Abstract

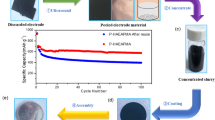

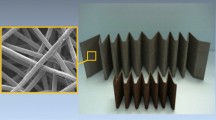

The increasing use of fibre-reinforced plastics (FRPs) has triggered an urgent need for proper end-of-life management strategies. Currently, most adopted methods are landfilling, incineration and solvolysis, which lead to undesirable environmental contamination and waste of resources. To address this issue, we develop a solvent-free and energy-efficient flash upcycling method enabling ultrafast conversion of the mixture of different FRPs to SiC, a widely used reinforcement and semiconducting material, with high yields (>90%). By tuning operation conditions, SiC with two different phases, 3C-SiC and 6H-SiC, can be selectively synthesized with high phase purity (90–99%). The obtained SiC powders can be used as the anode material for lithium-ion batteries. The 3C-SiC anode exhibits superior reversible capacity and rate performance at 0.2 C over the 6H-SiC anode (741 mAh g−1 vs 626 mAh g−1), while both show good cycling stability. Life cycle assessment reveals that the flash upcycling method developed here greatly reduces the energy demand, greenhouse gas emissions and water consumption over other available FRP disposal methods. Overall, this work provides a viable method for sustainable management of end-of-life FRPs, contributing to clean production and circular economy.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Source data are provided with this paper.

References

Goncalves, R. M., Martinho, A. & Oliveira, J. P. Recycling of reinforced glass fibers waste: current status. Materials 15, 1596 (2022).

Cunliffe, A. M. & Williams, P. T. Characterisation of products from the recycling of glass fibre reinforced polyester waste by pyrolysis. Fuel 82, 2223–2230 (2003).

Cui, G. et al. Massive growth of graphene quartz fiber as a multifunctional electrode. ACS Nano 14, 5938–5945 (2020).

Cheng, Y. et al. Graphene infrared radiation management targeting photothermal conversion for electric-energy-free crude oil collection. J. Am. Chem. Soc. 144, 15562–15568 (2022).

Sathishkumar, T., Satheeshkumar, S. & Naveen, J. Glass fiber-reinforced polymer composites–a review. J. Reinf. Plast. Compos. 33, 1258–1275 (2014).

Xue, X., Liu, S.-Y., Zhang, Z.-Y., Wang, Q.-Z. & Xiao, C.-Z. A technology review of recycling methods for fiber-reinforced thermosets. J. Reinf. Plast. Compos. 41, 459–480 (2021).

Karuppannan Gopalraj, S. & Kärki, T. A review on the recycling of waste carbon fibre/glass fibre-reinforced composites: fibre recovery, properties and life-cycle analysis. SN Appl. Sci. 2, 433 (2020).

Jensen, J. P. & Skelton, K. Wind turbine blade recycling: experiences, challenges and possibilities in a circular economy. Renew. Sustain. Energy Rev. 97, 165–176 (2018).

Krauklis, A. E., Karl, C. W., Gagani, A. I. & Jørgensen, J. K. Composite material recycling technology—state-of-the-art and sustainable development for the 2020s. J. Compos. Sci. 5, 28 (2021).

Thomason, J., Jenkins, P. & Yang, L. Glass fibre strength—a review with relation to composite recycling. Fibers 4, 18 (2016).

Zheng, Y., Yanful, E. K. & Bassi, A. S. A review of plastic waste biodegradation. Crit. Rev. Biotechnol. 25, 243–250 (2005).

Bahl, S., Dolma, J., Jyot Singh, J. & Sehgal, S. Biodegradation of plastics: a state of the art review. Mater. Today Proc. 39, 31–34 (2021).

Jacob, A. Composites can be recycled. Reinf. Plast. 55, 45–46 (2011).

Naqvi, S. R. et al. A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resour. Conserv. Recycl. 136, 118–129 (2018).

Liu, Y., Meng, L., Huang, Y. & Liu, L. Method of recovering the fibrous fraction of glass/epoxy composites. J. Reinf. Plast. Compos. 25, 1525–1533 (2006).

Ahrens, A. et al. Catalytic disconnection of C–O bonds in epoxy resins and composites. Nature 617, 730–737 (2023).

Wang, J.-F. et al. Magnetic detection under high pressures using designed silicon vacancy centres in silicon carbide. Nat. Mater. 22, 489–494 (2023).

Booker, I. D., Farkas, I., Ivanov, I. G., Ul Hassan, J. & Janzén, E. Chloride-based SiC growth on a-axis 4H–SiC substrates. Physica B Condens. Matter 480, 23–25 (2016).

