Abstract

The goal of 3D printing is to realize complex 3D structures by locally adding material in small volume elements called voxels — in contrast to successively subtracting material by etching, milling or machining. This field started with optics-based proposals in the 1970s. Progress has required breakthroughs in physics, chemistry, materials science, laser science and engineering. This Review focuses on the physics underlying optics-based approaches, including interference lithography, tomographic volumetric additive manufacturing, stereolithography, continuous liquid-interface printing, light-sheet printing, parallelized spatiotemporal focusing and (multi-)focus scanning. Light–matter interactions that are discussed include one-photon, two-photon, multi-photon or cascaded nonlinear optical absorption processes for excitation and stimulated-emission depletion or excited-state absorption followed by reverse intersystem crossing for de-excitation. The future physics challenges lie in further boosting three metrics: spatial resolution, rate of voxel creation and range of available dissimilar material properties. Engineering challenges lie in achieving these metrics in compact, low-cost and low-energy-consumption instruments and in identifying new applications.

Key points

-

Three-dimensional printing with light is an additive manufacturing process in which light irradiation locally adds a solid material (typically from a liquid ‘ink’), rather than subtracting it from a solid by machining or drilling, to form complex 3D structures from the macroscale to the nanoscale.

-

All current light-based 3D printing modalities (including interference lithography, spatial focusing, spatiotemporal focusing, tomographic volumetric additive manufacturing and layer-by-layer approaches) can be seen as approximations of an ideal light exposure scheme in which a tailored 3D pattern of light exposes an ink in a single shot.

-

Light shone during 3D printing couples to the ink via electric-dipole-mediated light–matter interactions to dedicated trigger (photoinitiator) molecules; sometimes ordinary one-photon absorption suffices, yet often other processes such as multi-photon absorption or two-colour two-step absorption are needed to sufficiently localize the excitation in 3D space.

-

Material formation from the ink following the light trigger is highly material dependent, with different chemical and physical processes involved for the formation of polymers, metals and semiconductors.

-

Although researchers strive to improve the speed and resolution of 3D printing technologies, the formation of a certain voxel unavoidably requires delivering a certain light energy; therefore, increasing the number of voxels printed per unit time requires increasing light power.

-

The challenges of 3D printing remain: enable ever finer feature sizes, increase print speed, open the door to more dissimilar materials and make 3D laser printers more compact and less expensive.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$99.00 per year

only $8.25 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

A maintained and updated version of Fig. 5 is provided at https://3DprintingSpeed.com.

References

Gottwald, J. F. Liquid metal recorder. US Patent US3596285A (1971).

Sachs, E. M., Haggerty, J. S., Cima, M. J. & Williams, P. A. Three-dimensional printing techniques. US Patent US5204055A (1993).

de Gans, B. J., Duineveld, P. C. & Schubert, U. S. Inkjet printing of polymers: state of the art and future developments. Adv. Mater. 16, 203–213 (2004).

Delrot, P., Modestino, M. A., Gallaire, F., Psaltis, D. & Moser, C. Inkjet printing of viscous monodisperse microdroplets by laser-induced flow focusing. Phys. Rev. Appl. 6, 024003 (2016).

Crump, S. S. Apparatus and method for creating three-dimensional objects. US Patent US5121329A (1992).

Landauer, R. Light faster than light? Nature 365, 692–693 (1993).

Hell, S. W. & Wichmann, J. Breaking the diffraction resolution limit by stimulated emission: stimulated-emission-depletion fluorescence microscopy. Opt. Lett. 19, 780 (1994).

Klar, T. A., Jakobs, S., Dyba, M., Egner, A. & Hell, S. W. Fluorescence microscopy with diffraction resolution barrier broken by stimulated emission. Proc. Natl Acad. Sci. USA 97, 8206–8210 (2000).

Hell, S. W. Strategy for far-field optical imaging and writing without diffraction limit. Phys. Lett. A 326, 140–145 (2004).

Thiel, M., Ott, J., Radke, A., Kaschke, J. & Wegener, M. Dip-in depletion optical lithography of three-dimensional chiral polarizers. Opt. Lett. 38, 4252 (2013).

Kaschke, J. & Wegener, M. Gold triple-helix mid-infrared metamaterial by STED-inspired laser lithography. Opt. Lett. 40, 3986 (2015).

Fischer, J. et al. Exploring the mechanisms in STED-enhanced direct laser writing. Adv. Opt. Mater. 3, 221–232 (2015).

Müller, P. et al. STED-inspired laser lithography based on photoswitchable spirothiopyran moieties. Chem. Mater. 31, 1966–1972 (2019).

Liaros, N. & Fourkas, J. T. Ten years of two-color photolithography [Invited]. Opt. Mater. Express 9, 3006 (2019).

He, M. et al. 3D sub‐diffraction printing by multicolor photoinhibition lithography: from optics to chemistry. Laser Photon Rev. 16, 2100229 (2022).

