Abstract

Chemical vapour deposition (CVD) enables nanoscale control for the synthesis of high-purity polymer thin films. Ultrathin (<20 nm) and ultrasmooth (<1 nm r.m.s. roughness) layers of CVD polymers can conform to the geometry of the growth surface. This Review focuses on CVD polymerization methods adapted from solution chemistry for selectively forming different classes of macromolecules. The mechanistically based CVD approaches provide full retention of the monomer’s organic functional groups and thus provide a rational basis for designing and optimizing film characteristics for a diverse array of applications. These include conjugated polymers for energy storage, thin dielectrics for low-power, flexible devices and responsive hydrogels for controlled drug release. Systematic variation in the CVD process parameters provides remarkable control of π–π stacking in conducting polymers, mesh sizes in hydrogels, crystallographic texture, surface energy, permeation rates of molecules and ions, optoelectronic properties and switchable smart behaviour. The initial research focus on process fundamentals, including adsorption, reaction kinetics, mass transport and conformality, formed a strong basis for the recent rapid expansion of materials, applications and scale-up activities in multiple laboratories. The materials and approaches used in CVD polymerization are also extending into hybrid inorganic/organic materials and devices.

Key points

The purity, precision and pinhole-free nature of CVD expands the realm of utility for polymer films in applications including optoelectronics, energy and wearable devices; membranes for molecular separation; and biointerfaces.

Conformal CVD polymers are compatible with nanostructured substrates and 3D device architectures, while low growth temperatures and the absence of solvent allow CVD polymers to form directly on fragile substrates, even liquids, without the need for a complex transfer step.

Adapting the mechanisms developed for solution synthesis enables the growth of different families of CVD macromolecules, representing hundreds of organic homopolymers, copolymers, crosslinked networks and hybrid organic/inorganic materials.

The diverse library of compositions allows CVD polymers to span full ranges of properties, for instance, from electronic conductors to insulators, from superhydrophobic to superhydrophilic and from mass-transport barriers to semipermeable layers for molecular and ionic transport.

Preserving the organic functional groups present in monomers is essential for designing and rationally optimizing the properties of CVD polymers, such as the fine-tuning of surface energy, forming a high density of sites for further surface reaction, or achieving smart, responsive behaviour for applications including sensing and controlled drug release.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$99.00 per year

only $8.25 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Gleason, K. CVD Polymers: Fabrication of Organic Surfaces and Devices (Wiley, 2015).

Wang, M. et al. CVD polymers for devices and device fabrication. Adv. Mater. 29, 1604606 (2017).

Matsumura, H., Umemoto, H., Gleason, K. K. & Schropp, R. E. I. Catalytic Chemical Vapor Deposition 179–247 (Wiley, 2019).

Manawi, Y. M., Ihsanullah, Samara, A., Al-Ansari, T. & Atieh, M. A. A review of carbon nanomaterials’ synthesis via the chemical vapor deposition (CVD) method. Materials 11, 822 (2018).

Liu, X. et al. A review of perovskite photovoltaic materials’ synthesis and applications via chemical vapor deposition method. Materials 12, 1–17 (2019).

Howden, R. M., Flores, E. J., Bulović, V. & Gleason, K. K. The application of oxidative chemical vapor deposited (oCVD) PEDOT to textured and non-planar photovoltaic device geometries for enhanced light trapping. Org. Electron. 14, 2257–2268 (2013).

Gupta, M. & Gleason, K. K. Large-scale initiated chemical vapor deposition of poly(glycidyl methacrylate) thin films. Thin Solid Films 515, 1579–1584 (2006).

Kovacik, P., Del Hierro, G., Livernois, W. & Gleason, K. K. Scale-up of oCVD: large-area conductive polymer thin films for next-generation electronics. Mater. Horiz. 2, 221–227 (2015).

Yilmaz, K., Sakalak, H., Gürsoy, M. & Karaman, M. Initiated chemical vapor deposition of poly(ethylhexyl acrylate) films in a large-scale batch reactor. Ind. Eng. Chem. Res. 58, 14795–14801 (2019).

Cheng, C. & Gupta, M. Roll-to-roll surface modification of cellulose paper via initiated chemical vapor deposition. Ind. Eng. Chem. Res. 57, 11675–11680 (2018).

Pryce Lewis, H. G., Bansal, N. P., White, A. J. & Handy, E. S. HWCVD of polymers: commercialization and scale-up. Thin Solid Films 517, 3551–3554 (2009).

Randall, G. C., Gonzalez, L., Petzoldt, R. & Elsner, F. An evaporative initiated chemical vapor deposition coater for nanoglue bonding. Adv. Eng. Mater. 20, 1700839 (2018).

Ibanez, J. G. et al. Conducting polymers in the fields of energy, environmental remediation, and chemical-chiral sensors. Chem. Rev. 118, 4731–4816 (2018).

Petsagkourakis, I., Kim, N., Tybrandt, K., Zozoulenko, I. & Crispin, X. Poly(3,4-ethylenedioxythiophene): chemical synthesis, transport properties, and thermoelectric devices. Adv. Electron. Mater. 5, 1800918 (2019).

