Abstract

Solar heat management & green air-conditioning are among the major technologies that could mitigate heat islands phenomenon while minimizing significantly the CO2 global foot-print within the building & automotive sectors. Chromogenic materials in general, and thermochromic smart coatings especially are promising candidates that consent a noteworthy dynamic solar radiation Infrared (NIR-IR) regulation and hence an efficient solar heat management especially with the expected increase of the global seasonal temperature. Within this contribution, two major challenging bottlenecks in vanadium oxide based smart coatings were addressed. It is validated for the first time that the NIR-IR modulation of the optical transmission (∆TTRANS = T(T〈TMIT) − T(T〉TMIT) of Vanadium oxide based smart coatings can be controlled & tuned. This upmost challenging bottle-neck controllability/tunability is confirmed via a genuine approach alongside to a simultaneous drastic reduction of the phase transition temperature TMIT from 68.8 °C to nearly room temperature. More precisely, a substantial thermochromism in multilayered V2O5/V/V2O5 stacks equivalent to that of standard pure VO2 thin films but with a far lower transition temperature, is reported. Such a multilayered V2O5/V/V2O5 thermochromic system exhibited a net control & tunability of the optical transmission modulation in the NIR-IR (∆TTRANS) via the nano-scaled thickness’ control of the intermediate Vanadium layer. In addition, the control of ∆TTRANS is accompanied by a tremendous diminution of the thermochromic transition temperature from the elevated bulk value of 68.8 °C to the range of 27.5–37.5 ºC. The observed remarkable and reversible thermochromism in such multilayered nano-scaled system of V2O5/V/V2O5 is likely to be ascribed to a noteworthy interfacial diffusion, and an indirect doping by alkaline ions diffusing from the borosilicate substrate. It is hoped that the current findings would contribute in advancing thermochromic smart window technology and their applications for solar heat management in glass windows in general, skyscraper especially & in the automotive industry. If so, this would open a path to a sustainable green air-conditioning with zero-energy input.

Similar content being viewed by others

Introduction

The rise of the global average temperature correlated to climate change has generalized heat islands phenomenon. This latter is becoming a major concern especially with the fast rising rural to urban population exodus. Yet, this singularity was well known for almost a century, it became dominant recently as observed in densely populated cities where excessive temperatures were registered. Such recent elevated & localized temperatures are caused by the important release of anthropogenic heat, and the excess storage of solar radiation within the city compounds. In addition, it is exacerbated by the shortage of green spaces and cool sinks, the lack of effective circulation of air within the city landscape as well as the reduced ability of the emitted infrared radiations to escape in the atmosphere1. As summarized by Santamouris et al., Papanikolaou et al.2,3,4,5,6, several potential technologies can be used to mitigate such a heat islands phenomenon. Among which; (1) Roof greening, (2) White reflective roofing, (3) Walls greening, (4) Usage of natural heat sinks view of dissipating heat excess, (5) Expanding green spaces, (6) Usage of advanced reflective materials based on nanotechnology additives such as thermochromic paints and coated glass windows7,8,9, and (7) Generalization of the usage of smart windows in both buildings & automotives. This later mitigating cooling technology would not only improve the indoor thermal comfort but minimize the energy consumption due to air–conditioning in addition to the reduction of the CO2 footprint.

As per today, ~ 55% of the world’s population lives in urban areas. It is projected that it would reach ~ 2.5 billion by 2050, with ~ 90% of this increase in Asia & Africa. With such an upsurge of the urban population and climate change increase of the average seasonal atmospheric temperature, air-conditioning demand is expected to sky-rocket. The global stock of air conditioners in buildings & automotive sectors is expected to grow up to ~ 5.6 billion by 2050 from the current pool of ~ 1.6 billion today units. The International Energy Agency (IEA)’s projections10 for the global energy demand in air-conditioning is expected to triple by 2050. This paramount increase will entail the usage of a significant electricity supply. Henceforth, sustainable technologies are required to minimize the corresponding energy pressure and the related CO2 footprint. Chromogenics and/or radiative cooling coatings are potential genuine solutions as a sustainable pathway for green air-conditioning11,9,13.

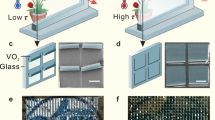

Among the chromogenic technologies, including electrochromism, and gasochromism, thermochromic nano-coatings for smart windows applications (Fig. 1) have attracted a special interest since the observation of the reversible semiconductor-metallic 1st order transition in Vanadium dioxide (VO2) by Morin in 195914. Since then, several oxides were found to exhibit such a 1st order phase transition as displayed in (Fig. 2a)15,13,17. As one can notice, several of these oxides are Vanadium based. Figure 2b reports the corresponding Pressure-Concentration stability phase- diagram of such a rich family of Vanadium oxides correlated to the multivalence of Vanadium; namely V+5, V+4, V+3, V+2, V+1. Moreover, there are 2 additional large VxOy families including the Magnussen (VnO2n+1) & Wadsley (V2nO5n−2) layered compounds15,13,14,18. However, VO2 was and is the most investigated compound in view of its sharp 1st order ultrafast phase transition taking place at the vicinity of TMIT ~ 68 °C14,18,19 which is close to room temperature and hence the corresponding potential technological applications in solar heat management as intelligent coating for smart windows in the building and automotive sectors in particular11.

Indeed, and as demonstrated both experimentally and theoretically, VO2 exhibits a 1st order reversible phase transition from a semiconductor state to a metallic state & vis-versa upon heating/cooling11,9,10,14. Such a reversible phase transition which can be stimulated via an external thermal, pressure or optical stimuli is both crystallographic and electronic18,19. From crystallographic viewpoint, the low temperature monoclinic VO2 structure transits reversibly to a tetragonal phase above TMIT ~ 68 °C (Fig. 3a). Such a femtosecond crystallographic transition is correlated to an electronic transition. This later originates from the splitting of the d// band inducing the creation of a band-gap of the order of 0.72 eV below TMIT ~ 68 °C which closes above (Fig. 3b)15.

Major properties related to the VO2 1st order phase transition. (a) Reversible Monoclinic-Rutile crystallographic phase transition of VO2 at the vicinity of TMiT ~ 68 ºC, (b) The corresponding reversible electronic phase transition due to the reversible opening-closing of the d band orbital, (c) Ideal optical response of a VO2 based thermochromic coating; (1) TVIS > 50%), (2) TMIT ~ 25 °C) and primarily, a large modulation in the (NIR) & (IR) spectral range (∆TTRANS).

Besides the thermochromic properties for smart windows applications, VO2 was found to be effective in a variety of technological applications. This includes o tunable nano-plasmonics20,21, ultrafast optoelectronic gating22,23, chemresistors for H2 gas sensing24,25 and tunable emissivity space coatings for small satellites26,27 as well as optical limiting and laser radiations protection coatings28,26,30.

In addition to these multifunctionalities, VO2 & related family oxides have raised and impacted substantially several fundamental questions in condensed matter specifically & solid state physics in general. As reported in Table 1, this includes but not limited to: shed-lighting on the sliding twin-domains in self-heated needle-like VO2 single crystals31, evolution of the Mott transition in chain structure of strained VO2 films revealed by coherent phonons32, investigation of the solid-state triple point at the metal–insulator transition in VO233, Observation of a large non-thermal contribution to picosecond strain pulse generation using the photo-induced phase transition in VO234, elucidating on the inhomogeneity of the ultrafast insulator-to-metal transition dynamics of VO235, clarifying the transient dynamics of the phase transition in VO2 revealed by mega-electron-volt ultrafast electron diffraction36, observation of the magnetic-field-induced insulator–metal transition in W-doped VO2 at 500 T37, demonstration of the reversible phase modulation and hydrogen storage in multivalent VO2 epitaxial thin films38, Decoupling the Lattice Distortion and Charge Doping Effects on the Phase Transition Behavior of VO2 by Titanium (Ti4+) Doping39, Observation of the photo-induced non-volatile VO2 phase transition for neuromorphic ultraviolet sensors40 in addition to numerous ultrafast technological proofs of concept41,39,43.

Yet, the above mentioned technological applications and fundamental focii are directly related to the modulation of the optical transmission of the VO2 in the NIR-IR spectral region especially, this latter is the pivotal and central parameter for solar heat management & smart windows applications10,8,12,16,17. As schematically summarized in Fig. 3c, an ideal VO2 based thermochromic coating should exhibit the following major characteristics: (1) a good and temperature independent optical transmission in the visible (VIS) spectral range (with a priori a VIS transmission > 50%), (2) a phase transition temperature TMIT close to room temperature (far below the bulk VO2 transition of TMiT ~ 68 °C) and primarily, a noteworthy large modulation in the Near Infrared (NIR) and Infrared (IR) spectral range (∆TTRANS). This latter is the difference between the optical transmissions below and above TMiT; (∆TTRANS = T(T〈TMIT) − T(T〉TMIT > 50%). Although, this later modulation in the NIR & IR spectral range is exceedingly challenging, the lowering of the TMIT and the raising of the VIS optical transmission have been successfully dealt with through an adequate doping (W, Mo, Mg,…) and via the usage of an additional anti-reflection treatment (TiO2, ZrO2,ZnO,…) respectively44,42,43,44,48.