Somers, P. et al. Photo-activated polymerization inhibition process in photoinitiator systems for high-throughput 3D nanoprinting. Nanophotonics https://doi.org/10.1515/NANOPH-2022-0611 (2023).

Jones, D. E. H. Ariadne. New Scientist. 80 (1974).

Swainson, W. K. Method, medium and apparatus for producing three-dimensional figure product. US Patent US4041476A (1971).

Ford, J. E. et al. in Photonics for Processors, Neural Networks, and Memories Vol. 2026 (eds Horner, J. L. et al.) 604–613 (SPIE, 1993).

Regehly, M. et al. Xolography for linear volumetric 3D printing. Nature 588, 620–624 (2020).

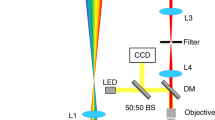

Hahn, V. et al. Light-sheet 3D microprinting via two-colour two-step absorption. Nat. Photonics 16, 784–791 (2022).

Kodama, H. Automatic method for fabricating a three‐dimensional plastic model with photo‐hardening polymer. Rev. Sci. Instrum. 52, 1770–1773 (1981).

Hull, C. W. Apparatus for production of three-dimensional objects by stereolithography. US Patent US4575330A (1986).

Maruo, S., Nakamura, O. & Kawata, S. Three-dimensional microfabrication with two-photon-absorbed photopolymerization. Opt. Lett. 22, 132 (1997).

Campbell, M., Sharp, D. N., Harrison, M. T., Denning, R. G. & Turberfield, A. J. Fabrication of photonic crystals for the visible spectrum by holographic lithography. Nature 404, 53–56 (2000).

Wu, X. Imaging and forming method using projection operation and back projection method. European Patent EP3333629A4 (2016).

Shusteff, M. et al. One-step volumetric additive manufacturing of complex polymer structures. Sci. Adv. 3, eaao5496 (2017).

Kelly, B. E. et al. Volumetric additive manufacturing via tomographic reconstruction. Science 363, 1075–1079 (2019).

Loterie, D., Delrot, P. & Moser, C. High-resolution tomographic volumetric additive manufacturing. Nat. Commun. 11, 852 (2020).

Melde, K. et al. Compact holographic sound fields enable rapid one-step assembly of matter in 3D. Sci. Adv. 9, eadf6182 (2023).

Pang, Y. K. et al. Chiral microstructures (spirals) fabrication by holographic lithography. Opt. Express 13, 7615 (2005).

Liu, L. et al. Fast fabrication of silver helical metamaterial with single-exposure femtosecond laser photoreduction. Nanophotonics 8, 1087–1093 (2019).

Cai, L. Z., Yang, X. L. & Wang, Y. R. All fourteen Bravais lattices can be formed by interference of four noncoplanar beams. Opt. Lett. 27, 900 (2002).

Meisel, D. C., Wegener, M. & Busch, K. Three-dimensional photonic crystals by holographic lithography using the umbrella configuration: symmetries and complete photonic band gaps. Phys. Rev. B Condens. Matter Mater. Phys. 70, 165104 (2004).

Kadic, M., Milton, G. W., van Hecke, M. & Wegener, M. 3D metamaterials. Nat. Rev. Phys. 1, 198–210 (2019).

Feth, N., Enkrich, C., Wegener, M. & Linden, S. Large-area magnetic metamaterials via compact interference lithography. Opt. Express 15, 501 (2007).

Behera, S. & Joseph, J. Design and realization of functional metamaterial basis structures through optical phase manipulation based interference lithography. J. Opt. 19, 105103 (2017).

Miklyaev, Y. V. et al. Three-dimensional face-centered-cubic photonic crystal templates by laser holography: fabrication, optical characterization, and band-structure calculations. Appl. Phys. Lett. 82, 1284–1286 (2003).

Divliansky, I., Mayer, T. S., Holliday, K. S. & Crespi, V. H. Fabrication of three-dimensional polymer photonic crystal structures using single diffraction element interference lithography. Appl. Phys. Lett. 82, 1667–1669 (2003).

Wu, L., Zhong, Y., Chan, C. T., Wong, K. S. & Wang, G. P. Fabrication of large area two- and three-dimensional polymer photonic crystals using single refracting prism holographic lithography. Appl. Phys. Lett. 86, 241102 (2005).

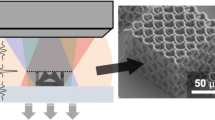

Frenzel, T., Kadic, M. & Wegener, M. Three-dimensional mechanical metamaterials with a twist. Science 358, 1072–1074 (2017).

Ullal, C. K. et al. Photonic crystals through holographic lithography: simple cubic, diamond-like, and gyroid-like structures. Appl. Phys. Lett. 84, 5434–5436 (2004).

Leibovici, M. C. R. & Gaylord, T. K. Photonic-crystal waveguide structure by pattern-integrated interference lithography. Opt. Lett. 40, 2806 (2015).