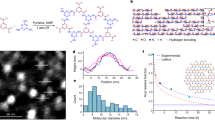

Heydari Gharahcheshmeh, M., Tavakoli, M. M. & Gleason, E. F. Tuning, optimization, and perovskite solar cell device integration of ultrathin poly (3,4-ethylene dioxythiophene) films via a single-step all-dry process. Sci. Adv. 5, eaay0414 (2019). Systematic tuning of the β-axis lattice parameter from 0.702 nm down to 0.697 nm, corresponded in 5,600% increase in electrical conductivity of face-on oriented semicrystalline thin films of oxidative CVD (oCVD) poly(3,4-ethylenedioxythiophene) (PEDOT).

Heydari Gharahcheshmeh, M. & Gleason, K. K. Device fabrication based on oxidative chemical vapor deposition (oCVD) synthesis of conducting polymers and related conjugated organic materials. Adv. Mater. Interfaces 6, 1801564 (2019).

Jaros, A. et al. Optical properties and carrier dynamics in inorganic and hybrid inorganic/organic ZnO- and GaN-based nanowire structures. Phys. Status Solidi B 256, 1800463 (2019).

Barr, M. C. et al. Direct monolithic integration of organic photovoltaic circuits on unmodified paper. Adv. Mater. 23, 3499–3505 (2011).

Andrew, T. L. et al. Melding vapor-phase organic chemistry and textile manufacturing to produce wearable electronics. Acc. Chem. Res. 51, 850–859 (2018).

Minami, T. Transparent conducting oxide semiconductors for transparent electrodes. Semicond. Sci. Technol. 20, S35 (2005).

Gleason, K. K. Chemically vapor deposited polymer nanolayers for rapid and controlled permeation of molecules and ions. J. Vac. Sci. Technol. A 38, 020801 (2020).

Schamberger, F., Ziegler, A. & Franz, G. Influence of film thickness and deposition rate on surface quality of polyparylene coatings. J. Vac. Sci. Technol. B 30, 051801 (2012).

Odian, G. Principles of Polymerization (Wiley, 2004).

Lock, J. P., Im, S. G. & Gleason, K. K. Oxidative chemical vapor deposition of electrically conducting poly(3,4-ethylenedioxythiophene) films. Macromolecules 39, 5326–5329 (2006).

Bilger, D., Homayounfar, S. Z. & Andrew, T. L. A critical review of reactive vapor deposition for conjugated polymer synthesis. J. Mater. Chem. C 7, 7159–7174 (2019).

Baba, K. et al. Conductive directly fused poly(porphyrin) coatings by oxidative chemical vapour deposition — from single- to triple-fused. Eur. J. Org. Chem. 2019, 2368–2375 (2019).

Schöfberger, W. et al. Biofunctionalized conductive polymers enable efficient CO2 electroreduction. Sci. Adv. 3, e1700686 (2017).

Im, S. G. et al. Conformal coverage of poly(3,4-ethylenedioxythiophene) films with tunable nanoporosity. ACS Nano. 2, 1959–1967 (2008).

Atanasov, S. E. et al. Highly conductive and conformal poly(3,4-ethylenedioxythiophene) (PEDOT) thin films via oxidative molecular layer deposition. Chem. Mater. 26, 3471–3478 (2014).

Nejati, S. & Lau, K. K. S. Chemical vapor deposition synthesis of tunable unsubstituted polythiophene. Langmuir 27, 15223–15229 (2011).

Smolin, Y. Y., Soroush, M. & Lau, K. K. S. Influence of oCVD polyaniline film chemistry in carbon-based supercapacitors. Ind. Eng. Chem. Res. 56, 6221–6228 (2017).

Farka, D. et al. Anderson-localization and the Mott–Ioffe–Regel limit in glassy-metallic PEDOT. Adv. Electron. Mater. 3, 1700050 (2017).

Chelawat, H., Vaddiraju, S. & Gleason, K. Conformal, conducting poly(3,4-ethylenedioxythiophene) thin films deposited using bromine as the oxidant in a completely dry oxidative chemical vapor deposition process. Chem. Mater. 22, 2864–2868 (2010).

Im, S. G., Yoo, P. J., Hammond, P. T. & Gleason, K. K. Grafted conducting polymer films for nano-patterning onto various organic and inorganic substrates by oxidative chemical vapor deposition. Adv. Mater. 19, 2863–2867 (2007).

Trujillo, N. J., Barr, M. C., Im, S. G. & Gleason, K. K. Oxidative chemical vapor deposition (oCVD) of patterned and functional grafted conducting polymer nanostructures. J. Mater. Chem. 20, 3968–3972 (2010).

Lassnig, A., Nakamura, N., Jörg, T., Reeja-Jayan, B. & Cordill, M. J. Molecularly grafted, structurally integrated multifunctional polymer thin films with improved adhesion. Surf. Coat. Technol. 349, 963–968 (2018).

Mao, Y. & Gleason, K. K. Hot filament chemical vapor deposition of poly(glycidyl methacrylate) thin films using tert-butyl peroxide as an initiator. Langmuir 20, 2484–2488 (2004).

Bose, R. K., Nejati, S., Stufflet, D. R. & Lau, K. K. S. Graft polymerization of anti-fouling PEO surfaces by liquid-free initiated chemical vapor deposition. Macromolecules 45, 6915–6922 (2012).

Gao, Y., Cole, B. & Tenhaeff, W. E. Chemical vapor deposition of polymer thin films using cationic initiation. Macromol. Mater. Eng. 303, 1700425 (2018).

