. & Ramakrishna, S. A review on nanomaterials for environmental remediation. Energy Environ. Sci. 5, 8075–8109 (2012).

Barhate, R. S. & Ramakrishna, S. Nanofibrous filtering media: filtration problems and solutions from tiny materials. J. Membr. Sci. 296, 1–8 (2007).

Yoon, K. et al. High flux ultrafiltration membranes based on electrospun nanofibrous PAN scaffolds and chitosan coating. Polymer 47, 2434–2441 (2006).

Dou, L. et al. High‐entropy‐nanofibers enhanced polymer nanocomposites for high‐performance energy storage. Adv. Energy Mater. 13, 2203925 (2023).

Ji, L., Lin, Z., Medford, A. J. & Zhang, X. Porous carbon nanofibers from electrospun polyacrylonitrile/SiO2 composites as an energy storage material. Carbon 47, 3346–3354 (2009).

Zhu, C., Mu, X., van Aken, P. A., Yu, Y. & Maier, J. Single-layered ultrasmall nanoplates of MoS2 embedded in carbon nanofibers with excellent electrochemical performance for lithium and sodium storage. Angew. Chem. Int. Ed. 53, 2152–2156 (2014).

Lee, S. et al. Nanomesh pressure sensor for monitoring finger manipulation without sensory interference. Science 370, 966–970 (2020).

Gao, Q. et al. Breathable and flexible polymer membranes with mechanoresponsive electric resistance. Adv. Funct. Mater. 30, 1907555 (2020).

Li, Z. et al. Highly sensitive and stable humidity nanosensors based on LiCl doped TiO2 electrospun nanofibers. J. Am. Chem. Soc. 130, 5036–5037 (2008).

Bairagi, S. et al. High-performance triboelectric nanogenerators based on commercial textiles: electrospun nylon 66 nanofibers on silk and PVDF on polyester. ACS Appl. Mater. Interfaces 14, 44591–44603 (2022).

Li, X. et al. Selective spectral absorption of nanofibers for color-preserving daytime radiative cooling. Mater. Horiz. 10, 2487–2495 (2023).

Shi, C. et al. Oregano essential oil/β-cyclodextrin inclusion compound polylactic acid/polycaprolactone electrospun nanofibers for active food packaging. Chem. Eng. J. 445, 136746 (2022).

Dehnad, D. et al. Bioactive-loaded nanovesicles embedded within electrospun plant protein nanofibers; a double encapsulation technique. Food Hydrocoll. 141, 108683 (2023).

Rezaeinia, H., Ghorani, B., Emadzadeh, B. & Tucker, N. Electrohydrodynamic atomization of balangu (Lallemantia royleana) seed gum for the fast-release of Mentha longifolia L. essential oil: characterization of nano-capsules and modeling the kinetics of release. Food Hydrocoll. 93, 374–385 (2019).

Krishnamoorthy, V. & Rajiv, S. Tailoring electrospun polymer blend carriers for nutrient delivery in seed coating for sustainable agriculture. J. Clean. Prod. 177, 69–78 (2018).

Lan, L. et al. Breathable nanogenerators for an on-plant self-powered sustainable agriculture system. ACS Nano 15, 5307–5315 (2021).

Ji, D. et al. The Kirkendall effect for engineering oxygen vacancy of hollow Co3O4 nanoparticles toward high-performance portable zinc–air batteries. Angew. Chem. Int. Ed. 58, 13840–13844 (2019).

Li, M. et al. Ni strongly coupled with Mo2C encapsulated in nitrogen-doped carbon nanofibers as robust bifunctional catalyst for overall water splitting. Adv. Energy Mater. 9, 1803185 (2019).

Luo, C. J., Stoyanov, S. D., Stride, E., Pelan, E. & Edirisinghe, M. Electrospinning versus fibre production methods: from specifics to technological convergence. Chem. Soc. Rev. 41, 4708 (2012).

Li, D. & Xia, Y. N. Electrospinning of nanofibers: reinventing the wheel? Adv. Mater. 16, 1151–1170 (2004).

Li, L. et al. Electrospun hollow nanofibers for advanced secondary batteries. Nano Energy 39, 111–139 (2017).

Meng, X. et al. Hierarchical triphase diffusion photoelectrodes for photoelectrochemical gas/liquid flow conversion. Nat. Commun. 14, 2643 (2023).

Lauricella, M., Succi, S., Zussman, E., Pisignano, D. & Yarin, A. L. Models of polymer solutions in electrified jets and solution blowing. Rev. Mod. Phys. 92, 035004 (2020).

Yan, Z. et al. Nanobiology dependent therapeutic convergence between biocompatibility and bioeffectiveness of graphene oxide quantum dot scaffold for immuno-inductive angiogenesis and nerve regeneration. Adv. Funct. Mater. 33, 2211709 (2023).

Ritzau-Reid, K. I. et al. Microfibrous scaffolds guide stem cell lumenogenesis and brain organoid engineering. Adv. Mater. 35, e2300305 (2023).

Zhou, X. et al. Flowerbed-inspired biomimetic scaffold with rapid internal tissue infiltration and vascularization capacity for bone repair. ACS Nano 17, 5140–5156 (2023).

Dai, X. et al. Hybrid biofabrication of neurosecretory structures as a model for neurosecretion. Int. J. Bioprint. 9, 129–141 (2023).

Cheng, R. et al. In-situ synthesis of stable perovskite quantum dots in core-shell nanofibers via microfluidic electrospinning. Chin. Chem. Lett. 34, 107384 (2023).

Brown, T. D., Dalton, P. D. & Hutmacher, D. W. Melt electrospinning today: an opportune time for an emerging polymer process. Prog. Polym. Sci. 56, 116–166 (2016).

Madruga, L. Y. C. & Kipper, M. J. Expanding the repertoire of electrospinning: new and emerging biopolymers, techniques, and applications. Adv. Healthc. Mater. 11, 2101979 (2022).

Gao, Q. et al. Biological tissue-inspired ultrasoft, ultrathin, and mechanically enhanced microfiber composite hydrogel for flexible bioelectronics. Nano Micro Lett. 15, 139 (2023).

Tebyetekerwa, M. & Ramakrishna, S. What is next for electrospinning? Matter 2, 279–283 (2020).

Reneker, D. H. & Yarin, A. L. Electrospinning jets and polymer nanofibers. Polymer 49, 2387–2425 (2008).

Taylor, G. I. Disintegration of water drops in an electric field. Proc. R. Soc. Lond. 280, 383–397 (1964).

Taylor, G. I. Electrically driven jets. Proc. R. Soc. Lond. 313, 453 (1969).

Han, D. & Steckl, A. J. Coaxial electrospinning formation of complex polymer fibers and their applications. ChemPlusChem 84, 1453–1497 (2019).

Sivan, M. et al. AC electrospinning: impact of high voltage and solvent on the electrospinnability and productivity of polycaprolactone electrospun nanofibrous scaffolds. Mater. Today Chem. 26, 101025 (2022).

Erben, J., Kalous, T. & Chvojka, J. AC bubble electrospinning technology for preparation of nanofibrous mats. ACS Omega 5, 8268–8271 (2020).

Joy, N., Anuraj, R., Viravalli, A., Dixit, H. N. & Samavedi, S. Coupling between voltage and tip-to-collector distance in polymer electrospinning: insights from analysis of regimes, transitions and cone/jet features. Chem. Eng. Sci. 230, 116200 (2021).