In the pursuit of engineering optimal thermochromic VO2 based coatings with a substantial elevated and tunable modulation in the NIR-IR spectral range (∆TTRANS = T(T〈TMIT) − T(T〉TMIT), several physical & chemical methodologies were & are used for its deposition49,47,48,49,50,51,52,53,54,55,56,57,61. Excluding limited cases, the general usage of single and unique layer of VO2 was and is the dominating trend in thermochromic VO2 based applications. Likewise, in its doped or un-doped form, the VO2 based thermochromic coatings suffer in terms of modulation in the Infrared region (∆TTRANS). The same situation is faced even in the case of the VO2 deposition onto various substrates; amorphous (glass, PET,…)44,45 or crystalline (Quartz, Silicon, Mica,…)46,44,48,62,63,64,65,66,67,68,69,70,71,72,73 in nature. Simply summarized, the VO2 based thermochromic coatings suffer drastically in terms of modulation in the Infrared region (∆TTRANS) specifically.

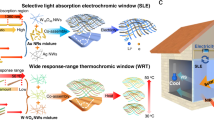

In this regard, and within the novelty & originality of this contribution, it is validated for the first time that the NIR-IR modulation of the optical transmission (∆TTRANS) can be controlled/tuned via an authentic novel approach with a simultaneous drastic reduction of TMIT. This latter original approach consists of using a multilayered configuration instead of the standard single VO2 layer approach as illustrated in Fig. 4a. In addition, it requires the usage of a Magnussen V oxide such as V2O5 and not the standard pure VO2. For the validation of such a NIR-IR modulation control with a simultaneous drastic reduction of TMIT, a tri-layer stack consisting of V2O5/V/V2O5 deposited onto glass substrate was considered. Within such a multi-layered stack of V2O5/V/V2O5 onto borosilicate glass substrate, the V2O5 layers’ thickness is fixed and that of the interlayer of pure V is varied followed by an optimal post annealing.

Configurations of the engineered thermochromic coating & its major surface morphological characteristics. (a) Standard Single VO2 layer configuration & the current considered multi-layered structure consisting of V2O5(Fixed thickness:20 nm)/pure V (Variable thickness)/V2O5 (Fixed thickness:40 nm) deposited onto glass substrate, (b) Surface Atomic Force Microscopy surface morphology of the 3 multilayered samples, (c) Evolution of corresponding average roughness Ra (yellow filled circles), the root mean square (Rσ) (black filled circles), and the average crystallites size (Ø) (yellow filled diamonds).

Yet original in terms of approach, it is to be stressed that this research work has been inspired by several partial contributions including but not limited to Long et al.74, Pellegrino et al.75, Wang, Miller et al.76, Zheng et al.77, Zhou et al.78, Han et al.79, Zhao et al.80 while fostering the previous work by Sfundo et al.81. As per the scientific & patented published literature, and as it was highlighted previously, other multi-layered nano-structures were proposed but none allowed a significant control of the NIR-IR modulation with a significant decrease of the TMIT simultaneously. Table 2 summarizes such multilayered nano-structures.

The specific objectives of this contribution are as follows.

-

1.

Validation of thermochromism in V2O5/V/V2O5 sandwich nanostructures,

-

2.

Validation of the tunability/control of the modulation in the NIR-IR spectral range (∆TTRANS = T (T〈TMIT) − T(T〉TMIT),

-

3.

Validation of the tunability/control of the transition temperature TMIT,

-

4.

Validation of the effectiveness of Alkaline doping in TMIT tenability.

Comparatively to the previous published literature as recapitulated in Table 2, the current research contributes in advancing the subject of Vanadium oxide based thermochromism via two major milestones; (1) the crucial role of the intermediate V layer within the V2O5/V/V2O5 sandwich nanostructures in terms of the tunability of both the optical modulation in the NIR-IR spectral range (∆TTRANS = T(T〈TMIT) − T(T〉TMIT), and that of the transition temperature TMIT, (2) the role of the alkaline ions doping originating from the borosilicate substrate. As per our best knowledge, none of the above mentioned parameters were investigated so far.

Materials and methods

Samples preparation

All chemicals & substrates used in these experiments are of high chemical grade (from Sigma-Aldrich &/or Alfa-Aesar). Following a sequential procedure, multi-layered films of V2O5/V/V2O5 were deposited by e-beam evaporation using V2O5 powder and V metal material targets and borosilicate glass substrates (10 × 10 × 2.5 mm3). The substrates were cleaned in an ultrasonic bath with methanol and de-ionized water for ~ 20 min prior to deposition. All substrates were dried with pressurized 100% pure N2 gas before being loaded into the deposition chamber, which was already loaded with highly pure vanadium (V) and vanadium pentoxide (V2O5) targets in separate crucibles. The multi-layered stacks were deposited at an initial chamber vacuum pressure of ~ 10−6 mbar and an evaporation rate of ~ 0.24 nm/s. The V2O5 & pure V layers’ thicknesses were monitored with a standard crystal monitor. The thickness of the 1st layer (bottom) of V2O5, was fixed to ~ 40 nm, while the thickness of the intermediate layer (V layer) was varied within a defined range of 3–12 nm at specific values of 3, 7 and 12 ± 0.2 nm. The thickness of the 3rd (top layer) of (V2O5) was fixed at 20 nm. These thicknesses were chosen based on a preliminary set of computations, which suggested that the film be chosen in such a way that sufficient diffusion of oxygen into that inter-layer would take place in addition of an additional interfacial stress/strain; with both layers allowing O atoms to diffuse into the V intermediate layer. All prepared samples were annealed for 120 min in a vacuum of ~ 10−6 mbar at the temperature of 500 °C.

Samples characterization

The surface morphology of the samples was investigated using Atomic Force Microscopy (AFM) in non-contact mode complemented by an in-depth/volume morphology studies using a Field Emission Scanning Electron Microscopy (FE-SEM, Jeol JSM-7800F). The crystal structure of the various samples was examined with a Bruker AXS D8 Advanced X-ray diffractometer, which was outfitted with a copper X-ray tube (λ = 0.15406 nm) and operated at 40 kV and 40 mA with data collection in the Θ–2Θ configuration within the angular range of 15–60 Deg (in steps of 0.01 Deg). For the elemental analysis and depth profiling, Auger Electron Spectroscopy (AES) and Time of Flight Secondary Ion Mass Spectrometry (ToF-SIMS) were used. The optical measurements within the spectral range of 250–2500 nm were carried out in transmittance mode (normal incidence) with a Cary 5000 UV–VIS–NIR spectrometer equipped with a controllable heating stage with a heating/cooling rate of 5 °C/min within the temperature range of 20–90 °C.

Results and discussions

Morphological investigations: AFM & FE SEM

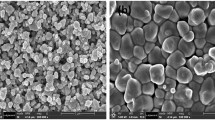

Figure 4b displays the Atomic Force Microscopy of the various samples. The surfaces are relatively rough suggesting, a priori, the crystalline nature of the multi-layered stack samples or at least the top surface of layer 3 (V2O5 top layer). Table 3 summarizes the corresponding values of the average roughness (Ra), the root mean square (Rσ), the average height (H) as well as the average crystallites size (Ø). Accordingly, thicker is the intermediate V layer, higher are the various parameters 〈Ra〉, 〈Rσ〉, 〈H〉 and 〈Ø〉. Yet limited to 3 values of the intermediate V layer’s thickness, it can be safely concluded that the effect of this latter (i.e. the intermediate V layer’s thickness) is of a prime effectiveness in view of the variations of Table 3 & Fig. 4c.

Figure 5 displays the FESEM edge cross-section of the various multi-layered samples. As one can notice, in each and all of the samples, it is not possible to distinguish the various layers of the stacks V2O5/V/V2O5 deposited onto the borosilicate glass substrates. Indeed, excluding the crystal-clear net interface with the substrate, there are no sharp interfaces between bottom layer 1 (V2O5) and the intermediate V layer as well as this latter and top layer 3 (V2O5). This is likely a signature of a noteworthy interfacial diffusion within both interfaces of the intermediate layer of V and top/bottom surrounding layers of V2O5. This observation seems to be supported by the observed various nano-crystals distributed isotropicaly within the transversal direction of the stack throughout the 2 interfaces of Fig. 5. If one considers the O and V atomic/ionic radii, it could be, safely concluded that Oxygen is prospectively to diffuse from the O rich regions i.e. from layers 1 & 3 of V2O5 towards the O poor region i.e. towards the pure V intermediate layer. Last but not least, one can observe several cracks within the substrate of sample 3 i.e. (12 nm V intermediate layer thickness). These cracks seem to be initiated from layer 1-substrate interface and propagating towards the inner section of the substrate. These cracks are likely to originate from a substantial stress/strain relaxation at the interface layer 1/substrate at least. As a preliminary pre-conclusion of this section, one could cautiously conclude on the elevated interfacial diffusion within the interfaces (top & bottom) surrounding the intermediate layer of pure Vanadium. Such a significant interfacial diffusion would not only affect the chemical composition profile of the multi-layered stack but also the strain/stress distribution.