Chan, K. & Gleason, K. K. Photoinitiated chemical vapor deposition of polymeric thin films using a volatile photoinitiator. Langmuir 21, 11773–11779 (2005).

Martin, T. P., Sedransk, K. L., Chan, K., Baxamusa, S. H. & Gleason, K. K. Solventless surface photoinitiated polymerization: grafting chemical vapor deposition (gCVD). Macromolecules 40, 4586–4591 (2007).

Boscher, N. D. et al. Metal–organic covalent network chemical vapor deposition for gas separation. Adv. Mater. 28, 7479–7485 (2016).

Loyer, F., Bulou, S., Choquet, P. & Boscher, N. D. Pulsed plasma initiated chemical vapor deposition (PiCVD) of polymer layers — a kinetic model for the description of gas phase to surface interactions in pulsed plasma discharges. Plasma Process. Polym. 15, 1800121 (2018).

Gleason, K. K. in Surface Modification of Polymers: Methods and Applications (eds Pinson, J. & Thiry, D.) 107–134 (Wiley, 2019).

Wang, X. et al. High electrical conductivity and carrier mobility in oCVD PEDOT thin films by engineered crystallization and acid treatment. Sci. Adv. 4, eaat5780 (2018).

Karnath, M. A., Sheng, Q., White, A. J. & Müftü, S. Frictional characteristics of ultra-thin polytetrafluoroethylene (PTFE) films deposited by hot filament-chemical vapor deposition (HFCVD). Tribol. Trans. 54, 36–43 (2011).

George, S. M., Dameron, A. A. & Yoon, B. Surface chemistry for molecular layer deposition of organic and hybrid organic–inorganic polymers. Acc. Chem. Res. 42, 498–508 (2009).

Zhou, H. & Bent, S. F. Fabrication of organic interfacial layers by molecular layer deposition: present status and future opportunities. J. Vac. Sci. Technol. A 31, 040801 (2013).

Chen, H. Y. & Lahann, J. Designable biointerfaces using vapor-based reactive polymers. Langmuir 27, 34–48 (2011).

Hassan, Z., Spuling, E., Knoll, D. M. & Bräse, S. Regioselective functionalization of [2.2]paracyclophanes: recent synthetic progress and perspectives. Angew. Chem. Int. Ed. 58, 2–17 (2019).

Wang, X. et al. High electrical conductivity and carrier mobility in oCVD PEDOT thin films by engineered crystallization and acid treatment. Sci. Adv. 4, eaat5780 (2018).

Gueye, M. N., Carella, A., Faure-Vincent, J., Demadrille, R. & Simonato, J.-P. Progress in understanding structure and transport properties of PEDOT-based materials: a critical review. Prog. Mater. Sci. 108, 100616 (2019).

Abessolo Ondo, D. et al. Atmospheric plasma oxidative polymerization of ethylene dioxythiophene (EDOT) for the large-scale preparation of highly transparent conducting thin films. Plasma Process. Polym. 15, e1700172 (2018).

Ugur, A. et al. Low-dimensional conduction mechanisms in highly conductive and transparent conjugated polymers. Adv. Mater. 27, 4604–4610 (2015).

Farka, D., Jones, A. O. F., Menon, R., Sariciftci, N. S. & Stadler, P. Metallic conductivity beyond the Mott minimum in PEDOT: sulphate at low temperatures. Synth. Met. 240, 59–66 (2018).

Xu, Y. et al. Molecular engineered conjugated polymer with high thermal conductivity. Sci. Adv. 4, eaar3031 (2018).

Moni, P. et al. Growth temperature and electrochemical performance in vapor-deposited poly(3,4-ethylenedioxythiophene) thin films for high-rate electrochemical energy storage. ACS Appl. Energy Mater. 1, 7093–7105 (2018).

Klemens, P. G. Phonon scattering and thermal resistance due to grain boundaries. Int. J. Thermophys. 15, 1345–1351 (1994).

Franco-Gonzalez, J. F. & Zozoulenko, I. V. Molecular dynamics study of morphology of doped PEDOT: from solution to dry phase. J. Phys. Chem. B 121, 4299–4307 (2017).

Noriega, R. et al. A general relationship between disorder, aggregation and charge transport in conjugated polymers. Nat. Mater. 12, 1038–1044 (2013).

Mollinger, S. A., Krajina, B. A., Noriega, R., Salleo, A. & Spakowitz, A. J. Percolation, tie-molecules, and the microstructural determinants of charge transport in semicrystalline conjugated polymers. ACS Macro Lett. 4, 708–712 (2015).

Drewelow, G., Wook Song, H., Jiang, Z. T. & Lee, S. Factors controlling conductivity of PEDOT deposited using oxidative chemical vapor deposition. Appl. Surf. Sci. 501, 144105 (2020).

Lee, S., Paine, D. C. & Gleason, K. K. Heavily doped poly(3,4-ethylenedioxythiophene) thin films with high carrier mobility deposited using oxidative CVD: conductivity stability and carrier transport. Adv. Funct. Mater. 24, 7187–7196 (2014).

Salaneck, W. R., Friend, R. H. & Brédas, J. L. Electronic structure of conjugated polymers: consequences of electron–lattice coupling. Phys. Rep. 319, 231–251 (1999).

Heeger, A. J., Sarichiftci, N. S. & Namdas, E. B. Semiconducting and Metallic Polymers (Oxford Univ. Press, 2010).