Hsu, Y.-H., Chan, C.-H. & Tang, W. C. Alignment of multiple electrospun piezoelectric fiber bundles across serrated gaps at an incline: a method to generate textile strain sensors. Sci. Rep. 7, 15436 (2017).

Okutan, N., Terzi, P. & Altay, F. Affecting parameters on electrospinning process and characterization of electrospun gelatin nanofibers. Food Hydrocoll. 39, 19–26 (2014).

Li, Y. et al. Developments of advanced electrospinning techniques: a critical review. Adv. Mater. Technol. 6, 2100410 (2021).

Li, D., Wang, Y. & Xia, Y. Electrospinning nanofibers as uniaxially aligned arrays and layer-by-layer stacked films. Adv. Mater. 16, 361–366 (2004).

Li, D., Wang, Y. & Xia, Y. Electrospinning of polymeric and ceramic nanofibers as uniaxially aligned arrays. Nano Lett. 3, 1167–1171 (2003).

Dalton, P. D., Klee, D. & Möller, M. Electrospinning with dual collection rings. Polymer 46, 611–614 (2005).

Wu, J. et al. Electrospun nanoyarn scaffold and its application in tissue engineering. Mater. Lett. 89, 146–149 (2012).

Wei, L., Sun, R., Liu, C., Xiong, J. & Qin, X. Mass production of nanofibers from needleless electrospinning by a novel annular spinneret. Mater. Des. 179, 107885 (2019).

Zhang, X., Xie, L., Wang, X., Shao, Z. & Kong, B. Electrospinning super-assembly of ultrathin fibers from single- to multi-Taylor cone sites. Appl. Mater. Today 26, 101272 (2022).

Niu, H. & Lin, T. Fiber generators in needleless electrospinning. J. Nanomater. 2012, 725950 (2012).

Silva, P. M., Torres‐Giner, S., Vicente, A. A. & Cerqueira, M. A. Management of operational parameters and novel spinneret configurations for the electrohydrodynamic processing of functional polymers. Macromol. Mater. Eng. 307, 2100858 (2022).

Hohman, M. M., Shin, M., Rutledge, G. & Brenner, M. P. Electrospinning and electrically forced jets. II. applications. Phys. Fluids 13, 2221–2236 (2001).

Lee, J. J. L., Andriyana, A., Ang, B. C., Huneau, B. & Verron, E. Electrospun PMMA polymer blend nanofibrous membrane: electrospinability, surface morphology and mechanical response. Mater. Res. Express 5, 065311 (2018).

Singh, M., Chauhan, D., Das, A. K., Iqbal, Z. & Solanki, P. R. PVA/PMMA polymer blended composite electrospun nanofibers mat and their potential use as an anti-biofilm product. J. Appl. Polym. Sci. 138, 50340 (2021).

Mailley, D., Hébraud, A. & Schlatter, G. A review on the impact of humidity during electrospinning: from the nanofiber structure engineering to the applications. Macromol. Mater. Eng. 306, 2100115 (2021).

Marquez, A. L., Emilio Gareis, I., Jose Dias, F., Gerhard, C. & Florencia Lezcano, M. Methods to characterize electrospun scaffold morphology: a critical review. Polymers 14, 467 (2022).

Tan, E. P. S. & Lim, C. T. Novel approach to tensile testing of micro- and nanoscale fibers. Rev. Sci. Instrum. 75, 2581–2585 (2004).

Shibata, Y. & Miyazaki, T. New methods for the evaluation of bone quality. Nanoindentation protocol for measurement of bone mechanical properties of material level [Japanese]. Clin. Calcium 27, 1139–1145 (2017).

Srivastava, R. Synthesis and characterization techniques of nanomaterials. Int. J. Green. Nanotechnol. 4, 17–27 (2012).

Hodge, J. G. & Quint, C. Improved porosity of electrospun poly(lactic-co-glycolic) scaffolds by sacrificial microparticles enhances cellular infiltration compared to sacrificial microfiber. J. Biomater. Appl. 37, 77–88 (2022).

Gu, J. et al. Electrostatic-modulated interfacial crosslinking and waterborne emulsion coating toward waterproof, breathable, and antifouling fibrous membranes. Chem. Eng. J. 454, 140439 (2023).

Zhou, M. et al. Continuously fabricated nano/micro aligned fiber based waterproof and breathable fabric triboelectric nanogenerators for self-powered sensing systems. Nano Energy 104, 107885 (2022).

Qiu, Q. et al. Silane-functionalized polyionenes-coated cotton fabrics with potent antimicrobial and antiviral activities. Biomaterials 284, 121470 (2022).

Al-Abduljabbar, A. & Farooq, I. Electrospun polymer nanofibers: processing, properties, and applications. Polymers 15, 65 (2022).

Tian, L. et al. A humidity‐induced nontemplating route toward hierarchical porous carbon fiber hybrid for efficient bifunctional oxygen catalysis. Small 16, 2001743 (2020).

Ding, Y., Hou, H., Zhao, Y., Zhu, Z. & Fong, H. Electrospun polyimide nanofibers and their applications. Prog. Polym. Sci. 61, 67–103 (2016).

Cho, D., Zhou, H., Cho, Y., Audus, D. & Joo, Y. L. Structural properties and superhydrophobicity of electrospun polypropylene fibers from solution and melt. Polymer 51, 6005–6012 (2010).

Xu, X. et al. Recent progress in electrospun nanofibers and their applications in heavy metal wastewater treatment. Front. Chem. Sci. Eng. 17, 249–275 (2023).

Jang, J. et al. Rapid production of large-area, transparent and stretchable electrodes using metal nanofibers as wirelessly operated wearable heaters. NPG Asia Mater. 9, e432 (2017).

Li, D. & Xia, Y. Fabrication of titania nanofibers by electrospinning. Nano Lett. 3, 555–560 (2003).

Deng, L. & Zhang, H. Recent advances in probiotics encapsulation by electrospinning. ES Food Agrofor. 2, 3–12 (2020).

Hong, J., Yeo, M., Yang, G. H. & Kim, G. Cell-electrospinning and its application for tissue engineering. Int. J. Mol. Sci. 20, 6208 (2019).

Zussman, E. Encapsulation of cells within electrospun fibers: encapsulation of cells. Polym. Adv. Technol. 22, 366–371 (2011).

Feng, K. et al. Improved viability and thermal stability of the probiotics encapsulated in a novel electrospun fiber mat. J. Agric. Food Chem. 66, 10890–10897 (2018).

Sahu, S. et al. Role of nanofibers in encapsulation of the whole cell. Int. J. Polym. Sci. 2021, 1–9 (2021).

Koombhongse, S., Liu, W. & Reneker, D. H. Flat polymer ribbons and other shapes by electrospinning. J. Polym. Sci. Part. B Polym. Phys. 39, 2598–2606 (2001).

Mann‐Lahav, M. et al. Electrospun ionomeric fibers with anion conducting properties. Adv. Funct. Mater. 30, 1901733 (2020).

Lim, J.-M., Moon, J. H., Yi, G.-R., Heo, C.-J. & Yang, S.-M. Fabrication of one-dimensional colloidal assemblies from electrospun nanofibers. Langmuir 22, 3445–3449 (2006).

Han, T., Reneker, D. H. & Yarin, A. L. Buckling of jets in electrospinning. Polymer 48, 6064–6076 (2007).