Elemental analysis & depth profiling: Auger analysis

Figure 6a displays the elemental depth profiling of Carbon (C), Oxygen (O), Vanadium (V) and Silicon (Si) of the 3 samples obtained via Auger spectrometry investigations. The C originates from the Carbon coating layer deposited onto the surface sample initially for charge removal. By contrast, Si originates from the borosilicate glass substrate. This latter consists of 70–80 wt% SiO2 of amorphous SiO2 in addition to other oxides (7–13 wt% of B2O3, 4–8 wt% Na2O, K2O, and 2–8 wt% of Al2O384. As one can notice, the Si diffusion is mainly localized at the substrate-1st layer of V2O5 in the 3 multi-layered stacks independently from the intermediate V layer’s thickness. Hence, one could, a priori, conclude that the 1st layer of V2O5 might acted as a barrier minimizing the diffusion of Si & Al from the borosilicate substrate towards the multi-layered stack.

By contrast, If the O & V concentration depth profiles of Fig. 6a are considered, one can crystal clearly notice the presence of oxygen through-out the transversal direction of the 3 stacks. This is in support of the significant interfacial diffusion mentioned formerly, especially the O diffusion from the surrounding V2O5 layers towards the intermediate V layer.

Likewise, the O & V concentration depth profiles seem substantially correlated while in phase in the case of samples 2 (VIntermediate-layer = 7 nm) and 3 (VIntermediate-layer = 12 nm) by opposite to sample 1 (VIntermediate-layer = 3 nm). Figure 6b reports the corresponding depth variation of the O/V ratio. Subsequently, and within the bar error of ± 5%, the average value of the O/V ratio seems increasing quasi linearly for sample 1 (VIntermediate-layer = 3 nm) while fluctuating between 1.5 and 2 for sample 2 (VIntermediate-layer = 7 nm) and sample 3 (VIntermediate-layer = 12 nm). Henceforth, it can safely be concluded that in the 2 thicker stacks, the dominating phase or phase are within the V2O3 & VO2 families from stoichiometric viewpoint and/or phases under significant strain/stress (if one considers the observed cracks relaxation in the FESEM images of Fig. 5c).

Alkaline doping via substrate-stack interfacial diffusion & depth profiling: SIMS analysis

Because of the small ionic radius of alkaline ions and their low activation energy, It is established that they diffuse relatively fast within the substrate surface via established exchange mechanisms84,85. In the case of Na+, its low activation energy Qa & its elevated diffusion constant D0 (D = D0e − Qa, activation energy of Qa = 1.36 eV and D0 = 3.12 × 10−4 m2) fovours its diffusion both within the bulk and the surface of the glass substrate86,87. Hence, it is necessary to depth profile the alkaline ions. For such Secondary Ions Mass Spectrometry (SIMS) analysis were carried out.

Figure 7 displays the SIMS elemental depth profiling of several ions proper to the stack (V+, VO+) and those alkaline ions from the borosilicate substrate (Na+, Ca+ & K+). These latter explicit ions were targeted in view of the chemical composition of the borosilicate glass substrate (consisting of SiO2: 72.5%, Na2O: 13.7%, CaO: 9.1%, KO: 12% MgO: 4.2%,…)70,84,86,87. Once again, the distribution profiles of V+, VO+ are alike throughout the multi-layered stack samples and the stack-substrate interface. This matching depth distributions of V+ & VO+ is in an ample support of the O diffusion observed in the previous Auger profiles. The Si profiles exhibit a heavy-side type variation for each & all samples with a nearly zero counts within the stack in support of a very weak if not a no diffusion of Si originating from the substrate. This latter behaviour is also in accordance with the previous Auger observations. Contrasting with such a Si limited interfacial diffusion is the alkaline ions; namely Na+, Ca+ and K+. All of them display a long-range diffusion from the borosilicate glass throughout the stacks with Na+ followed by K+ and Ca+ up to the air-stacks interface. Such an prominent extended diffusion is likely due to the small ionic radius (ØNa+ ≈ 0.102 nm, ØK+ ≈ 0.138 nm, ØCa+ ≈ 0.118 nm),and the low activation energy of the concerned alkaline and henceforth their elevated diffusion coefficient (DoNa+ ≈ 0.330 × 10−9 m2/s, DoK+ ≈ 1.960 × 10−9 m2/s, DoCa+ ≈ 0.79310−9 m2/s) by contrast to Mg & Si as well as to V. Nevertheless, there is a crystal-clear difference between the depth distributions of Na+, Ca+ & K+. Relatively to Na+, Ca+ profiles, the profile of K+ is singular. While its depth distribution is inhomogeneous for stack 1 (intermediate VInt-layer = 3 nm), it is very low and nearly constant throughout the V2O5/V/V2O5 stacks 2 & 3 i.e. (intermediate VInt-layer = 7 & 12 nm). Besides, the K+ profiles exhibit a net localized peak at the interface substrate-stacks 2 & 3. While such an accumulation at the substrate-multi-layered stacks interface is not understood, the constant diffusion within the multi-layered stacks up to the air- multi-layered stacks interface would likely affect the thermochromic properties if any. Indeed, considering the K+ & Ca+ concentrations within the stacks, this indirect doping would likely affect the thermochromic properties of the multi-layered stacks, especially the transition temperature as in the case of doping with various Materials including W, Mo, Mg. Cr, Ti, Nb,Cs, Sn, F, among others was reported within the literature88,86,87,88,89,90,91,92,93,97

In-depth profile O/V ratio variation derived from Secondary Ion Mass spectrometry (SIMS) elemental depth profiling of various halides (Na+, K+, Ca+), Silicon Si+ and Vanadium (V+) as well as VO+ of the various multi-layered stacks of V2O5/V/V2O5 deposited onto borosilicate glass substrate for various intermediate Vanadium layer’s thickness; 3 nm, 7 nm and 12 nm.

Crystallographic properties: texture & crystallites orientations

Figure 8 reports the room temperature X-ray diffraction pattern of the 3 multilayered stacks of V2O5/ V /V2O5 onto borosilicate glass substrate within the Θ–2Θ diffraction configuration. The pattern was limited to the angular region of 25–31 Deg. Such an angular restriction is due to the fact there were no diffraction signatures below and above 25 Deg respectively. On the other hand, one can markedly distinguish the (011) main Bragg diffraction peak of the monoclinic VO2 thermochromic active phase which for the bulk or non-strained VO2 thin films generally is centred around 2Θ ~ 27.85 Deg. Nevertheless, those observed on the investigated samples are displaced toward higher values by at least ~ 1 Deg (samples 2 & 3). Such an angular shift can only be ascribed to a significant compressive strain/stress on the (011) reticular planes. The relative compression on such a set of reticular atomic planes is relatively high, of the order of ∆d011/d011 ~ ∆Θ011/tan Θ011 ≈ 11 & 17% for samples corresponding to intermediate V layer of 7 and 12 nm. On the other hand, the one corresponding to the thinnest intermediate V layer i.e. 3 nm seems to be under a far higher strain/stress in view of the larger angular shift of almost ~ 1.73 Deg. It is to be mentioned that this sample’s XRD profile exhibits, rather, a rich diffraction pattern with 3 consecutive potential low intensity Bragg peaks centred approximately at the vicinity of 27.07, 28.29 and 29.90 Deg. This set of low intensity peaks may correspond to a sub-structure within the 1st sample i.e. (VIntermediate-layer = 3 nm), if any. To shed-light correctly on the nature of such a rich diffraction pattern, it would require, a priori, synchrotron type investigations. More accurately, grazing incidence x-rays diffraction studies98,96,100. One can point out to the absence of the Bragg diffraction peaks of pure Vanadium and V2O5 including the major most intense ones; V(100), 2Θ ~ 42.172 Deg) & single phase V2O5 (001), 2Θ ~ 20.251 Deg. As a pre-conclusion of this crystallographic investigation study, it is safe deducing on the significant strain/stress on the nanocrystals and their atomic reticular plans especially those of (011) orientation.