Rolland, N., Franco-Gonzalez, J. F. & Zozoulenko, I. Can mobility negative temperature coefficient be reconciled with the hopping character of transport in conducting polymers? ACS Appl. Polym. Mater. 1, 2833–2839 (2019).

Lee, S., Borrelli, D. C., Jo, W. J., Reed, A. S. & Gleason, K. K. Nanostructured unsubstituted polythiophene films deposited using oxidative chemical vapour deposition: hopping conduction and thermal stability. Adv. Mater. Interfaces 5, 1701513 (2018).

Petsagkourakis, I., Kim, N., Tybrandt, K., Zozoulenko, I. & Crispin, X. Poly(3,4-ethylenedioxythiophene): chemical synthesis, transport properties, and thermoelectric devices. Adv. Electron. Mater. 5, 1800918 (2019).

Smith, P. M. et al. Thermal conductivity of poly(3,4-ethylenedioxythiophene) films engineered by oxidative chemical vapor deposition (oCVD). RSC Adv. 8, 19348–19352 (2018).

Arnold, S. P., Harris, J. K., Neelamraju, B., Rudolph, M. & Ratcliff, E. L. Microstructure-dependent electrochemical properties of chemical-vapor deposited poly(3,4-ethylenedioxythiophene) (PEDOT) films. Synth. Met. 253, 26–33 (2019).

Zhang, L. & Andrew, T. L. Deposition dependent ion transport in doped conjugated polymer films: insights for creating high-performance electrochemical devices. Adv. Mater. Interfaces 4, 1700873 (2017).

Evans, D. et al. Structure-directed growth of high conductivity PEDOT from liquid-like oxidant layers during vacuum vapor phase polymerization. J. Mater. Chem. 22, 14889–14895 (2012).

Xu, G. L. et al. Building ultraconformal protective layers on both secondary and primary particles of layered lithium transition metal oxide cathodes. Nat. Energy 4, 484–494 (2019). In addition to enhancing ion transport, ultrathin encapsulation by oxidative CVD (oCVD) poly(3,4-ethylenedioxythiophene) (PEDOT) improves cathode stability by suppressing undesired phase transformation and reducing mechanical cracking.

Su, L., Smith, P. M., Anand, P. & Reeja-Jayan, B. Surface engineering of a LiMn2O4 electrode using nanoscale polymer thin films via chemical vapor deposition polymerization. ACS Appl. Mater. Interfaces 10, 27063–27073 (2018).

Nejati, S., Minford, T. E., Smolin, Y. Y. & Lau, K. K. S. Enhanced charge storage of ultrathin polythiophene films within porous nanostructures. ACS Nano 8, 5413–5422 (2014).

Zhou, Y. et al. Ultrahigh-areal-capacitance flexible supercapacitor electrodes enabled by conformal P3MT on horizontally aligned carbon-nanotube arrays. Adv. Mater. 31, 1901916 (2019).

Lachman, N. et al. Synthesis of polymer bead nano-necklaces on aligned carbon nanotube scaffolds. Nanotechnology 28, 24LT01 (2017).

Lachman, N. et al. Tailoring thickness of conformal conducting polymer decorated aligned carbon nanotube electrodes for energy storage. Adv. Mater. Interfaces 1, 1400076 (2014).

Smolin, Y. Y. et al. Engineering ultrathin polyaniline in micro/mesoporous carbon supercapacitor electrodes using oxidative chemical vapor deposition. Adv. Mater. Interfaces 4, 1601201 (2017).

Liu, A. et al. Monolithic flexible supercapacitors integrated into single sheets of paper and membrane via vapor printing. Adv. Mater. 29, 160691 (2017).

Zhang, L. & Andrew, T. L. Using the surface features of plant matter to create all-polymer pseudocapacitors with high areal capacitance. ACS Appl. Mater. Interfaces 10, 38574–38580 (2018).

Kim, J. J., Allison, L. K. & Andrew, T. L. Vapor-printed polymer electrodes for long-term, on-demand health monitoring. Sci. Adv. 5, eaaw0463 (2019).

Kaviani, S., Mohammadi Ghaleni, M., Tavakoli, E. & Nejati, S. Electroactive and conformal coatings of oxidative chemical vapor deposition polymers for oxygen electroreduction. ACS Appl. Polym. Mater. 1, 552–560 (2019). Electrocatalysts that are metal-free and capable of being scaled up to large deposition areas are fabricated from conformal layers of oxidative CVD (oCVD) poly(3,4-ethylenedioxythiophene) (PEDOT) on carbon cloth.

De Luna, M. M., Karandikar, P. & Gupta, M. Interactions between polymers and liquids during initiated chemical vapor deposition onto liquid substrates. Mol. Syst. Des. Eng. 5, 15–21 (2020). Provides synthetic guidelines for producing organic and hybrid organic/inorganic particles, films and gels using initiated CVD (iCVD) onto silicone oils and ionic liquids.

Wang, Y. et al. Polymer-based gate dielectrics for organic field-effect transistors. Chem. Mater. 31, 2212–2240 (2019).

Moon, H. et al. Synthesis of ultrathin polymer insulating layers by initiated chemical vapour deposition for low-power soft electronics. Nat. Mater. 14, 628–635 (2015).