Leibovici, M. C. R. & Gaylord, T. K. Custom-modified three-dimensional periodic microstructures by pattern-integrated interference lithography. J. Opt. Soc. Am. A 31, 1515 (2014).

Ohlinger, K., Lutkenhaus, J., Arigong, B., Zhang, H. & Lin, Y. Spatially addressable design of gradient index structures through spatial light modulator based holographic lithography. J. Appl. Phys. https://doi.org/10.1063/1.4837635 (2013).

Wolf, E. Electromagnetic diffraction in optical systems — I. An integral representation of the image field. Proc. R. Soc. Lond. A Math. Phys. Sci. 253, 349–357 (1959).

Abbe, E. Beiträge zur theorie des mikroskops und der mikroskopischen wahrnehmung. Arch. für Mikrosk. Anat. 9, 413–468 (1873).

Gu, M. & Sheppard, C. J. R. Comparison of three‐dimensional imaging properties between two‐photon and single‐photon fluorescence microscopy. J. Microsc. 177, 128–137 (1995).

Fischer, J. & Wegener, M. Three-dimensional optical laser lithography beyond the diffraction limit. Laser Photon Rev. 7, 22–44 (2013).

Wong, S. et al. Direct laser writing of three-dimensional photonic crystals with a complete photonic band gap in chalcogenide glasses. Adv. Mater. 18, 265–269 (2006).

Williams, H. E., Luo, Z. & Kuebler, S. M. Effect of refractive index mismatch on multi-photon direct laser writing. Opt. Express 20, 25030 (2012).

Deckard, C. Method and apparatus for producing parts by selective sintering. US Patent US4863538A (1989).

Gu, D. D., Meiners, W., Wissenbach, K. & Poprawe, R. Laser additive manufacturing of metallic components: materials, processes and mechanisms. Int. Mater. Rev. 57, 133–164 (2012).

Matsuo, S., Juodkazis, S. & Misawa, H. Femtosecond laser microfabrication of periodic structures using a microlens array. Appl. Phys. A 80, 683–685 (2005).

Obata, K. et al. Multi-focus two-photon polymerization technique based on individually controlled phase modulation. Opt. Express 18, 17193–17200 (2010).

Yang, L. et al. Parallel direct laser writing of micro-optical and photonic structures using spatial light modulator. Opt. Lasers Eng. 70, 26–32 (2015).

Geng, Q., Wang, D., Chen, P. & Chen, S. C. Ultrafast multi-focus 3-D nano-fabrication based on two-photon polymerization. Nat. Commun. https://doi.org/10.1038/s41467-019-10249-2 (2019).

Hahn, V. et al. Rapid assembly of small materials building blocks (voxels) into large functional 3D metamaterials. Adv. Funct. Mater. 30, 1907795 (2020).

Manousidaki, M., Papazoglou, D. G., Farsari, M. & Tzortzakis, S. 3D holographic light shaping for advanced multiphoton polymerization. Opt. Lett. 45, 85 (2020).

Ouyang, W. et al. Ultrafast 3D nanofabrication via digital holography. Nat. Commun. 14, 1716 (2023).

Kiefer, P. et al. A multi-photon (7×7)-focus 3D laser printer based on a 3D-printed diffractive optical element and a 3D-printed multi-lens array. Light Adv. Manuf. (in the press).

Keller, J., Schönle, A. & Hell, S. W. Efficient fluorescence inhibition patterns for RESOLFT microscopy. Opt. Express 15, 3361 (2007).

Arlt, J. & Padgett, M. J. Generation of a beam with a dark focus surrounded by regions of higher intensity: the optical bottle beam. Opt. Lett. 25, 191 (2000).

Zhang, S. J. et al. Two-photon polymerization of a three dimensional structure using beams with orbital angular momentum. Appl. Phys. Lett. 105, 061101 (2014).

Tang, J., Ren, J. & Han, K. Y. Fluorescence imaging with tailored light. Nanophotonics 8, 2111–2128 (2019).

Gerchberg, R. W. & Saxton, W. O. A practical algorithm for the determination of phase from image and diffraction plane pictures. Optik 35, 237–246 (1972).

Haist, T., Schönleber, M. & Tiziani, H. J. Computer-generated holograms from 3D-objects written on twisted-nematic liquid crystal displays. Opt. Commun. 140, 299–308 (1997).

Yang, L. et al. Projection two-photon polymerization using a spatial light modulator. Opt. Commun. 331, 82–86 (2014).

Yang, L. et al. Two-photon polymerization of microstructures by a non-diffraction multifoci pattern generated from a superposed Bessel beam. Opt. Lett. 42, 743 (2017).

Yang, D., Liu, L., Gong, Q. & Li, Y. Rapid two‐photon polymerization of an arbitrary 3D microstructure with 3D focal field engineering. Macromol. Rapid Commun. 40, 1900041 (2019).

Durfee, C. G., Greco, M., Block, E., Vitek, D. & Squier, J. A. Intuitive analysis of space-time focusing with double-ABCD calculation. Opt. Express 20, 14244 (2012).