Optical properties: NIR-IR modulation tunability & control

Figure 9 reports the pivotal results of this contribution. It displays the experimental optical transmission profiles of the 3 multi-layered stacks of V2O5/V/V2O5 onto borosilicate substrate within the solar spectral range of 250–2500 nm below and above the transition temperature TMIT ~ 68 °C. More precisely at 25 °C and 70 °C. Further down, they are labelled as cooling and heating respectively. As one can notice in Fig. 9a, while all of the 3 multi-layered stacks exhibit a net thermochromic signature with a crystal-clear dependence on the intermediate Vanadium layer’s thickness in terms of TVIS as well as the NIR-IR modulation ∆TTRANS. This latter is about 1.47%, 42.01% & 32.10% for V2O5/3nmV/V2O5, V2O5/ 7 nm V/V2O5, and V2O5/12 nm V/V2O5 samples respectively. Accordingly and within this multi-layered configuration of V2O5/V/V2O5/glass substrate, it is, therefore, safe to conclude that the targeted control/tunability of the NIR-IR modulation ∆TTRANS versus the intermediate V layer’s thickness is validated.

Optical response of the various multi-layered V2O5(20 nm)/pure V(Variable thickness)/V2O5 (40 nm)deposited onto borosilicate glass substrate. (a) Their room temperature XRD pattern. (b) Their corresponding optical transmissions at 25 °C and 70 oC within solar spectrum range of 250–2500 nm. (c) Their corresponding optical transmissions at 25 °C and 70 °C within NIR-IR spectral range of 1000–2500 nm and (d) their corresponding optical transmissions at 25 °C and 70 °C within VIS spectral range of 250–1000 nm.

Figure 9b,c display the zoom on the NIR-IR (1000–2500 nm) and VIS (250–1000 nm) solar spectral ranges. In addition to the modulation in the NIR-IR, the transmission in the VIS spectral range is also affected. The corresponding maximum of the optical transmission 〈TVIS〉 is about 60.53%, 22.62% and 46.48% for V2O5/3 nm V/V2O5, V2O5/7 nm V/V2O5, V2O5/12 nm V/V2O5 samples respectively. By contrast to single VO2 thermochromic coatings, the wavelength corresponding to the maximum of transmission in the VIS spectral range is varying with the intermediate V layer’s thickness too. The spectral position of such a maximum of transmission λMaxVIS is centered approximately at 528.7, 682.6, and 665.1 nm for the V2O5/3nmV/V2O5, V2O5/7nmV/V2O5, V2O5/12 nm V/V2O5 samples respectively.

Figure 9d summarizes graphically Table 4 and reports on the evolution of the optical transmission in the VIS; 〈TVIS〉 and the optical transmission modulation in the NIR-IR ∆TTRANS (∆TTRANS = T(T〈TMIT) − T(T〉TMIT). This figure seems indicating that 〈TVIS〉 and ∆TTRANS variations versus the thickness of the intermediate V layer, are in opposition of phase within the considered configuration of V2O5/V/V2O5/ onto borosilicate glass substrate. This seems indicating that there is still room for optimization of ∆TTRANS with a sort of trade-off between 〈TVIS〉 and ∆TTRANS (shaded region of Fig. 9d).

In addition to the morphological & interfacial diffusion aspects, the major findings so far identified were quantified in terms of the visible optical transmission TVIS and specifically the NIR-IR optical modulation ∆TTRANS.

In light of the various interfacial diffusion phenomena and the observed elevated interfacial stress/strain, it is necessary to shed-light on the effective transition temperature of the investigated multi-layered stacks and its evolution versus the intermediate Vanadium layer’s thickness if any. This later, if it does should be diffusional alkaline dopant or/and stress–strain related in view of the non-negligible large lattice mismatch between the V2O5 and V layers. Concerning this second aspect of crystalline lattice mismatch, this latter would likely induce a noteworthy interfacial stress/strain. This has been evidenced previously through the substantial shift of the (011) Bragg peak observed in the X-rays diffraction spectrum of Fig. 8. This interfacial stress–strain would likely affect the transition temperature of the stack as was reported in the literature by various authors42,44,64,74. Likewise, the observed interfacial diffusion of various alkaline ions (K+, Na+ & Ca+) from the borosilicate substrate throughout the multi-layered would prospectively act as potential dopants and hence would impinge on the transition temperature. Such doping with various Materials including W, Mo, Mg. Cr, Ti, Nb, Cs, Sn, F, among others was reported within the literature88,86,87,88,89,90,91,92,93,97

Henceforth, hysteresis measurements were carried out on the various multi-layered stack samples as shown in Fig. 10a. This latter displays the standard hysteresis of the optical transmission versus temperature for a fixed wavelength (2500 nm) for the multi-layered stack corresponding to the intermediate Vanadium layer‘s thickness of 7 and 12 nm. The hysteresis for the 3 nm V was inconsequential and thus omitted. It can be noticed that the width of the hysteresis for both 7 & 12 nm V layer’s thickness are almost similar in order of δT ~ 7 °C. This value is relatively smaller than the generally reported hysteresis of single VO2 thin films which is of the order of δT ≥ 10 °C. The low value of such a hysteresis (δT ~ 7 °C) might be due to the initial large density of nucleating defects during the films growth as observed and concluded by Zhang et al.101.

Thermochromic signatures & transition temperatures of the various multi-layered V2O5(20 nm)/pure V(Variable thickness)/V2O5 (40 nm)deposited onto borosilicate glass substrate. (a) Their optical transmission at 2500 nm during the cooling & heating cycles. (b) The derivative of the optical transmission at 2500 nm during the cooling & heating cycles of sample 2 (Intermediate V layer thickness = 7 nm). (c) The derivative of the optical transmission at 2500 nm during the cooling & heating cycles of sample 3 (Intermediate V layer thickness = 12 nm),

To estimate the corresponding transition temperatures, the standard derivative approach is used. Figure 10b,c display the corresponding derivative hysteresis profiles. The average of the corresponding minima are 27.5 °C and 37.5 °C for the V2O5/V/V2O5 multi-layered stacks with the intermediate Vanadium layer’s thickness of 7 and 12 nm respectively. This substantial lowering of the TMIT which is the second prominent finding of this contribution is likely to be ascribed to the above mentioned interfacial diffusion, stress–strain and/or alkaline ions doping.

As a pre-conclusion, one might consider with provision that the investigated V2O5/V/V2O5 stacks (with 7 & 12 nm V layer’s thickness) onto borosilicate glass substrate behave as an hypothetic thermochromic VxOy phase which exhibits a thickness dependent NIR-IR ∆TTRANS with a lower phase transition temperature of TMiT = 27.5 or 37.5 ºC while under a stern interfacial stress/strain and an alkaline doping. This conjugated doping & stress/strain effects seem to be the most plausible major parameter if one considers the extensive published literature on the subject102,100,101,102,103,104,105,106,107,108,109,110,111,112,116.

Firstly, Tselev et al., and several other authors reported on the prime role of the stress/strain effects in Vanadium dioxide nanocrystals102,100,101,102,106. These studies illustrated that a complete picture of the phase transitions in single-crystalline and disordered VO2 structures can be drawn only if both ferroelastic and metal–insulator strain effects are taken into consideration.

Secondly, similar stress/strain related behaviour was observed by Nagashima et al.107,108. It was found that the stress relaxation affects drastically the transport properties of strained VO2 epitaxial thin films grown on TiO2 (001) single crystal. When varying the film thickness ranging from 10 to 30 nm, there were no significant changes on the crystal structures. On the other hand, increasing the film thickness resulted in a drastic change on the transport properties including emerging multi-steps in the metal–insulator transition as well as an increase of the resistivity. The discrepancy between the observed crystal structure and the transport properties was related to the presence of nano-scaled line cracks due to thermal stress. It was concluded that controlling thermal stress relaxation rather than the stress due to the lattice mismatch is critical to the intrinsic nature on the transport properties of strained VO2 epitaxial thin films.

Thirdly, and likewise, Mathevula et al.109, reported that the interfacial stress between VO2 thin films deposited onto highly crystalline natural substrates of mica gain considerably in crystallinity without any annealing. This unexpected crystalline growth was observed even with the drastic lattice mismatch between mica & VO2 deposited thin films. In this later case, the VO2-Mica substrate mismatch induced even a textured VO2 films’ crystallographic orientation with a variation of 4 orders of magnitude of the electrical resistance upon the MiT transition with a relatively small hysteresis of about δT ~ 7 °C.

Fourthly and most importantly, a similar behaviour was observed in V2O5 thin films by Ramana et al.108. In this latter case, the V2O5 thin films were deposited by pulsed-laser deposition and were investigated for their surface-structure evolution in relation to the growth temperature. The deposition was made onto various substrate materials and in the wide range of substrate temperatures, 30–500 °C, keeping the oxygen partial pressure at 100 mTorr. The results gave a consistent picture of the evolution of vanadium oxide film surface morphology and microstructure in terms of growth, behaviour, shape, and distribution of the grains making up films. Their grain size, surface texture, and external morphology of V2O5 thin films were found to be highly sensitive to the substrate temperature while the effect of substrate material characteristics is dominant only at higher temperatures. The grain size varied in the range 50–600 nm and the surface roughness in the range 9–20 nm with the increasing substrate temperature for crystalline vanadium oxide thin films. Within this study, it was concluded that strain stress relaxation via thermal annealing permit the growth of highly crystalline V2O5 thin films.