Yang, S. C. et al. Large-scale, low-power nonvolatile memory based on few-layer MoS2 and ultrathin polymer dielectrics. Adv. Electron. Mater. 5, 1800688 (2019). Ultrathin, ultrasmooth and flexible high-κ dielectrics (κ ≈ 6.2) form from the initiated CVD (iCVD) copolymerization of the monomer 2-cyanoethyl acrylate and the di(ethylene glycol) divinyl ether.

Yoo, H. et al. Highly stacked 3D organic integrated circuits with via-hole-less multilevel metal interconnects. Nat. Commun. 10, 2424 (2019).

Oh, J. G. et al. A high-performance top-gated graphene field-effect transistor with excellent flexibility enabled by an iCVD copolymer gate dielectric. Small 14, 1703035 (2018).

Choi, J. et al. Spontaneous generation of a molecular thin hydrophobic skin layer on a sub-20 nm, high-k polymer dielectric for extremely stable organic thin-film transistor operation. ACS Appl. Mater. Interfaces 11, 29113–29123 (2019).

Jang, B. C. et al. Polymer analog memristive synapse with atomic-scale conductive filament for flexible neuromorphic computing system. Nano Lett. 19, 839–849 (2019).

Kim, M. J., Pak, K., Hwang, W. S., Im, S. G. & Cho, B. J. Novel vapor-phase synthesis of flexible, homogeneous organic–inorganic hybrid gate dielectric with sub 5 nm equivalent oxide thickness. ACS Appl. Mater. Interfaces 10, 37326–37334 (2018).

Kim, M. J. et al. Ultrathin ZrOx-organic hybrid dielectric (EOT 3.2 nm) via initiated chemical vapor deposition for high-performance flexible electronics. ACS Appl. Mater. Interfaces 11, 44513–44520 (2019).

Schröder, S., Strunskus, T., Rehders, S., Gleason, K. K. & Faupel, F. Tunable polytetrafluoroethylene electret films with extraordinary charge stability synthesized by initiated chemical vapor deposition for organic electronics applications. Sci. Rep. 9, 2237 (2019). Mechanical-flexible, triboelectric energy harvesters compatible with wearable electronics are demonstrated using initiated CVD (iCVD) fluoropolymer films ranging from 0.5 μm to 12 μm in thickness.

Kim, D. et al. A study of the charge distribution and output characteristics of an ultra-thin tribo-dielectric layer. Nano Energy 62, 458–464 (2019).

Wanwong, S., Sangkhun, W., Homayounfar, S. Z., Park, K. W. & Andrew, T. L. Wash-stable, oxidation resistant conductive cotton electrodes for wearable electronics. RSC Adv. 9, 9198–9203 (2019).

Pak, K., Choi, J., Lee, C. & Im, S. G. Low-power, flexible nonvolatile organic transistor memory based on an ultrathin bilayer dielectric stack. Adv. Electron. Mater. 5, 1800799 (2019).

Chen, N. et al. iCVD cyclic polysiloxane and polysilazane as nanoscale thin-film electrolyte: synthesis and properties. Macromol. Rapid Commun. 37, 446–452 (2016).

Sassin, M. B., Long, J. W., Wallace, J. M. & Rolison, D. R. Routes to 3D conformal solid-state dielectric polymers: electrodeposition versus initiated chemical vapor deposition. Mater. Horiz. 2, 502–508 (2015).

Carter, R. et al. Initiated chemical vapor deposition of ultrathin polymer coatings at graphite electrodes for enhanced performance in Li-ion batteries. J. Electrochem. Soc. 167, 060510 (2020).

Shen, B. H., Wang, S. & Tenhaeff, W. E. Ultrathin conformal polycyclosiloxane films to improve silicon cycling stability. Sci. Adv. 5, eaaw4856 (2019).

Li, W., Bradley, L. C. & Watkins, J. J. Copolymer solid-state electrolytes for 3D microbatteries via initiated chemical vapor deposition. ACS Appl. Mater. Interfaces 11, 5668–5674 (2019).

Mao, X. et al. Enhancing performance stability of electrochemically active polymers by vapor-deposited organic networks. Adv. Funct. Mater. 28, 1706028 (2018).

Kim, J. H. et al. Conformal, wafer-scale and controlled nanoscale doping of semiconductors via the iCVD process. In 2018 IEEE International Electron Devices Meeting (IEDM), https://doi.org/10.1109/IEDM.2018.8614494 (IEEE, 2018).

Suh, H. S. et al. Sub-10-nm patterning via directed self-assembly of block copolymer films with a vapour-phase deposited topcoat. Nat. Nanotechnol. 12, 575–581 (2017). Ultrathin, crosslinked initiated CVD (iCVD) films grown from divinylbenzene (DVB) adjust the favoured orientation of underlying block copolymer layer for high-resolution patterning of silicon wafers.

Moni, P. et al. Ultrathin and conformal initiated chemical-vapor-deposited layers of systematically varied surface energy for controlling the directed self-assembly of block copolymers. Langmuir 34, 4494–4502 (2018).

Dolejsi, M. et al. Ultrathin initiated chemical vapor deposition polymer interfacial energy control for directed self-assembly hole-shrink applications. J. Vac. Sci. Technol. B 37, 061804 (2019).

Yang, G. G. et al. Conformal 3D nanopatterning by block copolymer lithography with vapor-phase deposited neutral adlayer. ACS Nano 13, 13092–13099 (2019).