Oron, D., Tal, E. & Silberberg, Y. Scanningless depth-resolved microscopy. Opt. Express 13, 1468 (2005).

Zhu, G., van Howe, J., Durst, M., Zipfel, W. & Xu, C. Simultaneous spatial and temporal focusing of femtosecond pulses. Opt. Express 13, 2153 (2005).

Somers, P. et al. Rapid, continuous projection multi-photon 3D printing enabled by spatiotemporal focusing of femtosecond pulses. Light Sci. Appl. 10, 199 (2021).

Chu, W. et al. Centimeter-height 3D printing with femtosecond laser two-photon polymerization. Adv. Mater. Technol. 3, 1700396 (2018).

Kim, D. & So, P. T. C. High-throughput three-dimensional lithographic microfabrication. Opt. Lett. 35, 1602 (2010).

Li, Y.-C. et al. Fast multiphoton microfabrication of freeform polymer microstructures by spatiotemporal focusing and patterned excitation. Opt. Express 20, 19030 (2012).

Saha, S. K. et al. Scalable submicrometer additive manufacturing. Science 366, 105–109 (2019).

Sun, B. et al. Four-dimensional light shaping: manipulating ultrafast spatiotemporal foci in space and time. Light Sci. Appl. 7, 17117 (2017).

Dinc, N. U. et al. From 3D to 2D and back again. Nanophotonics https://doi.org/10.1515/nanoph-2022-0512 (2023).

Radon, J. On the determination of functions from their integral values along certain manifolds. IEEE Trans. Med. Imaging 5, 170–176 (1986).

Bhattacharya, I., Toombs, J. & Taylor, H. High fidelity volumetric additive manufacturing. Addit. Manuf. 47, 102299 (2021).

Rackson, C. M. et al. Object-space optimization of tomographic reconstructions for additive manufacturing. Addit. Manuf. 48, 102367 (2021).

Madrid-Wolff, J., Boniface, A., Loterie, D., Delrot, P. & Moser, C. Controlling light in scattering materials for volumetric additive manufacturing. Adv. Sci. 9, 2105144 (2022).

Bertsch, A., Jézéquel, J. Y. & André, J. C. Study of the spatial resolution of a new 3D microfabrication process: the microstereophotolithography using a dynamic mask-generator technique. J. Photochem. Photobiol. A Chem. 107, 275–281 (1997).

Sun, C., Fang, N., Wu, D. M. & Zhang, X. Projection micro-stereolithography using digital micro-mirror dynamic mask. Sens. Actuators A Phys. 121, 113–120 (2005).

Huang, Y. M. & Jiang, C. P. On-line force monitoring of platform ascending rapid prototyping system. J. Mater. Process. Technol. 159, 257–264 (2005).

Jin, J., Yang, J., Mao, H. & Chen, Y. A vibration-assisted method to reduce separation force for stereolithography. J. Manuf. Process. 34, 793–801 (2018).

Tumbleston, J. R. et al. Continuous liquid interface production of 3D objects. Science 347, 1349–1352 (2015).

Walker, D. A., Hedrick, J. L. & Mirkin, C. A. Rapid, large-volume, thermally controlled 3D printing using a mobile liquid interface. Science 366, 360–364 (2019).

De Beer, M. P. et al. Rapid, continuous additive manufacturing by volumetric polymerization inhibition patterning. Sci. Adv. 5, eaau8723 (2019).

Anandakrishnan, N. et al. Fast stereolithography printing of large-scale biocompatible hydrogel models. Adv. Healthc. Mater. 10, 2002103 (2020).

Mueller, P., Thiel, M. & Wegener, M. 3D direct laser writing using a 405 nm diode laser. Opt. Lett. 39, 6847 (2014).

Wickberg, A. et al. Second-harmonic generation by 3D laminate metacrystals. Adv. Opt. Mater. 7, 1801235 (2019).

Sanli, U. T. et al. High-resolution kinoform X-ray optics printed via 405 nm 3D laser lithography. Adv. Mater. Technol. 7, 2101695 (2022).

Wang, H. et al. Two‐photon polymerization lithography for optics and photonics: fundamentals, materials, technologies, and applications. Adv. Funct. Mater https://doi.org/10.1002/adfm.202214211 (2023).

Dirac, P. A. M. The quantum theory of the emission and absorption of radiation. Proc. R. Soc. Lond. Ser. A 114, 243–265 (1927).

Schäfer, W. & Wegener, M. Interaction of Matter and Electromagnetic Fields. In: Semiconductor Optics and Transport Phenomena. Advanced Texts in Physics. 7–49 (Springer, 2002).

Poynting, J. H. X. V. On the transfer of energy in the electromagnetic field. Philos. Trans. R. Soc. Lond. 175, 343–361 (1884).

Mauri, A. et al. Two- and three-photon processes in photoinitiators for 3D laser printing. Preprint at Res. Sq. https://doi.org/10.21203/rs.3.rs-1797484/v1 (2022).