Liu, S. et al. Direct microscopic observation of shish-kebab structure in high-temperature electrospun iPP fibers. Mater. Lett. 172, 149–152 (2016).

Wang, B., Li, B., Xiong, J. & Li, C. Y. Hierarchically ordered polymer nanofibers via electrospinning and controlled polymer crystallization. Macromolecules 41, 9516–9521 (2008).

Sun, Z., Zussman, E., Yarin, A. L., Wendorff, J. H. & Greiner, A. Compound core–shell polymer nanofibers by co-electrospinning. Adv. Mater. 15, 1929–1932 (2003).

Liu, Z., Sun, D. D., Guo, P. & Leckie, J. O. An efficient bicomponent TiO2/SnO2 nanofiber photocatalyst fabricated by electrospinning with a side-by-side dual spinneret method. Nano Lett. 7, 1081–1085 (2007).

Zhao, Y., Cao, X. & Jiang, L. Bio-mimic multichannel microtubes by a facile method. J. Am. Chem. Soc. 129, 764–765 (2007).

Li, D. & Xia, Y. Direct fabrication of composite and ceramic hollow nanofibers by electrospinning. Nano Lett. 4, 933–938 (2004).

Li, Z., Zhang, J. T., Chen, Y. M., Li, J. & Lou, X. W. Pie-like electrode design for high-energy density lithium–sulfur batteries. Nat. Commun. 6, 8850 (2015).

Ji, D. et al. Design of 3-dimensional hierarchical architectures of carbon and highly active transition metals (Fe, Co, Ni) as bifunctional oxygen catalysts for hybrid lithium–air batteries. Chem. Mater. 29, 1665–1675 (2017).

Tian, J. et al. Preparation of Janus microfibers with magnetic and fluorescence functionality via conjugate electro-spinning. Mater. Des. 170, 107701 (2019).

Ranjbar-Mohammadi, M., Zamani, M., Prabhakaran, M. P., Bahrami, S. H. & Ramakrishna, S. Electrospinning of PLGA/gum tragacanth nanofibers containing tetracycline hydrochloride for periodontal regeneration. Mater. Sci. Eng. C. 58, 521–531 (2016).

Ali, N. et al. Porous, flexible, and core-shell structured carbon nanofibers hybridized by tin oxide nanoparticles for efficient carbon dioxide capture. J. Colloid Interface Sci. 560, 379–387 (2020).

Maccaferri, E. et al. Rubbery nanofibers by co-electrospinning of almost immiscible NBR and PCL blends. Mater. Des. 186, 108210 (2020).

Pal, P. et al. Bilayered nanofibrous 3D hierarchy as skin rudiment by emulsion electrospinning for burn wound management. Biomater. Sci. 5, 1786–1799 (2017).

Yang, Y., Li, X., Qi, M., Zhou, S. & Weng, J. Release pattern and structural integrity of lysozyme encapsulated in core–sheath structured poly(dl-lactide) ultrafine fibers prepared by emulsion electrospinning. Eur. J. Pharm. Biopharm. 69, 106–116 (2008).

Shen, L. et al. Highly porous nanofiber-supported monolayer graphene membranes for ultrafast organic solvent nanofiltration. Sci. Adv. 7, eabg6263 (2021).

Lu, T.-D. et al. Electrospun nanofiber substrates that enhance polar solvent separation from organic compounds in thin-film composites. J. Mater. Chem. A 6, 15047–15056 (2018).

Rezabeigi, E., Wood-Adams, P. M. & Demarquette, N. R. Complex morphology formation in electrospinning of binary and ternary poly(lactic acid) solutions. Macromolecules 51, 4094–4107 (2018).

Xue, J., Xie, J., Liu, W. & Xia, Y. Electrospun nanofibers: new concepts, materials, and applications. Acc. Chem. Res. 50, 1976–1987 (2017).

Xu, C. Y., Inai, R., Kotaki, M. & Ramakrishna, S. Aligned biodegradable nanofibrous structure: a potential scaffold for blood vessel engineering. Biomaterials 25, 877–886 (2004).

Sundaray, B. et al. Electrospinning of continuous aligned polymer fibers. Appl. Phys. Lett. 84, 1222–1224 (2004).

Yang, D., Lu, B., Zhao, Y. & Jiang, X. Fabrication of aligned fibrous arrays by magnetic electrospinning. Adv. Mater. 19, 3702–3706 (2007).

Liu, Y., Zhang, X., Xia, Y. & Yang, H. Magnetic-field-assisted electrospinning of aligned straight and wavy polymeric nanofibers. Adv. Mater. 22, 2454–2457 (2010).

Xie, J. et al. Radially aligned, electrospun nanofibers as dural substitutes for wound closure and tissue regeneration applications. ACS Nano 4, 5027–5036 (2010).

Osali, S., Ghiyasi, Y., Esfahani, H., Jose, R. & Ramakrishna, S. Electrospun nanomembranes at the liquid–liquid and solid–liquid interface—a review. Mater. Today 67, 151–177 (2023).

Abdelaziz, A. G. et al. A review of 3D polymeric scaffolds for bone tissue engineering: principles, fabrication techniques, immunomodulatory roles, and challenges. Bioengineering 10, 204 (2023).

Brown, T. D., Dalton, P. D. & Hutmacher, D. W. Direct writing by way of melt electrospinning. Adv. Mater. 23, 5651–5657 (2011).

Vong, M., Diaz Sanchez, F. J., Keirouz, A., Nuansing, W. & Radacsi, N. Ultrafast fabrication of nanofiber-based 3D macrostructures by 3D electrospinning. Mater. Des. 208, 109916 (2021).

Bao, M. et al. Electrospun biomimetic fibrous scaffold from shape memory polymer of PDLLA- co-TMC for bone tissue engineering. ACS Appl. Mater. Interfaces 6, 2611–2621 (2014).

Wei, W. et al. Ultrathin flexible electrospun EVA nanofiber composite with electrothermally-driven shape memory effect for electromagnetic interference shielding. Chem. Eng. J. 446, 137135 (2022).

Huang, Y. et al. Electrohydrodynamic direct-writing. Nanoscale 5, 12007 (2013).

Sun, D., Chang, C., Li, S. & Lin, L. Near-field electrospinning. Nano Lett. 6, 839–842 (2006).

Partheniadis, I., Nikolakakis, I., Laidmäe, I. & Heinämäki, J. A mini-review: needleless electrospinning of nanofibers for pharmaceutical and biomedical applications. Processes 8, 673 (2020).

Yarin, A. L. & Zussman, E. Upward needleless electrospinning of multiple nanofibers. Polymer 45, 2977–2980 (2004).

He, J.-H., Liu, Y., Xu, L., Yu, J.-Y. & Sun, G. BioMimic fabrication of electrospun nanofibers with high-throughput. Chaos Solitons Fractals 37, 643–651 (2008).

Lukas, D., Sarkar, A. & Pokorny, P. Self-organization of jets in electrospinning from free liquid surface: a generalized approach. J. Appl. Phys. 103, 084309 (2008).

Jiang, G., Zhang, S. & Qin, X. High throughput of quality nanofibers via one stepped pyramid-shaped spinneret. Mater. Lett. 106, 56–58 (2013).

Niu, H., Wang, X. & Lin, T. Needleless electrospinning: influences of fibre generator geometry. J. Text. Inst. 103, 787–794 (2012).