Clavaguera-Mora, M. T. et al. Growth of SiC films obtained by LPCVD. Diam. Relat. Mater. 6, 1306–1310 (1997).

Yan, J. Y., Chen, Q. S., Jiang, Y. N. & Zhang, H. Improvement of the thermal design in the SiC PVT growth process. J. Cryst. Growth 385, 34–37 (2014).

Herro, Z. et al. Investigation of mass transport during PVT growth of SiC by 13C labeling of source material. J. Cryst. Growth 258, 261–267 (2003).

Shin, Y., Wang, C. M. & Exarhos, G. Synthesis of SiC ceramics by the carbothermal reduction of mineralized wood with silica. Adv. Mater. 17, 73–77 (2005).

Guo, X., Zhu, L., Li, W. & Yang, H. Preparation of SiC powders by carbothermal reduction with bamboo charcoal as renewable carbon source. J. Adv. Ceram. 2, 128–134 (2013).

Jiang, R. et al. Ultrafast synthesis for functional nanomaterials. Cell Rep. Phys. Sci. 2, 100302 (2021).

Cheng, Y. et al. Electric current aligning component units during graphene fiber Joule heating. Adv. Funct. Mater. 32, 202103493 (2022).

Liu, S. et al. Dislocation-strained IrNi alloy nanoparticles driven by thermal shock for the hydrogen evolution reaction. Adv. Mater. 32, 2006034 (2020).

Zhu, W. et al. Ultrafast non-equilibrium synthesis of cathode materials for Li-ion batteries. Adv. Mater. 35, 2208974 (2023).

Wyss, K. M., Deng, B. & Tour, J. M. Upcycling and urban mining for nanomaterial synthesis. Nano Today 49, 101781 (2023).

Yu, F. et al. Rapid self-heating synthesis of Fe-based nanomaterial catalyst for advanced oxidation. Nat. Commun. 14, 4975 (2023).

Jia, C. et al. Graphene environmental footprint greatly reduced when derived from biomass waste via flash Joule heating. One Earth 5, 1394–1403 (2022).

Luong, D. X. et al. Gram-scale bottom-up flash graphene synthesis. Nature 577, 647–651 (2020).

Deng, B. et al. Heavy metal removal from coal fly ash for low carbon footprint cement. Commun. Eng. 2, 13 (2023).

Deng, B. et al. High-temperature electrothermal remediation of multi-pollutants in soil. Nat. Commun. 14, 6371 (2023).

Shen, Z. et al. Tunable fabrication and photoluminescence property of SiC nanowires with different microstructures. Appl. Surf. Sci. 506, 144979 (2020).

Persson, C. & Lindefelt, U. Dependence of energy gaps and effective masses on atomic positions in hexagonal SiC. J. Appl. Phys. 86, 5036–5039 (1999).

Kong, L. et al. Two novel SiC phases: structure, mechanical, and transport properties. Mater. Res. Express 7, 085902 (2020).

Shimojo, F. et al. Molecular dynamics simulation of structural transformation in silicon carbide under pressure. Phys. Rev. Lett. 84, 3338 (2000).

Yoo, W. S. Y. W. S. & Matsunami, H. M. H. Solid-state phase transformation in cubic silicon carbide. Jpn. J. Appl. Phys. 30, 545 (1991).

Feldman, D. W., Parker, J. H., Choyke, W. J. & Patrick, L. Phonon dispersion curves by Raman scattering in SiC, polytypes 3C, 4H, 6H, 15R, and 21R. Phys. Rev. 173, 787–793 (1968).

Yu, M., Temeche, E., Indris, S. & Laine, R. M. Adjusting SiO2:C mole ratios in rice hull ash (RHA) to control carbothermal reduction to nanostructured SiC, Si3N4 or Si2N2O composites. Green Chem. 23, 7751–7762 (2021).

Son, N. T., Carlsson, P., ul Hassan, J., Magnusson, B. & Janzén, E. Defects and carrier compensation in semi-insulating 4H-SiC substrates. Phys. Rev. B 75, 155204 (2007).

Sun, C. et al. Interfacial coupled design of epitaxial graphene@SiC schottky junction with built-in electric field for high-performance anodes of lithium ion batteries. Nano Energy 77, 105092 (2020).

Yu, M., Temeche, E., Indris, S., Lai, W. & Laine, R. M. Silicon carbide (SiC) derived from agricultural waste potentially competitive with silicon anodes. Green Chem. 24, 4061–4070 (2022).