Hahn, V. et al. Two-step absorption instead of two-photon absorption in 3D nanoprinting. Nat. Photonics 15, 932–938 (2021).

Liaros, N. et al. Elucidating complex triplet-state dynamics in the model system isopropylthioxanthone. iScience 25, 103600 (2022).

Yang, L. et al. On the Schwarzschild effect in 3D two-photon laser lithography. Adv. Opt. Mater. 7, 1901040 (2019).

Johnson, J. E., Chen, Y. & Xu, X. Model for polymerization and self-deactivation in two-photon nanolithography. Opt. Express 30, 26824 (2022).

Kiefer, P. et al. Sensitive photoresists for rapid multiphoton 3D laser micro- and nanoprinting. Adv. Opt. Mater. 8, 2000895 (2020).

Kawata, S., Sun, H.-B., Tanaka, T. & Takada, K. Finer features for functional microdevices. Nature 412, 697–698 (2001).

Göppert‐Mayer, M. Über elementarakte mit zwei quantensprüngen. Ann. Phys. 401, 273–294 (1931).

Strickler, J. H. & Webb, W. W. in CAN-AM Eastern '90 Vol. 1398 (eds Antos, R. L. & Krisiloff, A. J.) 107–118 (SPIE, 1991).

Boyd, R. W. Nonlinear Optics (Academic, 2008).

Pucher, N. et al. Structure-activity relationship in D-π-a-π-D-based photoinitiators for the two-photon-induced photopolymerization process. Macromolecules 42, 6519–6528 (2009).

Li, Z. et al. A straightforward synthesis and structure-activity relationship of highly efficient initiators for two-photon polymerization. Macromolecules 46, 352–361 (2013).

Nazir, R. et al. Donor-acceptor type thioxanthones: synthesis, optical properties, and two-photon induced polymerization. Macromolecules 48, 2466–2472 (2015).

Chi, T. et al. Substituted thioxanthone-based photoinitiators for efficient two-photon direct laser writing polymerization with two-color resolution. ACS Appl. Polym. Mater. 3, 1426–1435 (2021).

Ladika, D. et al. Synthesis and application of triphenylamine-based aldehydes as photo-initiators for multi-photon lithography. Appl. Phys. A Mater. Sci. Process. 128, (2022).

Lunzer, M. et al. Beyond the threshold: a study of chalcogenophene-based two-photon initiators. Chem. Mater. 34, 3042–3052 (2022).

Fischer, J. et al. Three-dimensional multi-photon direct laser writing with variable repetition rate. Opt. Express 21, 26244 (2013).

Tomova, Z., Liaros, N., Gutierrez Razo, S. A., Wolf, S. M. & Fourkas, J. T. In situ measurement of the effective nonlinear absorption order in multiphoton photoresists. Laser Photon Rev. 10, 849–854 (2016).

Maruo, S. & Ikuta, K. Three-dimensional microfabrication by use of single-photon-absorbed polymerization. Appl. Phys. Lett. 76, 2656–2658 (2000).

Delrot, P., Loterie, D., Psaltis, D. & Moser, C. Single-photon three-dimensional microfabrication through a multimode optical fiber. Opt. Express 26, 1766 (2018).

Hsu, S. et al. High‐speed one‐photon 3D nanolithography using controlled initiator depletion and inhibitor transport. Adv. Opt. Mater. 10, 2102262 (2022).

Bojanowski, N. M. et al. Search for alternative two‐step‐absorption photoinitiators for 3D laser nanoprinting. Adv. Funct. Mater. 33, 2212482 (2022).

Rocheva, V. V. et al. High-resolution 3D photopolymerization assisted by upconversion nanoparticles for rapid prototyping applications. Sci. Rep. 8, 3663 (2018).

Chen, Y. et al. Noninvasive in vivo 3D bioprinting. Sci. Adv. 6, eba7406 (2020).

Zhu, J., Zhang, Q., Yang, T., Liu, Y. & Liu, R. 3D printing of multi-scalable structures via high penetration near-infrared photopolymerization. Nat. Commun. 11, 3462 (2020).

Sanders, S. N. et al. Triplet fusion upconversion nanocapsules for volumetric 3D printing. Nature 604, 474–478 (2022).

Zhang, Q., Boniface, A., Parashar, V. K., Gijs, M. A. M. & Moser, C. Multi-photon polymerization using upconversion nanoparticles for tunable feature-size printing. Nanophotonics https://doi.org/10.1515/nanoph-2022-0598 (2023).

Schloemer, T. et al. Nanoengineering triplet–triplet annihilation upconversion: from materials to real-world applications. ACS Nano 17, 3259–3288 (2023).

Limberg, D. K., Kang, J. H. & Hayward, R. C. Triplet-triplet annihilation photopolymerization for high-resolution 3D printing. J. Am. Chem. Soc. 144, 5226–5232 (2022).