Qiang, Z., Akolawala, S. A. & Wang, M. Simultaneous in-film polymer synthesis and self-assembly for hierarchical nanopatterns. ACS Macro Lett. 7, 566–571 (2018).

Park, H. et al. Organic solar cells with graphene electrodes and vapor printed poly(3,4-ethylenedioxythiophene) as the hole transporting layers. ACS Nano 6, 6370–6377 (2012).

Yang, H., Wang, H., Feng, J., Ye, Y. & Liu, W. Solventless synthesis and patterning of UV-responsive poly(allyl methacrylate) film. Macromol. Chem. Phys. 220, 190029 (2019).

Kim, S. et al. Ultrathin high-resolution flexographic printing using nanoporous stamps. Sci. Adv. 2, e1601660 (2016).

Mariappan, D. et al. Dynamics of liquid transfer from nanoporous stamps in high-resolution flexographic printing. Langmuir 35, 7659–7671 (2019).

Sojoudi, H. et al. Stable wettability control of nanoporous microstructures by iCVD coating of carbon nanotubes. ACS Appl. Mater. Interfaces 9, 43287–43299 (2017).

Moon, H., Jeong, K., Kwak, M. J., Choi, S. Q. & Im, S. G. Solvent-free deposition of ultrathin copolymer films with tunable viscoelasticity for application to pressure-sensitive adhesives. ACS Appl. Mater. Interfaces 10, 32668–32677 (2018).

Kwak, M. J. et al. A sub-minute curable nanoadhesive with high transparency, strong adhesion, and excellent flexibility. Macromolecules 51, 992–1001 (2018).

Seo, S. et al. Parylene based thin-film microfluidic lens array fabricated by iCVD nano-adhesive bonding. Polymer 181, 121763 (2019).

Baxamusa, S. H. et al. Initiated chemical vapor deposition polymers for high peak-power laser targets. Thin Solid Films 635, 37–41 (2017).

Soto, D., Ugur, A., Farnham, T. A., Gleason, K. K. & Varanasi, K. K. Short-fluorinated iCVD coatings for nonwetting fabrics. Adv. Funct. Mater. 28, 1707355 (2018).

Cheng, C. & Gupta, M. Surface functionalization of 3D-printed plastics via initiated chemical vapor deposition. Beilstein J. Nanotechnol. 8, 1629–1639 (2017).

Seok, J. H., Kim, S. H., Cho, S. M., Yi, G. R. & Lee, J. Y. Crosslinked organosilicon-acrylate copolymer moisture barrier thin film fabricated by initiated chemical vapor deposition (iCVD). Macromol. Res. 26, 1257–1264 (2018).

Vilaró, I., Yagüe, J. L. & Borrós, S. Superhydrophobic copper surfaces with anticorrosion properties fabricated by solventless CVD methods. ACS Appl. Mater. Interfaces 9, 1057–1065 (2017).

Chen, Y., Ye, Y. & Chen, Z. R. Vapor-based synthesis of bilayer anti-corrosion polymer coatings with excellent barrier property and superhydrophobicity. J. Mater. Sci. 54, 5907–5917 (2019). Arrays of micrometre-scale conical features form spontaneously by growing a crosslinked fluoropolymer synthesized initiated CVD (iCVD) on top of a higher-surface-energy, fluorine-free iCVD crosslinked layer.

McGaughey, A., Karandikar, P., Gupta, M. & Childress, A. Hydrophobicity versus pore size: polymer coatings to improve membrane wetting resistance for membrane distillation. ACS Appl. Polym. Mater. 2, 1256–1267 (2020).

Khalil, K. et al. Grafted nanofilms promote dropwise condensation of low-surface-tension fluids for high-performance heat exchangers. Joule 3, 1377–1388 (2019).

Sojoudi, H. et al. Scalable and durable polymeric icephobic and hydrate-phobic coatings. Soft Matter 14, 3443–3454 (2018).

Sojoudi, H. et al. Micro-/nanoscale approach for studying scale formation and developing scale-resistant surfaces. ACS Appl. Mater. Interfaces 11, 7330–7337 (2019).

Zhao, J., Wang, M., Jebutu, M. S., Zhu, M. & Gleason, K. Fundamental nanoscale surface strategies for robustly controlling heterogeneous nucleation of calcium carbonate. J. Mater. Chem. A 7, 17242–17247 (2019).

Çıtak, E., İstanbullu, B., Şakalak, H., Gürsoy, M. & Karaman, M. All-dry hydrophobic functionalization of paper surfaces for efficient transfer of CVD graphene. Macromol. Chem. Phys. 220, 1900277 (2019).

Annavarapu, R. K., Kim, S., Wang, M., Hart, A. J. & Sojoudi, H. Explaining evaporation-triggered wetting transition using local force balance model and contact line-fraction. Sci. Rep. 9, 405 (2019).

Coclite, A. M., Shi, Y. & Gleason, K. K. Controlling the degree of crystallinity and preferred crystallographic orientation in poly-perfluorodecylacrylate thin films by initiated chemical vapor deposition. Adv. Funct. Mater. 22, 2167–2176 (2012).

Coclite, A. M., Shi, Y. & Gleason, K. K. Grafted crystalline poly-perfluoroacrylate structures for superhydrophobic and oleophobic functional coatings. Adv. Mater. 24, 4534–4539 (2012).