Computational-modelling studies

As pointed out previously If one considers the O and V atomic/ionic radii, it could be, safely concluded that Oxygen is likely to diffuse from the O rich regions i.e. from layers 1 & 3 of V2O5 towards the O poor region i.e. towards the pure V intermediate layer. In addition to the experimental confirmation (Fig. 6), this claim can be confirmed by comparing the energy gained from forming VO2 from bulk V and O2 (in the gas phase) by the energy required to create a double O vacancy in the V2O5 lattice. The DFT simulations indicate that ~ 7.45 eV are gained when forming VO2, while the energy required to create a double Oxygen vacancy in V2O5 is about ~ 5.92 eV. Therefore, the diffusion of O from V2O5 into the middle layer and forming VO2 is an energetic favourable process.

To sustain or sap the stress/strain effects on the observed thermochromic properties specifically, the change in structure and electronic properties of V2O5 under the pressure were investigated using DFT61. Such studies are summarized in Figs. 11 and 12. The calculated density of states shows that the energy band gap around the Fermi level shrinks from 2.476 eV at 0 GPa and vanish at ~ 75 GPa. Hence, the material shows insulator behaviour characteristic at low pressure and semiconductor to metallic behaviour at higher pressures. Henceforth, one can conclude that pressure affects significantly the electronic conductivity of the V2O5 material at relatively excessive elevated values. These extreme pressures are exceedingly elevated to those observed in XRD of Fig. 8. Accordingly, it is safe to conclude that the observed decrease of the transition temperatures of Fig. 10 is unlikely to be interfacial strain/stress/pressure driven.

In line with the SIMS observations, Na+, Ca+2 & K+ insertion into \(\alpha\)-V2O5 was investigated using DFT performed in Quantum-Espresso Package117,118 with the plane wave basis set and the PBE functional117,115,119. A plane-wave cut-off energy of 1200 eV and a Monkhorst–Pack k-mesh of \(2\times 1\times 1\)120 was chosen for all calculations. All structures first relaxed with a convergence threshold on forces of 0.01 eV/Å. The electronic structure calculations was performed using the tetrahedron method and a finer k-mesh of \(3\times 2\times 2\) points was utilized. For V d states, a rotationally invariant Hubbard correction was used with (U-J) = 3.5 eV121 and also a Grimme (D2) dispersion correction with pair-wise interactions was applied on the oxygen atoms122 to account the weak van-der Waals (vdW) interactions within the layered vanadium oxide. A single K/Na/Ca ion inserted into a \(2\times 3\times 1\) supercell of \(\alpha\)-V2O5 corresponding to a A0.06 V2O5 where A is K/Na/Ca ion. Once the most favourable insertion sites with the lowest energy were identified for all ions (Fig. 13a–d), the change in electronic structure upon insertion into these preferred locations was conducted. The density of states (DOS) of pristine \(\alpha\)-V2O5, K+/V2O5, Na+/V2O5, and Ca+2/V2O5 are plotted displaying significant band gaps of approximately 2 eV with zero net magnetic moment. The conduction bands consist of mainly V d orbitals, while the valence band have mostly O 2p orbital contribution. It is obvious that the insertion of alkaline ions shifts the Fermi energy.

The optimized \(2\times 3\times 1\) supercell of (a)—\(\alpha\)V2O5 (b) Na+/ \(\alpha\)—V2O5 (c) K+/ \(\alpha\)—V2O5 (d) Ca+2/ \(\alpha\)—V2O5. DOS for (a) pristine and (b) K/—\(\alpha\)V2O5, (c) Na/—\(\alpha\)V2O5, & (d) Ca/—\(\alpha\)V2O5 for the lowest-energy insertion sites. Positive and negative DOS values indicate the spin up and down, respectively. Energies are relative to the Fermi energy of each system. The partial densities of states for the different atomic species are indicated in green (vanadium), red (oxygen), and yellow (K/Na/Ca ion scaled by a factor of 100 for better visibility) in every panel, (e) The barrier energy for ion intercalation into the V2O5 slab.

The insertion energy is calculated by subtracting the energy of V2O5 and metal (A) from the ionated V2O5,

\({\text{E}}_{{{\text{ins}}}} = {\text{E}}({\text{A}}/\alpha - {\text{V}}_{2} {\text{O}}_{5} ) - {\text{E}}(\alpha - {\text{V}}_{2} {\text{O}}_{5} ) - {\text{E}}({\text{A}}).\)

The optimized structures’ corresponding insertion energies for K+, Na+ & Ca+2 are − 6.5, − 6.8 & − 13.3 eV, respectively which indicate the V2O5 is an effective host for ion insertion.

Since the insertion energies are relatively high, the energy barrier for intercalation of the alkaline ions into the surface of V2O5 using DFT was also investigated. The results are plotted in Fig. 13e, where d denote the distance from the slab in Å. Although all energies show a big barrier at around 2 Å, the intercalation energy for Na+ ion is always negative which means that it is favorable. For K+, if the energy required to pass the barrier at 2 Å is provided, the ion can intercalate between the layers easily. This trend indicates that the V2O5 is an effective host for ion insertion in general and those originating from the surface of the borosilicate substrate specifically.

As a pre-conclusion, and if one considers the intercalation aspect of Fig. 13a–d as well as the corresponding DOS distributions, one could safely conclude that the variations of the transition temperatures are likely to be caused by the alkaline ions doping and unlikely by the interfacial stress/strain. As a follow up & a foresight future investigations, the luminescence properties of the currently investigated samples will be studied123,121,122,126. This latter study would a priori shedlight on the role of the alkaline dopants on the local electronic & phonons configuration. Likewise, it might open new potential technological applications127,125,126,130 in the field of luminescence.

As a pre-conclusion, and in view of both the experimental observations and the additional computational investigations, it can be safely concluded that the observed significant reduction of the transition temperature is likely to be driven by the alkaline ions doping & not the interfacial strain/stress effect.

Conclusion

This contribution reported on the thermochromic properties of a novel configuration consisting of V2O5/V/V2O5 stacks deposited onto borosilicate glass substrates by electron beam deposition. While the thickness of the V2O5 top and bottom layers were fixed, that of the intermediate V layer was varied within the range of 3–12 nm i.e. within the coalescence threshold of Vanadium. Such a system exhibited a crystal-clear thermochromic behaviour similar at a certain extent to that of pure VO2 but with far lower TMiT and controllable/tunable thermochromic optical modulation in the NIR-IR; (∆TTRANS = T(T〈TMIT) − T(T〉TMIT). This latter tunability/control was validated via the intermediate V layer’s thickness. In addition to an elevated interfacial diffusion, a significant stress/strain in the V2O5/V/V2O5 stacks was observed. In a summary, the following findings can be highlighted.

-

1.

The investigated V2O5/V/V2O5 stacks onto borosilicate glass substrate exhibited a net thermo-chromic response equivalent to that of pure VO2 thin films,

-

2.

the investigated V2O5/V/V2O5 stacks onto borosilicate glass substrate exhibited a significantly low phase transition temperature of TMiT = 27.5 & 37.5 ºC,

-

3.

Such a significant lowering of TMiT is caused by Alkaline ions doping originating from the borosilicate glass substrate

-

4.

the investigated V2O5/V/V2O5 stacks experience a significant interfacial diffusion especially from Oxygen rich regions to Oxygen poor regions,

-

5.

from stoichiometric viewpoint, the investigated V2O5/V/V2O5 stacks seem to be equivalent to an hypothetical VxOy phase in between V2O3 & VO2,

-

6.

the investigated V2O5/V/V2O5 stacks onto borosilicate glass substrate exhibited a net controllability of the NIR-IR optical modulation ∆TTRANS versus the intermediate V layer’s thickness.

Data availability

The datasets used and/or analysed during the current study available from the corresponding authors on request.

References

Oke, T. R., Johnson, D. G., Steyn, D. G. & Watson, I. D. Simulation of surface urban heat island under ‘ideal’ conditions at night—Part 2: Diagnosis and causation. Bound.-Layer Meteorol. 56, 339–358 (1991).

Santamouris, M. (ed.) Energy and Climate in the Urban Built Environment (James and James Science Publishers, 2001).

Santamouris, M. Heat island research in Europe—The State of the art. J. Adv. Build. Energy Res. 1, 123–150 (2007).

Santamouris, A. & Synnefa, T. K. Using advanced cool materials in the urban built environment to mitigate heat islands and improve thermal comfort conditions. Solar Energy 85(12), 3085–3102 (2011).