Luo, Z. et al. Three-dimensional nanolithography with visible continuous wave laser through triplet up-conversion. J. Phys. Chem. Lett. 14, 709–715 (2023).

Hahn, V. et al. Challenges and opportunities in 3D laser printing based on (1 + 1)-photon absorption. ACS Photonics 10, 24–33 (2023).

Samsonas, D. et al. 3D nanopolymerization and damage threshold dependence on laser wavelength and pulse duration. Nanophotonics https://doi.org/10.1515/nanoph-2022-0629 (2023).

Denk, W., Strickler, J. H. & Webb, W. W. Two-photon laser scanning fluorescence microscopy. Science 248, 73–76 (1990).

Li, L., Gattass, R. R., Gershgoren, E., Hwang, H. & Fourkas, J. T. Achieving λ/20 resolution by one-color initiation and deactivation of polymerization. Science 324, 910–913 (2009).

Fischer, J. & Wegener, M. Three-dimensional direct laser writing inspired by stimulated-emission-depletion microscopy [Invited]. Opt. Mater. Express 1, 614 (2011).

Wollhofen, R., Katzmann, J., Hrelescu, C., Jacak, J. & Klar, T. A. 120 nm resolution and 55 nm structure size in STED-lithography. Opt. Express 21, 10831 (2013).

Fang, T.-S., Brown, R. E., Kwan, C. L. & Singer, L. A. Photophysical studies on benzil. Time resolution of the prompt and delayed emissions and a photokinetic study indicating deactivation of the triplet by reversible exciplex formation. J. Phys. Chem. 82, 2489–2496 (1978).

Yang, L. et al. Laser printed microelectronics. Nat. Commun. 14, 1103 (2023).

Yang, L. et al. In situ diagnostics and role of light-induced forces in metal laser nanoprinting. Laser Photon. Rev. 16, 2100411 (2022).

Tabrizi, S., Cao, Y. Y., Lin, H. & Jia, B. H. Two-photon reduction: a cost-effective method for fabrication of functional metallic nanostructures. Sci. China Phys. Mech. Astron. 60, 034201 (2017).

Spiegel, C. A. et al. 4D printing at the microscale. Adv. Funct. Mater. 30, 1907615 (2020).

Lay, C. L. et al. Two-photon-assisted polymerization and reduction: emerging formulations and applications. ACS Appl. Mater. Interfaces 12, 10061–10079 (2020).

Hobich, J., Blasco, E., Wegener, M., Mutlu, H. & Barner‐Kowollik, C. Synergistic, orthogonal, and antagonistic photochemistry for light‐induced 3D printing. Macromol. Chem. Phys. 224, 2200318 (2022).

Kowsari, K., Akbari, S., Wang, D., Fang, N. X. & Ge, Q. High-efficiency high-resolution multimaterial fabrication for digital light processing-based three-dimensional printing. 3D Print. Addit. Manuf. 5, 185–193 (2018).

Mayer, F. et al. Multimaterial 3D laser microprinting using an integrated microfluidic system. Sci. Adv. 5, eaau9160 (2019).

Maruyama, T., Hirata, H., Furukawa, T. & Maruo, S. Multi-material microstereolithography using a palette with multicolor photocurable resins. Opt. Mater. Express 10, 2522 (2020).

Yang, L., Mayer, F., Bunz, U. H. F., Blasco, E. & Wegener, M. Multi-material multi-photon 3D laser micro- and nanoprinting. Light Adv. Manuf. 2, 1 (2021).

Mueller, J. B., Fischer, J., Mayer, F., Kadic, M. & Wegener, M. Polymerization kinetics in three-dimensional direct laser writing. Adv. Mater. 26, 6566–6571 (2014).

Mueller, J. B., Fischer, J., Mange, Y. J., Nann, T. & Wegener, M. In-situ local temperature measurement during three-dimensional direct laser writing. Appl. Phys. Lett. 103, 123107 (2013).

Cao, Y. Y., Takeyasu, N., Tanaka, T., Duan, X. M. & Kawata, S. 3D metallic nanostructure fabrication by surfactant-assisted multiphoton-induced reduction. Small 5, 1144–1148 (2009).

Lu, W.-E. et al. Femtosecond direct laser writing of gold nanostructures by ionic liquid assisted multiphoton photoreduction. Opt. Mater. Express 3, 1660 (2013).

Lee, M. R. et al. Direct metal writing and precise positioning of gold nanoparticles within microfluidic channels for SERS sensing of gaseous analytes. ACS Appl. Mater. Interfaces 9, 39584–39593 (2017).

Komori, T., Furukawa, T., Iijima, M. & Maruo, S. Multi-scale laser direct writing of conductive metal microstructures using a 405-nm blue laser. Opt. Express 28, 8363 (2020).

Barton, P. et al. Fabrication of silver nanostructures using femtosecond laser-induced photoreduction. Nanotechnology 28, 505302 (2017).