Li, H. et al. Re-utilization of waste graphite anode materials from spent lithium-ion batteries. J. Electroanal. Chem. 932, 117247 (2023).

Chen, W. et al. Flash recycling of graphite anodes. Adv. Mater. 35, e2207303 (2023).

Qian, J. et al. Boosting fast sodium storage of a large-scalable carbon anode with an ultralong cycle life. Adv. Energy Mater. 8, 1703159 (2018).

Chen, C. et al. Na+ intercalation pseudocapacitance in graphene-coupled titanium oxide enabling ultra-fast sodium storage and long-term cycling. Nat. Commun. 6, 6929 (2015).

Kim, N., Park, H., Yoon, N. & Lee, J. K. Zeolite-templated mesoporous silicon particles for advanced lithium-ion battery anodes. ACS Nano 12, 3853–3864 (2018).

Yang, X. et al. Amorphous tin-based composite oxide: a high-rate and ultralong-life sodium-ion-storage material. Adv. Energy Mater. 8, 1701827 (2018).

Universal Matter Inc. (accessed 20 July 2023); https://www.universalmatter.com/

Eddy, L. et al. Automated laboratory kilogram-scale graphene production from coal. Small Methods https://doi.org/10.1002/smtd.202301144 (2023).

Dudarev, S. L., Botton, G. A., Savrasov, S. Y., Humphreys, C. & Sutton, A. P. Electron-energy-loss spectra and the structural stability of nickel oxide: an LSDA+ U study. Phys. Rev. B 57, 1505 (1998).

Kresse, G. & Furthmuller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953 (1994).

Perdew, J. P. & Wang, Y. Accurate and simple analytic representation of the electron-gas correlation energy. Phys. Rev. B 45, 13244 (1992).

Rauls, E., Frauenheim, T., Gali, A. & Deák, P. Theoretical study of vacancy diffusion and vacancy-assisted clustering of antisites in sic. Phys. Rev. B 68, 155208 (2003).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188 (1976).

Acknowledgements

Funding for this research was provided by the Air Force Office of Scientific Research (FA9550-22-1-0526, J.M.T.), the US Army Corps of Engineers, ERDC grant (W912HZ-21-2-0050, J.M.T.) and a Rice Academy Fellowship (Y. Cheng). We acknowledge the use of the Electron Microscopy Centre (EMC) at Rice University. The characterization equipment used in this project is partly from the Shared Equipment Authority (SEA) at Rice University. We thank B. Chen of Rice University for helpful discussion of the XPS results. DFT computing time was provided by National Energy Research Scientific Computing Center (NERSC) with the high-performance computing system, Perlmutter.

Author information

Authors and Affiliations

Contributions

J.M.T. and Y. Cheng conceived the idea and designed the experiments. Y. Cheng conducted the synthesis and most of the characterizations with the help of J.C., B.D., W.C., B.L., S.X. and T.S. Y. Cheng and J.C. conducted the assembly and electrochemical tests of the LIBs. B.D. conducted the TEM and SAED tests. K.J.S. helped with the GC–MS tests. L.E. maintained the flash system and assisted with the scale-up experiments. G.W. conducted the EPR test. Y. Chen and A.A.M. conducted the UV–Vis measurement. C.K. provided the waste GFRP samples. Y.Z. and B.I.Y. conducted the MD and DFT simulation. Y. Cheng analysed the simulation results with the assistance of Y.Z. Y. Cheng, J.C., B.D., Y.Z. and J.M.T. wrote and edited the paper. All aspects of the research were overseen by J.M.T. All authors discussed the results and commented on the paper.

Corresponding authors

Ethics declarations

Competing interests

Y. Cheng, J.C., B.D. and J.M.T. are listed as inventors of a patent application filed by Rice University, United States Provisional Application No. 63/585,465. The other authors declare no competing interests.

Peer review

Peer review information

Nature Sustainability thanks Yanan Chen, Nanda Sahoo and Xiangdong Zhu for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1–4, Figs. 1–46 and Tables 1–10.

Source data

Source Data Fig. 1

Statistical source data.

Source Data Fig. 2

Statistical source data.

Source Data Fig. 3

Statistical source data.

Source Data Fig. 4

Statistical source data.

Source Data Fig. 5

Statistical source data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cheng, Y., Chen, J., Deng, B. et al. Flash upcycling of waste glass fibre-reinforced plastics to silicon carbide. Nat Sustain 7, 452–462 (2024). https://doi.org/10.1038/s41893-024-01287-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41893-024-01287-w

This article is cited by

-

Flash upcycling of glass fibre-reinforced plastics waste

Nature Sustainability (2024)