Papanikolaou, N. et al. On the impact of urban climate to the energy consumption of buildings. Solar Energy 70(3), 01–216 (2001).

Tracking Progress: Building Envelopes. International Energy Agency (2017).

Ma, Y., Zhu, B. & Wu, K., Preparation and solar reflectance spectra of chameleon-type building coatings. J. Sol. Energy 70, 417–422 (2001).

Ma, Y., Zhang, X., Zhu, B. & Wu, K., Research on reversible effects and mechanism between the energy-absorbing and energy-reflecting states of chameleon-type building coatings. J. Sol. Energy 72, 511–520 (2002).

Karlessi, T., Santamouris, M., Apostolakis, A., Synnefa, A. & Livada, I., Development and testing of thermochromic coatings for buildings and urban structures. Sol. Energy 83(4), 538–551(2009).

Kammen, D. M. & Sunter, D. A. City-integrated renewable energy for urban sustainability. Science 352, 922–928 (2016).

Rogelj, J. et al. Energy system transformations for limiting end-of-century warming to below 1.5 °C. Nat. Clim. Change 5, 519–527 (2015).

Granqvist, C. G. in Handbook of Inorganic Chromogenic Materials (Elsevier, 1995) (and references therein (1995)).

Jelle, B. P., Kalnæs, S. E. & Gao, T. Low-emissivity materials for building applications: A state-of-the-art review and future research perspectives. Energy Build. 96, 329–356 (2015).

Morin, F. J. Oxides which show a metal-to-insulator transition at the Neel temperature. Phys. Rev. Lett. 3, 34 (1959).

Adler, D. Mechanisms for metal-nonmetal transitions in transition-metal oxides and sulfides. Rev. Mod. Phys. 40, 714 (1968).

Wang, S. et al. Scalable thermochromic smart windows with passive radiative cooling regulation. Science 374, 1501–1504 (2021).

Tang, K. et al. Temperature-adaptive radiative coating for all-season household thermal regulation. Science 374, 1504–1509 (2021).

Lobastov, V.A,, Srinivasan, R., Zewail ,A.H. (2005) Proc. Natl. Acad. Sci. USA. 102, 7069–7073.

Baum, P., Yang, D. S. & Zewail, A. H. 4-D visualization of transitional structures in phase transformations by electron diffraction. Science 318(5851), 788–792. https://doi.org/10.1126/science.114772 (2007).

Nemraoui, O., Sella, C., Beye, A. C. & Baruch-Barak, B. Thermal induced tunability of surface plasmon resonance in Au-VO2 nano-photonics. Opt. Commun. 254(1–3), 188–195 (2005).

Nemraoui, O., Sella, C. & Beye, A. C. Surface plasmon resonance tunability in Au-VO2 thermochromic nano-composites. Gold Bull. 38(3), 100–106 (2005).

Kana Kana, J. B., Ndjaka, J. M., Vignaud, G. & Gibaud, A. Thermally tunable optical constants of vanadium dioxide thin films measured by spectroscopic ellipsometry. Opt. Commun. 284(3), 807–812 (2011).

Maaza, M. et al. Phase transition in a single VO2 nano-crystal: Potential femtosecond tunable opto- electronic nano-gating. J. Nanoparticle Res. 16(5), 2397 (2014).

Simo, A. et al. VO2 nanostructures based chemiresistors for low power energy consumption hydrogen sensing. Int. J. Hydrogen Energy 39(15), 8147–8157 (2014).

Simo, A., Kaviyarasu, K., Mwakikunga, B. & Mokwena, M. Room temperature volatile organic compound gas sensor based on vanadium oxide 1-dimension nanoparticles. Ceram. Int. 43(1), 1347–1353 (2017).

Maaza, M. Optoelectronic ultrafast tunability in VO2 based Mott/Peierls nanostructures. Ann. Nanosci. Nanotechnol. 1(1), 1002 (2017).

Numan, N., Mabakachaba, B., Simo, A. & Nuru, Z. VO2-based active tunable emittance thermochromic flexible coatings. J. Opt. Soc. Am. A Opt. Image Sci. Vision 37(11), 45–49 (2020).

Ngom, B. D., Achouri, M. & Manikandan, K. Functional nanostructured oxides. Vacuum 114, 172–187 (2015).

Hamidi, D. et al. Optical limiting in pulsed laser deposited VO2 nanostructures. Opt. Commun. 285(6), 1190–1193 (2012).

Théry, V. et al. Structural and electrical properties of large area epitaxial VO2 films grown by electron beam evaporation. Appl. Phys. 121, 055303 (2017).

Fisher, B., Patlagan, L. & Reisner, G. M. Sliding twin-domains in self-heated needle-like VO2 single crystals. Sci. Rep. 10, 6833. https://doi.org/10.1038/s41598-020-63694-1 (2020).

Slusar, T. V. et al. Mott transition in chain structure of strained VO2 films revealed by coherent phonons. Sci. Rep. 7, 16038. https://doi.org/10.1038/s41598-017-16188-6 (2017).

Park, J. et al. Measurement of a solid-state triple point at the metal–insulator transition in VO2. Nature 500, 431–434. https://doi.org/10.1038/nature12425 (2013).

Mogunov, I. A. et al. Large non-thermal contribution to picosecond strain pulse generation using the photo-induced phase transition in VO2. Nat. Commun. 11, 1690. https://doi.org/10.1038/s41467-020-15372-z (2020).

O’Callahan, B. et al. Inhomogeneity of the ultrafast insulator-to-metal transition dynamics of VO2. Nat. Commun. 6, 6849. https://doi.org/10.1038/ncomms7849 (2015).

Xu, C. et al. Transient dynamics of the phase transition in VO2 revealed by mega-electron-volt ultrafast electron diffraction. Nat. Commun. 14, 1265. https://doi.org/10.1038/s41467-023-37000-2 (2023).

Matsuda, Y. H. et al. Magnetic-field-induced insulator–metal transition in W-doped VO2 at 500 T. Nat. Commun. 11, 3591. https://doi.org/10.1038/s41467-020-17416-w (2020).

Yoon, H. et al. Reversible phase modulation and hydrogen storage in multivalent VO2 epitaxial thin films. Nat. Mater. 15, 1113–1119. https://doi.org/10.1038/nmat4692 (2016).

Wu, Y. et al. Decoupling the lattice distortion and charge doping effects on the phase transition behavior of VO2 by titanium (Ti4+) doping. Sci. Rep. 5, 9328. https://doi.org/10.1038/srep09328 (2015).

Li, G. et al. Photo-induced non-volatile VO2 phase transition for neuromorphic ultraviolet sensors. Nat. Commun. 13, 1729. https://doi.org/10.1038/s41467-022-29456-5 (2022).

Johnson, A. S. et al. Ultrafast X-ray imaging of the light-induced phase transition in VO2. Nat. Phys. 19, 215–220. https://doi.org/10.1038/s41567-022-01848-w (2023).

Wang, Y. et al. Reversible switching between pressure-induced amorphization and thermal-driven recrystallization in VO2(B) nanosheets. Nat. Commun. 7, 12214. https://doi.org/10.1038/ncomms12214 (2016).

Yajima, T., Nishimura, T. & Toriumi, A. Positive-bias gate-controlled metal–insulator transition in ultrathin VO2 channels with TiO2 gate dielectrics. Nat. Commun. 6, 10104. https://doi.org/10.1038/ncomms10104 (2015).

Long, S. et al. Effects of V2O3 buffer layers on sputtered VO2 smart windows: Improved thermochromic properties, tunable width of hysteresis loops and enhanced durability. Appl. Surface Sci. 441, 764–772 (2018).

Leroy, J., Bessaudou, A., Cosset, F. & Crunteanu, A. Structural, electrical, and optical properties of thermochromic VO2 thin films obtained by reactive electron beam evaporation. Thin Solid Films 520, 4823–4825 (2012).

Wang, C. et al. New intelligent multifunctional SiO2/VO2 composite films with enhanced infrared light regulation performance, solar modulation capability, and superhydrophobicity. Sci. Technol. Adv. Mater. 18, 563–573 (2017).

Chen, S. et al. The visible transmittance and solar modulation ability of VO2 flexible foils simultaneously improved by Ti doping: An optimization and first principle study. Phys. Chem. Chem. Phys. 15, 17537 (2013).

Pellegrino, L. et al. Multistate memory devices based on free-standing VO2/TiO2 microstructures driven by joule self-heating. Adv. Mater. 24, 2929 (2012).

Sella, C. M., Nemraoui, O., Renard, N. & Sampeur, Y. Preparation, characterization and properties of sputtered electrochromic and thermochromic devices. Surface Coatings Technol. 98(1–3), 1477–1482 (1998).

Kana Kana, J. B. et al. High substrate temperature induced anomalous phase transition temperature shift in sputtered VO2 thin films. Opt. Mater. 32(7), 739–742 (2010).