Zarzar, L. D. et al. Multiphoton lithography of nanocrystalline platinum and palladium for site-specific catalysis in 3D microenvironments. J. Am. Chem. Soc. 134, 4007–4010 (2012).

Ashkin, A. Acceleration and trapping of particles by radiation pressure. Phys. Rev. Lett. 24, 156–159 (1970).

Ashkin, A., Dziedzic, J. M., Bjorkholm, J. E. & Chu, S. Observation of a single-beam gradient force optical trap for dielectric particles. Opt. Lett. 11, 288 (1986).

Mie, G. Beiträge zur optik trüber medien, speziell kolloidaler metallösungen. Ann. Phys. 330, 377–445 (1908).

Maruo, S. & Saeki, T. Femtosecond laser direct writing of metallic microstructures by photoreduction of silver nitrate in a polymer matrix. Opt. Express 16, 1174 (2008).

Blasco, E. et al. Fabrication of conductive 3D gold-containing microstructures via direct laser writing. Adv. Mater. 28, 3592–3595 (2016).

Vyatskikh, A. et al. Additive manufacturing of 3D nano-architected metals. Nat. Commun. https://doi.org/10.1038/s41467-018-03071-9 (2018).

Shukla, S., Furlani, E. P., Vidal, X., Swihart, M. T. & Prasad, P. N. Two-photon lithography of sub-wavelength metallic structures in a polymer matrix. Adv. Mater. 22, 3695–3699 (2010).

Shukla, S. et al. Subwavelength direct laser patterning of conductive gold nanostructures by simultaneous photopolymerization and photoreduction. ACS Nano 5, 1947–1957 (2011).

Yeo, J. et al. Rapid, one-step, digital selective growth of ZnO nanowires on 3D structures using laser induced hydrothermal growth. Adv. Funct. Mater. 23, 3316–3323 (2013).

Farrell, J. et al. Advances in selective laser sintering of polymers. Int. J. Extrem. Manuf. 4, 042002 (2022).

Qu, J., Kadic, M., Naber, A. & Wegener, M. Micro-structured two-component 3D metamaterials with negative thermal-expansion coefficient from positive constituents. Sci. Rep. 7, 40643 (2017).

Münchinger, A., Hsu, L. Y., Fürniß, F., Blasco, E. & Wegener, M. 3D optomechanical metamaterials. Mater. Today 59, 9–17 (2022).

Groß, M. F. et al. Tetramode metamaterials as phonon polarizers. Adv. Mater. 35, e2211801 (2023).

Žukauskas, A. et al. Tuning the refractive index in 3D direct laser writing lithography: towards GRIN microoptics. Laser Photon. Rev. 9, 706–712 (2015).

Gissibl, T., Thiele, S., Herkommer, A. & Giessen, H. Two-photon direct laser writing of ultracompact multi-lens objectives. Nat. Photonics 10, 554–560 (2016).

Liu, Y. et al. Structural color three-dimensional printing by shrinking photonic crystals. Nat. Commun. 10, 4340 (2019).

Kiyan, R., Bagratashvili, V. N., Kurselis, K., Popov, V. K. & Chichkov, B. N. 3D fabrication of all-polymer conductive microstructures by two photon polymerization. Opt. Express 21, 31029–31035 (2013).

Li, J. et al. Hybrid additive manufacturing of 3D electronic systems. J. Micromech. Microeng. 26, 105005 (2016).

Mu, Q. et al. Digital light processing 3D printing of conductive complex structures. Addit. Manuf. 18, 74–83 (2017).

Qian, D. et al. Flexible and rapid fabrication of silver microheaters with spatial-modulated multifoci by femtosecond laser multiphoton reduction. Opt. Lett. 43, 5335 (2018).

Takenouchi, M., Mukai, M., Furukawa, T. & Maruo, S. Fabrication of flexible wiring with intrinsically conducting polymers using blue-laser microstereolithography. Polymers 14, 4949 (2022).

Meza, L. R., Das, S. & Greer, J. R. Strong, lightweight, and recoverable three-dimensional ceramic nanolattices. Science 345, 1322–1326 (2014).

Frenzel, T., Findeisen, C., Kadic, M., Gumbsch, P. & Wegener, M. Tailored buckling microlattices as reusable light-weight shock absorbers. Adv. Mater. 28, 5865–5870 (2016).

Bauer, J. et al. Nanolattices: an emerging class of mechanical metamaterials. Adv. Mater. 29, 1701850 (2017).

Elliott, L. V., Salzman, E. E. & Greer, J. R. Stimuli responsive shape memory microarchitectures. Adv. Funct. Mater. 31, 2008380 (2021).

Maruo, S. & Inoue, H. Optically driven viscous micropump using a rotating microdisk. Appl. Phys. Lett. 91, 084101 (2007).

Zeng, H. et al. Light-fueled microscopic walkers. Adv. Mater. 27, 3883–3887 (2015).

Huang, T.-Y. et al. 3D printed microtransporters: compound micromachines for spatiotemporally controlled delivery of therapeutic agents. Adv. Mater. 27, 6644–6650 (2015).