Perrotta, A., Christian, P., Jones, A. O. F., Muralter, F. & Coclite, A. M. Growth regimes of poly(perfluorodecyl acrylate) thin films by initiated chemical vapor deposition. Macromolecules 51, 5694–5703 (2018).

Christian, P. & Coclite, A. M. Vapor-phase-synthesized fluoroacrylate polymer thin films: thermal stability and structural properties. Beilstein J. Nanotechnol. 8, 933–942 (2017).

Lee, H. S., Kim, H., Lee, J. H. & Kwak, J. B. Fabrication of a conjugated fluoropolymer film using one-step iCVD process and its mechanical durability. Coatings 9, 430 (2019).

Özpirin, M. & Ebil, Ö. Transparent block copolymer thin films for protection of optical elements via chemical vapor deposition. Thin Solid Films 660, 391–398 (2018).

Liu, A., Goktekin, E. & Gleason, K. K. Cross-linking and ultrathin grafted gradation of fluorinated polymers synthesized via initiated chemical vapor deposition to prevent surface reconstruction. Langmuir 30, 14189–14194 (2014).

Yun, G. T. et al. Springtail-inspired superomniphobic surface with extreme pressure resistance. Sci. Adv. 4, eaat4978 (2018).

Chen, Z. & Lau, K. K. S. Suppressing crystallinity by nanoconfining polymers using initiated chemical vapor deposition. Macromolecules 52, 5183–5191 (2019).

Aktas, O. C. et al. Superhydrophobic 3D porous PTFE/TiO2 hybrid structures. Adv. Mater. Interfaces 6, 2–6 (2019).

Coclite, A. M. & Gleason, K. K. Global and local planarization of surface roughness by chemical vapor deposition of organosilicon polymer for barrier applications. J. Appl. Phys. 111, 073516 (2012).

Ichiki, K., Altemus, B., Gildea, A. & Faguet, J. Feasibility study into the deposition of an organic planarization layer using sequential polymerization initiated chemical vapor deposition. Thin Solid Films 635, 23–26 (2017).

Dianat, G., Movsesian, N. & Gupta, M. Process–structure–property relationships for porous membranes formed by polymerization of solid monomer by a vapor-phase initiator. Macromolecules 51, 10297–10303 (2018).

Movsesian, N., Tittensor, M., Dianat, G., Gupta, M. & Malmstadt, N. Giant lipid vesicle formation using vapor-deposited charged porous polymers. Langmuir 34, 9025–9035 (2018).

Dianat, G., Movsesian, N. & Gupta, M. Vapor deposition of functional porous polymer membranes. ACS Appl. Polym. Mater. 2, 98–104 (2020).

Nguyen, B., Dabir, S., Tsotsis, T. & Gupta, M. Fabrication of hydrogen-selective silica membranes via pyrolysis of vapor deposited polymer films. Ind. Eng. Chem. Res. 58, 15190–15198 (2019).

De Luna, M. M., Karandikar, P. & Gupta, M. Synthesis of inorganic/organic hybrid materials via vapor deposition onto liquid surfaces. ACS Appl. Nano Mater. 1, 6575–6579 (2018).

Lee, Y. I. et al. A low-temperature thin-film encapsulation for enhanced stability of a highly efficient perovskite solar cell. Adv. Energy Mater. 8, 1701928 (2018).

Unger, K. et al. Novel light-responsive biocompatible hydrogels produced by initiated chemical vapor deposition. ACS Appl. Mater. Interfaces 9, 17408–17416 (2017).

Burk, M. H. et al. Fabrication of diazocine-based photochromic organic thin films via initiated chemical vapor deposition. Macromolecules https://doi.org/10.1021/acs.macromol.9b02443 (2020).

Coclite, A. M. Smart surfaces by initiated chemical vapor deposition. Surf. Innov. 1, 6–14 (2013).

Buchberger, A., Peterka, S., Coclite, A. & Bergmann, A. Fast optical humidity sensor based on hydrogel thin film expansion for harsh environment. Sensors 19, 999 (2019).

Tufani, A. & Ozaydin Ince, G. Protein gating by vapor deposited Janus membranes. J. Memb. Sci. 575, 126–134 (2019). Nanogates formed from initiated CVD (iCVD) hydrogels enable a pH-responsive membrane for blocking, delaying or releasing biomolecules, including drugs.

Shi, X., Ye, Y., Wang, H., Liu, F. & Wang, Z. Designing pH-responsive biodegradable polymer coatings for controlled drug release via vapor-based route. ACS Appl. Mater. Interfaces 10, 38449–38458 (2018).

Sayin, S. et al. Electrospun nanofibers with pH-responsive coatings for control of release kinetics. Front. Bioeng. Biotechnol. 7, 309 (2019).

Unger, K., Resel, R. & Coclite, A. M. Dynamic studies on the response to humidity of poly (2-hydroxyethyl methacrylate) hydrogels produced by initiated chemical vapor deposition. Macromol. Chem. Phys. 217, 2372–2379 (2016).

Christian, P. et al. Controlling indomethacin release through vapor-phase deposited hydrogel films by adjusting the cross-linker density. Sci. Rep. 8, 1–12 (2018). Systematic increase in the mesh size from 0.15 nm to 3.1 nm for iCVD hydrogels utilized as layers for controlling the release of drugs.