Ngom, B. D. et al. Competitive growth texture of pulsed laser deposited vanadium dioxide nanostructures on a glass substrate. Acta Materialia 65, 32–41 (2014).

Ngom, B. D., Kotsedi, L. & Ghouti, M. Thermochromic VO2 on Zinnwaldite Mica by pulsed laser deposition. Appl. Surface Sci. 314, 476–480 (2014).

Madiba, I. G. et al. Submicronic VO2-PVP composites coatings for smart windows applications and solar heat management. Solar Energy 107, 758–769 (2014).

Granqvist, C. G. Handbook of Inorganic Chromogenic Materials (Elsevier, 1995) (and references therein).

Soltani, M. et al. Micro-optical switch device based on semiconductor-to-metallic phase transition characteristics of W-doped VO2 smart coatings. J. Vac. Sci. Technol. A 25, 971 (2007).

Soltani, M. et al. 1 × 2 optical switch devices based on semiconductor-to-metallic phase transition characteristics of VO2 smart coatings. Meas. Sci. Technol. 17, 1052 (2006).

Leroy, J. et al. High-speed metal-insulator transition in vanadium dioxide films induced by an electrical pulsed voltage over nano-gap electrodes. Appl. Phys. Lett. 100, 213507 (2012).

Numan, N. Madiba, I. G., Khanyile, B. S., Khumalo, Z. M. & Maaza, M. Hydrothermal synthesis and characterization of undoped and W-doped vanadium dioxide nanorods for thermochromic application. J. Cryst. Growth 590, 126702 (2022).

Li, S.-Y., Niklasson, G. A. & Granqvist, C. G. Thermochromic fenestration with VO2-based materials: Three challenges and how they can be met. Thin Solid Films 520, 3823–3828 (2012).

Nagashima, K., Yanagida, T., Tanaka, H. & Kawai, T. Interface effect on the metal-insulator transition of strained vanadium dioxide ultrathin films. J. Appl. Phys. 101, 026103 (2007).

Clark, S. J. et al. First principles methods using CASTEP. Zeitschrift fuer Kristallographie 220, 567 (2005).

Jiang, M. et al. Improved luminous transmittance and diminished yellow color in VO2 energy efficient smart thin films by Zn doping. Ceram. Int. 40, 4 (2013).

Wu, Y. et al. Decoupling the lattice distortion and charge doping effects on the phase transition behavior of VO2 by titanium (Ti4+) doping. Sci. Rep. 5, 9328 (2015).

Zhang, et al. VO2 thermochromic films on quartz glass substrate grown by RF plasma assisted oxide molecular beam epitaxy. Materials 10, 314 (2017).

Lu, L. et al. Effect of Fe doping on thermochromic properties of VO2 films. J. Mater. Sci. Mater. Electron. 29, 5501 (2018).

Vernardou, D. et al. Thermochromic amorphous VO2 coatings grown by APCVD using a single-precursor. Solar Energy Mater. Solar Cells 128, 36 (2014).

Drosos, C. et al. Advancements, challenges and prospects of chemical vapour pressure at atmospheric pressure on vanadium dioxide structures. Materials 11, 384 (2018).

Vinichenko, D. A. et al. Synthesis of vanadium dioxide films by a modified sol–gel process. Inorg. Mater. 47, 3 (2011).

Pan, G. et al. Synthesis and thermochromic property studies on W doped VO2 films fabricated by sol–gel method. Sci. Rep. 7, 6132 (2017).

Marvel, R. E. et al. Electron beam deposition of vanadium dioxide thin films. Appl. Phys. A 111(3), 975–981 (2013).

.

Marvel, R. E. et al. Influence of deposition process and substrate on the phase transition of vanadium dioxide thin films. Acta Materialia 91, 217 (2015).

Tan, X. et al. Unraveling metal-insulator transition mechanism of VO2 triggered by Tungsten doping. Sci. Rep. 2, 466. https://doi.org/10.1038/srep00466 (2012).

Long, S. et al. Effects of V2O3 buffer layers on sputtered VO2 smart windows: Improved thermochromic properties, tunable width of hysteresis loops and enhanced durability. Appl. Surface Sci. 441, 764–772 (2018).

Pellegrino, L. et al. Multistate memory devices based on free-standing VO2/TiO2 microstructures driven by Joule self-heating. Adv. Mater. 24, 2929 (2012).

Miller, M. J. & Wang, J. Multilayer ITO/VO2/TiO2 thin films for control of solar and thermal spectra. Solar Energy Mater. Solar Cells 154, 88–93 (2016).

Zheng, J. et al. TiO2(R)/VO2(M)/TiO2(A) multilayer film as smart window: Combination of energy-saving, antifogging and self-cleaning functions. Nano Energy 11, 136–145. https://doi.org/10.1016/j.nanoen.2014.09.023 (2015).

Zhou, L. et al. Modified color for VO2/Au/VO2 sandwich structure-based smart windows. Appl. Phys. A 124, 505 (2018).

Han, Y.-H. et al. Fabrication of vanadium oxide thin film with high-temperature coefficient of resistance using V2O5/V/V2O5 multi-layers for uncooled microbolometers. Thin Solid Films 425, 260–264 (2003).

Zhao, Y. et al. Simulation of smart windows in the ZnO/VO2/ZnS sandwiched structure with improved thermochromic properties. Energy Buildings 66, 545–552 (2013).

Khanyile, B. S. et al. Effect of varying the vanadium thickness layer of V2O5/V/V2O5 film on its microstructural and thermochromic properties. J. Vacuum Sci. Technol. A Vacuum Surfaces Films 37(5), 051511 (2019).

Wang, C. et al. New intelligent multifunctional SiO2/VO2 composite films with enhanced infrared light regulation performance, solar modulation capability, and super-hydrophobicity. Sci. Technol. Adv. Mater. 18, 563–573 (2017).

Long, S. et al. Thermochromic multilayer films of WO3/VO2/WO3 sandwich structure with enhanced luminous transmittance and durability. RSC Adv. 6, 106435 (2016).

Hasanuzzaman, M., Rafferty, A., Sajjia, M. & Olabi, A.-G. Properties of glass materials. Encyclopedia Mater. Tech. Ceram. Glasses 2(2016), 647–657 (2016).

Maaza, M., Farnoux, B., Samuel, B., Sella, C. & Trocellier, P. Effect of mechanical polishing on the surface structure of glasses studied by grazing angle neutron reflectometry. Opt. Commun. 100(1–4), 220–230 (1993).

Kumar, S. et al. Sodium diffusion in sodium borosilicate glass used for immobilization of high level liquid waste. J. Radioanal. Nuclear Chem. 274(2), 225–228 (2007).

Maaza, M., Farnoux, B., Samuel, F., Sella, C. & Trocellier, P. Effect of mechanical polishing on the surface structure of glasses, studied by grazing angle neutron reflectometry. Opt. Commun. 100, 220–230 (1993).

Lee, M. H., Kim, M. G. & Song, H. K. Thermochromism of rapid thermal annealed VO2 and Sn-doped VO2 thin films. Thin Solid Films 290–291, 30–33 (1996).

Jin, P., Nakao, S. & Tanemura, S. “Tungsten doping into vanadium dioxide thermochromic films by high-energy ion implantation and thermal annealing. Thin Solid Films 324, 151–158 (1998).

Paone, A. et al. Influence of doping in thermochromic V1−xWxO2 and V1−xAlxO2 thin films: Twice improved doping efficiency in V1−xWxO2. J. Alloys Compd. 621, 206–211 (2015).

Song, L. et al. Preparation and thermochromic properties of Ce-doped VO2 films. Mater. Res. Bull. 48, 2268–2271 (2013).

Kiri, P., Warwick, M. E. A., Ridley, I. & Binions, R. Fluorine doped vanadium dioxide thin films for smart windows. Thin Solid Films 520, 1363–1366 (2011).

Hanlon, T. J., Coath, J. A. & Richardson, M. A. Molybdenum-doped vanadium dioxide coatings on glass produced by the aqueous sol-gel method. Thin Solid Films 436, 269–272 (2003).

Chae, B. G., Kim, H. T. & Yun, S. J. Characteristics of W- and Ti-doped Vo2 thin films prepared by sol-gel method. Electrochem. Solid State 11(6), D53–D55 (2008).

Wu, X. et al. Enhancement of VO2 thermochromic properties by Si doping. Surf. Coat. Technol. 276, 248–253 (2015).

Kakiuchida, H., Jin, P. & Tazawa, M. Optical characterization of vanadium–titanium oxide films. Thin Solid Films 516, 4563–4567 (2008).

Burkhardt, W. et al. Tungsten and fluorine co-doping of VO2 films. Thin Solid Films 402, 226–231 (2002).