Wang, X. et al. 3D printed enzymatically biodegradable soft helical microswimmers. Adv. Funct. Mater. 28, 1804107 (2018).

Ma, Z.-C. et al. Femtosecond laser programmed artificial musculoskeletal systems. Nat. Commun. 11, 4536 (2020).

Nuñez Bernal, P. et al. Volumetric bioprinting of complex living-tissue constructs within seconds. Adv. Mater. 31, 1904209 (2019).

Hippler, M. et al. 3D scaffolds to study basic cell biology. Adv. Mater. 31, e1808110 (2019).

Kozaki, S. et al. Additive manufacturing of micromanipulator mounted on a glass capillary for biological applications. Micromachines 11, 174 (2020).

Bernal, P. N. et al. Volumetric bioprinting of organoids and optically tuned hydrogels to build liver-like metabolic biofactories. Adv. Mater. 34, 2110054 (2022).

Jiao, B. J. et al. Acousto-optic scanning spatial-switching multiphoton lithography. Int. J. Extrem. Manuf. 5, 035008 (2023).

Bock, S., Rades, T., Rantanen, J. & Scherließ, R. Additive manufacturing in respiratory sciences — current applications and future prospects. Adv. Drug Deliv. Rev. 186, 114341 (2022).

Kato, J., Takeyasu, N., Adachi, Y., Sun, H.-B. & Kawata, S. Multiple-spot parallel processing for laser micronanofabrication. Appl. Phys. Lett. 86, 044102 (2005).

Dong, X. Z., Zhao, Z. S. & Duan, X. M. Micronanofabrication of assembled three-dimensional microstructures by designable multiple beams multiphoton processing. Appl. Phys. Lett. 91, 124103 (2007).

Gittard, S. D. et al. Fabrication of microscale medical devices by two-photon polymerization with multiple foci via a spatial light modulator. Biomed. Opt. Express 2, 3167 (2011).

Zheng, X. et al. Design and optimization of a light-emitting diode projection micro-stereolithography three-dimensional manufacturing system. Rev. Sci. Instrum. 83, 125001 (2012).

Zheng, X. et al. Ultralight, ultrastiff mechanical metamaterials. Science 344, 1373–1377 (2014).

Zheng, X. et al. Multiscale metallic metamaterials. Nat. Mater. 15, 1100–1106 (2016).

ProJet 7000 HD. 3D Systems. https://www.3dsystems.com/3d-printers/projet-7000-hd (2012).

Nanoscribe Photonic Professional GT datasheet. https://www.nanoscribe.com (2014).

Bückmann, T., Thiel, M., Kadic, M., Schittny, R. & Wegener, M. An elasto-mechanical unfeelability cloak made of pentamode metamaterials. Nat. Commun. 5, 4130 (2014).

Yan, W., Cumming, B. P. & Gu, M. High-throughput fabrication of micrometer-sized compound parabolic mirror arrays by using parallel laser direct-write processing. J. Opt. 17, 075803 (2015).

EOS P 770 with PA 2200 Top Speed 1.0 datasheet and vendor information. https://www.eos.info (2016).

EOS P 110 with PA 2200 Top Quality 1.0 datasheet and vendor information. https://www.eos.info (2016).

Pearre, B. W., Michas, C., Tsang, J.-M., Gardner, T. J. & Otchy, T. M. Fast micron-scale 3D printing with a resonant-scanning two-photon microscope. Addit. Manuf. 30, 100887 (2019).

Maibohm, C. et al. Multi-beam two-photon polymerization for fast large area 3D periodic structure fabrication for bioapplications. Sci. Rep. https://doi.org/10.1038/s41598-020-64955-9 (2020).

Stüwe, L. et al. Continuous volumetric 3D printing: xolography in flow. Adv. Mater. 11, e2036716 (2023).

Acknowledgements

The authors thank V. Hahn for the valuable discussions. The authors acknowledge support by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) via the Excellence Cluster “3D Matter Made to Order”, EXC-2082/1-390761711, by the Carl Zeiss Foundation through the “Carl-Zeiss-Foundation-Focus@HEiKA”, by the Helmholtz Association via the program “Materials Systems Engineering”, by the Karlsruhe School of Optics & Photonics (KSOP) at KIT and by the Max Planck School of Photonics (MPSP). X.X. acknowledges the support by the US National Science Foundation (CMMI-2135585). S.M. acknowledges the support by JST CREST JPMJCR1905.

Author information

Authors and Affiliations

Contributions

M.W. and P.S. wrote the first draft. P.S. and A.M. arranged the figures. All authors contributed to the writing of all parts of the review.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Reviews Physics thanks Saulius Juodkazis and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Somers, P., Münchinger, A., Maruo, S. et al. The physics of 3D printing with light. Nat Rev Phys 6, 99–113 (2024). https://doi.org/10.1038/s42254-023-00671-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s42254-023-00671-3