Wang, X., Niu, H., Wang, X. & Lin, T. Needleless electrospinning of uniform nanofibers using spiral coil spinnerets. J. Nanomater. 2012, 1–9 (2012).

Xiong, J. et al. Mass production of high-quality nanofibers via constructing pre-Taylor cones with high curvature on needleless electrospinning. Mater. Des. 197, 109247 (2021).

Um, I. C., Fang, D., Hsiao, B. S., Okamoto, A. & Chu, B. Electro-spinning and electro-blowing of hyaluronic acid. Biomacromolecules 5, 1428–1436 (2004).

Sóti, P. L. et al. Comparison of spray drying, electroblowing and electrospinning for preparation of Eudragit E and itraconazole solid dispersions. Int. J. Pharm. 494, 23–30 (2015).

Démuth, B. et al. Investigation of deteriorated dissolution of amorphous itraconazole: description of incompatibility with magnesium stearate and possible solutions. Mol. Pharm. 14, 3927–3934 (2017).

Paajanen, J. et al. Novel electroblowing synthesis of submicron zirconium dioxide fibers: effect of fiber structure on antimony(V) adsorption. Nanoscale Adv. 1, 4373–4383 (2019).

Paajanen, J. et al. Novel electroblowing synthesis of tin dioxide and composite tin dioxide/silicon dioxide submicron fibers for cobalt(II) uptake. RSC Adv. 11, 15245–15257 (2021).

Smit, E., Bűttner, U. & Sanderson, R. D. Continuous yarns from electrospun fibers. Polymer 46, 2419–2423 (2005).

Teo, W.-E., Gopal, R., Ramaseshan, R., Fujihara, K. & Ramakrishna, S. A dynamic liquid support system for continuous electrospun yarn fabrication. Polymer 48, 3400–3405 (2007).

Yousefzadeh, M., Latifi, M., Teo, W.-E., Amani-Tehran, M. & Ramakrishna, S. Producing continuous twisted yarn from well-aligned nanofibers by water vortex. Polym. Eng. Sci. 51, 323–329 (2011).

Kamireddi, D., Street, R. M. & Schauer, C. L. Electrospun nanoyarns: a comprehensive review of manufacturing methods and applications. Polym. Eng. Sci. 63, 677–690 (2023).

Liao, X. et al. High strength in combination with high toughness in robust and sustainable polymeric materials. Science 366, 1376–1379 (2019).

Al-Dhahebi, A. M. et al. Electrospinning research and products: the road and the way forward. Appl. Phys. Rev. 9, 011319 (2022).

Shi, L., Liu, X., Wang, W., Jiang, L. & Wang, S. A self‐pumping dressing for draining excessive biofluid around wounds. Adv. Mater. 31, e1804187 (2018).

Abdulhamid, M. A. & Muzamil, K. Recent progress on electrospun nanofibrous polymer membranes for water and air purification: a review. Chemosphere 310, 136886 (2023).

Zhang, Z., Ji, D., He, H. & Ramakrishna, S. Electrospun ultrafine fibers for advanced face masks. Mater. Sci. Eng. R. Rep. 143, 100594 (2021).

Aghaei-Zarch, S. M. et al. Non-coding RNAs: an emerging player in particulate matter 2.5-mediated toxicity. Int. J. Biol. Macromol. 235, 123790 (2023).

Koo, W.-T. et al. Hierarchical metal–organic framework-assembled membrane filter for efficient removal of particulate matter. ACS Appl. Mater. Interfaces 10, 19957–19963 (2018).

Wen, F. et al. Association of long-term exposure to air pollutant mixture and incident cardiovascular disease in a highly polluted region of China. Environ. Pollut. 328, 121647 (2023).

Rao, Y. et al. Biocompatible curcumin coupled nanofibrous membrane for pathogens sterilization and isolation. J. Membr. Sci. 661, 120885 (2022).

Fu, J., Liu, T., Binte Touhid, S. S., Fu, F. & Liu, X. Functional textile materials for blocking COVID-19 transmission. ACS Nano 17, 1739–1763 (2023).

Kadam, V. et al. Electrospun bilayer nanomembrane with hierarchical placement of bead-on-string and fibers for low resistance respiratory air filtration. Sep. Purif. Technol. 224, 247–254 (2019).

Hao, J., Chattopadhyay, S. & Rutledge, G. C. Chemical separation in a binary liquid aerosol by filtration using electrospun membranes. Chem. Eng. J. 382, 122924 (2020).

Burgard, M. et al. Mesostructured nonwovens with penguin downy feather-like morphology — top-down combined with bottom-up. Adv. Funct. Mater. 29, 1903166 (2019).

Bian, Y., Wang, S., Zhang, L. & Chen, C. Influence of fiber diameter, filter thickness, and packing density on PM2.5 removal efficiency of electrospun nanofiber air filters for indoor applications. Build. Env. 170, 106628 (2020).

Jiang, S., Schmalz, H., Agarwal, S. & Greiner, A. Electrospinning of ABS nanofibers and their high filtration performance. Adv. Fiber Mater. 2, 34–43 (2020).

Kadam, V. V., Wang, L. & Padhye, R. Electrospun nanofibre materials to filter air pollutants — a review. J. Ind. Text. 47, 2253–2280 (2018).

Oldal, D. G., Topuz, F., Holtzl, T. & Szekely, G. Green electrospinning of biodegradable cellulose acetate nanofibrous membranes with tunable porosity. ACS Sustain. Chem. Eng. 11, 994–1005 (2023).

Xiong, J. et al. Multi-scale nanoarchitectured fibrous networks for high-performance, self-sterilization, and recyclable face masks. Small 18, 2105570 (2022).

Foong, C. Y., Wirzal, M. D. H. & Bustam, M. A. A review on nanofibers membrane with amino-based ionic liquid for heavy metal removal. J. Mol. Liq. 297, 111793 (2020).

Ahmadijokani, F. et al. Electrospun nanofibers of chitosan/polyvinyl alcohol/UiO-66/nanodiamond: versatile adsorbents for wastewater remediation and organic dye removal. Chem. Eng. J. 457, 141176 (2023).

Bao, J. et al. Multi-functional polyethersulfone nanofibrous membranes with ultra-high adsorption capacity and ultra-fast removal rates for dyes and bacteria. J. Mater. Sci. Technol. 78, 131–143 (2021).

Huang, X., Hadi, P., Joshi, R., Alhamzani, A. G. & Hsiao, B. S. A comparative study of mechanism and performance of anionic and cationic dialdehyde nanocelluloses for dye adsorption and separation. ACS Omega 8, 8634–8649 (2023).

Wu, K. et al. The simultaneous adsorption of nitrate and phosphate by an organic-modified aluminum–manganese bimetal oxide: adsorption properties and mechanisms. Appl. Surf. Sci. 478, 539–551 (2019).

Nthumbi, R. M. & Ngila, J. C. Electrospun and functionalized PVDF/PAN nanocatalyst-loaded composite for dechlorination and photodegradation of pesticides in contaminated water. Environ. Sci. Pollut. Res. 23, 20214–20231 (2016).

Ghiasvand, S. et al. Application of polystyrene nanofibers filled with sawdust as separator pads for separation of oil spills. Process. Saf. Environ. Prot. 146, 161–168 (2021).