Ghasemi-Mobarakeh, L. et al. Manipulating drug release from tridimensional porous substrates coated by initiated chemical vapor deposition. J. Appl. Polym. Sci. 136, 47858 (2019).

Muralter, F., Perrotta, A. & Coclite, A. M. Thickness-dependent swelling behavior of vapor-deposited smart polymer thin films. Macromolecules 51, 9692–9699 (2018).

Salzmann, P., Perrotta, A. & Coclite, A. M. Different response kinetics to temperature and water vapor of acrylamide polymers obtained by initiated chemical vapor deposition. ACS Appl. Mater. Interfaces 10, 6636–6645 (2018).

Muralter, F., Perrotta, A., Werzer, O. & Coclite, A. M. Interlink between tunable material properties and thermoresponsiveness of cross-linked poly(N-vinylcaprolactam) thin films deposited by initiated chemical vapor deposition. Macromolecules 52, 6817–6824 (2019).

Muralter, F., Greco, F. & Coclite, A. M. Applicability of vapor-deposited thermoresponsive hydrogel thin films in ultrafast humidity sensors/actuators. ACS Appl. Polym. Mater. 2, 1160–1168 (2020).

Werzer, O., Tumphart, S., Keimel, R., Christian, P. & Coclite, A. M. Drug release from thin films encapsulated by a temperature-responsive hydrogel. Soft Matter 15, 1853–1859 (2019).

Donadt, T. B. & Yang, R. Vapor-deposited biointerfaces and bacteria: an evolving conversation. ACS Biomater. Sci. Eng. 6, 182–197 (2020).

O’Shaughnessy, W. S., Murthy, S. K., Edell, D. J. & Gleason, K. K. Stable biopassive insulation synthesized by initiated chemical vapor deposition of poly(1,3,5-trivinyltrimethylcyclotrisiloxane). Biomacromolecules 8, 2564–2570 (2007).

Choi, M. et al. Polymer thin film–induced tumor spheroids acquire cancer stem cell-like properties. Cancer Res. 78, 6890–6902 (2018).

You, J. B. et al. Surface-modified mesh filter for direct nucleic acid extraction and its application to gene expression. Anal. Adv. Healthc. Mater. 6, 1700642 (2017).

Choi, Y. et al. Direct solvent-free modification of the inner wall of the microchip for rapid DNA extraction with enhanced capturing efficiency. Macromol. Res. https://doi.org/10.1007/s13233-020-8028-x (2019).

Wang, H. et al. Heparin free coating on PLA membranes for enhanced hemocompatibility via iCVD. Appl. Surf. Sci. 433, 869–878 (2018).

Hanak, B. W. et al. Reduced cell attachment to poly(2-hydroxyethyl methacrylate)-coated ventricular catheters in vitro. J. Biomed. Mater. Res. B 106, 1268–1279 (2018).

Choi, G. et al. Robust thin film surface with a selective antibacterial property enabled via a cross-linked ionic polymer coating for infection-resistant medical applications. ACS Biomater. Sci. Eng. 4, 2614–2622 (2018).

Youn, Y. H. et al. Simple and facile preparation of recombinant human bone morphogenetic protein-2 immobilized titanium implant via initiated chemical vapor deposition technique to promote osteogenesis for bone tissue engineering application. Mater. Sci. Eng. C. 100, 949–958 (2019).

Kim, S. H. et al. A biofunctionalized viral delivery patch for spatially defined transfection. Chem. Commun. 55, 2317–2320 (2019).

Lau, K. K. S. & Gleason, K. K. Particle surface design using an all-dry encapsulation method. Adv. Mater. 18, 1972–1977 (2006).

Şakalak, H., Yılmaz, K., Gürsoy, M. & Karaman, M. Roll-to roll initiated chemical vapor deposition of super hydrophobic thin films on large-scale flexible substrates. Chem. Eng. Sci. 215, 115466 (2020).

Zhi, B., Song, Q. & Mao, Y. Vapor deposition of polyionic nanocoatings for reduction of microglia adhesion. RSC Adv. 8, 4779–4785 (2018).

Kwong, P., Flowers, C. A. & Gupta, M. Directed deposition of functional polymers onto porous substrates using metal salt inhibitors. Langmuir 27, 10634–10641 (2011).

Boscher, N. D. et al. Gas separation: metal–organic covalent network chemical vapor deposition for gas separation. Adv. Mater. 28, 7479–7485 (2016).

Acknowledgements

The author thanks M. H. Gharahcheshmeh for help with the figures.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

K.K.G. is a co-founder of two companies that commercialize CVD polymer technologies: GVD Corporation and Dropwise Technology.

Additional information

Peer review information

Nature Reviews Physics thanks anonymous reviewers for their contribution to the peer review of this work.

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gleason, K.K. Nanoscale control by chemically vapour-deposited polymers. Nat Rev Phys 2, 347–364 (2020). https://doi.org/10.1038/s42254-020-0192-6

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s42254-020-0192-6

This article is cited by

-

Engineering solvation in initiated chemical vapour deposition for control over polymerization kinetics and material properties

Nature Synthesis (2023)

-

Chemical vapour deposition

Nature Reviews Methods Primers (2021)

-

Toward three-dimensional hybrid inorganic/organic optoelectronics based on GaN/oCVD-PEDOT structures

Nature Communications (2020)