O. Sakata & M. Nakamura. Grazing incidence X-ray diffraction, surface science techniques (2013). Vol. 51. ISBN: 978-3-642-34242-4.

Shvyd’ko, Y. et al. Near-100% Bragg reflectivity of X-rays. Nat. Photon 5, 539–542. https://doi.org/10.1038/nphoton.2011.197 (2011).

Paul, N. et al. Surface distortion of Fe dot-decorated TiO2 nanotubular templates using time-of-flight grazing incidence small angle scattering. Sci. Rep. 10, 4038. https://doi.org/10.1038/s41598-020-60899-2 (2020).

Zhang, H., Wu, Z., Yan, D., Xu, X. & Jiang, Y. Tunable hysteresis in metal-insulator transition of nanostructured vanadium oxide thin films deposited by reactive direct current magnetron sputtering. Thin Solid Films 552, 218–224 (2014).

Tselev, A. et al. Mesoscopic metal-insulator transition at ferroelastic domain walls in VO2. ACS Nano. 4(8), 4412–4419. https://doi.org/10.1021/nn1004364 (2010).

Tselev, A. et al. Symmetry relationship and strain-induced transitions between insulating M1 and M2 and metallic R phases of vanadium dioxide. Nano Lett. 10(11), 4409–4416. https://doi.org/10.1021/nl1020443 (2010).

Wei, J., Wang, Z., Chen, W. & Cobden, D. H. New aspects of the metal-insulator transition in single-domain vanadium dioxide nanobeams. Nat. Nanotechnol. 4(7), 420–424. https://doi.org/10.1038/nnano.2009.141 (2009).

Favaloro, T. et al. Direct observation of nanoscale Peltier and Joule effects at metal-insulator domain walls in vanadium dioxide nanobeams. Nano Lett. 14(5), 2394–2400. https://doi.org/10.1021/nl500042x (2014) (Epub 2014 Apr 17).

Salje, E. K. H. & Kustov, S. Dynamic domain boundaries: Chemical dopants carried by moving twin walls. Phys. Chem. Chem. Phys. 25(3), 1588–1601. https://doi.org/10.1039/d2cp04908b (2023).

Nagashima K., Yanagida T., Tanaka H., & Kawai, T. Stress relaxation effect on transport properties of strained vanadium dioxide epitaxial thin films. Phys. Rev. B 74, 172106

Ramana, C. V., Smith, R. J., Hussain, O. M. & Julien, C. M. On the growth mechanism of pulsed-laser deposited vanadium oxide thin films. Mater. Sci. Eng. B 111, 218–225 (2004).

Mathevula, L. et al. Thermochromic VO2 on Zinnwaldite Mica by pulsed laser deposition. Appl. Surface Sci. 314, 476–480 (2014).

Hwang, I.-H., Park, C.-I., Yeo, S., Sun, C.-J. & Han, S.-W. Decoupling the metal insulator transition and crystal field effects of VO2. Sci. Rep. https://doi.org/10.1038/s41598-021-82588-4 (2021).

Planer, J., Mittendorfer, F. & Redinger, J. First principles studies of the electronic and structural properties of the rutile VO2 (110) surface and its oxygen-rich terminations. J. Phys. Condensed Matter. 33(47), 475002. https://doi.org/10.1088/1361-648X/ac2203 (2021).

Mohebbi, E. et al. Insights into first-principles characterization of the monoclinic VO2 (B) polymorph via DFT + U calculation: Electronic, magnetic and optical properties. Nanosc. Adv. 4(17), 3634–3646. https://doi.org/10.1039/D2NA00247G (2022).

Zhang, S., Yen Chou, J. & Lauhon, L. J. Direct correlation of structural domain formation with the metal insulator transition in a VO2 nanobeam. Nano Lett. 9(12), 4527–4532. https://doi.org/10.1021/nl9028973 (2009).

Tselev, A. et al. Interplay between ferroelastic and metal−insulator phase transitions in strained Quasi-two-dimensional VO2 nanoplatelets. Nano Lett. 10(6), 2003–2011. https://doi.org/10.1021/nl1008794 (2010).

Strelcov, E., Davydov, A. V., Lanke, U., Watts, C. & Kolmakov, A. In situ monitoring of the growth, intermediate phase transformations and templating of single crystal VO2 nanowires and nanoplatelets. ACS Nano 5(4), 3373–3384. https://doi.org/10.1021/nn2007089 (2011).

Zhang, S., Kim, I. S. & Lauhon, L. J. Stoichiometry Engineering of Monoclinic to Rutile phase transition in suspended single crystalline Vanadium Dioxide nanobeams. Nano Lett. 11(4), 1443–1447. https://doi.org/10.1021/nl103925m (2011).

Scandolo, S. et al. First-principles codes for computational crystallography in the Quantum-ESPRESSO package. Zeitschrift fu ̈r Kristallographie Crystalline Mater. 220, 574–579 (2005).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Dudarev, S. L., Botton, G. A., Savrasov, S. Y., Humphreys, C. J. & Sutton, A. P. Phys. Rev. B Condens. Matter 57(3), 1505–1509 (1998).

Clark, S. J. et al. First principles methods using CASTEP. Zeitschrift fuer Kristallographie 220(5–6), 567–570 (2005).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-Zone integrations. Phys. Rev. B 13, 5188 (1976).

Grimme, S. Semiempirical GGA-type density functional constructed with a long-range dispersion correction. J. Comput. Chem. 27(15), 1787–1799 (2006).

Sreehari Sastry, S. & Rao, V. Structural and optical properties of vanadium doped akaline earth lead zinc phosphate glasses. Indian J. Pure Appl. Phys. 52(7), 491–498 (2014).

Kawabe, Y., Yamanaka, A., Horiuchi, H., Takashima, H. & Hanamura, E. Luminescence of color centers formed in alkali-earth-doped yttrium orthoaluminate crystals. J. Luminescence 121(2), 517–526 (2006).

Krasnikov, A., Mihokova, E., Nikl, M., Zazubovich, S. & Zhydachevskyy, Y. Luminescence spectroscopy and origin of luminescence centers in Bi-doped materials. Crystals 10(3), 208 (2020).

Said, D. et al. Influence of vanadium in sensitized luminescence mechanism and Judd-Ofelt analysis in doped mixed ionic-electronic glass system. Opt. Mater. 143, 114169 (2023).

Khalid Hossain, M., Shahadat Hossain, S., Hafez Ahmed, M., Ishak Khan, H. N. & Raihan, G. A review on optical applications, prospects, and challenges of rare-earth oxides. ACS Appl. Electron. Mater. 9, 3715–3746 (2021).

Khalid Hossain, M. et al. Current applications and future potential of rare earth oxides in sustainable nuclear, radiation, and energy devices: A review. ACS Appl. Electron. Mater. 4(7), 3327–3353 (2022).

Khalid Hossain, M. et al. A review on recent applications and future prospects of rare earth oxides in corrosion and thermal barrier coatings, catalysts, tribological, and environmental sectors. Ceram. Int. 48(22), 32588–32612 (2022).

Munjer, M. A., Hasan, Z., Khalid Hossain, M. & Ferdous Rahman, M. The obstruction and advancement in sustainable energy sector to achieve SDG in Bangladesh. Sustainability 15(5), 3913 (2023).

Acknowledgements

We are grateful to the various supporting institutions including, the University of South Africa, iThemba LABS (ITLABS), the National Research Foundation of South Africa (NRF), the African Laser Centre (ALC), the international Organization of Women in Science (OWSD), the Abdus Salam International Centre for Theoretical Physics (The Abdus Salam-ICTP), the Royal Society-London and naturally the United Nations Education, Sciences & Culture Organization (UNESCO) as well as the French Foreign Ministry and the ADESFA program. Likewise, the Centre for High Performance Computation (CHPC) as well as the UNISA High Performance Computing (HPC) are acknowledged.

Author information

Authors and Affiliations

Contributions

B.S.K.: Deposition & various characterizations, N.N.:various characterizations, A.S.: Theory, M.N.: AFM investigations,C.B.M.: Rutherford Backscattering investigations, Z.K.: Elastic Recoil Detection investigations, I.G.M. Deposition, B.M.: Optical characterization, H.S.: SIMS investigations, E.C.H.: Auger investigations, M.M.D.: SIMS investigations, E.L.: Auger investigations, M.H.: Interpretation & manuscript reading, A.G.: Guidance , M.C.: Guidance, P.R.: Computation & Modelling,N.L..: Computation & Modelling,R.M.: Computation & Modelling,M.A.: Computation & Modelling, M.M.: Conceptualization, interpretation & manuscript writing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Khanyile, B.S., Numan, N., Simo, A. et al. Towards Room Temperature Thermochromic Coatings with controllable NIR-IR modulation for solar heat management & smart windows applications. Sci Rep 14, 2818 (2024). https://doi.org/10.1038/s41598-024-52021-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-52021-7

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.