Aghalari, Z., Dahms, H.-U., Sillanpää, M., Sosa-Hernandez, J. E. & Parra-Saldívar, R. Effectiveness of wastewater treatment systems in removing microbial agents: a systematic review. Glob. Health 16, 13 (2020).

Wang, H. et al. Hepatitis E virus genotype 3 strains and a plethora of other viruses detected in raw and still in tap water. Water Res. 168, 115141 (2020).

Cui, J. et al. Electrospun nanofiber membranes for wastewater treatment applications. Sep. Purif. Technol. 250, 117116 (2020).

Yan, X. et al. Recent progress in the removal of mercury ions from water based MOFs materials. Coord. Chem. Rev. 443, 214034 (2021).

Fahimirad, S., Fahimirad, Z. & Sillanpää, M. Efficient removal of water bacteria and viruses using electrospun nanofibers. Sci. Total. Environ. 751, 141673 (2021).

Rajapaksha, P. et al. Broad spectrum antibacterial zinc oxide-reduced graphene oxide nanocomposite for water depollution. Mater. Today Chem. 27, 101242 (2023).

Piao, H. et al. Ultra-low power light driven lycopodium-like nanofiber membrane reinforced by PET braid tube with robust pollutants removal and regeneration capacity based on photo-Fenton catalysis. Chem. Eng. J. 450, 138204 (2022).

Aravind, M. et al. Hydrothermally synthesized Ag–TiO2 nanofibers (NFs) for photocatalytic dye degradation and antibacterial activity. Chemosphere 321, 138077 (2023).

Norouzi, M., Fazeli, A. & Tavakoli, O. Phenol contaminated water treatment by photocatalytic degradation on electrospun Ag/TiO2 nanofibers: optimization by the response surface method. J. Water Process. Eng. 37, 101489 (2020).

Wang, Q., Hu, L., Ma, H., Venkateswaran, S. & Hsiao, B. S. High-flux nanofibrous composite reverse osmosis membrane containing interfacial water channels for desalination. ACS Appl. Mater. Interfaces 15, 26199–26214 (2023).

Li, H.-N. et al. A self-descaling Janus nanofibrous evaporator enabled by a “moving interface” for durable solar-driven desalination of hypersaline water. J. Mater. Chem. A 10, 20856–20865 (2022).

Ura, D. P. et al. Surface potential driven water harvesting from fog. ACS Nano 15, 8848–8859 (2021).

Hussey, G. S., Dziki, J. L. & Badylak, S. F. Extracellular matrix-based materials for regenerative medicine. Nat. Rev. Mater. 3, 159–173 (2018).

Xie, X. et al. Electrospinning nanofiber scaffolds for soft and hard tissue regeneration. J. Mater. Sci. Technol. 59, 243–261 (2020).

Yao, T. et al. Thiol-ene conjugation of a VEGF peptide to electrospun scaffolds for potential applications in angiogenesis. Bioact. Mater. 20, 306–317 (2023).

Xi, K. et al. Microenvironment-responsive immunoregulatory electrospun fibers for promoting nerve function recovery. Nat. Commun. 11, 4504 (2020).

Liu, H. et al. Recent progress of electrospun herbal medicine nanofibers. Biomolecules 13, 184 (2023).

Pattnaik, S., Swain, K. & Ramakrishna, S. Optimal delivery of poorly soluble drugs using electrospun nanofiber technology: challenges, state of the art, and future directions. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnol. 15, e1859 (2023).

Pandey, G. et al. Multilayered nanofibrous scaffold of polyvinyl alcohol/gelatin/poly(lactic-co-glycolic acid) enriched with hemostatic/antibacterial agents for rapid acute hemostatic wound healing. Int. J. Pharm. 638, 122918 (2023).

Jayasinghe, S. N. Unspooling the history of cell electrospinning. Matter 5, 4–7 (2022).

Jayasinghe, S. N. Cell electrospinning: revolutionising cell scaffolding for healthcare. Adv. Biol. 7, e2300224 (2023).

Kong, B. et al. Fiber reinforced GelMA hydrogel to induce the regeneration of corneal stroma. Nat. Commun. 11, 1435 (2020).

Shalumon, K. T. et al. Braided suture-reinforced fibrous yarn bundles as a scaffold for tendon tissue engineering in extensor digitorum tendon repair. Chem. Eng. J. 454, 140366 (2023).

Zhang, M. et al. Development of tropoelastin-functionalized anisotropic PCL scaffolds for musculoskeletal tissue engineering. Regen. Biomater. 10, rbac087 (2023).

Wu, Y., Wang, L., Guo, B. & Ma, P. X. Interwoven aligned conductive nanofiber yarn/hydrogel composite scaffolds for engineered 3D cardiac anisotropy. ACS Nano 11, 5646–5659 (2017).

Yang, Q. et al. Development of cell adhesive and inherently antibacterial polyvinyl alcohol/polyethylene oxide nanofiber scaffolds via incorporating chitosan for tissue engineering. Int. J. Biol. Macromol. 236, 124004 (2023).

Taemeh, M. A., Shiravandi, A., Korayem, M. A. & Daemi, H. Fabrication challenges and trends in biomedical applications of alginate electrospun nanofibers. Carbohydr. Polym. 228, 115419 (2020).

Tiwari, N. et al. Recent progress in polymeric biomaterials and their potential applications in skin regeneration and wound care management. J. Drug. Deliv. Sci. Technol. 82, 104319 (2023).

Habibi, S. et al. A bilayer mupirocin/bupivacaine-loaded wound dressing based on chitosan/poly(vinyl alcohol) nanofibrous mat: preparation, characterization, and controlled drug release. Int. J. Biol. Macromol. 240, 124399 (2023).

Mao, Y. et al. Electrospun polymers: using devices to enhance their potential for biomedical applications. React. Funct. Polym. 186, 105568 (2023).

Allizond, V. et al. Facile one-step electrospinning process to prepare AgNPs-loaded PLA and PLA/PEO mats with antibacterial activity. Polymers 15, 1470 (2023).

Yi, N. et al. Highly hygroscopicity and antioxidant nanofibrous dressing base on alginate for accelerating wound healing. Colloids Surf. B Biointerfaces 225, 113240 (2023).

Yu, H. et al. Multifunctional porous poly(l-lactic acid) nanofiber membranes with enhanced anti-inflammation, angiogenesis and antibacterial properties for diabetic wound healing. J. Nanobiotechnol. 21, 110 (2023).

Yu, B. et al. Asymmetric wettable composite wound dressing prepared by electrospinning with bioinspired micropatterning enhances diabetic wound healing. ACS Appl. Bio Mater. 3, 5383–5394 (2020).

Kumar, M., Hilles, A. R., Ge, Y., Bhatia, A. & Mahmood, S. A review on polysaccharides mediated electrospun nanofibers for diabetic wound healing: their current status with regulatory perspective. Int. J. Biol. Macromol. 234, 123696 (2023).

Cleeton, C., Keirouz, A., Chen, X. & Radacsi, N. Electrospun nanofibers for drug delivery and biosensing. Acs Biomater. Sci. Eng. 5, 4183–4205 (2019).

Han, D. et al. Multi-layered core-sheath fiber membranes for controlled drug release in the local treatment of brain tumor. Sci. Rep. 9, 17936 (2019).

Tort, S., Han, D., Frantz, E. & Steckl, A. J. Controlled drug release of parylene-coated pramipexole nanofibers for transdermal applications. Surf. Coat. Technol. 409, 126831 (2021).

Sroczyk, E. A., Berniak, K., Jaszczur, M. & Stachewicz, U. Topical electrospun patches loaded with oil for effective γ-linoleic acid transport and skin hydration towards atopic dermatitis skincare. Chem. Eng. J. 429, 132256 (2022).

Honarbakhsh, S., Guenther, R. H., Willoughby, J. A., Lommel, S. A. & Pourdeyhimi, B. Polymeric systems incorporating plant viral nanoparticles for tailored release of therapeutics. Adv. Healthc. Mater. 2, 1001–1007 (2013).

Ling, Y. et al. Disruptive, soft, wearable sensors. Adv. Mater. 32, 1904664 (2020).

Peng, X. et al. A breathable, biodegradable, antibacterial, and self-powered electronic skin based on all-nanofiber triboelectric nanogenerators. Sci. Adv. 6, eaba9624 (2020).

Wang, C., Yokota, T. & Someya, T. Natural biopolymer-based biocompatible conductors for stretchable bioelectronics. Chem. Rev. 121, 2109–2146 (2021).

Yang, T., Zhan, L. & Huang, C. Z. Recent insights into functionalized electrospun nanofibrous films for chemo-/bio-sensors. TrAC Trends Anal. Chem. 124, 115813 (2020).

Lin, C. et al. Ultrafine electrospun fiber based on ionic liquid/AlN/copolyamide composite as novel form-stable phase change material for thermal energy storage. Sol. Energy Mater. Sol. Cell 223, 110953 (2021).

Wu, J. et al. A trimode thermoregulatory flexible fibrous membrane designed with hierarchical core–sheath fiber structure for wearable personal thermal management. ACS Nano 16, 12801–12812 (2022).

Zhao, L. et al. Emulsion-electrospinning n-octadecane/silk composite fiber as environmental-friendly form-stable phase change materials. J. Appl. Polym. Sci. 134, 45538 (2017).

Li, D. et al. Scalable and hierarchically designed polymer film as a selective thermal emitter for high-performance all-day radiative cooling. Nat. Nanotechnol. 16, 153–158 (2021).

Wu, X. et al. An all-weather radiative human body cooling textile. Nat. Sustain. 6, 1446–1454 (2023).

Gao, Q. et al. Breathable and flexible dual-sided nonwovens with adjustable infrared optical performances for smart textile. Adv. Funct. Mater. 32, 2108808 (2022).

Wang, Y. et al. Reversible water transportation diode: temperature‐adaptive smart Janus textile for moisture/thermal management. Adv. Funct. Mater. 30, 1907851 (2020).

Dai, B. et al. Bioinspired Janus textile with conical micropores for human body moisture and thermal management. Adv. Mater. 31, 1904113 (2019).

Fan, C. et al. Dynamically tunable subambient daytime radiative cooling metafabric with Janus wettability. Adv. Funct. Mater. 33 https://doi.org/10.1002/adfm.202300794 (2023).

Fan, L., Yang, X. & Sun, H. Pressure sensors combining porous electrodes and electrospun nanofiber-based ionic membranes. ACS Appl. Nano Mater. 6, 3560–3571 (2023).

Tian, L. et al. Large-area MRI-compatible epidermal electronic interfaces for prosthetic control and cognitive monitoring. Nat. Biomed. Eng. 3, 194–205 (2019).

Son, D. et al. An integrated self-healable electronic skin system fabricated via dynamic reconstruction of a nanostructured conducting network. Nat. Nanotechnol. 13, 1057–1065 (2018).

Li, Q. et al. Highly stretchable and permeable conductors based on shrinkable electrospun fiber mats. Adv. Fiber Mater. 3, 302–311 (2021).

Wang, P. et al. Wearable, ultrathin and breathable tactile sensors with an integrated all-nanofiber network structure for highly sensitive and reliable motion monitoring. Nano Energy 104, 107883 (2022).

Puttananjegowda, K., Takshi, A. & Thomas, S. Silicon carbide nanoparticles electrospun nanofibrous enzymatic glucose sensor. Biosens. Bioelectron. 186, 113285 (2021).

Zhao, C. et al. Improving the sensitivity of nanofibrous membrane-based ELISA for on-site antibiotics detection. ACS Sens. 7, 1458–1466 (2022).

Kim, W., Lee, J. S. & Jang, J. Aptamer-functionalized three-dimensional carbon nanowebs for ultrasensitive and free-standing PDGF biosensor. ACS Appl. Mater. Interfaces 12, 20882–20890 (2020).

Lee, G., Wei, Q. & Zhu, Y. Emerging wearable sensors for plant health monitoring. Adv. Funct. Mater. 31, 2106475 (2021).

Chen, K. et al. Surface functionalization of porous In2O3 nanofibers with Zn nanoparticles for enhanced low-temperature NO2 sensing properties. Sens. Actuators B Chem. 308, 127716 (2020).

Guan, X. et al. Breathable, washable and wearable woven-structured triboelectric nanogenerators utilizing electrospun nanofibers for biomechanical energy harvesting and self-powered sensing. Nano Energy 80, 105549 (2021).

Sanchez, F. J. D. et al. Sponge-like piezoelectric micro- and nanofiber structures for mechanical energy harvesting. Nano Energy 98, 107286 (2022).

Su, Y. et al. High-performance piezoelectric composites via β phase programming. Nat. Commun. 13, 4867 (2022).

Wu, S. et al. Cesium lead halide perovskite decorated polyvinylidene fluoride nanofibers for wearable piezoelectric nanogenerator yarns. ACS Nano 17, 1022–1035 (2023).

Persano, L., Ghosh, S. K. & Pisignano, D. Enhancement and function of the piezoelectric effect in polymer nanofibers. Acc. Mater. Res. 3, 900–912 (2022).

Zhi, C. et al. Bioinspired all-fibrous directional moisture-wicking electronic skins for biomechanical energy harvesting and all-range health sensing. Nano Micro Lett. 15, 60 (2023).

Ma, L. et al. Continuous and scalable manufacture of hybridized nano-micro triboelectric yarns for energy harvesting and signal sensing. ACS Nano 14, 4716–4726 (2020).

He, X. et al. Continuous manufacture of stretchable and integratable thermoelectric nanofiber yarn for human body energy harvesting and self-powered motion detection. Chem. Eng. J. 450, 137937 (2022).

Sun, Z., Wen, X., Wang, L., Yu, J. & Qin, X. Capacitor-inspired high-performance and durable moist-electric generator. Energy Environ. Sci. 15, 4584–4591 (2022).

Sun, Z. et al. Emerging design principles, materials, and applications for moisture-enabled electric generation. eScience 2, 32–46 (2022).

Zambrzycki, M., Piech, R., Raga, S. R., Lira-Cantu, M. & Fraczek-Szczypta, A. Hierarchical carbon nanofibers/carbon nanotubes/NiCo nanocomposites as novel highly effective counter electrode for dye-sensitized solar cells: a structure–electrocatalytic activity relationship study. Carbon 203, 97–110 (2023).

Yin, X. et al. A new strategy for efficient light management in inverted perovskite solar cell. Chem. Eng. J. 439, 135703 (2022).

Bandodkar, A. J. et al. Soft, stretchable, high power density electronic skin-based biofuel cells for scavenging energy from human sweat. Energy Environ. Sci. 10, 1581–1589 (2017).

Bhatta, T. et al. Siloxene/PVDF composite nanofibrous membrane for high‐performance triboelectric nanogenerator and self‐powered static and dynamic pressure sensing applications. Adv. Funct. Mater. 32, 2202145 (2022).

Li, X. et al. Boosting piezoelectric and triboelectric effects of PVDF nanofiber through carbon-coated piezoelectric nanoparticles for highly sensitive wearable sensors. Chem. Eng. J. 426, 130345 (2021).

Wei, Q. et al. Porous one‐dimensional nanomaterials: design, fabrication and applications in electrochemical energy storage. Adv. Mater. 29, 1602300 (2017).

Wang, S. et al. Li+ affinity ultra-thin solid polymer electrolyte for advanced all-solid-state lithium-ion battery. Chem. Eng. J. 461, 141995 (2023).

Peng, S. et al. Electronic and defective engineering of electrospun CaMnO3 nanotubes for enhanced oxygen electrocatalysis in rechargeable zinc–air batteries. Adv. Energy Mater. 8, 1800612 (2018).

Gao, S. et al. Pea‐like MoS2@NiS1.03–carbon heterostructured hollow nanofibers for high‐performance sodium storage. Carbon Energy 5, e319 (2023).

Miao, X. et al. Electrospun V2MoO8 as a cathode material for rechargeable batteries with Mg metal anode. Nano Energy 34, 26–35 (2017).

Hwang, C.-K. et al. Perpendicularly stacked array of PTFE nanofibers as a reinforcement for highly durable composite membrane in proton exchange membrane fuel cells. Nano Energy 101, 107581 (2022).

Liu, D. S. et al. Spray layer-by-layer electrospun composite proton exchange membranes. Adv. Funct. Mater. 23, 3087–3095 (2013).

Niu, C. et al. General synthesis of complex nanotubes by gradient electrospinning and controlled pyrolysis. Nat. Commun. 6, 7402 (2015).

Arrese-Igor, M. et al. Solid-state Li-ion batteries with carbon microfiber electrodes via 3D electrospinning. Appl. Phys. Lett. 122, 173903 (2023).

Ji, D. et al. Atomically transition metals on self-supported porous carbon flake arrays as binder-free air cathode for wearable zinc–air batteries. Adv. Mater. 31, 1808267 (2019).

Ilango, P. R. et al. Electrospun flexible nanofibres for batteries: design and application. Electrochem. Energy Rev. 6, 12 (2023).

Radacsi, N., Campos, F. D., Chisholm, C. R. I. & Giapis, K. P. Spontaneous formation of nanoparticles on electrospun nanofibres. Nat. Commun. 9, 4740 (2018).

Lu, C. & Chen, X. Electrospun polyaniline nanofiber networks toward high‐performance flexible supercapacitors. Adv. Mater. Technol. 4, 1900564 (2019).

Xu, T. et al. Carbon nanofibrous sponge made from hydrothermally generated biochar and electrospun polymer nanofibers. Adv. Fiber Mater. 2, 74–84 (2020).

Archana, P. S., Jose, R., Yusoff, M. M. & Ramakrishna, S. Near band-edge electron diffusion in electrospun Nb-doped anatase TiO2 nanofibers probed by electrochemical impedance spectroscopy. Appl. Phys. Lett. 98, 152106 (2011).

Archana, P. S., Gupta, A., Yusoff, M. M. & Jose, R. Tungsten doped titanium dioxide nanowires for high efficiency dye-sensitized solar cells. Phys. Chem. Chem Phys 16, 7448–7454 (2014).

Balilonda, A. et al. Lead-free and electron transport layer-free perovskite yarns: designed for knitted solar fabrics. Chem. Eng. J. 410, 128384 (2021).

Li, Q. et al. Flexible solar yarns with 15.7% power conversion efficiency, based on electrospun perovskite composite nanofibers. Sol. RRL 4, 2000269 (2020).

Archana, P. S., Jose, R., Vijila, C. & Ramakrishna, S. Improved electron diffusion coefficient in electrospun TiO2 nanowires. J. Phys. Chem. C. 113, 21538–21542 (2009).

Wen, X., Xiong, J., Lei, S., Wang, L. & Qin, X. Diameter refinement of electrospun nanofibers: from mechanism, strategies to applications. Adv. Fiber Mater. 4, 145–161 (2022).

Liao, X. et al. Extremely low thermal conductivity and high electrical conductivity of sustainable carbonceramic electrospun nonwoven materials. Sci. Adv. 9, eade6066 (2023).

Tian, T. et al. Durable organic nonlinear optical membranes for thermotolerant lightings and in vivo bioimaging. Nat. Commun. 14, 4429 (2023).

Zhang, Z. et al. Synergistic effect of Cu2+ and Cu+ in SrTiO3 nanofibers promotes the photocatalytic reduction of CO2 to methanol. Appl. Surf. Sci. 609, 155297 (2023).

Kim, D.-H. et al. Ex-solution hybrids functionalized on oxide nanofibers for highly active and durable catalytic materials. ACS Nano 17, 5842–5851 (2023).

Lin, C. C. et al. Water-resistant efficient stretchable perovskite-embedded fiber membranes for light-emitting diodes. ACS Appl. Mater. Interfaces 10, 2210–2215 (2018).

Tian, T. et al. Large-area waterproof and durable perovskite luminescent textiles. Nat. Commun. 14, 234 (2023).

Liao, X. et al. Polarized blue photoluminescence of mesoscopically ordered electrospun non-conjugated polyacrylonitrile nanofibers. Mater. Horiz. 7, 1605–1612 (2020).

Romano, L. et al. Intelligent non-colorimetric indicators for the perishable supply chain by non-wovens with photo-programmed thermal response. Nat. Commun. 11, 5991 (2020).

Tang, Q. et al. Flexible, breathable, and self-powered patch assembled of electrospun polymer triboelectric layers and polypyrrole-coated electrode for infected chronic wound healing. ACS Appl. Mater. Interfaces 15, 17641–17652 (2023).

Cho, Y. et al. Multifunctional filter membranes based on self-assembled core–shell biodegradable nanofibers for persistent electrostatic filtration through the triboelectric effect. ACS Nano 16, 19451–19463 (2022).

Zhang, J.-H. et al. Versatile self-assembled electrospun micropyramid arrays for high-performance on-skin devices with minimal sensory interference. Nat. Commun. 13, 5839 (2022).

Xia, M. et al. High efficiency antibacterial, moisture permeable, and low temperature comfortable Janus nanofiber membranes for high performance air filters and respiration monitoring sensors. Adv. Mater. Interfaces 10, 2201952 (2023).

Soares, R. M. D., Siqueira, N. M., Prabhakaram, M. P. & Ramakrishna, S. Electrospinning and electrospray of bio-based and natural polymers for biomaterials development. Mater. Sci. Eng. C 92, 969–982 (2018).

Vass, P. et al. Scale‐up of electrospinning technology: applications in the pharmaceutical industry. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnol. 12, e1611 (2020).

Keirouz, A. et al. The history of electrospinning: past, present, and future developments. Adv. Mater. Technol. 8, 2201723 (2023).

Song, W. et al. Electrospinning spinneret: a bridge between the visible world and the invisible nanostructures. Innovation 4, 100381 (2023).

He, H., Wang, Y., Farkas, B., Nagy, Z. K. & Molnar, K. Analysis and prediction of the diameter and orientation of AC electrospun nanofibers by response surface methodology. Mater. Des. 194, 108902 (2020).

Zhang, B. et al. Solvent-free electrospinning: opportunities and challenges. Polym. Chem. 8, 333–352 (2017).

Ray, S. S., Chen, S.-S., Li, C.-W., Nguyen, N. C. & Nguyen, H. T. A comprehensive review: electrospinning technique for fabrication and surface modification of membranes for water treatment application. RSC Adv. 6, 85495–85514 (2016).

Lei, S., Wang, L., Wang, R., Qin, X. & Yu, J. Controllable diameter of electrospun nanofibers based on the velocity of whipping jets for high-efficiency air filtration. Sci. China Technol. Sci. 65, 481–489 (2022).

Cho, C.-J. et al. Green electrospun nanofiber membranes filter prepared from novel biomass thermoplastic copolyester: morphologies and filtration properties. J. Taiwan. Inst. Chem. Eng. 106, 206–214 (2020).

Zhuge, Y. & Liu, F. Controlled preparation of polyimide/polysulfone amide (PI/PSA) porous micro–nano fiber membranes by microemulsion electrospinning for excellent thermal insulation. Eur. Polym. J. 194, 112170 (2023).

Huang, S. et al. A comprehensive review of electrospray technique for membrane development: current status, challenges, and opportunities. J. Membr. Sci. 646, 120248 (2022).

Niu, H., Lin, T. & Wang, X. Needleless electrospinning. I. A comparison of cylinder and disk nozzles. J. Appl. Polym. Sci. 114, 3524–3530 (2009).

Zhou, M. et al. Large-scale preparation of micro-gradient structured sub-micro fibrous membranes with narrow diameter distributions for high-efficiency air purification. Environ. Sci. Nano 6, 3560–3578 (2019).

Lunni, D. et al. Light-assisted electrospinning monitoring for soft polymeric nanofibers. Sci. Rep. 10, 16341 (2020).

Guo, Y. et al. Research progress, models and simulation of electrospinning technology: a review. J. Mater. Sci. 57, 58–104 (2022).

Yang, D., Faraz, F., Wang, J. & Radacsi, N. Combination of 3D printing and electrospinning techniques for biofabrication. Adv. Mater. Technol. 7, 2101309 (2022).

Drosou, C., Krokida, M. & Biliaderis, C. G. Composite pullulan–whey protein nanofibers made by electrospinning: impact of process parameters on fiber morphology and physical properties. Food Hydrocoll. 77, 726–735 (2018).

Qiu, Q. et al. Functional nanofibers embedded into textiles for durable antibacterial properties. Chem. Eng. J. 384, 123241 (2020).

Lv, D. et al. Green electrospun nanofibers and their application in air filtration. Macromol. Mater. Eng. 303, 1800336 (2018).

Chaudhary, K. & Kandasubramanian, B. Self-healing nanofibers for engineering applications. Ind. Eng. Chem. Res. 61, 3789–3816 (2022).

Yuan, L. et al. Piezoelectric PAN/BaTiO3 nanofiber membranes sensor for structural health monitoring of real-time damage detection in composite. Compos. Commun. 25, 100680 (2021).

Lan, X. et al. Multidrug-loaded electrospun micro/nanofibrous membranes: fabrication strategies, release behaviors and applications in regenerative medicine. J. Controlled Rel. 330, 1264–1287 (2021).

Dou, Y., Zhang, W. & Kaiser, A. Electrospinning of metal–organic frameworks for energy and environmental applications. Adv. Sci. 7, 1902590 (2020).

Das, K. P., Sharma, D. & Satapathy, B. K. Electrospun fibrous constructs towards clean and sustainable agricultural prospects: SWOT analysis and TOWS based strategy assessment. J. Clean. Prod. 368, 133137 (2022).

Acknowledgements

This work was partly supported by grants from the National Natural Science Foundation of China (51973027 and 52202218), the Fundamental Research Funds for the Central Universities (2232020A-08), the Chang Jiang Scholars Program and the Innovation Program of Shanghai Municipal Education Commission (2019–01–07–00–03-E00023) to X.Q., and the DHU Distinguished Young Professor Program, National Key Research and Development Project (2022YFB4700602), the Shanghai Committee of Science and Technology (no.22ZR1401000) and the Shanghai Pujiang Program (21PJ1400200) to D.J. R.J. acknowledges Universiti Malaysia Pahang research grant RDU223101.

Author information

Authors and Affiliations

Contributions

Introduction (D.J. and N.R.); Experimentation (B.R., N.R., R.J., S.R. and D.J.); Results (D.J., Y.L. and X.G.); Applications (D.J., X.G. and N.R.); Reproducibility and data deposition (B.R. and R.J.); Limitations and optimizations (D.J., R.W., N.R. and X.Q.); Outlook (D.J., R.W., X.Q. and S.R.); Overview of the Primer (all authors).

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Reviews Methods Primers thanks Ick Soo Kim, Mayakrishnan Gopiraman and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Glossary

- 3D printing

-

(Also known as additive manufacturing). The process of creating 3D objects layer by layer from a digital model or design.

- 4D printing

-

The process of using materials that can react to external stimuli, allowing for the fabrication of structures that change shape and behaviour as time progresses.

- Anatase

-

One of the three crystalline forms of titanium dioxide (TiO2), characterized by its tetragonal crystal structure. The other two forms are rutile and brookite.

- Aptamers

-

Short, single-stranded DNA or RNA molecules that can bind to specific target molecules, used in various biotechnological and medical applications.

- Artificial neural networks

-

Computational models inspired by the structure and functioning of biological neural networks, used in machine learning and artificial intelligence (AI) for tasks such as pattern recognition and prediction.

- Bioprinting

-

The layer by layer deposition of living cells, tissues and biomaterials to construct biological structures, mimicking natural tissues or organs, often used in regenerative medicine and tissue engineering.

- Collector

-

A substrate or target surface where the charged nanofibres or particles are collected and deposited to form a fibrous mat or film.

- Electrified liquid jet

-

A stream of liquid charged with electricity to create a flow of charged liquid particles.

- Microfluidics

-

The study of fluids at the microscale, typically within channels with dimensions in the order of micrometres.

- Perovskite

-

A crystal-structured material (ABX3), where A is a larger cation, B is a smaller cation and X is an anion.

- Phase change nanofibres

-

Materials composed of nanoscale fibres that can undergo a phase change, such as melting or solidification, typically used for applications such as thermal energy storage.

- Polymer melt

-

Refers to a state in which a polymer has been heated to a temperature above its melting point, resulting in a molten, viscous material that can be moulded or shaped.

- Response surface methodology

-

(RSM). A statistical technique used to model and optimize the relationship between multiple variables and the response of a system to achieve the desired outcome.

- Spinneret

-

A small, fine nozzle or device used in the electrospinning process to extrude a polymer solution or melt.

- Taylor cone

-

A conical shape with specific geometry that is formed when a liquid is subjected to high voltage during the electrospinning process.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ji, D., Lin, Y., Guo, X. et al. Electrospinning of nanofibres. Nat Rev Methods Primers 4, 1 (2024). https://doi.org/10.1038/s43586-023-00278-z

Accepted:

Published:

DOI: https://doi.org/10.1038/s43586-023-00278-z